ALLEGATO C: Verifiche Strutturali del Modulo

Gestione Cambio, condizioni di carico 2

ANSYS Analysis By

April 28, 2005 An ANSYS Analysis

Report Generated by ANSYS Mechanical Toolbar

Summary Model Information Analysis Information Results Information

Summary

This report documents a linear static analysis of the assembly untima_struttura_asm which was imported from the file F:/STUDIO/ANSYS/aaa/untima_struttura_asm.igs and subjected to the load environment Environment 1 . The analysis was performed using the ANSYS 8.0 CAE software. The assembly untima_struttura_asm was assigned properties of the materials given in Table 2 and showed the following results:

Maximum total displacement is 0.21011 mm Maximum equivalent stress is 29.041 MPa

For details about the analysis, see Model Information, Analysis Information, and Results Information.

Model Information

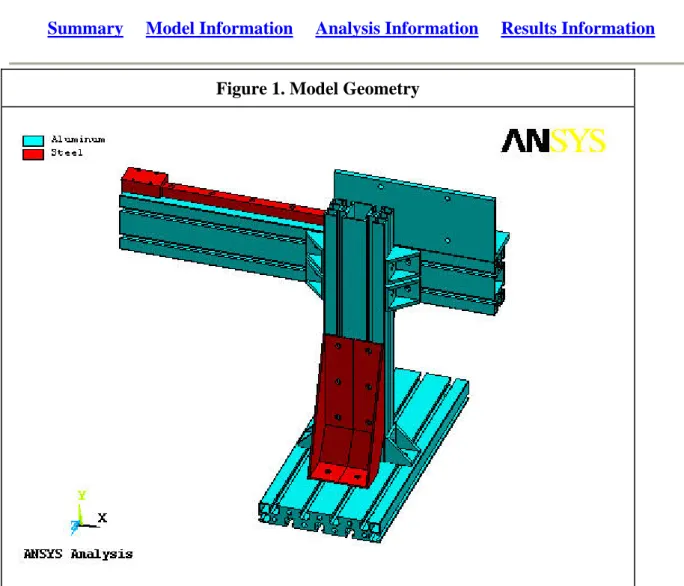

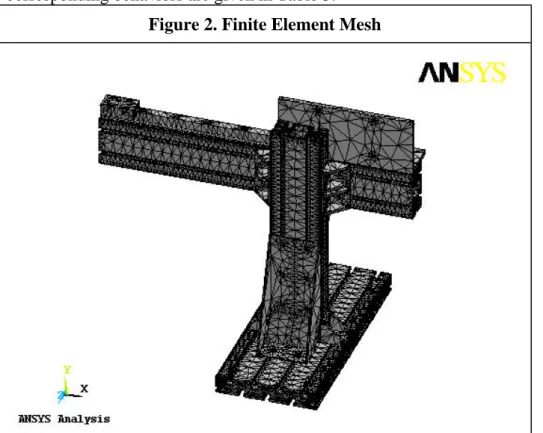

The assembly untima_struttura_asm has a weight of 99.01 N ( 10.10 kg ) and was imported from F:/STUDIO/ANSYS/aaa/untima_struttura_asm.igs . Figure 1 shows the model geometry and Figure 2 shows the finite element mesh. Table 1 lists the number of nodes and elements and Table 2 lists the properties of the materials used in the model.

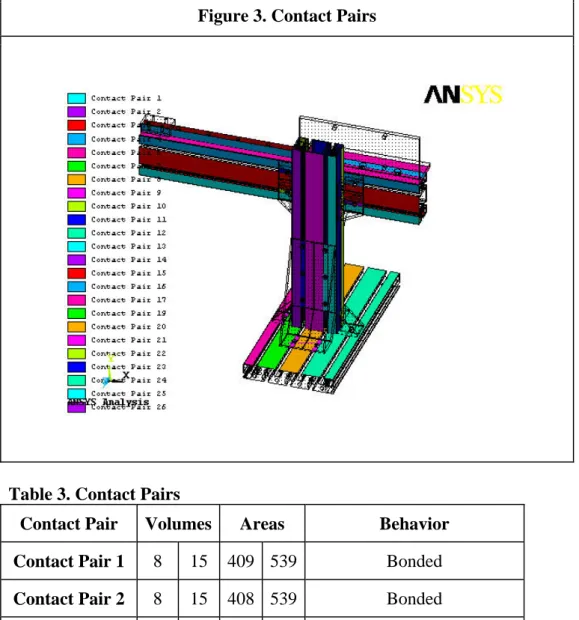

The model is an assembly consisting of 18 parts. Figure 3 shows the contact pairs and their corresponding behaviors are given in Table 3.

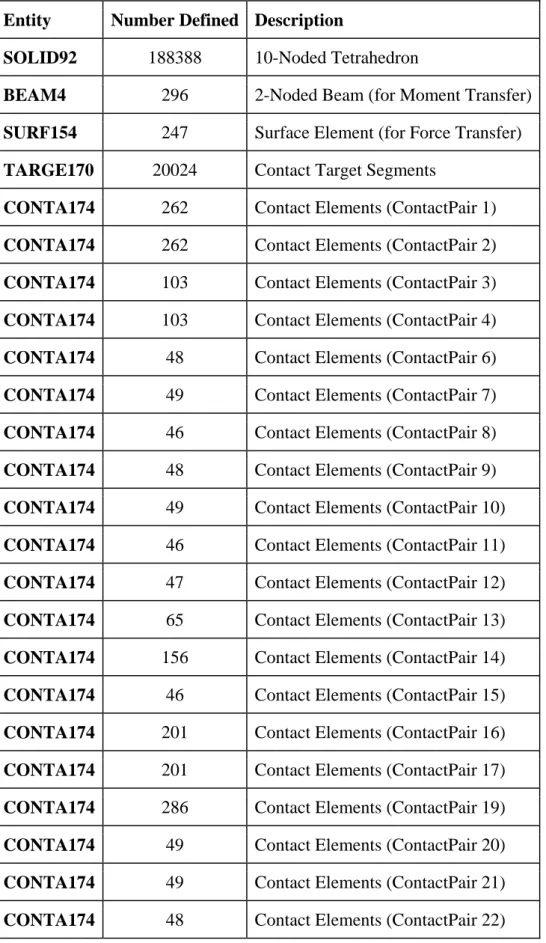

Table 1. Details of the Finite Element Model Entity Number Defined Description

SOLID92 188388 10-Noded Tetrahedron

BEAM4 296 2-Noded Beam (for Moment Transfer)

SURF154 247 Surface Element (for Force Transfer)

TARGE170 20024 Contact Target Segments

CONTA174 262 Contact Elements (ContactPair 1)

CONTA174 262 Contact Elements (ContactPair 2)

CONTA174 103 Contact Elements (ContactPair 3)

CONTA174 103 Contact Elements (ContactPair 4)

CONTA174 48 Contact Elements (ContactPair 6)

CONTA174 49 Contact Elements (ContactPair 7)

CONTA174 46 Contact Elements (ContactPair 8)

CONTA174 48 Contact Elements (ContactPair 9)

CONTA174 49 Contact Elements (ContactPair 10)

CONTA174 46 Contact Elements (ContactPair 11)

CONTA174 47 Contact Elements (ContactPair 12)

CONTA174 65 Contact Elements (ContactPair 13)

CONTA174 156 Contact Elements (ContactPair 14)

CONTA174 46 Contact Elements (ContactPair 15)

CONTA174 201 Contact Elements (ContactPair 16)

CONTA174 201 Contact Elements (ContactPair 17)

CONTA174 286 Contact Elements (ContactPair 19)

CONTA174 49 Contact Elements (ContactPair 20)

CONTA174 49 Contact Elements (ContactPair 21)

CONTA174 48 Contact Elements (ContactPair 23)

CONTA174 49 Contact Elements (ContactPair 24)

CONTA174 476 Contact Elements (ContactPair 25)

CONTA174 49 Contact Elements (ContactPair 26)

CONTA174 226 Contact Elements (ContactPair 27)

CONTA174 48 Contact Elements (ContactPair 28)

CONTA174 48 Contact Elements (ContactPair 29)

CONTA174 476 Contact Elements (ContactPair 30)

CONTA174 286 Contact Elements (ContactPair 32)

CONTA174 65 Contact Elements (ContactPair 33)

CONTA174 50 Contact Elements (ContactPair 34)

CONTA174 156 Contact Elements (ContactPair 35)

CONTA174 46 Contact Elements (ContactPair 36)

CONTA174 476 Contact Elements (ContactPair 37)

CONTA174 226 Contact Elements (ContactPair 38)

CONTA174 47 Contact Elements (ContactPair 39)

CONTA174 50 Contact Elements (ContactPair 40)

CONTA174 476 Contact Elements (ContactPair 41)

CONTA174 48 Contact Elements (ContactPair 43)

CONTA174 65 Contact Elements (ContactPair 44)

CONTA174 146 Contact Elements (ContactPair 45)

CONTA174 48 Contact Elements (ContactPair 46)

CONTA174 48 Contact Elements (ContactPair 47)

CONTA174 48 Contact Elements (ContactPair 48)

CONTA174 146 Contact Elements (ContactPair 49)

CONTA174 48 Contact Elements (ContactPair 50)

CONTA174 476 Contact Elements (ContactPair 52)

CONTA174 226 Contact Elements (ContactPair 53)

CONTA174 48 Contact Elements (ContactPair 54)

CONTA174 286 Contact Elements (ContactPair 55)

CONTA174 65 Contact Elements (ContactPair 56)

CONTA174 48 Contact Elements (ContactPair 57)

CONTA174 476 Contact Elements (ContactPair 58)

CONTA174 48 Contact Elements (ContactPair 60)

CONTA174 48 Contact Elements (ContactPair 61)

CONTA174 48 Contact Elements (ContactPair 62)

CONTA174 46 Contact Elements (ContactPair 63)

CONTA174 46 Contact Elements (ContactPair 64)

CONTA174 48 Contact Elements (ContactPair 65)

CONTA174 48 Contact Elements (ContactPair 66)

CONTA174 48 Contact Elements (ContactPair 67)

CONTA174 48 Contact Elements (ContactPair 68)

CONTA174 48 Contact Elements (ContactPair 69)

CONTA174 48 Contact Elements (ContactPair 70)

CONTA174 48 Contact Elements (ContactPair 71)

Nodes 360651

Table 2. Material Properties

Material Properties for Aluminum

Modulus of Elasticity [ MPa ] 7.3000E+04

Density [ kg/mm^3 ] 2.7700E-06

Poisson's Ratio 0.3300

Material Properties for Steel

Modulus of Elasticity [ MPa ] 1.9300E+05

Density [ kg/mm^3 ] 8.0300E-06

Poisson's Ratio 0.2900

Thermal Expansion Coefficient [ 1/degC ] 1.7800E-05

Figure 3. Contact Pairs

Table 3. Contact Pairs

Contact Pair Volumes Areas Behavior

Contact Pair 1 8 15 409 539 Bonded

Contact Pair 2 8 15 408 539 Bonded

Contact Pair 3 15 16 568 587 Bonded

Contact Pair 4 15 16 566 585 Bonded

Contact Pair 7 8 11 420 484 Bonded

Contact Pair 8 8 12 421 500 Bonded

Contact Pair 9 1 5 50 310 Bonded

Contact Pair 10 8 11 421 484 Bonded

Contact Pair 11 8 12 422 500 Bonded

Contact Pair 12 1 7 50 342 Bonded

Contact Pair 13 1 3 50 264 Bonded

Contact Pair 14 2 3 205 266 Bonded

Contact Pair 15 2 10 239 468 Bonded

Contact Pair 16 8 17 409 596 Bonded

Contact Pair 17 8 17 408 596 Bonded

Contact Pair 19 1 2 50 167 Frictionless (No Separation)

Contact Pair 20 2 5 203 301 Bonded

Contact Pair 21 2 5 202 301 Bonded

Contact Pair 22 8 10 383 459 Bonded

Contact Pair 23 8 10 384 459 Bonded

Contact Pair 24 2 11 203 475 Bonded

Contact Pair 25 2 8 239 420 Frictionless (No Separation)

Contact Pair 26 2 11 202 475 Bonded

Contact Pair 27 2 8 239 421 Frictionless (No Separation)

Contact Pair 28 2 12 203 491 Bonded

Contact Pair 29 2 12 202 491 Bonded

Contact Pair 30 2 8 239 422 Frictionless (No Separation)

Contact Pair 32 1 2 48 167 Frictionless (No Separation)

Contact Pair 33 1 3 48 264 Bonded

Contact Pair 34 2 7 239 333 Bonded

Contact Pair 36 2 10 240 468 Bonded

Contact Pair 37 2 8 240 420 Frictionless (No Separation)

Contact Pair 38 2 8 240 421 Frictionless (No Separation)

Contact Pair 39 1 7 48 342 Bonded

Contact Pair 40 2 7 240 333 Bonded

Contact Pair 41 2 8 240 422 Frictionless (No Separation)

Contact Pair 43 1 6 48 326 Bonded

Contact Pair 44 1 4 48 294 Bonded

Contact Pair 45 2 4 206 282 Bonded

Contact Pair 46 2 9 240 452 Bonded

Contact Pair 47 2 6 240 317 Bonded

Contact Pair 48 8 9 384 443 Bonded

Contact Pair 49 2 4 207 282 Bonded

Contact Pair 50 2 9 241 452 Bonded

Contact Pair 51 8 9 383 443 Bonded

Contact Pair 52 2 8 241 420 Frictionless (No Separation)

Contact Pair 53 2 8 241 421 Frictionless (No Separation)

Contact Pair 54 1 6 51 326 Bonded

Contact Pair 55 1 2 51 167 Frictionless (No Separation)

Contact Pair 56 1 4 51 294 Bonded

Contact Pair 57 2 6 241 317 Bonded

Contact Pair 58 2 8 241 422 Bonded

Contact Pair 60 1 18 51 637 Bonded

Contact Pair 61 8 13 420 516 Bonded

Contact Pair 62 8 13 421 516 Bonded

Contact Pair 63 8 14 421 532 Bonded

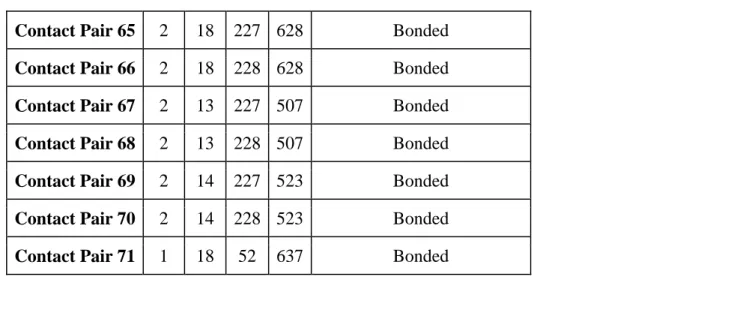

Contact Pair 65 2 18 227 628 Bonded

Contact Pair 66 2 18 228 628 Bonded

Contact Pair 67 2 13 227 507 Bonded

Contact Pair 68 2 13 228 507 Bonded

Contact Pair 69 2 14 227 523 Bonded

Contact Pair 70 2 14 228 523 Bonded

Contact Pair 71 1 18 52 637 Bonded

Analysis Information

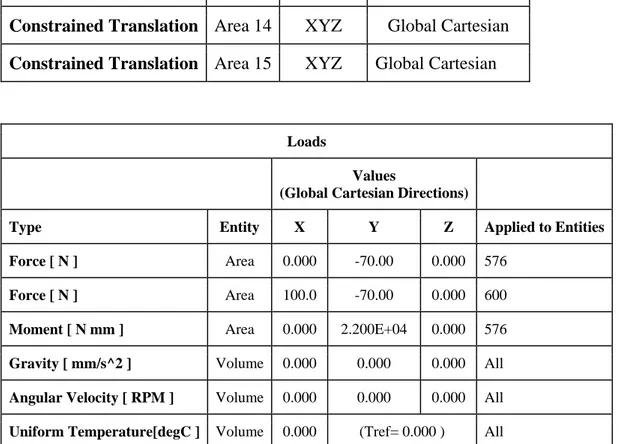

The assembly untima_struttura_asm was subjected to the load environment Environment 1 (see Figure 4 and Table 4) and evaluated with a linear static analysis.

Figure 4. Loads and Boundary Conditions

Table 4. Boundary Conditions for Environment: Environment 1 Constraints

Type Entity Direction Coordinate System

Constrained Translation Area 14 XYZ Global Cartesian

Constrained Translation Area 15 XYZ Global Cartesian

Loads

Values

(Global Cartesian Directions)

Type Entity X Y Z Applied to Entities

Force [ N ] Area 0.000 -70.00 0.000 576

Force [ N ] Area 100.0 -70.00 0.000 600

Moment [ N mm ] Area 0.000 2.200E+04 0.000 576

Gravity [ mm/s^2 ] Volume 0.000 0.000 0.000 All

Angular Velocity [ RPM ] Volume 0.000 0.000 0.000 All

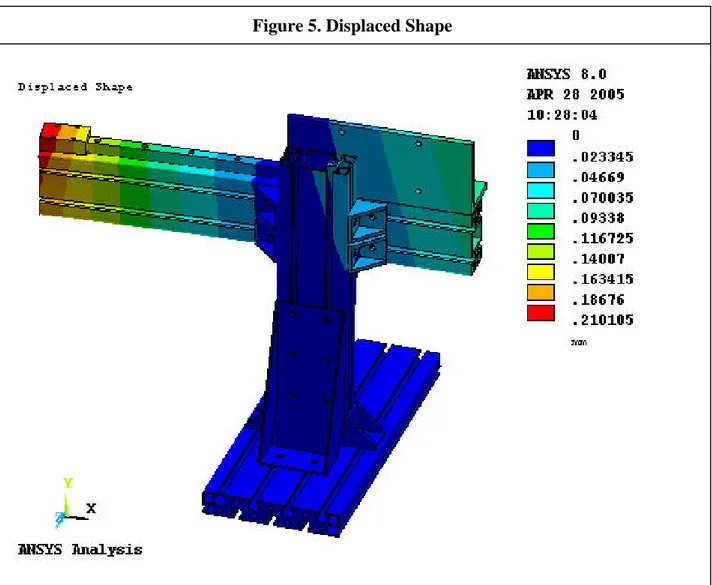

Results Information

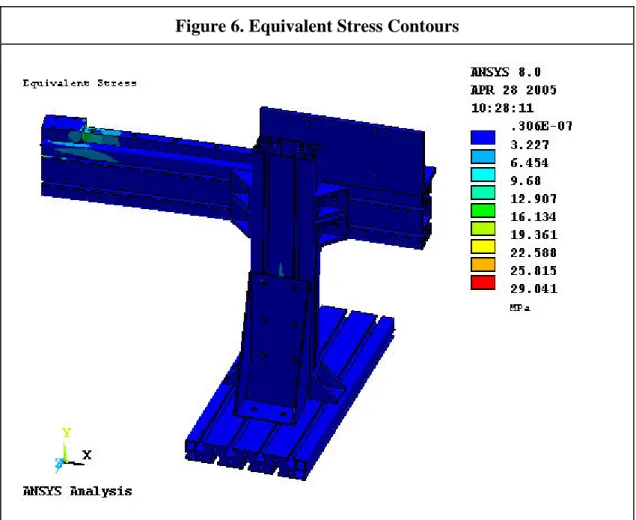

The following figures and tables show the response of the assembly untima_struttura_asm to the load environment Environment 1 . The maximum total displacement is 0.21011 mm and the maximum equivalent stress is 29.041 MPa .

Figure 5. Displaced Shape

Figure 6. Equivalent Stress Contours

Table 5. Sum of the Reaction Forces

Total Reaction Force [ N ]

X Y Z

-100.00 140.00 5.26569E-04

Table 6. Moment About the Global Origin Due to the Reactions

Total Moment [ N mm ]

X Y Z

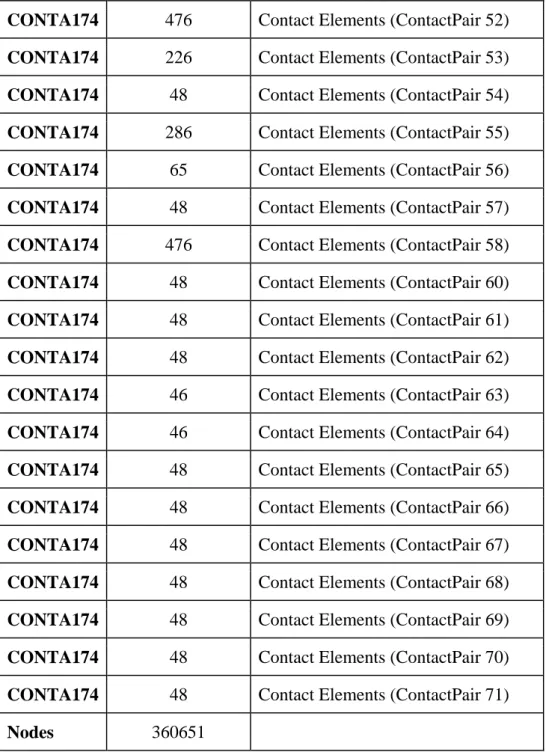

Table 7. Forces Transmitted Between Parts in Global Cartesian Forces [ N ] Contact Pair X Y Z Contact Pair 1 0.42100 -71.255 -2.4492 Contact Pair 2 0.42100 -71.255 -2.4492 Contact Pair 3 -241.32 -32.515 8.4816 Contact Pair 4 241.32 -37.486 -8.4816 Contact Pair 6 5.9102 37.138 31.668 Contact Pair 7 -118.18 62.809 -44.487 Contact Pair 8 -49.506 21.391 -6.2041 Contact Pair 9 5.9102 37.138 31.668 Contact Pair 10 -118.18 62.809 -44.487 Contact Pair 11 -49.506 21.391 -6.2041 Contact Pair 12 -29.993 34.111 54.171 Contact Pair 13 54.618 22.167 -9.3758 Contact Pair 14 -78.628 446.84 -94.904 Contact Pair 15 -27.609 -143.57 40.567

Contact Pair 16 100.00 -70.002 3.69146E-06 Contact Pair 17 100.00 -70.002 3.69146E-06 Contact Pair 19 -1.5328 -122.12 4.3152 Contact Pair 20 -3.4037 -38.134 -29.288 Contact Pair 21 -3.4037 -38.134 -29.288 Contact Pair 22 23.790 145.23 -59.241 Contact Pair 23 23.790 145.23 -59.241 Contact Pair 24 120.88 -65.369 61.363 Contact Pair 25 77.498 -5.8265 15.960 Contact Pair 26 120.88 -65.369 61.363

Contact Pair 27 89.869 -39.254 57.634 Contact Pair 28 47.399 -23.891 12.801 Contact Pair 29 47.399 -23.891 12.801 Contact Pair 30 17.368 -9.4744 -77.225 Contact Pair 32 -1.5328 -122.12 4.3152 Contact Pair 33 54.618 22.167 -9.3758 Contact Pair 34 28.744 -46.249 -60.192 Contact Pair 35 -78.628 446.84 -94.904 Contact Pair 36 -27.609 -143.57 40.567 Contact Pair 37 77.498 -5.8265 15.960 Contact Pair 38 89.869 -39.254 57.634 Contact Pair 39 -29.993 34.111 54.171 Contact Pair 40 28.744 -46.249 -60.192 Contact Pair 41 17.368 -9.4744 -77.225 Contact Pair 43 -18.994 -73.658 -61.913 Contact Pair 44 60.216 47.728 6.8594 Contact Pair 45 -45.788 -518.16 93.232 Contact Pair 46 -59.543 63.092 -37.905 Contact Pair 47 18.669 85.721 62.171 Contact Pair 48 57.448 -57.515 43.435 Contact Pair 49 -45.788 -518.16 93.232 Contact Pair 50 -59.543 63.092 -37.905 Contact Pair 51 57.448 -57.515 43.435 Contact Pair 52 77.498 -5.8265 15.960 Contact Pair 53 89.869 -39.254 57.634 Contact Pair 54 -18.994 -73.658 -61.913 Contact Pair 55 -1.5328 -122.12 4.3152

Contact Pair 56 60.216 47.728 6.8594 Contact Pair 57 18.669 85.721 62.171 Contact Pair 58 17.368 -9.4744 -77.225 Contact Pair 60 34.831 -84.449 -26.588 Contact Pair 61 -20.491 -22.450 34.124 Contact Pair 62 -20.491 -22.450 34.124 Contact Pair 63 4.3293 -14.753 2.4175 Contact Pair 64 4.3293 -14.753 2.4175 Contact Pair 65 -31.118 95.091 24.615 Contact Pair 66 -31.118 95.091 24.615 Contact Pair 67 18.957 20.805 -33.576 Contact Pair 68 18.957 20.805 -33.576 Contact Pair 69 -2.8149 13.092 -0.30258 Contact Pair 70 -2.8149 13.092 -0.30258 Contact Pair 71 34.831 -84.449 -26.588 Table 8. Displacements Displacements [ mm ] X Y Z Vector Sum

Maximum -2.76946E-02 -1.50580E-02 0.20814 0.21011

Table 9. Direct Stresses Direct Stresses [ MPa ]

X Y Z

Minimum -18.546 -12.348 -20.812 Maximum 18.425 8.4995 21.466

Table 10. Shear Stresses Shear Stresses [ MPa ]

XY YZ XZ

Minimum -3.4597 -15.606 -4.5799 Maximum 3.4136 3.7607 4.6478 Table 11. Principal Stresses

Principal Stresses [ MPa ]

1st 2nd 3rd

Minimum -5.1529 -9.1184 -26.670 Maximum 26.007 8.7572 3.5150

Table 12. Stress Intensity and Equivalent Stress Stress Intensity and Equivalent Stress [ MPa ]

Stress Intensity Equivalent Stress

Minimum 3.42065E-08 3.05664E-08

![Table 7. Forces Transmitted Between Parts in Global Cartesian Forces [ N ] Contact Pair X Y Z Contact Pair 1 0.42100 -71.255 -2.4492 Contact Pair 2 0.42100 -71.255 -2.4492 Contact Pair 3 -241.32 -32.515 8.4816 Contact Pair](https://thumb-eu.123doks.com/thumbv2/123dokorg/7227643.78089/13.892.78.469.162.1157/transmitted-global-cartesian-contact-contact-contact-contact-contact.webp)