4th INTERNATIONAL CONFERENCE

BITUMINOUS MIXTURES AND PAVEMENTS Thessaloniki, Greece, 19-20 April 2007

LABORATORY PERFORMANCE EVALUATION OF CEMENT

STABILIZED RECYCLED CRUSHED CONCRETE

F. Lancieri

Full Professor, University of Pisa, IT

A. Marradi *

Senior Researcher, University of Pisa, IT

S. Mannucci

PhD Student, University of Pisa, IT

*

University of Pisa, Department of Civil Engineering, Road and Transportation

Division, 56126 Pisa, Italy, [email protected]

ABSTRACT

The use of mixtures for road pavement construction constituted by granular materials recycled from demolition wastes is becoming increasingly widespread, due to the well known economic and environmental advantages. The present research was conducted within this sector of studies in order to assess the performance of recycled concrete mixtures stabilized with different cement contents and designed for pavement base layers in terms of unconfined compressive strength, indirect diametrical tensile strength and elastic modulus. The influence of two different compaction methods, Proctor compaction and gyratory compaction, on resistance characteristics was evaluated. In particular, using the gyratory compactor, which more successfully simulates the passing of rollers, the degree to which the period of time intervening between humidification of the mixture and its compaction (workability period) influences maximum dry density and resistance parameters was investigated. Finally, the performances were evaluated by the fatigue test, also as a means of comparing the durability of crushed concrete mixtures stabilized with cement to that of traditional cement stabilized aggregate mixtures, indicated in the current technical literature. Based on the analysis of laboratory test results, it is possible to state that the performance of the crushed concrete stabilized mixtures is comparable to that of natural aggregate mixtures, even at relatively low percentages (2 %) of added cement.

1. INTRODUCTION

This paper is the continuation of a previous study analyzing the mechanical behavior of aggregate obtained from construction and demolition work, stabilized with different contents and typologies of hydraulic binders [1]. In the present work, experiments focused on mixtures composed of crushed concrete stabilized with low quantities of cement.

In order to prepare specimens for laboratory analysis, we used both the traditional AASHTO Mod. compaction procedure, in conformity with the specifications and technical regulations for use of the types of stabilized aggregate currently adopted in road construction in Italy, and also the gyratory compaction procedure. With the gyratory compactor, the stress-strain path induced in the mixture is very similar to that produced on site by the action of rollers [2, 8].

Tests were performed on the specimens to determine the mechanical characteristics of the mixtures, with particular attention to Unconfined Compressive Strength (UCS) CNR B.U. n. 29/1972, Indirect Diametrical Tensile Strength (IDT) UNI EN 12390-6/2002 and the elastic modulus (E) prEN 13286-43/2002. Specific tests were also conducted to determine the workability period and to assess the effects of delayed compaction on both physical and mechanical characteristics.

In addition, dynamic Indirect Diametrical Tensile tests were conducted in order to compare the durability of stabilized recycled crushed concretewith that oftraditional stabilized virgin aggregate.

2. OBJECTIVES

The aims of the present study can be summarized as follows:

• evaluation of the workability of stabilized recycled crushed concrete; • analysis of the mechanical characteristics of mixtures compacted with

the AASHTO Mod. methodology or the gyratory compactor;

• analysis of fatigue behavior, also in comparison to the typical fatigue behavior of traditional stabilized virgin aggregate.

3. MATERIALS

The aggregate analyzed was obtained by laboratory crushing of concrete (Rck ≥ 30 MPa), using a jaw crusher. Sieve analysis of the aggregate is shown in

Table 1.

Table 1: Particle size of crushed concrete

Sieve [mm] 25.4 19.0 12.7 4.76 2.00 0.84 0.42 0.177 0.075 Passing [%] 100 98.8 74.5 29.8 11.4 7.0 4.8 2.8 1.2

The crushed concrete, which was found to be free from fine plastic fractions as demonstrated by the Atterberg limits (n.p.) and by the value of the sand equivalent (SE = 83 %), presented an abrasion resistance value LA=33%.

The type of binder added was UNI EN 197-1 CEM II/B-M 32.5 Portland cement.

4. SPECIMEN PREPARATION TECHNIQUES AND CURING

Optimum compaction moisture content of the material was determined both with the AASHTO Mod. procedure and also with the gyratory compactor. With the latter method, ram pressure was set at 600 kPa, gyratory speed at 30 rev/min and the gyratory angleat 1.25°. The revolutions adopted for compaction was set at 90, because specific prior analyses showed that for the material under study this number of revolutions gave a compaction curve with maximum dry density values virtually identical to those obtained with the AASHTO Mod. test.

Optimum compaction moisture as measured with the gyratory compactor was found to be 10%, while that obtained with the AASHTO Mod. test was 11.5%. Maximum dry density, with both compaction techniques, was

γd max = 1.87 Mg/m3 for the mixture containing 2% cement and

γd max = 1.91 Mg/m3 for the 4% cement mixture.

Specimens were compacted one hour after the end of mixing. They were then stored for 24 hours in the molds and subsequently subjected to curing in an environment with 90% relative humidity and temperature of 20°C.

5. MATERIAL CHARACTERIZATION TEST 5.1 Workability period

It is known that proper laying of cement stabilized mixtures requires knowledge of their workability. This issue, which is of major importance when recycled aggregate is used, has also been addressed by other Researchers [3].

European legislation has introduced a specific standard, recently implemented in Italy (UNI EN 13286-45/2004), which defines the experimental procedures for determining the "workability period" of mixtures stabilized with hydraulic binders.

To conduct the investigation, specimens containing 2% cement were set up using both compaction methods, i.e. the Proctor compaction method and the gyratory compactor. Intervals of 0, 1, 3 and 5 hours were allowed between the end of mixing and the beginning of specimen compaction. The Dry Density Ratio (Ratio between dry density obtained with specimens compacted at time ti

and that of specimens compacted immediately after humidification of the material t = 0) was then determined. Furthermore, in order to evaluate the performances associated both with the different degrees of compaction achieved and with the different delays to compaction, the corresponding IDT ratio (ratio between Indirect Diametrical Tensile strength of specimens compacted at time ti

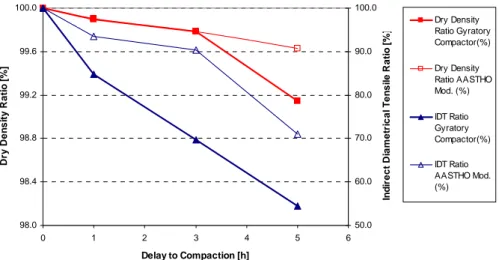

add that of specimens compacted immediately after humidification t = 0) was evaluated on specimens cured for 7 days. The results thereby obtained are shown in Figure 1. 98.0 98.4 98.8 99.2 99.6 100.0 0 1 2 3 4 5 6 Delay to Compaction [h] Dry Den s it y Rat io [ % ] 50.0 60.0 70.0 80.0 90.0 100.0 In d irect Di amet ri cal T e n s il e Rat io [ % ] Dry Density Ratio Gyratory Compactor(%) Dry Density Ratio AASTHO Mod. (%) IDT Ratio Gyratory Compactor(%) IDT Ratio AASTHO Mod. (%)

Figure 1: Effect of delay between mixing and compaction

5.2 UCS and IDT Test

UCS and IDT tests were performed applying a pressure gradient of 1.0 MPa/s and 0.05 MPa/s respectively.

Tensile strength values obtained for each type of test, curing duration, type of mixture and compaction method were determined as means of the values obtained on four specimens (Table 2).

Table 2: Results of UCS and IDT tests

Curing time [days]

7 28 Cement content [%] Delay to compaction [h] Moisture content [%] UCS [MPa] IDT [MPa] UCS [MPa] IDT [MPa] 2 0 10.0 - 0.33 - - 2 1 10.0 3.17 0.28 3.64 0.38 2 3 10.0 - 0.23 - - 2 5 10.0 - 0.18 - - Gyratory Compact ion 4 1 10.0 3.48 0.38 4.49 0.58 2 0 11.5 - 0.31 - - 2 1 11.5 2.61 0.29 - - 2 3 11.5 - 0.28 - - 2 5 11.5 - 0.22 - - 2 1 10.0 2.93 - - - 2 1 8.0 2.84 - - - Pro cto r Compact ion 2 1 8.0 2.84 - - -

5.3 Determination of elastic modulus E

Tests for determination of the elastic modulus were performed with controlled load according to the procedures established by prEN 13286-43/2002, adopting the same speed of load application used for the UCS tests. In addition to the mean value of the secant modulus (Es), calculated at 30% ultimate strength,

mean values of the tangent modulus at the origin (Et) and of the modulus of

rupture (Er) were also determined.

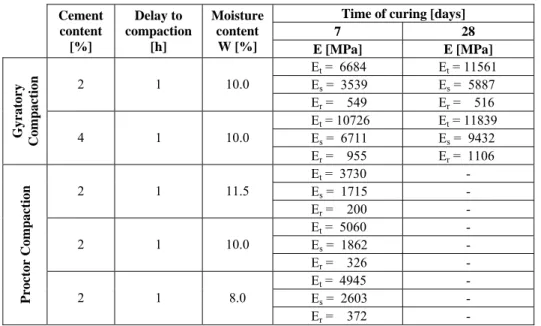

The results shown in Table 3 were likewise determined as means of values obtained on four specimens.

Table 3: Results of tests for calculation of the elastic modulus E

Time of curing [days]

7 28 Cement content [%] Delay to compaction [h] Moisture content W [%] E [MPa] E [MPa] Et = 6684 Et = 11561 Es = 3539 Es = 5887 2 1 10.0 Er = 549 Er = 516 Et = 10726 Et = 11839 Es = 6711 Es = 9432 Gyratory Compaction 4 1 10.0 Er = 955 Er = 1106 Et = 3730 - Es = 1715 - 2 1 11.5 Er = 200 - Et = 5060 - Es = 1862 - 2 1 10.0 Er = 326 - Et = 4945 - Es = 2603 - Procto r Compa ction 2 1 8.0 Er = 372 - 5.4 Fatigue Test

Fatigue resistance tests were performed on cylindrical specimens, cured for 28 days, having 150 mm diameter and 100 mm height. Use of the gyratory compactor was preferred rather than the traditional AASHTO method because it allows greater density homogeneousness both between different specimens of a given mixture and also along the specimen axis [6,7]. With the aid of an oleodynamic press designed by Prof. M. Losa and built by AIP (Varese, Italy), controlled effort tests were carried out by applying load levels ranging from 50 % (SR = 0.50) to 90 % (SR = 0.90) of indirect diametrical tensile ultimate strength.

An indirect diametrical tensile effort with haversine waveform of a 0.1 s load-unload period followed by a 0.4 s rest period was induced on the specimens. During the rest period, specimens were maintained at a constant level of stress corresponding to 10% of ultimate strength. This type of load was adopted on the basis of ASTM 4123-87, since in the case of cement stabilized

materials the speed of load application in a range between 1 and 15 Hz does not influence significantly fatigue behavior [4,5]. Tests were continued up to failure of the specimen.

As the indirect diametrical tensile strength of cement stabilized granular mixtures depends to a large extent on the preparation of the mixture (water content, mixing procedures, waiting period between humidification and compaction), even small variations in these parameters can lead to differences of as much as 20% among IDT values. Therefore, series of at least 4 specimens for fatigue tests and for rigorous control of Stress Ratio (SR) values were obtained from each mixture.

6. ANALYSIS OF RESULTS 6.1. Workability period

Results of maximum workability period tests showed that even at 5-hour intervals between mixing and compaction (a considerably longer period than the limit normally stated in technical specifications), the material retained good compactibility and reached over 99% compaction both with the AASHTO Mod method and the gyratory compactor. Thus on the basis of the indications contained in Standard UNI EN 13286-45/2004, mixture workability time was longer than 5 hours, as even beyond this period the material reached over 98% compaction.

However, these good workability characteristics were not associated with corresponding levels of mechanical performance. The results shown in Figure 1 demonstrate that even in cases where variations in physical characteristics (Dry Density Ratio) were only slight, significant reductions in mixture IDT could be found when waiting time before compaction was extended up to 5 hours. Thus roughly 30% and 45% reduction in IDT were found on specimens compacted according to the AASHTO Mod. and the gyratory method respectively.

6.2 UCS, IDT and E tests

The results of the UCS and IDT tests showed that the mixtures analyzed were able to develop substantial mechanical resistance even at low percentages of added binder, with resistance values satisfying the requirements generally stated for traditional cement stabilized aggregate mixtures. But a comparison between results obtained with the two different compaction techniques allows the conclusion that specimens compacted with the gyratory compactor, under equal conditions of dry density or moisture content, led to better performances, above all as regards E modulus values (Table 3).

The better behavior exhibited by specimens prepared with the gyratory compactor can be partially attributed to the effect of a 1.5% lower optimum moisture content compared to that obtained with the AASHTO Mod. method, as the water-cement ratio involved in gyratory compaction is closer to the ratio considered to be optimal. This hypothesis was confirmed in tests conducted by

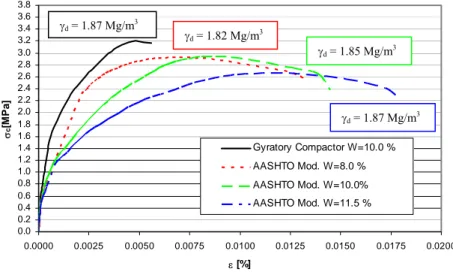

compacting the samples with the AASHTO Mod. method and adopting lower than optimum moisture content (8 % and 10 %). As expected, specimen dry density decreased with decreasing quantity of mixing water, but since these mixtures are characterized by compaction curves having low sensitivity to variations in water content, the degree of compaction was found to be above 97% even when moisture content was 3.5% lower than optimum. Despite this decrease in density, the better water-cement ratio of the mixtures led to an appreciable increase in modulus value, although it remained lower than that obtained by compacting the material with the gyratory compactor (Figure 2). UCS values also showed a slight increase as compared to the value corresponding to optimum moisture.

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6 3.8 0.0000 0.0025 0.0050 0.0075 0.0100 0.0125 0.0150 0.0175 0.0200 ε [%] σ c [M P a ] Gyratory Compactor W=10.0 % AASHTO Mod. W=8.0 % AASHTO Mod. W=10.0% AASHTO Mod. W=11.5 %

Figure 2: Stress-Strain curves

Therefore, as can be seen in Figure 2, on specimens cured for 7 days the variation in water-cement ratio mainly caused a marked variation in deformability.

It can also be noted that the two compaction techniques did not give specimens with the same mechanical characteristics either under conditions of equal dry density or under equal moisture content. The better behavior obtained with use of the gyratory compactor can be attributed to different particle positioning during the compaction process, which was achieved with a stress-strain path similar to that which the material undergoes in situ through the action of rollers [2,8]. It therefore seems appropriate to extend application of this compaction method to mixtures of the type under examination in the present study, with the aim of obtaining laboratory specimens characterized by performance parameters that are more representative of on site mixtures, at least during the pre-cracked phase.

Values of the Es modulus, calculated according to prEN 13286-43/2002 on

samples compacted with the AASHTO Mod. method, showed that by using

γd = 1.87 Mg/m3

γd = 1.82 Mg/m3

γd = 1.85 Mg/m3

recycled crushed concrete aggregate with a low percentage of added cement (2%) it becomes possible to obtain fairly similar results to the cement stabilized aggregate mixtures currently utilized, which involve use of virgin aggregate and appreciably higher quantities of cement (≥ 3 %). This equivalence was found even though the low apparent dry density values of the recycled concrete aggregate led to lower density values of the mixture (γd = 1.87 Vs γd = 2.35

Mg/m3) and considerably higher AASHTO optimum compaction moisture values (Wopt = 11.5 Vs Wopt = 5.5 %), with a correspondingly rather less

favorable water-cement ratio, partly due to the lower binder requirement.

6.3 Fatigue test

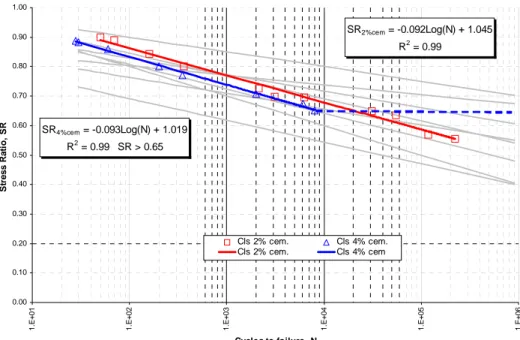

The crushed concrete mixtures showed good behavior under the action of repeated dynamic loads, even when mixtures were stabilized with relatively low quantities of cement. Their behavior in the fatigue test, represented in the graph of Figure 3, can be expressed by equation (1).

( )

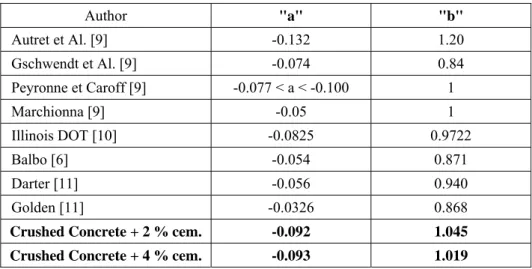

N b Log a SR tr t = ⋅ + σ σ = (1)Parameters "a" and "b", obtained by interpolation, were included within the range which, according to numerous Authors, characterizes the fatigue of traditional stabilized virgin aggregate, as can be seen both from the curve in Figure 3 and from the values given in Table 4.

The results obtained demonstrate that for SR values greater than 0.65 the 2% cement mixture had slightly greater fatigue resistance than the 4% mixture. This was probably due to the greater rigidity and consequent fragility of the latter mixture [12].

For SR values lower than 0.65 an inversion of this behavior was observed, as an endurance limit was identifiable with the 4% cement mixture.

Table 4: Coefficients "a" and "b" of the fatigue laws in Figure 3

Author "a" "b" Autret et Al. [9] -0.132 1.20 Gschwendt et Al. [9] -0.074 0.84 Peyronne et Caroff [9] -0.077 < a < -0.100 1 Marchionna [9] -0.05 1 Illinois DOT [10] -0.0825 0.9722 Balbo [6] -0.054 0.871 Darter [11] -0.056 0.940 Golden [11] -0.0326 0.868

Crushed Concrete + 2 % cem. -0.092 1.045 Crushed Concrete + 4 % cem. -0.093 1.019

SR2%cem = -0.092Log(N) + 1.045 R2 = 0.99 SR4%cem = -0.093Log(N) + 1.019 R2 = 0.99 SR > 0.65 0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 1. E + 01 1. E + 02 1. E + 03 1. E + 04 1. E + 05 1. E + 06 Cycles to failure, N St re s s R a ti o , SR Cls 2% cem. Cls 4% cem. Cls 2% cem. Cls 4% cem

Figure 3: Fatigue resistance curves

7. CONCLUSIONS

The results of the workability tests show that the crushed concrete mixture stabilized with only 2% of cement was characterized by a prolonged workability period. However, this mixture underwent a non negligible decline in resistance during this period. The results obtained demonstrate that depending on the compaction method utilized, IDT values after a 5-hours wait between mixing and compaction decreased by roughly 30% and 45% for samples compacted according to the AASHTO Mod. and the gyratory method respectively.

Under equal dry density or moisture content, specimens obtained with the gyratory compactor gave performances (UCS, IDT and E) that were not only more representative, during the pre-cracked phase, of the behavior of the material when in place, but were also higher compared to performances obtained by the AASHTO Mod. compaction procedure. In particular, values of the Es modulus obtained for the mixture stabilized with 2% cement were found

to be of the same order of magnitude as values normally obtained on samples produced by using virgin aggregate stabilized with greater quantities of cement (≥ 3 %).

It was found that on account of the elevated optimum compaction moisture that characterizes recycled aggregate, adoption of this moisture value for compaction of cement stabilized mixtures, as is generally done for virgin aggregate, can impair mixture performance due to the unfavorable water-cement ratio. Future studies could thus aim to also assess the influence of the water-cement ratio on fatigue behavior in such mixtures.

Analysis of the fatigue behavior of mixtures compacted to Wopt suggested

that for Stress Ratio values SR greater then 0.65, the mixture stabilized with 2% fresh cement exhibited slightly better fatigue resistance than the mixture containing 4% of binder. By contrast, for SR values lower than 0.65 an inversion of the behavioral trend was observed, with the presence of a possible endurance limit for the 4% cement stabilized mixture.

These results suggest that a relatively inexpensive base course containing recycled aggregate with low quantities of cement (2 %) is very promising in terms of fatigue strength characterized by behavior similar to that of stabilized virgin aggregate.

REFERENCES:

[1] Marradi A. and Mannucci S., Use of crushed concrete for road pavement base layer, XVI° National SIIV Congress, Cosenza 20-22 September 2006 [2] George K.P., Resilient testing of soils using gyratory testing machine,

Transportation Research Record No. 1369, TRB, pp.63-72, 1992.

[3] Yeo R. E. Y. and Sharp K. G. - Recycled crushed concrete stabilised with

cementitious binders - Report prepared by VicRoads et Alii, 1997.

[4] Sobhan K. and Mashnad M., Fatigue damage in roller compacted pavement foundation with recycled aggregate and waste plastic strips,

Transportation Research Record No. 1798, TRB, pp.8-16, 2002.

[5] American Concrete Institute Committee 554, consideration for design of concrete structures subjected to fatigue loading. ACI Manual of Concrete

Practice part I, 1990.

[6] Balbo J.T., High quality cement treated crushed stones for concrete pavement bases, Proceedings of the Sixth International Purdue Conference

on Concrete Pavement, Nov. 18-21, vol.1, pp.195-207, Indianapolis, 1997.

[7] Sidoroff G. V., Delplanque G. and Rami M., Compactage D'éprouvettes en Graves-Ciment. Comparaison de Résultats Obtenus en Laboratoire avec un Marteau Electrique et un Compacteur Proctor Modifié. Bullettin de liaison

des Laboratoires des Ponts e Chaussées, n. 26, 1967.

[8] Simone A., La caratterizzazione dei terreni mediante l'utilizzo della pressa giratoria, X° National SIIV Congress, Catania 26-28 Ottobre 2000.

[9] Giannattasio P., Caliendo C., Festa B., Nicolosi V. and Pernetti M., Materiali stabilizzati con leganti idraulici, Napoli Luglio 1993.

[10] Arellano D. and Thompson M. R., Stabilized base properties for mechanistic-based airport pavement design, February 1998.

[11] Transport Research - Cost 333, Development of new bituminous pavement design method, 1999.

[12] Sobhan K. and Krizek R., Fatigue behavior of fiber-reinforced recycled aggregate base course, Journal of materials in civil engineering, May 1999.