UNIVERSITÀ DI PISA

Scuola di Ingegneria

Corso di Laurea Magistrale in Ingegneria Biomedica

Tesi di Laurea Magistrale

Desing, fabrication and characterization of Bioactive

microstructures to promote vascular network

development

Relatori:

Ing. Giovanni Vozzi

Prof. Paolo Madeddu

Ing. Carmelo De Maria

Candidato:

Michele Carrabba

1

Index

INTRODUCTION ... 4

1. TISSUE REGENERATION ... 6

1.1. Peripheral Artery Diseases ... 8

1.2. Vasculogenesis, Angiogenesis and Arteriogenesis ... 11

1.2.1. Angiogenic Disorders ... 13 1.2.2. Mechanism of angiogenesis ... 13 1.3. BIOMATERIALS ... 15 1.3.1. Used Biopolymers ... 17 1.4. MICROFABRICATION TECHNIQUES ... 23 1.4.1. Soft-Lithography ... 25 1.4.2. Electrospinning ... 30 1.4.3. Rapid Prototyping ... 37

1.4.4. Pressure Activated Microsyringe2 ... 39

1.5. Aim of the Thesis ... 40

REFERENCE: ... 45

2. MATERIALS AND METHODS ... 48

2.1. Scaffolds Preparation ... 48

2.1.1. Scaffolds microfabrication ... 48

2.1.2. Nanofibers assessment ... 60

2.1.3. Mechanical Characterization ... 65

2.2. Cells experimental techniques ... 70

2.3. Sterilization of scaffolds ... 70

2

2.4.1. Saphenous vein pericytes (SVPs) ... 70

2.4.2. Cell density assay ... 71

2.4.3. Functional assays ... 72 2.5. In-Vivo tests ... 76 2.5.1. Laser Doppler ... 76 2.5.2. Immunohistochemistry ... 77 2.5.3. Azan Mallory ... 80 2.5.4. Cell count ... 81 REFERENCE: ... 82

3. RESULTS AND DISCUSSION ... 83

3.1. Tuning of Electrospinning machinary ... 83

3.2. Tuning of PAM2 machinary ... 87

3.3. Manifaturing of scaffolds ... 87

3.3.1. Hydrogel fabrication ... 87

3.3.2. Hybrid Scaffold fabrication ... 88

3.3.3. Mechanical results ... 88 In vitro results ... 92 3.3.4. Density assessment ... 92 3.3.5. Viability assessment ... 93 3.3.6. Proliferation assessment ... 94 3.3.7. Discussion ... 96 3.4. In vivo results ... 97

3.4.1. Laser Doppler Flowmetry ... 97

3.4.2. Capillary and Arteriolar Density ... 97

3.4.3. Discussion ... 99

3 4. RESULTS AND DISCUSSION ... 100

4

INTRODUCTION

The world of medicine has made great strides in the last century, being able to accept and capitalizing on technological innovations from other research areas. In recent years the variety of conditions that cause tissue loss and the lack of donors stimulated the growth and development of medical and technological fields related to it. From this capability to go beyond the limit of specific scientific area, the interdisciplinary field of tissue engineering has blossomed in the brief two decades with the aim to provide permanent solutions to problems of organs lack or biological tissue regeneration. Of particular interest to this study is the research done on the creation of tissue engineering scaffolds that mimic the native extracellular matrix (ECM) and allow cells grow and proliferate until the point to recreate an entire tissue.

If on one hand the thrust is due to technological advancement on the other is due to the occurrence of always new obstacles to overcome. One of these important issues to deal with are the disorders that affect the cardiovascular system. Indeed vascular disease is the leading cause of deaths worldwide. Among the type of this dysfunctions, that depends on the areas involved, like heart, blood vessels (arteries, capillaries and veins) or both, a particular interest felt on Peripheral Artery diseases (PAD). PAD is a narrowing of the arteries and it mainly occurs in those that supply blood to the legs and its most advanced form is Critical Limb Ischemia (CLI). In the UK, around 1 in 5 men and 1 in 8 women aged 50-75 years have PAD. It becomes more common with increasing age. There are some fixed risk factors that can increase the probability like family history or being male, or variable factors among which the most important is lifestyle. In condition of unhealthy quality of life, 1 patient out of 4 with CLI requires foot amputation 1 year far from diagnosis and furthermore still 1 out of 4 will die in the same period. Even if is not associated with an high rate of mortality, related to other diseases, CLI represents an index of heart disease. Indeed patient in which is detected the limb ischemia have 6-7 higher than average risk of developing heart attack ok stroke. Traditional medical approach expect use of drugs and for severe cases the use of surgical angioplasty; but in some chronic patient it is unfeasible.

Understood the importance of treatments of PDA, in the last years a new impulse stared to search new methods of revascularization. In this context tissue engineering started to be considered like a possible solution.

5 In this thesis was applied a novel approach exploiting the advantage to use scaffolds seeded with cells, able to stimulate revascularization. This work started with the design, analysis and comparison of different type of microfabricated scaffolds. The comparison were performed on two classes of scaffold: hydrogel and hybrid scaffolds.

Hydrogels, made by a solution on crosslinked Gelatin, were fabricated with the more traditional Soft-lithographic process. The scaffold obtained displays a defined surface pattern consisting in micrometric channels.

Hybrid scaffolds were realized with a bottom-up approach: in order to mimic the hierarchical organization of biological tissue, a macrometric 3D structure of synthetic polymer (Polycaprolactone) is realized with PAM2 technique and on top of this last one, a mat of nanofibers of natural polymer (Gelatin) were deposed with eletrospinning technique.

Gelatin was crosslinked by two different agents: (I)Genipin and (GPTMS). Analysis and comparision of crosslinked fibers of gelatin was a key step for tuning and optimization of microfabrication technique.

Scaffolds must be designed to serve as a temporary artificial extracellular matrix (ECM) in order to support cell attachment and guide three-dimensional (3D) tissue formation. The native ECM is comprised of a complex network of structural and regulatory proteins that are arrayed into a fibrous matrix, indeed, many studies reveled how tissue regeneration in strongly realted to micro and nanotopology. For this reason our hybrid scaffold has the macrometric structure to provide mechanical properties and physical support, and nanofibers layers of natural polymer to enhance binding and give chemcal cues. In this work microfabricated scaffolds were prepared and characterized with the aim to compare their mechanical properties.

Saphenous Veins Perycites (SVPs) cells were cultured on the different type of scaffold to perfmorm the in vitro assessment. Various functional assays were performed in order to evaluate adhesion, viability and proliferation of cells on scaffolds and the comparison of these results was fundamental to choose the type of scaffold which shows the best property.

The last part of the project consisted on implantation of scaffolds in vivo. Mice were subjected to limb ischemia surgery to reproduce a clinical condition of artery occlusion and empty scaffolds or scaffold with cells seeded were implanted in the perivascular area, around the femoral artery.

6 Flowmetry and immunoistochemisty assessment were performed to evaluate recovery in angiogenesis.

The thesis is developed in organized and presented in all their stages.

Chapter 1 present the analysis of PAD and briefly explains the concept behind the process of vasculogenesis, angiogenesis and arteriogenesis. Then the use and the importance of biopolymers in biomedical application will be introduced, followed by the description of microfabrication techniques. We will focus on the description of microfabrication used for our works: Soft-Lithography, PAM2 and electrospinning.

In Chapter 2 methodologies and materials are discussed, that have been used in various experimental tests. We will do a deep analysis of the many protocols used, giving space to describe the most crucial designing stages to allow a clear comprehension of the work.

In Chapter 3 results, extrapolated from the previous analysis and comparison, will be analyzed and discussed. From these analyis, in chapter 4, we will give an overview on the entire realized work and we will draw conclusion from which can be analyzed future development.

1. TISSUE REGENERATION

Tissue Engineering (TE) is a rapidly developing field that takes advantage of an interdisciplinary approach that involves the use of biological science and engineering to develop tissues that restore, maintain or improve tissue function [1]. TE has particular advantages over other therapies such as drug, because it can provide a permanent solution to the problems of lack of the organs. In general, there are three main approaches: (i) use of isolated cells or cellular systems as parts replacement, (ii) use of non-cellularized biomaterials capable of inducing the regeneration of tissues, and (iii) use of a combination of cells and biomaterials (usually in the form of scaffold). One of the thrust of present TE is to find the most suitable method to achieve the desired structure so as to guide the best growth and development of cells. Ideally, a suitable biomaterial should have first of all biocompatibility, a certain degree of porosity and thus well controlled pores size, easily reproducible, enjoy thermal and biochemical stability and preferably be soluble in non-toxic solvents.

In the context of TE, microfabrication techniques are used to make the matrix on which cells are seeded and then grow and thus they play a fundamental role. The

7 degradable matrix on which cells are implanted is usually realized with polymeric biomaterials because they have in comparison with other classes of materials significant advantages such as:

greater biocompatibility;

chance to have a wide range of composition and chemical and physical properties;

low coefficients of friction;

easy processability and workability even in complex forms and structures;

possibility to change the surface chemically and/or physically;

possibility of immobilizing cells or biomolecules

Figure 1-1

In figure 1.1 is shown a series of subsequent events that theoretically must represent a sort of life cycle of tissue regeneration. We can see that scaffolds play a fundamental role in these processes, acting as a delivers support for cells to be implanted.

8 With the word "scaffold", we mean the artificial device used in TE, with the aim of providing a desirable micro environment for allows the newly generated tissue properly for the repair and possibly the replacement of damaged tissues or organs. Scaffolds act as temporary substitutes of the extracellular matrix (ECM) [2]. The challenge that arises TE is to create biological replicates such that they can be used for implantation in vivo, in which the TE construct should work in a coordinated way with the rest of the body [32]. To this end, there is the necessity to create structures which mimics the natural one exploiting the great variety of novel microfabrication techniques that in the last decades had a massive development.

In this chapter we will introduce the main disease of distal vasculature on which this work is focused and the research and the methodologies that are the basis of the realization of biocompatible scaffolds for tissue engineering. In particular we will show the state of art of the materials and microfabrication techniques used of major concern in this application field.

1.1.

Peripheral Artery Diseases

Peripheral arterial disease (PAD) consists in the obstruction to blood flow in the arteries. It mainly occurs in arteries that supply blood to the legs and it is an important manifestation of systemic atherosclerosis, which is a specific form of arteriosclerosis caused by the buildup of fatty plaques and cholesterol in the artery. The narrowing of the arteries is caused by atheroma. Atheroma is like fatty patches (plaques) that develop within the inner lining of arteries. A patch of atheroma starts quite small, and causes no problems at first. Over the years, a patch of atheroma can become thicker. A thick patch of atheroma makes the artery narrower. This reduces the flow of blood through the affected section of artery. Tissues downstream have a reduced blood supply, which can lead to symptoms and problems.

9

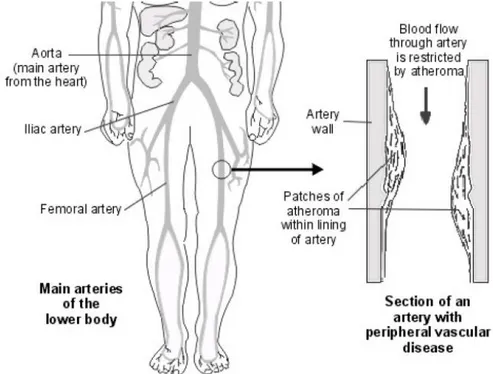

Figure 1-2:Types of atherosclerotic lesions

Patients with peripheral arterial disease, even in the absence of a history of myocardial infarction or ischemic stroke, have approximately the same relative risk of death from cardiovascular causes as do patients with a history of coronary or cerebrovascular disease [4].

PAD affects up to 15% of people older than 55 years. Critical limb ischemia (CLI), the most advanced form of PAD, is associated with poor quality of life and requires foot amputation in 25% of cases within one year from the diagnosis. Furthermore, 25% of patients with CLI will die during the same period. Amputation and mortality rates are higher in the subgroup (~30% of CLI patients) in which revascularization by percutaneous or surgical angioplasty is unfeasible.

10

Figure 1-3:Scheme of peripheral artery diseases

The most important clinical manifestation of peripheral disease is claudication. It is shown by one third of patients with PAD, defined as pain in one or both legs on walking, primarily affecting the calves, that does not go away with continued walking and is relieved by rest. In patients with claudication, the severity of the condition increases slowly; 25 % have worsening claudication, and 5% undergo an amputation within five years. Less than 5 to 10 % of patients have critical leg ischemia (ischemic pain in the distal foot, ischemic ulceration, or gangrene), but their risk of limb loss is substantial [5]. The estimate is dependent, however, on demographic factors of the specific population under study, including age, sex, and geographic area. Studies that use an objective method of diagnosis, such as measurement of Doppler systolic ankle pressures, are most accurate. An “anklebrachial index” (ABI) can be calculated by dividing the ankle systolic pressure measured with a blood pressure at the malleolar level by the higher of the two brachial pressures; this is used more in North America than Europe. Normally, the ABI is greater than 1.0. The index is decreased to 0.50–0.90 in patients with claudication and to lower levels in patients with pain at rest or tissue-loss [6].A variety of risk factors have been identified for peripheral arterial occlusive disease; risk factors that are almost identical to those of atherosclerotic disease elsewhere. The most important of these are age and sex; atherosclerosis of the lower

11 extremities is more common in elderly individuals and in men. Diabetes mellitus is a most important risk factor for large vessel atherosclerotic occlusive disease. Smoking is also closely linked to PAD, a relation first identified by Erb in 1911, when the risk of intermittent claudication was reported to be three times greater in smokers [7].

Treatment of the patient’s lower extremity symptoms should be chosen on the basis of the severity of the symptoms. Invasive intervention for symptomless disease is never appropriate, but the presence of even symptomless disease should serve as a marker of generalised atherosclerosis and therapy should be directed at primary prevention of the systemic complications such as myocardial infarction and stroke. Pharmacotherapy for intermittent claudication can be added as adjunctive treatment to improve walking. While significant differences in such endpoints as treadmill walking distance can be shown in clinical trials, the lack of robust clinical impact has limited the widespread use of these agents. Surgical revascularisation is unquestioned as appropriate therapy for patients with chronic critical limb ischaemia, directed at the prevention of limb-loss and its accompanying disability. By contrast, surgical intervention is rarely indicated in patients with intermittent claudication alone, since the risk of major amputation is exceedingly low. Only in the occasional patient whose symptoms interfere with the patient’s lifestyle or performance of an occupation will the benefits of surgical revascularisation outweigh the risks. There are two basic choices when surgery is considered for chronic lower extremity disease, endarterectomy and bypass grafting. Endarterectomy is an acceptable option when truly localised disease is present, for example, narrowing of the aorta and common iliac arteries alone. Otherwise, patency rates are unsatisfactory and bypass grafting is more appropriate. [8].

Stem cell therapy is emerging an attractive approach for treatment of no-option patients as well as a complement of revascularization [8]. Clinical trials using bone marrow (BM)-derived mononuclear cells showed significant benefit, including improvement of ankle brachial index, transcutaneous partial pressure of oxygen, reduction of pain, and decreased need for amputation [9].

1.2.

Vasculogenesis, Angiogenesis and Arteriogenesis

The vasculature is the first organ to arise during development. Blood vessels run through virtually every organ in the body (except the avascular cornea and the cartilage). Normal tissue functions depends on adequate flow of blood able to assuring

12 metabolic homeostasis by supplying oxygen and nutrients and removing waste products. Not surprisingly therefore, vessels are critical for organ growth in the embryo and for repair of wounded tissue in the adult.

Blood vessels in the embryo form through vasculogenesis; that is, through in situ differentiation of undifferentiated precursor cells (angioblasts) to endothelial cells that assemble into a vascular labyrinth. Historically, the term angiogenesis was first used to describe the growth of endothelial sprouts from preexisting postcapillary venules. More recently, this term has been used to generally denote the growth and remodeling process of the primitive network into a complex network. This involves the enlargement of venules, which sprout or become divided by pillars of periendothelial cells or by transendothelial cell bridges, which then split into individual capillaries. New vessels in the adult arise mainly through angiogenesis, although vasculogenesis also may occur (Fig.1.4). Because vasculogenesis only leads to an immature, poorly functional vasculature, angiogenesis is a therapeutic goal [10]. Endothelium-lined channels, furthermore, can mature via recruitment of smooth muscle cells. During this phase, called artereogenesis, vessels become covered by a muscular coat, thereby endowing blood vessels with viscoelastic and vasomotor properties, necessary to accommodate the changing needs in tissue perfusion. As the cellular and molecular mechanisms of angiogenesis differ in various tissues (vessels in psoriatic skinenlarge, but they sprout in ischemic retina), the therapeutic stimulation or inhibition of angiogenesis should be adjusted to the target tissue.

13

1.2.1.

Angiogenic Disorders

After birth, angiogenesis still contributes to organ growth, but during adulthood most blood vessels remain quiescent; angiogenesis only occurs in the cycling ovary and placenta during pregnancy. However, endothelial cells (ECs) retain the remarkable ability of dividing rapidly in response to a physiological stimulus, such as hypoxia and inflammation. Angiogenesis is also reactivated during wound healing and repair. In many disorders, however, this stimulus becomes excessive, and the balance between stimulators and inhibitors is disturbed, resulting in an angiogenic switch. The best-known conditions in which angiogenesis is switched on are malignant, ocular and inflammatory disorders. In obesity, adipose tissue may also show excessive growth. In other diseases, such as ischaemic heart disease or pre-eclampsia, the angiogenic switch is insufficient and so as they induce EC dysfunction, vessel malformation and regression, or prevent revascularization, healing and regeneration. In the skin, age-dependent reductions in vessel density and maturation cause vessel fragility, leading to hair loss and the development of purpura, telangiectasia, angioma and venous lake formation. A progressive loss of the microvasculature in elderly people has been implicated in nephropathy [11], bone loss and impaired re-endothelialisation after arterial injury. Diabetes, atherosclerosis and hyperlipidaemia also impair vessel growth. Besides its vascular activity, vascular endothelial growth factor (VEGF) is also trophic for nerve cells, cardiac muscle fibres and lung epithelial cells, further explaining why insufficient VEGF levels contribute to cardiac failure, respiratory distress and motor neuron degeneration, reminiscent of amyotrophic lateral sclerosis. At present, angiogenesis has been implicated in more than 70 disorders, and the list is ever-growing.

1.2.2.

Mechanism of angiogenesis

As mentioned previously, an imbalance in growth of blood vessels contributes to the pathogenesis of numerous malignant inflammatory, ischemic, infectious and immune disorders. During the last twenty years, a growing interest in angiogenesis research has generated the necessary insights to develop the first clinically approved anti-angiogenic agents for cancer and blindness. Unfortunately, studies on angiogenesis

14 has for too long remained descriptive, mainly because the agents were not well defined. But in the last years new candidates able to stimulate or inhibit endothelial cells were discovered and it thrust the interest in using these molecules for therapeutic applications. With the aim to understand the basis for design of future anti- or pro-angiogenic treatments it’s important to study the basic molecular mechanisms of how endothelial and smooth muscle cells interact with each other to form blood vessels [12].

Figure 1-5:Processes occurring during vasculature angiogenesis

In embryo development as well as in adult tissues, key events and distinct mechanisms exist to establish and maintain a functional vascular network (Fig.1.4). Endothelial progenitor cells (EPCs) are recruited from embryonic regions or from adult bone marrow and can form vessels in a process referred to as vasculogenesis. Angiogenesis is more linked to the process in which budding from preexisting vessels gives rise to sprouts of new blood vessels, while arteriogenesis refers to the stabilisation of these new sprouts by mural cells such as pericytes and smooth muscle cells (SMCs). Arteriogenesis is critical for the new vasculature to become stable, mature and functional. Collateral vessel growth represents the formation of collateral bridges between arterial networks and remodelling of pre-existing vessels after occlusion of a main artery-this type of vessel growth is of major therapeutic importance. A fine-tuned interplay between molecular signals in a spatial and temporal manner is necessary for these essential events to occur.

15 The process of angiogenesis, in response of different types of stimuli, expands and remodels and expand in a more complex, hierarchically and stereotypically organized network of larger vessels starting from a primitive vascular labyrinth. We can try to analyze the process in a progression of following series of events.

Permeabilization of membrane

Endothilial budding and sprouting

Vascular lumen formation

Guided Navigation of Vassels

Remodeling

Arteriogenesis

1.3.

BIOMATERIALS

Over the last years, the role of TE in the current science world has been considerably strengthened and due to this great development the interest in materials study is raising hand in hand. In particular it is focused on behavior of these materials related to the interaction with biological environment; from this thrust it is born what is called the class of biomaterials. The aim of recent studies is to get to identify materials that can provide supports and stimulate tissues regeneration and that once implanted in the human organism they are able to replace a damaged part and/or replace the function damaged tissue. The design process, that is behind the scene of the creation of a biomaterial for TE, needs a planning that has to consider the compromise between different and important material properties as superficial chemistry and morphology, stiffness, degradability and porosity. The lack of balance of these characteristics, or an unexpected response of a single one, may cause the therapeutic failure of the device and the implant rejection. A lot of different materials has been experimented, but not all exhibited an appropriate biocompatibility; furthermore it is useful, in many biomedical applications, that the material is degradable, in order to extinct with no need of any additional surgery. Biodegradable materials more widely used in the field of TE could be natural or synthetic. The difference between the two classes is that the former are extracted from organic material and subsequently worked to make it stable and usable in industry, while the seconds are industrially synthesized from petrochemical intermediates. The natural materials in use, often have the advantage of possessing

16 specific cellular interactions [13]. However, such materials are taken from human or animal tissues and, therefore, are not always available in large quantities. In addition, the materials of natural origin can be carriers of pathogens and, in addition, also differ considerably in dependently by the body from which they are taken. Moreover, these materials have a limited versatility in the construction of scaffolds with specific properties (eg. in terms of mechanical strength). In contrast, the synthetic materials can be industrially reproducible on large scale and can be transformed into a 3D matrix in which the main structure, the mechanical properties and the degradation rate may be controlled and manipulated. The main disadvantage of synthetic materials is in the absence of specific signals for cell recognition .

Overall synthetic polymers offer more advantages than the naturals seeing as they are designed to cover a wide range of properties and furthermore they are also free from the risk of immunogenicity.

For both the two classes of materials, the ideal polymers to use in a specific application should be designed to have some particular characteristics:

1. have mechanical properties that match up with the application 2. have the capability to be fabricated in easy way

3. do not induce inflammation or toxic response

4. be metabolized by biological tissues at the end of the task 5. have reasonable lifespan

6. be easily sterilized

Among the most used material in the field of TE in both category are:

Polymer Type Solvent

Poly(vinyl chloride) synthetic polymer Tetrahydrofuran N-N dimethylformamide

Poly(vinyl alcohol) synthetic polymer Water at 80°C

Poly(ɛ-caprolactone) Biodegradable Polymer Chloroforrm

Polyglycolide Biodegradable Polymer hexafluoro-2-propanol

Poly(L-lactic acid) Biodegradable Polymer Dichloromethane n,n-dimethyl-formamide hexafluoro-2-propanol

Poly(D,L-lactide-co-glycolide) [85 : 15,PLGA]

Biodegradable Polymer Tetrahydrofuran

17

Chitosan Natural polymer Trifluoroacetic acid Methylene Chloride

Collagen Type I Natural polymer hexafluoro-2-propanol

Collagen Type II Natural polymer hexafluoropropanol

Collagen Type III Natural polymer hexafluoro-2-propanol

Fibrinogen Fraction Natural polymer hexafluoro-2-propanol: essential medium [90/10%]]

Gelatin Type A Natural polymer trifluorethanol

Acetic Acid: Stilled water [60/40%]

1.3.1.

Used Biopolymers

In this thesis used both natural and synthetic polymers have been, seeing the great interest in their study and their increasing application in clinical trials.

Gelatin

Gelatin (GL) is the product of thermal denaturation or disintegration of

insoluble collagen with various molecular weights (MWs) and isoionic points (IEPs) depending on the source of collagen and the method of its manufacturing process of recovery from collagen.

18

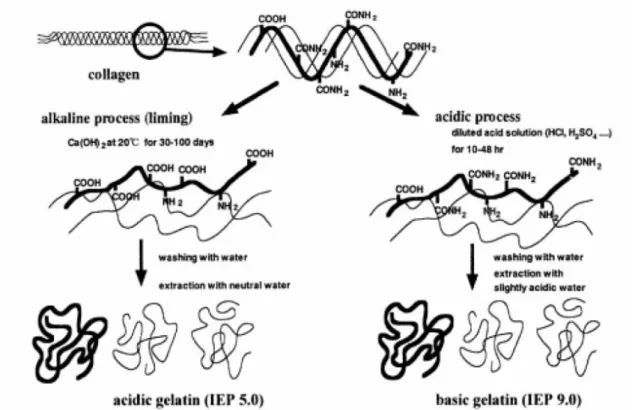

Figure 1-6:Two methods for gelatine extraction from tissues containing collagen

Collagen exists in many different forms, but gelatin is only derived from sources rich in Type I Collagen that generally contains no cysteine. Collagen used for gelatin manufacturing can be from different sources, among which anyhow bovine and porcine gelatins are more-widely used. Gelatin is a polypeptide chain produced by partial denaturation and hydrolysis of collagen that can be extracted from different source. The amino acid composition and sequence of gelatin are different from one source to the other but always consists of large amounts of glycine, proline and hydroxyproline. It is repeated with typical sequence, Gly-X-Y where glycine is the most abundant amino acid in gelatin; X and Y are mostly proline and hydroxyproline, respectively. 25% of dry gelatin contains proline and hydroxyproline that stabilize its structure [14]. The most widely used type of natural polymer are gelatin from bovine skin and from porcine skin because are the most available sources. Gelatin from bovine skin produced from alkaline treatment is known as type B gelatin while porcine skin gelatin produced from acidic treatment is known as type A gelatin.

Collagen is resistant to most proteases and requires special collagenases for its enzyme hydrolysis. Gelatin, however, is susceptible to most proteases, but they do not break down into peptides containing much less than 20 amino acids. Gelatin forms

19 physical gels in hydrogen-bond friendly solvents above a concentration larger than the chain overlap concentration (~ 2 % w/v). These solutions undergoes a first order thermo-reversible gelation transition at temperatures lower then Tg with is ~30°C, during which gelatin molecules undergo an association-mediated conformational transition from random coil to triple helix. The solution has polydisperse random coils of gelatin molecules and aggregates, whereas in gel state there is propensity of triple helices stabilized through intermolecular hydrogen bonding, during which, three dimensional (3D) interconnected network connecting large fractions of the gelatin chains is formed [15]. On the other hand, gelatin was employed as biomaterials more recently, i.e. tissue engineering from ~ 1970s and in recent years as a cell-interactive coating or micro-carrier embedded in other biomaterials. Additionally, its properties can be adapted to desired requirements by additional cross-linking, although shape-instability due to swelling, poor mechanical strength, and low elasticity in vivo, may limit its unrestricted usage. GL is a commercially available biomaterial that is widely used in biomedical engineering due to its similarity to the more expensive collagen adhesive protein [16]. In this work has been used gelatin from porcine skin purchased from Sigma-Aldrich. Gelatin has attracted considerably the attention of various research group for tissue engineering application because it is functionally superior respect to synthetic polymers being able to give chemical signals to facilitate cell adhesion, it is biodegradable and moreover it is easily commercially available. Unfortunately, gelatin hold a great limitation for the production of tissue substitutes for long-term application that arises from its rapid dissolution in aqueous environments. So it is necessary to improve the water resistance of the gelatin, indeed, cross-linking treatment of these materials must prevent gelatin dissolution in water and preserve the peculiar biomimetic morphology [17].

Various method exist to enhance the resistance of this natural polymer in aqueous media and the most wide used are chemical and physical crosslinking methods. Physical crosslinking method include microwave. They have the advantage that they do not cause potential damage. The exact rate of crosslinking instead, represent a crucial drawback in their application; indeed the problem arises from the difficulty to obtain the desired crosslinking degree and in consequence it’s impossible to decide the time life of the material. Among most used chemical crosslinkers there are aldehydes (formaldehyde, glutaraldehyde, glyceraldehyde), polyepoxy compounds. The use of these products hold a great disadvantage that consist in the possibility that not the entire

20 amount of crosslinker reacts during the process. The unreacted substances can remain inside the scaffold with consequent formation of toxic products during in vivo biodegradation. For this reason, increasing interest has been recently gained by enzymatically [18] or naturally derived crosslinking agents, with a low. Two interesting different cross-linking agents are: GPTMS and Genipin.

γ-Glycidoxypropyltrimethoxysilane (GPTMS) is a silane coupling agent, which has epoxy and methoxysilane groups. The epoxy group has a cyclic ether with three atoms and they make the oxirane ring strained. This produce instability in the agent that makes this silane group highly reactive and able to allow the bond between GPTMS molecules and the amino groups on the gelatin chains. During this reaction happened also hydration of the trimethoxy groups on the GPTMS that forms pendent silanol groups (Si-OH) through an acid catalyzed reaction. The final crosslinking of the structure is allowed by the condensation of two Si-OH that occurs while the solvent of the membrane or the unwoven mat is evaporation. This reaction, that happened during drying phase, allows the formation of Si-O-Si linkages that provides inter-chain covalent bonds to achieve a more stable and organized structure.

Figure 1-7: a) Chemical formula of GPTMS; b) crosslinkking reaction involving gelatin and GPTMS

Genipin is an aglycone derived from geniposide, as hydrolytic product, which is found in the fruit of Gardenia jasminoides Ellis. It is from the plant family Rubiaceace and is native to China. The fruit has been used to treat many diseases in traditional

21 Chinese medicine. Its molecular structure (Fig.1.9) is a not old discovery, indeed only after the second half of the century was defined its molecular formula (C11H14O5).

Genipin itself is colorless but it reacts spontaneously with amino acids to form blue pigments.

Figure 1-8: chemical formula of Genipin

Genipin, is a naturally occurring agent that can be used as a coupling agent for amino containing materials. GL indeed is chemically crosslinked through the creation of bonds between functional groups of amino acids. Crosslinking mechanism of genipin with gelatin consists of two reactions, involving different sites on genipin molecule [19]. The process starts with the nucleophilic attack of the genipin C3 carbon atom from a primary amine group to form an intermediate aldehyde group. The just formed secondary amine reacts with the aldehyde group to form a heterocyclic compound. The following step is a nucleophilic substitution reaction that involves the replacement of the ester group on the gelatin molecule by a secondary amide linkage. The reaction is complicated by the oxygen radical-induced polymerization of genipin that occurs once the heterocyclic compound has formed, giving the gel a blue colour. It has been reported that Genipin is 5,000–10,000 times less cytotoxic than glutaraldehyde [20]. Genipin has been widely used as a crosslinking agent for natural polymers in tissue engineering and biomedicine.

22

Figure 1-9: Crosslinking reaction involving gelatin and Genipin

Polycaprolactone (PCL)

is an aliphatic polyester highly biocompatible obtained from the polymerization of the open cycle §- caprolactone. From the physical point of view, it is presented with a semi crystallized melting temperature of 58-63 ° C and a glass transition temperature of -60 ° C. The repeating unit of the PCL, as shown, is composed of five non-polar groups methylene and a relatively polar ester group. This structure gives the PCL unique properties similar to polyolefins for the presence of CH2 groups, while the presence of

foreign connections-aliphatic, hydrolytically unstable, cause degradation of the polymer. Because the homopolymer has a degradation time of the order of two years, copolymers were synthesized copolymers to accelerate the speed of absorption. It’s used not only for the production of degradable film, but even in the field of biotechnology in the creation of absorbable structures, for drug delivery to controlled release systems of drugs and, in recent years, TE. Such a wide use is due by chemical features and physical properties of the polymer accompanied by good qualities of biocompatibility. PCL is a linear aliphatic polyester [figure of formula], its main feature is the ability to degrade in physiological environment; in particular it is concerned with phenomena of degradation due to the easy interaction that the aliphatic ester bond, present long the main chain, shows with water molecules. This mechanism of

23 degradation activated by chemical hydrolysis allows the PCL to be counted as one of the main representatives of the class of biodegradable polymers. During mechanism of hydrolysis occurs the breaking of aliphatic bonds of macromolecules, which become increasingly shorter until the complete degradation of the polymer. Similarly, advancing in the mechanism of degradation, the polymer manifests a percentage reduction of its own mass. Less than six months is the period along which the process of degradation is achieved if the material is located in physiological environment. This is the main reason why it is widely used for TE.

Figure 1-10: PCL chemical formula

The PCL is a thermoplastic polymer and semi-crystalline, and characterized by high workability that enables the rapid remodeling. It shows a high propensity to form compatible mixtures with a large variety of polymers with the aim to have better requirements of biocompatibility and mechanical properties. The main limitation of polycaprolactone, in fact, lies in the confined mechanical properties (compressive strength of 1,58 MPa and resistance to traction of 20,7-42 MPa) if compared, for example, with the main features of natural bone tissue; this is not a restrictive limit if this material is used to study the regeneration soft biological.

Polycaprolactone is an approved material by Food and Drug Administration (FDA) for use in human body. The biocompatible polymer is in form of granules and it must be dissolved in appropriate solvent.

1.4.

MICROFABRICATION TECHNIQUES

With the significant technological progress over the last few years, TE has been able to become a valuable field support to modern medicine with regard to the replacement and repair of tissues or organs. The regeneration of a tissue, as has been

24 previously introduced, requires structures which support the physical and chemical. A scaffold, then, is designed with the purpose to act as a 3D model that mimics the extracellular matrix for the adhesion and cell proliferation. Typically these structures consist of a polymer matrix and preferably biodegradable. In order to guide the best growth and development of tissues biomaterial must have certain properties: biocompatible; should not release toxic substances; porous and the degree of porosity must be able to be controlled; reproducible; must possess thermal and chemical stability; must not be soluble in non-toxic substances; easy workability even in complex forms and structures. The ability of cells to interact with the substrate, thus reflecting the topology of the same, means that it is important to be able to model the polymers in complex architectures and modify surfaces. To this various microfabrication techniques have been developed in recent years. The type of technique to be applied may be different depending on what you want to achieve, since it depends on many variables, including the type of polymer, the required resolution and cost.

25

1.4.1.

Soft-Lithography

The soft-lithography is a technique derived from photolithography and developed by Whitesides at Harvard University, in which the lithographic process is used as starting point for the construction of non-rigid structures with micrometer resolution. The technique is based on chemical and physical processes that using the silicon as a starting material, in particular from silicon wafers (obtained from a crystal with lattice-type <110>), and merging processes of addition, subtraction and doping of the materials, we can obtain the final structures with topology, chemical and physical characteristics of materials appropriate to the goal.

The soft-lithography exploits UV rays to achieve the reactions. The resolution is a function of the materials used and the production process used.

This technique consists in transferring a predetermined pattern on a substrate using a series of chemical reactions, induced by a light radiation, on a photoresist. The

26 photoresist is a photosensitive epoxy resin used for micromachining, micro-electric applications, realization of devices for MEMS (Micro Electro-Mechanical System) technology and for the manufacture of micro lithography. You can recreate images and geometries chemically and thermally stable to UV radiation through creating areas of cross-linked and others are not. There are two types of photoresist positive and negative. 1) Positive: the portions of the resist exposed to UV rays undergo a chemical-structural modification making them more soluble and easily removable by the liquid developer. The mask is then an exact copy of the pattern on the wafer.

2) Negative: UV rays, in this case, have the effect to cause the cross-linking of the photosensitive materials. The exposed part, then, becomes insoluble in the developer. The mask represents the inverse of the pattern.

Figure 1-11: Schematic lithographic process with negative and positive photoresist

The lithographic process starts from silicon wafer (Fig.1.12), that is a material resulting from appropriate processing in order to be monocrystalline and have the surface as regular and smooth as possible.

27

Figure 1-12:Silicon wafer

The realization of the expected pattern on wafer provides distinct and elaborated steps:

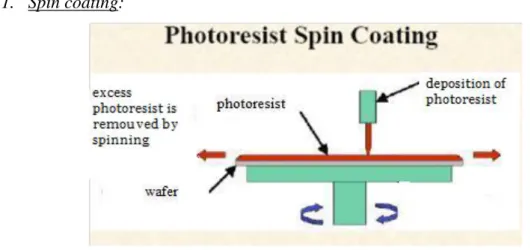

1. Spin coating:

Figure 1-13: schematization of spinning

This operation allows to spread the photoresist on the wafer in a uniform manner. The parameters that govern this process are the time of rotation and speed of rotation expressed in revolutions per minute (rpm). Varying them it’s possible to control the thicknesses of the resist layer, according to the necessity and the final application.

2. Soft-Bake:

Soft-bake is necessary to optimize the yield of the resist; it serves, in fact, to let the solvent evaporate. This phase is actually composed of a pre-cooking and subsequently the real Softbake; the backing time depends on the thickness. The lower initial temperature allows a thickening with controlled rate and thus a better resistance

28 and adhesion of the substrate and to reduce the mechanical stress [MicroChem:

http://www.microchem.com.].

3. Placing the mask on wafer surface and exposure:

It consists in the real impression upon the photoresist of the desired geometry exposing the matarial to UV rays . Excessive doses of radiation at wavelengths below 350 nm can result in an overexposure of the superficial part of the photoresist and consequent distortion of the geometry to achieve, while underexposure can cause a reduction in the effect of cross-linking, resulting in structures with microfractures on the exposed area or who do not adhere to the substrate.

4. Post Exposition Bake:

The PEB, together with the exhibition, is the critical step to achieve the desired structure. Thanks to this it’s possible to obtain a cross-linking by UV irradiated areas only, leaving the other hand, the soluble unexposed areas [MicroChem: http://www.microchem.com.]. Also in this case, to avoid excessive mechanical stress, the procedure can be performed either by gradually increasing the temperature in two steps at different temperatures using the hot plate. The cooking time depends on the thickness.

5. Development:

The development makes sure that on the surface of the wafer remains only the crosslinked structure, while the soluble areas are eliminated. It is used a proper solvent called Developer, that can be used by spray or immersion application. Are shown in the figure, the various development time for baths with solvents depending on the thickness of the film of photoresist.

6. Hard-Bake:

In applications that require the use of the photoresist as an integral part of the final device, it may be useful strengthen its structure increasing the mechanical properties. This is possible by further baking (Hard Bake), on the hotplate or in a conventional oven at temperatures between 150-200 °C, with cooking times that depend on the process used.

29 In order to obtain a final product in non-rigid material, the master on silicon wafer produced with the lithographic process is used as a mold from which derive a copy in the material more appropriate. This technique is generally used in the field of TE, in particular in the manufacture of membranes with which it is possible to alter the surface chemistry of substrates for cell. Once obtained, the master is used in the production of membranes, molds or stencils with which to modify the surface chemistry of other substrates.

The molds can be produced with different materials, including:

• Parylene: is deposited on the master developed and, once cured, removed, obtaining a microfabricated mold, reusable and easily sterilized;

• Polydimethylsiloxane (PDMS): where the mold is obtained by mixing its monomer with the catalyst of the polymerization process. It is cooked in the oven, getting the mold of silicone as a perfect replica of the master negative. The advantage of using the PDMS lies in its biocompatibility and by the fact that seals perfectly hydrophobic surfaces; in addition it hasgood characteristics of transparency and flexibility.

Using the PDMS, the membranes may be obtained by simple casting of the polymer solution directly on the master: once the solution deposited on the support, after baking in the oven for a few hours, the polymer is fully cured. Another method for the production of membranes in PDMS is for spin-coating on the master. The thickness of the membranes is determined by the lateral dimensions of the system, the spacing between the lines of the pattern on the master and the viscosity of the PDMS. Through the use of different membranes with different geometries, it is possible to realize complex geometries on the same substrate, varying from time to time the membrane used to bind different factors and which have different topologies. Once obtained the molds into the PDMS is possible to proceed to the implementation of pattern with different techniques. A first approach could be that of microcontact-Printing. It is accomplished by the transfer of the pattern from the PDMS, or another elastomeric mold, to a solid substrate [21]

30

1.4.2.

Electrospinning

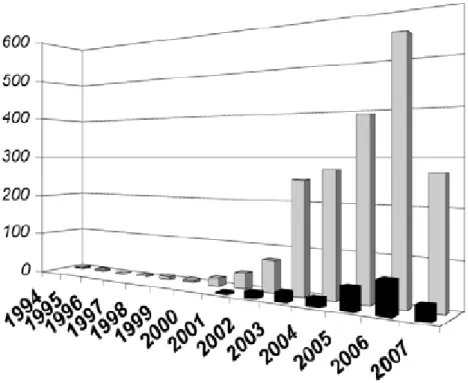

Electrospinning is currently the most important technology that enables the production of continuous polymeric or inorganic fibers in size that can range from tens of nanometers to a few micron. Its potentiality started to be reconsidered only in the last two decades even though this technology has been known since around a century. Indeed, the first to observe this technique was Reyleigh in 1897 and then was better studied by Zeleny in 1914 [22]. The first patent date back to 1934 when Formhals published the description of experimental machine to produce polymeric fibers from solution of esters of cellulose. Nevertheless until 1990 there was little interest for the electrospinning, technique that until that moment was known as 'electrostatic spinning', and only from 1995 (as a result of the affirmation of the nanoscience and nanotechnology) that has been observed a growing interest of researchers to a technology which allowed to produce nano-sized fibers. In this period, indeed, was associated the word Electrospinning to this technique. The increased interest is clear if we observe the scientific publication and patent in the last decades.

31 Much effort has been applied to understand the fundamental phenomena of fabrication process and the chemical and physical properties of material. Therefore a lot of researcher’s group focused their studies to the processing and brought them to have a flexible control of fiber morphology and patterning. In this context, nanofibers found application in a wide range of application field, like tissue engineering, protective textiles, filtration, biomedical technologies, optical electronics, biotechnology, defense and security.

Figure 1-15: overview of nanofibers application

Concerning the bioengineering applications, that represent, with the 20 %,a very large piece of market regarding nanofibers, the most developed researches concern tissue engineering, wound dressing and drug delivery[22]. Wound dressing can exploit the electrospun nanofibrous membrane for the properties such as higher gas permeation and protection of wound from infection and dehydration. The goal of wound dressing is the production of an ideal structure, which gives higher porosity and good barrier [23]. Nanofibers for drug delivery can be thought like a low release system. In fact chemical compound and polymer solution can be mixed to form a unique solution that will be electrospun. The design of fibers and polymer used depends on the releasing rate that the designer. In these field of TE, tissue scaffold consists in nanofiber scaffold

32 enhancing the ability of cell growing and proliferation. The nanofiber scaffolds with seeded cells can be implanted to patient's body to repair the damaged tissues.

ELECTROSPINNING PROCESS

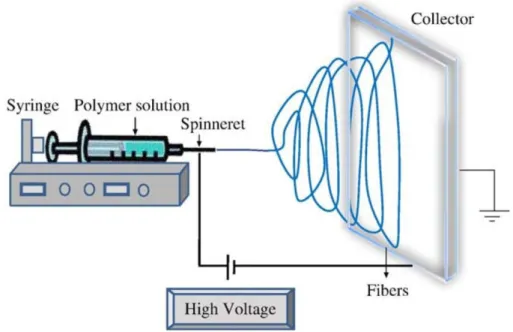

The electrospinning process consist in the use of electrostatic field of high voltage to produce a jet electrically charged from a polymer solution, which by drying which occurs during evaporation, lead to the formation of nanofibers. The traditional electrospinning machine is composed from a syringe pump to hold the polymer solution, two electrodes and a DC voltage supply in the kV range.

Figure 1-16: Electrospinning scheme

Electrospinning also involve the drawing of fluid, either in the form of molten polymer or polymer solution. Unlike conventional drawing method where there is an external mechanical force that pushes the solution, electrospinning makes use of charges that are applied to the fluid to provide a stretching force to a collector where there is a potential gradient. When a sufficient high voltage is applied, a jet of polymer solution will erupt from a polymer solution droplet. The polymer chain entanglements within the solution will prevent the electrospinning jet from breaking up. the electrospinning of polymer solution relies on the evaporation of the solvent for the polymer to solidify to form polymer fiber.

33 The process of formation of nanofiber may be divided in two phases:

A molten or in solution polymer, is immersed in an electric field to increase the electrostatic potential. Raising the potential, increases the electrostatic surface charge of the fluid. The volume of fluid contained in the tip of the needle, due to the charge surface acquired, can overcome the surface tension that influences the shape and take on the shape known as cone of Taylor. The electrical stress is concentrated on the tip of the Taylor cone and the fluid tends to be ejected by the attraction exerted by the external field which results higher at the tip than in the bulk.

Figure 1-17: Pictures shows the phases in which electrospinning is divided

The jet created in Phase I is the bearer of charge and so is directed in the sense of external electric field. After a certain route the jet will be vulnerable to factors instability. In particular the instability for bending is due to the perturbations that exist in the linear trajectory, that act on the fiber’s axis. This is a perpendicular force generated by repulsion between charges that arises when the perfect symmetry of the structure is lost, that is, when the fiber is extended and then tapers. When the jet dries during the flight phase the flow of current go from ohmic to convective as the charge migrates to the surface of the fiber. The jet

34 then stretches under the effect of a process of whipping determined by the electrostatic repulsion initiated by a small flexion and this process continues throughout the phase flight to stop on the ground collector. In this way is obtained a mat of un-woven fibers with nanometric diameter, completely randomly arranged. There is also the possibility to find some collectors, specifically designed, to make the fibers deposit on them in an organized pattern.

Polymers:

Polymers are the most widely applied material for the production of nanofibers other classes ceramic and composite. Most of them are inexpensive as they contain simple elements and they are relatively easy to synthesize. Polymers, with their low density can easily be molded into complex shape, which are strong and relatively inert. They have found applications in many areas such as clothing, food packaging, medical devices and aircraft. Natural polymers such as silks, collagen and agarose have found usage in many TE applications.

We can distinguish polymers in two classes: A. Synthetic Polymers

Among the most used in this category there polyethylene, vinyl chloride polymers and copolymers, and polystyrene. For instance electrospun polystyrene fibers have potential applications in filter membranes and protective clothing. The great interest in the use of electrospun fibers in the area of bioengineering is due to the fact that sub-micron dimension of electrospun fibers resembles that of natural ECM. The most frequently used for tissue scaffolds are the biodegradable aliphatic polyesters such as PCL, PLA and PGA. Another important materials widely used in biomedical application are Polyurethanes. Current applications include catheters, blood bags and artificial heart systems. In the last years, therefore, electrospun polyurethane fibers have shown great promises in the area of wound healing application.

B. Natural Polymers

For many biomedical applications, the materials used have to be biocompatible, thus natural polymers have a distinct advantage over synthetic materials. Since most natural polymer can be degraded by naturally occurring enzymes, it can be used in applications where temporary implants are desired or in drug release. It is also possible to control the degradation rate of the implanted polymer by chemical cross-linking or

35 other chemical modifications thus allowing greater versatility in the design of the implant [25]. Most polymers that have been electrospun are proteins and polysaccharides. Proteins that have been electrospun include collagen, gelatin, fibrinogen.

PARAMETERS OF THE PROCESS

A. Distance between tip and collector

The distance between the tip and the arrival collector, influences the deposition time of the fiber, the degree of evaporation, and the range and degree of instability to which is submitted the jet. These factors will have an impact on the morphology of the fibers. In general, a more aqueous solution needs a greater distance for drying than it requires a system with highly volatile solvent. Megelski et al. [26], have shown that decreasing the distance between the collectors, the fibers of polystyrene had defects producing spheroidal agglomerates of material at the expense of the linearity of the fibers. Even the final diameter of the fibers results to be influenced by the distance. The jet of the polymer, as the distance increases, more time remains at the grip of electromagnetic chaos between the collectors and the prolonged running of the jet in the direction of the collector for collecting the fibers, will work in the way to thin more and more the departure jet leading to visible improvements in the linearity of the fiber and its diameter which will be largely decreased.

B. Voltage

Various motions of instability occur during the process of fiber formation. Most of them are due to the interaction of the electrostatic field and the characteristics of the polymeric material. The initial shape of the jet, its mass and its continuous mutations also impacts on the degree of instability leading to continuous fluctuations in the current spinning. Deitzel et al. [26] have shown that the voltage applied, will greatly influence the degree of instability and therefore the morphology of the fibers. In general the increase of potential provocs a greater deposition rate of the fibers related to an increase in mass flow from the tip of the needle. Other studies such as Magelsky et al. [26] have demonstrated the dependence of the diameter of the fiber from the voltage, using a solution of polystyrene (PS). The size of the fiber was found to be decreased by about 10 microns with an increase of the voltage from 5 to 12 kV, while no significant change was observed in the distribution of pore size.

36

C. Feed/Flow rate

The flow rate affects the speed of the jet and on the transfer rate of the material. Even this time Megelsky et al. [26], have observed that an increase in the flow rate causes a higher porosity and a considerable increase of the size of the fibers. As expected, the amount of individual defects or entire defective structures increases proportionally with increasing flow rate.

ENVIRONMENTAL CONDITIONS

The environmental conditions, so even if a minimum compared to the mentioned parameters influence the process of electrospinning. The air surrounding the machine, its relative humidity (RH), the conditions of vacuum, temperature, also contribute to the final structure of the electrospun fibers. Baumgarden noted, for example, that acrylic fibers electrospun in an atmosphere with relative humidity to 60% dried not properly and had defects. Specific studies have also shown that in special cases the effect of moisture on the fibers can be profitable. Srinivasarao et al. [Srinivasan G, Reneker DH. Structure and morphology of small diameter] have in fact proposed an innovative mechanism for the formation of pores through evaporative cooling called "breathe figures".

SOLUTION PARAMETERS

A. Concentration

Concentration of the solution decides the boundaries for limiting the formation of electrospun fibers causes variations in the viscosity and surface tension. High levels of concentration and surface tension favor the occurrence of defects in the fibers. Too high a concentration prevents the formation of fibers due to the increased viscosity. Dietzel et al. [26], have reported the average fiber diameter and the contraction of the solution with a power law. This agrees with the observations of Zong et al. according to which the causes of corrugated fiber morphology and behavior to be related to the stress relaxation of the fibers that you get a lower polymer concentrations. The primary factor responsible for the success or failure of the process is therefore the viscosity. No matter how important the distance and voltage, an inappropriate choice of the viscosity of the solution does not allow the creation of fibers by electrospinning.

B. Conductivity

The polymers are mostly conductive, with a few exceptions of dielectric materials. Charged ions in the polymer solution highly influence the formation of the

37 jet, increasing the ability to charge transport. Baumgarden has shown that the radius of the jet is inversely proportional to the cube root of the electrical conductivity of the solution electrical conductivity of the solution. Zong et al. [27] have shown the effect of ions on the morphology and diameter of electrospun fibers by adding salt.

C. Volatility

The electrospinning process involves a rapid evaporation of the solvent and phase separations due to thinning of the jet. The vapor pressure determines the flow rate of evaporation and consequently the drying time. The volatility therefore influence the process of phase separation play an important role on the morphology of electrospun structures.

The main advantage to use this technique for the production of tissue scaffolds lies in the possibility that the cells seeded on these non-woven fabrics are able to maintain their shape and drive growth in accordance with the orientation of the fibers. Furthermore, the fabric structure has a morphology similar to the extracellular matrix of native tissue. However, this technology does not allow an accurate control of the shape of the scaffold and allows the creation of structures with limited thickness. Many studies reveal that the use successfully of electrospun fibers as support for cells growing. In the work of A. Subramanian et Al. use aligned nanofibers of PLGA-PCL to realize nonofibrous scaffold for neuronal regeneration. Nanofibers of Collagen are also used to evaluate the long-term performances of the scaffolds seeded with mesenchymal stem cells.

1.4.3.

Rapid Prototyping

The term RP indicates a group of technologies that allows the automatic realization of physical model based on design data using a computer [28.]. RP processes belong to the generative (or additive) production processes. Generative production processes is the generic term (seldom used in practice) to indicate an additive production process. More common are the expressions “additive manufacturing” (AM), or “solid freeform manufacturing” (SFM) and “solid freeform fabrication” (SFF) which emphasize the ability to produce framed solids by means of free form surfaces. In contrast to abrasive

38 (or subtractive) processes such as lathing, milling, drilling, grinding, eroding, and so forth in which the form is shaped by removing material, in RP processes the final object is formed by joining volume elements. This approach applied to TE takes the name of bioprinting [29], defined as the use of computer-aided transfer processes for patterning and assembling living and non-living materials with prescribed 2D or 3D organization in order to produce bio-engineered structures serving in regenerative medicine, pharmacokinetic and basic cell biology studies. Bioprinting can be inserted in the broader field of Computer Aided Tissue Engineering (CATE), the application of advanced computer-aided technologies to TE. RP techniques follow a Computer-Aided-Design/Computer-Aided-Manufacturing (CAD/CAM) approach. Practically, the object is designed using a computer (CAD) which then sends to the machine the instructions to obtain the desired shape (CAM), fabricated layer by layer. In some cases (especially in biomedical field) the geometry is extracted, using dedicated segmentation algorithms, from tomographic scan of the human body. The two-dimensional (2D) layer is shaped (contoured) in a (x-y) plane. The third dimension results from single layers being stacked up on top of each other.

For the implementation of the rapid prototyping principle several fundamentally different physical processes are suitable:

• Solidification of liquid materials (e.g photo-polymerization process);

• Generation from the solid phase:

– incipiently or completely melted solid materials, powder, or powder mixtures (extrusion, ballistic and sinter processes);

– conglutination of granules or powders by additional binders; • Precipitation from the gaseous phase.

Other classifications have been also proposed. An important parameter to choose between different rapid prototyping techniques is the used material, in particular the

39 chemical-physical properties which interact with the working methods of manufacture process.

1.4.4.

Pressure Activated Microsyringe

2Pressure Activated Microsyringe2 (PAM2) is a microfabrication technique developed at the Research Center "E. Piaggio ", University of Pisa. This methodology uses a motorized system along the axes orthogonal xyz for the movement in space of a system controlled in pressure for the extrusion of material to the liquid state. All the system microfabrication is controlled and managed by a computerized system. The manufacture of three-dimensional topologies for manufacturing multilayer occurs through a CAD/CAM system controlled, whose dedicated software uses a bottom-up approach to reconstruct the final three-dimensional model. [30]

The PAM2 allows the manufacturing of scaffolds with a well-defined architecture, using wide range of biomaterials: solutions of synthetic and natural polymers, suspensions containing viable cells (bio-ink). This system has a modular architecture: different microfabrication devices can be mounted on the vertical axis (z axis) of a manipulator Robotic three orthogonal axes. The xy plane moving respect the z-axis draws the trajectories for the achievement of each slice; for the construction of additional slice the microfabrication tool moves up of Δz that depends on the particular type of material used for obtain the scaffold.

40

Figure 1-18: PAM^2; magnification shows the use of the PAM's module using laser rays

All microfabrication modules have a mechanical specific layout, independent tanks, carefully designed nozzles, and all operating parameters are controlled independently.

The software interface of PAM2 system allows to design the needed architecture in easy way. For the realization of path with complex geometry is necessary to choose the right strategy in which design the pathway that the machine will follow. Indeed this is a system that uses the approach called “direct writing” in which there is the need to anticipate a continuous extrusion pathways.

Picture of software