ContentslistsavailableatSciVerseScienceDirect

Journal

of

Molecular

Catalysis

A:

Chemical

j o ur na l ho me p ag e :w w w . e l s e v i e r . c o m / l o c a t e / m o l c a t a

Acid

catalyzed

alkylation

of

phenols

with

cyclohexene:

Comparison

between

homogeneous

and

heterogeneous

catalysis,

influence

of

cyclohexyl

phenyl

ether

equilibrium

and

of

the

substituent

on

reaction

rate

and

selectivity

L.

Ronchin

∗,

A.

Vavasori,

L.

Toniolo

DepartmentofMolecularScienceandNanosystems,UniversityCa’FoscariofVenice,Dorsoduro2137,30123Venice,Italy

a

r

t

i

c

l

e

i

n

f

o

Articlehistory: Received1August2011 Receivedinrevisedform 28November2011 Accepted7December2011 Available online 16 December 2011 Keywords: Acidcatalysis Sulfonatedresins Phenolsalkylation Alkylationselectivity

a

b

s

t

r

a

c

t

Thereactivityofseveralphenolstowardliquidphasealkylationwithcyclohexeneinthepresenceof heterogeneousandhomogeneousacidcatalystat358Kisstudied.ThecomparisonbetweenAmberlyst 15andCH3SO3H,asexamplesofheterogeneousandhomogeneoussystems,showsahigheractivityof

theformerwithdifferentbehaviorofselectivitybetweenthetwosystems,anyway,inbothsystems O-alkylationandringalkylationsoccur.Aremarkabledifferenceintheselectivityofthering alkyla-tionbetweenheterogeneousandhomogeneoussystemsisobserved:Amberlyst15showsaconstant ortho/pararatiocloseto2,whileinthepresenceofCH3SO3Hortho/paraisvariablefrom3to5,

sug-gestinganinvolvementofthecyclohexylphenyletherrearrangement.Thisisprovedalsobyadirect relationshipbetweentheortho/pararatioandtheconcentrationofthecyclohexylphenyletherwhen CH3SO3Hisusedasacatalyst.Theformationofcyclohexylarylethersisreversible;onthecontrary,ring

alkylationappearsirreversible.Thereactivityofthedimethylphenolsshowsastronginfluenceofthe sterichindranceofthesubstituentontheelectrophilicattackofthecyclohexylcation,whichispoorly influencedbytheinductiveeffectofthemethylgroup.

© 2011 Published by Elsevier B.V.

1. Introduction

Organicindustrial processesemploy acidcatalyzed reactions

such as alkylation, acylation, isomerization, cracking, nitration,

condensation,esterification,etc.Thegreentechnologiesinorder

to replacethe traditional polluting mineralacid catalysts with

solidonesarecontinuouslyimproved[1–6].Zeolites,acidtreated

clays,ionexchangeresinsandsupportedacidsareinvestigatedby

severalresearchersfortheirapplicationinpharmaceutical,

per-fumery, agro-chemicals, dye-stuffs, intermediates and specialty

chemicalindustries[5–12].Alkylationreactionsinparticularare

really importantin theindustrialsynthesis ofmany largescale

productioncompounds[11,12].

Alkylationof phenolwithcyclohexene hasattracted

consid-erableinterest becauseofitsindustrialand academicrelevance

[13–21]. This reaction leads to a variety of products such as

4-cyclohexylphenol, 2-cyclohexylphenol, and cyclohexyl phenyl

etherdependingonboththecatalystandthereactionconditions.

Theuseof solid acidcatalystsappearsa suitable alternativeto

theusualproceduresinhomogeneousphasewithcatalystssuch

asAlCl3,BF3,TiCl4,HF.Onconsideringthecurrentefforttoward

∗ Correspondingauthor.Fax:+390412348517. E-mailaddress:[email protected](L.Ronchin).

processinnovationaimedtoavoidenvironmentalconcerns,

ion-exchangeresinsappeartobeidealcatalyststoconvertpolluting

processesintogreenerones[2–6].

Inalargenumberofindustrialprocessesthecation-exchange

resinsareusedasacatalystsuchasinMTBEorTAMEsynthesis,

themanufactureofalkylphenolsandbisphenolA,the

esterifica-tionofavarietyofcarboxylicacids,thehydrationofalkenes,the

dimerizationofisobutene,etc.[4–6,19,22,23].

Themechanismofacidcatalyzedalkylationiswellknownfor

alongtimeanditiswidelyacceptedthecarboniumionattackto

theelectronicrichcenterasthekeystepofthereaction[24,25].

Cyclohexeneinthepresence ofacidgivesthecyclohexylcation

asatransientspeciesthatreadilyreactswithanucleophilegiving

thecorrespondingcyclohexylderivative.Therearrangementtothe

morestablemethylcyclopentylcationoccursonlyinanegligible

extentsincetheskeletonrearrangementisslowerthanthe

nucle-ophilicattack,whichoccurs,formanynucleophiles,atencounter

[26].

ThestudyofRichardandcoworkersonthereactivityof

phe-nolasnucleophiletowardmethylphenylcarbocationshowedthat

therelativeratesforalkylationofphenolat OH,C-4andC-2are

230:20:1,respectively.Onthecontrary,thealkylationofthe

corre-spondingnucleophilicsitesofphenoxideion,whichisanencounter

reaction,showedtherelative rates of2:2:1 [27]. Otherauthors

pointedoutthattheselectivitytowardtheorthopositioninthe

1381-1169/$–seefrontmatter © 2011 Published by Elsevier B.V. doi:10.1016/j.molcata.2011.12.007

phenolalkylation is favored when theless hindered secondary

carboniumionsaretheelectrophiles,whiletertiarycarbocations

giveprevalentlyparaalkylation[28,29].ThestudiesofSharmaand

coworkers,carriedoutintheearlyninetyrelatingthereactivity

ofphenolinthepresenceofsulfonatedresins,pointed outthat

theortho–paraselectivityintheringalkylationofphenolisstrictly

relatedtothenatureoftheolefinemployed.Inparticular,propene

and1-butenegiveanortho–pararatiocloseto2,whileisobutene,

␣-methylstyreneand diisobutene give almost exclusivelypara

alkylation[29].Recently,BhattandPatelreportedthatsupported

12-tungstosilicicacidcatalyzesonlyringcyclohexylationofphenol

givinganortho–pararatiocloseto2[15].Morerecently,Hölderich

andcoworkersshowedthathighparaselectivityisobtainedinthe

alkylationofphenolwithisobuteneinthepresenceofcatalysts

withLewisorBrønstedacidsites,indifferently.Theselectivityisnot

sensibletothetypeofacidpresentinthecatalystbuttheactivity

isinfluencedbytheamountandthestrengthofthesites[30].

Thecomparisonofactivityandselectivitybetween

heteroge-neousandhomogeneousBF3/SiO2 and BF3·(H2O)2 catalystswas

studiedbyClarkandcoworkers[21].Theypointedoutthat

cyclo-hexylphenyl ether, and cyclohexyl phenols are formed in the

presenceofbothsystems,butonlybythehomogeneousBF3·(H2O)2

asacatalyst therearrangementoftheether toalkylphenols is

observed[21].YadavandKumarhaverecentlystudiedthekinetics

ofphenolcyclohexylationcatalyzedbydifferentsolidacids,which

catalyzetheformationofphenylcyclohexyletherandthe

prod-uctsof ringalkylationina ortho–pararatiocloseto2 [14].The

mechanisticaspectoftheelectrophilicattacktothephenolis

inves-tigatedfromatheoreticalpointofviewbyTangandcoworkers.

Theseauthorssuggestedthattheadditionofthesulfonicacidto

theolefinsoccursleadingtotheformationofasulfonicester

inter-mediate,which,inturns,reactswithphenoltoformtheproducts

ofalkylation[31].

Inthispaperwestudythecyclohexylationofsomephenolsand

thereactivityofcyclohexylphenyletherinthepresenceofboth

CH3SO3Handsulfonicresins.Inparticular,weinvestigatetherole

ofthecyclohexylphenyletherontheortho–paraselectivityandthe

reactivityofthedimethylphenolsinordertoaccountforthesteric

hindranceofthemethylgroupsontheelectrophilicattackofthe

cyclohexylcation.

2. Experimental

2.1. Materials

Reagentsandsolventswereusedafterpurificationofthe

com-merciallyavailablesamplesandtheirpuritywascheckedbythe

usualmethods(meltingpoint,TLC,HPLC,GCandGC–MS).The

sol-ventsweretreatedinadoublebedcolumn,filledwithH2SO4/SiO2

andSiO2toadsorbwaterandimpurities.Theresidualwatercontent

wascheckedbyHPLCanalysis[32].Commercialcatalysts:

macro-reticularsulfonatedstyrenedivinylbenzeneresinsAmberlyst15TM

andAmberlyst36TM(atrademarkofRohmandHaas)were

pur-chasedfromAldrich.

2.2. Reactions

The reactions and the kinetic runs were performed in a

stirred glass reactor thermostatted by a circulation bath at

358K,containingweighedsamplesofsolvent,reagentsand

cat-alyst at autogenous solvent pressure (122 and 158kPa for 1,2

dichloroethaneandbenzene,respectively).Inatypicalexperiment

10mLofsolutioncontaining10mmolofphenol,10mmolof

cyclo-hexeneplus5mmolofmethylcyclohexaneasinternalstandardand

thedesiredamountofcatalyst(100–500mg)wereplacedinthe

reactor.Alltheoperationswerecarriedoutintoagloveboxinorder

tominimizecatalystdeactivationbyairmoisture.Smallamounts

ofthesolutionweredrawnatdifferenttimesandthesampleswere

analyzedbyGC,andGC–MSusingaHP5capillarycolumn(300m

i.d.30mlong,95%methyl,5%phenylsiliconephase).Thesamples

werecheckedalsobyHPLCusingaPerkinElmerapparatusanda

Lichrosphere100(RP-18,5m)column.Thefirstderivativeattime

0ofathirdorderpolynomialfunction,obtainedbyfitting

cyclohex-eneconcentrationvs.timeat10%ofconversion,gavetheinitialrate

ofreaction.

Forareliablecomparisonoftheperformancesofdifferent

cat-alystsitisessentialtoknownifreactionratedataareaffectedby

diffusionphenomena.Thisisverifiedbystudyingtheinfluenceof

thegranulometryandofthecatalystamountonthereactionrate

catalyzedbythemostactivecatalyst(Amberlyst36)at373K.The

experimentalevidencessuggestthatthekineticsisnotinfluenced

bydiffusionphenomena,sincetherearenodifferencesinthe

ini-tialrateusingresinswithdifferentgranulometryandtheinitial

reactionratesarestrictlyproportionaltothecatalystamount.In

addition,theinspectionofCarberryandWheeler-Weisznumbers

showsvalueslowerthan0.1and0.4,respectively[33].

3. Resultsanddiscussion

3.1. Influenceofsolventandcatalystonreactionrate,conversion

andselectivity

Table1reportstheactivityoftwosulfonatedresinsinthe

alkyla-tionofphenol.Maximumyield,asreportedinTable1,iscomprised

between20and26%at40–50%ofconversion.DespiteofAmberlyst

36promotesainitialrateofreactionhigherthanthatofAmberlyst

15,thelattergivesthehighestyieldintheether.Asamatteroffact,

Amberlyst36(5.5meq.H+g−1cat)showsahigheractivitythanthe

Amberlyst15(4.7meq.H+g−1cat),thisislikelyduetothehigher acidcontentoftheformer.Infact,theactivitiesofthetwocatalysts

arequitesimilarconsideringtheinitialturnoverfrequencyreferred

tothewholeH+sites(Table1).CH

3SO3H(inhomogeneousphase)is

theleastactivecatalystanditsTOFis20timeslowerthanthatofthe sulfonicresins,likelyduetothehigheracidityofthelatter[34].As

amatteroffact,byconsideringp-toluensulfonicacidassimplified

modelforthesulfonicresins,thepKaofthep-toluensulfonicacidsis

2.7pKaunitslowerthanthatofmethanesulfonicacid(−4.7and−2,

respectively)[35].InthepresenceofAlCl3thereactionisfaster,but

thecomparisonoftheactivitiesofsulfonatedresins,

methanesul-fonicacid(proticacids)andAlCl3(Lewisacid)iscumbersomedueto

thedifferentnatureoftheacidsite.Itisnoticeablethatthe

reactiv-ityoftheorthoandparapositionsofphenolisnotinfluencedbythe

typeofsulfonicresinsemployed.Ortho-andpara-positionsofthe

phenolshowsimilarrelativereactivitygivingortho–pararatio ∼= 2

ineitherbenzeneor1,2-dichloroethane.Incontrast,anot

negligi-blesolventeffectseemstobeplayedbynitromethane,sincethe

initialreactionratesarealmostoneorderofmagnitudelowerthan

thosemeasuredinbenzeneand1,2-dichloroethane.Inaddition,the

ortho–pararatioclearlydiminishes(o/p ∼= 1.5),thussuggestingan

influenceofthesolventontheelectrophilicattack[36].

DespiteofthelargedifferenceofactivitybetweenCH3SO3Hand

AlCl3inhomogeneousphase,thereactionsshowasimilaro/pratio

(4.2and4.5),thussuggestingsimilarrelativereactionrateforeach

stageinthishomogeneousreactions.

Theconcentration–timeprofilesreportedinFigs.1–3,relativeto

thereactionsinthepresenceofAmberlyst15,CH3SO3HandAlCl3,

respectively,showdifferenttrends.Fig.1reportsthereaction

cat-alyzedbyAmberlyst15.Itappearsthatcyclohexylphenyletheris

atransientspecies,whichisalmostcompletelyconsumedatthe

Table1

Alkylationofphenol:selectivityafter240minofreactionat358K.Runconditions:phenol1.1molL−1,cyclohexene1.1molL−1,catalyst400mg,reactionvolume10mL.

Catalyst Conv.(%) r0a TOFb Ethermaximum

yield(%)

Selectivityc(%) o/p

2-Cyclohexylphenol 4-Cyclohexylphenol Dicyclohexylphenols Cyclohexylcyclohexene Ratio Benzene Amb.15 42 15 5.3 25 29 16 13 15 1.9 Amb.36 48 18 5.8 23 38 21 14 18 1.9 1,2-Dichloroethane Amb.15 51 18 6.8 26 29 14 15 12 2.0 Amb.36 64 22 6.9 23 31 16 18 15 1.9 CH3SO3Hd 21 3.5 0.34 17 10 2.4 2.3 2 4.2 AlCl3d,e 44 58 7.7 15 5 1.1 4.6 1 4.5 Nitromethane

Amb.15 16 3.8 0.81 10 24 16 Traces Traces 1.5

Amb.36 19 6.0 1.1 10 24 16 Traces Traces 1.5

a(105molL−1s−1gcat−1).

bInitialturnoverfrequency(104s−1)

c Productsintraceamount,astheisomersofalkylatedthecyclohexylether,hasbeenneglected. d Homogeneousreactions. eT288K,AlCl 31mmol. 1200 1000 800 600 400 200 0 0.0 0.2 0.4 0.6 0.8 1.0 1.2 cyclohexene phenol

cyclohexyl phenyl ether

2-cyclohexylphenol 4-cyclohexylphenol co nc en tr a tio n (M ol L -1 )

time (miinutes)

1200 1000 800 600 400 200 0 0.00 0.02 0.04 0.06

cyclohexycyclohexene

di-cyclohexylphenol

Fig.1.Reactionprofileofalkylationofphenolat358KcatalyzedbyAmberlyst 36.Runconditions:phenol1.1molL−1,cyclohexene1.2molL−1,catalyst400mg, solvent1,2-dichloroethane,reactionvolume10mL.

1200 1100 200 100 0 0.0 0.1 0.2 0.4 0.6 0.8 1.0 co n centr ation (mol L -1 )

time (minutes)

cyclohexene

cyclohexyl phenyl ether

2-cyclohexylphenol

4-cyclohexylphenol

cyclohexylcyclohexene

Fig.2.Reactionprofileofalkylationofphenolat358Kcatalyzedby methanesul-fonicacid.Runconditions:phenol1molL−1,cyclohexene1molL−1,catalyst400mg, solvent1,2-dichloroethane,reactionvolume10mL.

di-cyclohexyl phenols increasesmonotonically duringthe

reac-tioncourse.Formationofdi-cyclohexylphenolsisobservedalso

atverylowconversion,becauseofalkylphenolsarehighly

acti-vatedtowardtheelectrophilicattack[37].Under theconditions

usedthemainsidereactioniscyclohexenedimerization,whose

product(cyclohexylcyclohexene) showsanalmostlinear

mono-tonicincreaseduringreactioncourse.Itisnoteworthythatdimer

formationisstronglyinhibitedusingnitromethaneasthesolvent,

suggestinganinhibitingeffectofthesolventontheformationof

theelectrophile[36].

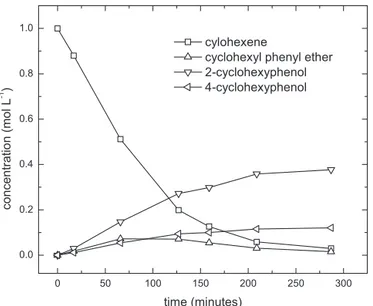

Fig.2showsthereactionprofileinthepresenceofCH3SO3H:

thereactionisalmosttentimeslowerthanthatinthepresence

ofAmberlyst15asacatalyst(Table1)andafter20hofreaction

all theproductsare still increasing, while theformation of

di-cylohexylphenolsisnegligible.Theconcentration–timeprofileof

phenolcyclohexylationcatalyzedbyAlCl3(Fig.3)evidencesafast

reactionalsoat288K(almosttwiceofthatmeasuredinthe

pres-enceofAmberlyst15at358K)butthereactioncompletelystops

after55min,withamodestconversionandwithanoticeableloss

ofthemassbalance.Suchabehaviorsuggestsafastcatalyst

deac-tivationduetotheformationofheavypitch,whichisconfirmedby

HPLCanalysis. 1200 1000 250 200 150 100 50 0 0.00 0.05 0.10 0.15 0.6 0.8 1.0 1200 1000 200 150 100 50 0 0.000 0.005 0.010 0.015 0.020 co nc e n tr a tio n ( m o l L -1) time (minutes) cyclohexene

cyclohexyl phenyl ether

2-cyclohexyphenol 4-cyclohexylphenol cyclohexylcyclohexene di-alkykphenol

Fig.3. ReactionprofileofalkylationofphenolcatalyzedbyAlCl3at288K.Run conditions:phenol1molL−1,cyclohexene1molL−1,catalyst140mg,solvent 1,2-dichloroethane,reactionvolume10mL.

100 80 60 40 20 0 2 3 4 5 o/ p ra tio conversion (%) CH3SO3H Amberlyst 15 AlCl3

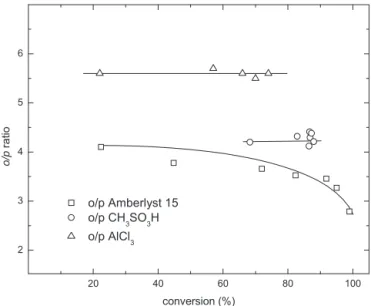

Fig.4.Comparisonofortho/pararatiovs.conversioninthecyclohexylationof phe-nolinthepresenceofliquidandsolidacidcatalysts.Runconditions:cyclohexene andphenol1molL−1,Amberlyst15andCH3SO3H1.8meqH+,AlCl310mmol,solvent 1,2-dichloroethane,reactionvolume10mLT358K.

InFig.4 thetrend oftheortho–pararatio vs. conversionfor

eachcatalyst isreported.EmployingAmberlyst15 asa catalyst

ortho–pararatioremainspracticallyconstant(1.9–2.1),whereas,

inthepresenceofCH3SO3H,monotonicallyincreasesfrom2.4to

4.2astheconversionincreases.AlsointhepresenceofAlCl3,the

ortho–pararatiovs.conversionincreasesfrom4.1to4.5.These

evi-dencessuggestadifferentnatureintheformationoftheorthoand

paraisomersasthecatalystnaturechange.Thisisconfirmedby

thetrendsoftheortho–pararatiovs.cyclohexylphenylether

con-centrationreportedinFig.5.Clearly,thereisalinearrelationship

betweentheetherconcentrationandtheformationoftheortho

iso-merinthepresenceofCH3SO3H,thussuggestingtheinvolvement

ofthecyclohexylphenyletherintheformationoftheorthoisomer,

likelyviarearrangement[37,38].Onthecontrary,inthepresenceof

Amberlyst15,thereisaverysmallinfluenceoftheconcentrationof

0.30 0.25 0.20 0.15 0.10 0.05 0.00 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 o/ p rat io

cylohexyl phenyl ether (mol L-1) o/p CH3SO3H

o/p Amberlyst 15 o/p AlCl3

Fig.5. Comparisonofortho/pararatiovs.cyclohexylphenyletherconcentration inthecyclohexylationofphenolinthepresenceofliquidandsolidacidcatalysts. Runconditions:cyclohexeneandphenol1molL−1,Amberlyst15,400mg,CH3SO3H 1.8meqH+andAlCl

31mmol,solvent1,2-dichloroethane,reactionvolume10mLT 358K. 1300 1200 1100 1000 200 100 0 0.00 0.05 0.10 0.15 0.20 1200 1000 200 0 0.00 0.02 0.04 0.06 0.08 0.10 co nc ent rat ion (mol L -1)

time (minutes)

cyclohexene

phenol

cyclohexyl phenyl ether

cyclohexylcyclohexene

2-cyclohexylphenol

4-cyclohexylphenol

di-alkylphenols

Fig.6.Reactivityofcyclohexylphenylether.Runconditions:T358KAmberlyst15, 400mg,solvent1,2-dichloroethane,reactionvolume10mL.

thecyclohexylphenylethertowardorthoandparaselectivity.Such

abehaviorsuggeststhat,inthepresenceofAmberlyst15,theortho

andparaselectivityismainlyinfluencedbythemesomericeffect

ofthehydroxylgroup[37–39].Besidesthereactioncatalyzedby

AlCl3showsasmallincreaseoftheortho/pararatiovs.cyclohexyl

phenyletherconcentration,butwithaneatprevalenceoftheortho

isomer.Thereasonsofsuchabehaviorarenotclearandatleast

twoeffectsmayconcurtogivethisresult:theetherrearrangement

andaspecificinteractionbetweenphenolandAlCl3,assuggested

bySartoriandcoworkers[40].

3.2. Reactivityofcyclohexylphenylether

Thereactivityofcyclohexylphenylether,inpresenceofacid

catalysts,isreportedinFigs.6–8andinTable2.Fig.6showsthe

concentration–timeprofileofthereactioncatalyzedbyAmberlyst

15:cyclohexenereachesamaximumafter2hofreaction,andthen

itdecreasestocompleteconsumption.Atthesametime,phenol

concentrationreaches toa maximum and subsequently

dimin-ishessmoothly(almosttoaplateau).Asamatteroffact,phenol

islessconvertedthancyclohexenebecauseallreactions,suchas

alkylation,dialkylationandcyclohexenedimerization,concurto

consumecyclohexene.Theinitialreactionrateof ether

decom-positioniscomparabletothatofthephenolcyclohexylationand

250 200 150 100 50 0 0.00 0.05 0.10 0.15 0.20 co nce n tr at io n ( m ol L -1 ) time (minutes)

cyclohexene

phenol

cyclohexyl phenyl ether

2-cyclohexyl phenol

4-cyclohexyl phenol

Fig.7.Reactivityofcyclohexylphenylether.Runconditions:cyclohexylphenyl ether0.21molL−1,T358K,CH3SO3H180mg,solvent1,2-dichloroethane,reaction volume10mL.

Table2

Reactivityofcyclohexylphenylether:selectivityafter240minofreactionat358K.Runconditions:cyclohexylphenylether0.2molL−1,solvent1,2-dichloroethane,reaction volume10mL.

Catalyst Conv.(%) r0a Selectivity(%) o/p

2-Cyclohexylphenol 4-CyclohexylPhenol Dicyclohexylphenols Ratio

Amberlyst15b 92 10 10 33 18 3.3 CH3SO3Hc 85 40 4 0.9 Traces 4.2 AlCl3d 74 75 19 3.4 22 5.6 a(105molL−1s−1g−1cat). bAmberlyst15,400mg. c CH 3SO3H180mg. d T288K,AlCl 30.2mmol.

consideringthewholereactionsteps,ringalkylationsarelikelythe

slowerstage,thusallowingaccumulationofphenoland

cyclohex-ene.InthepresenceofCH3SO3H(Fig.7)thereverseetherification

occurs with an initial reaction rate 4 times higher than when

Amberlyst15 isusedasa catalyst,and after50minofreaction

75%ofcyclohexylphenylether isconverted tocyclohexeneand

phenolin95%ofoverallselectivity.Infact,CH3SO3Hasacatalyst

doesnotgiveringalkylationproductsinhighyields,butallowsfast

decompositionoftheether.Fig.8showstheconcentration–time

profileofthereactivityofthecyclohexylphenyletherat288K,in

thepresenceofAlCl3,theinitialreactionrateismuchhigherthan

inthepresenceofAmberlyst15(7times)butitdoesnotreach

com-pletenessprobablybecauseofcatalystpoisoning,inagreementto

whatfoundinphenolalkylation.Inthiscase,theconcentrationof

cyclohexeneisnegligiblewithrespecttothatofphenol,duetoa

fastformationofcyclohexeneoligomerizationproducts,whichare

probablyoneofthereasonsofcatalystdeactivation.

Theortho/paraselectivity(seeTable2)withdifferentcatalysts

after4hofreactionisintherange3.3–5.6,and,asexpected,the

etherfavorstheortho-selectivity.Apparently,thetrendsoftheo/p

ratiovs.etherconversion,showedinFig.9,arenotinagreement

withthosefoundinthephenolcyclohexylation(Fig.5),because

bothAlCl3andCH3SO3Hshowaconstanto/pratio(5.3,4.3,

respec-tively),whileinthepresenceofAmberlyst15theo/pratiodecreases

from4.2to2.7.Despiteofthecomplexityofthereactionitisclear

thatcyclohexylphenyletherisinvolvedintheselectivityofthe

orthoandparaisomersofthealkylatedphenols,butfurther

inves-tigationsneedstohighlightsuchabehavior.

250 200 150 100 50 0 0.00 0.05 0.10 0.15 0.20 concent rat ion (mol L -1 )

time (minutes)

cyclohexyl phenyl ether

cyclohexene

phenol

2-cyclohexyl phenol

4-cyclohexyl phenol

Fig.8.Reactivityofcyclohexylphenylether.Runconditions:cyclohexylphenyl ether0.21molL−1,T358K,AlCl31mmol,solvent1,2-dichloroethane,reaction vol-ume10mL.

3.3. Reactivityofdimethylphenolsand2,4,6-trimethylphenol

Furtherinsightonthereactivityofthecyclohexylcationas

elec-trophiletowardphenolsmaybegainedbystudyingthereactivity

ofdimethylphenolsandofthe2,4,6-trimethylphenol,inorderto

test theinfluence ofthemethyl substituentboth for its

induc-tiveeffectaswellasforthesterichindrance.InFigs.10and11,

theconcentration–timeprofileofthecyclohexylationofthe

2,3-dimethylphenolcatalyzedbybothAmberlyst15andCH3SO3Hare

shown.Thegeneraltrendobservedinthis caseissimilarfor all

phenols,thussuggestingtheinvolvementofasamereactionpath.

Inagreementwiththatobservedforthephenoltheactivityofthe

Amberlyst15is,inanycase,higherthanthatofCH3SO3H(Table3),

whichislikelyduetothesuperiorprotonationabilityofthesolid

acidwithrespecttotheliquid one [34,35]. Theactivityof

3,5-dimethylphenoland2,6-dimethylphenolarelowerthanthatof

neatphenol(Table1),thephenomenonmaybeascribedtothe

sterichindranceofthesubstituents, whichslowdownthe

elec-trophilicattack[37,38].Suchaneffectismorepronouncedonthe

initialreactionrateofthe2,6-isomerthanthe3,5-one.Thesmall

increase of the reaction rateof the 2,3-dimethyl-phenol

cyclo-hexylationwithrespecttothatofneatphenolmaybeduetothe

inductiveeffectofmethylgroups,eventhoughthesterichindrance

mayplaya non-negligibleeffect.Infact,theinitialreactionrate

of2,4-dimethyl-phenol isequivalenttothatof phenol,the

rea-sonofthisbehaviorisnotclear,butitmightbeascribedtothe

100 80 60 40 20 2 3 4 5 6 o/p r a tio conversion (%) o/p Amberlyst 15 o/p CH3SO3H o/p AlCl3

Fig.9.Comparisonofortho/pararatiovs.conversioninthecyclohexylationof phenolandintherearrangementofcyclohexylphenylether.Runconditions: cyclo-hexeneandphenol1molL−1,Amberlyst15,CH3SO3H1.8meqH+andAlCl31mmol ascatalysts,solvent1,2-dichloroethane,reactionvolume10mLT358K.Cyclohexyl phenyletherrearrangementarecarriedoutwiththesamerunconditionsexcept theinitialconcentrationof0.2molL−1.

Table3

Alkylationofdimethylphenolsand2,4,6-trimethylphenol:selectivityafter240minofreactionat358K.Runconditions:dimethylphenols1.2molL−1,cyclohexene1.1molL−1, Amberlyst15,400mgorCH3SO3H180mg,solvent1,2-dichloroethane,reactionvolume10mL.

Catalyst Conv.(%) r0a Selectivity(%)

Ether 2-CyclohexylDMPb 3-CyclohexylDMPb 4-CyclohexylDMPb Cyclohexyl cyclohexene 2,6-Dimethylphenol Amberlyst15 15 2.6 26 – 5 15 13 CH3SO3H 7.2 0.9 18 – 11 16 55 3,5-Dimethylphenol Amberlyst15 35 16 24 27 – 5 10 CH3SO3H 14 4.1 29 14 – 0.1 13 2,3-Dimethylphenol Amberlyst15 95 44 4 38 5 12 4 CH3SO3H 13 3.1 18 19 – 5 55 2,4-Dimethylphenol Amberlyst15 80 30 10 42 10c – 5 CH3SO3H 12 2.1 12 10 2c – 62 2,5-Dimethylphenol Amberlyst15 57 14 16 16 – 16 2 CH3SO3H 16 1.5 16 9 – 4 15 2,4,6-Trimethylphenol Amberlyst15c 1 0.2 – – – – 50 CH3SO3Hc 5 0.6 – – – – 50 a(105molL−1s−1gcat−1). b DMP=dimethylphenol.

c Betweenthetwopossibleisomer(in3or5position)ithasnotverifiedwhatisformed,butthe5isomerismoreplausible,duetothelowersterichindranceofthe5 position.

dLargepartoftheproductsarepeach,formationoftracesoftheetherandthem-isomerhasbeenobservedafter20hofreaction.

simultaneouspresenceoftwocontraryeffects:thesterichindrance

andtheinductiveeffectofthemethylgroups.Thereactivityof

2,5-dimethyl-phenolis clearlyinfluencedbythesterichindranceof

themethylgroups,inparticulartheonein2-positionsslowsdown

theattackof thecyclohexyl cationtoward thehydroxyl group,

whilethatin5-positionsimultaneouslyhamperstheattacktoboth

orthoandparapositions.Asamatteroffact,2,4,6-trimethyl-phenol

showsanegligiblereactivitytowardelectrophilicattack,thus

sug-gestingthecyclohexylcation isgreatly influencedby thesteric

hindrancebothontheattacktothehydroxyl groupandtothe

phenylring.

Theinfluenceofthemethylgroupsontheringalkylation

selec-tivityisstrictlyrelatedtothepositionofthesubstituentratherthan

theirinductiveeffect.Forinstance,3,5-and2,3-dimethylphenol

show,inthepresenceofAmberlyst15asacatalyst,anortho–para

ratioof5.4and3.2,respectively.Asamatteroffact,suchabehavior

suggeststhattherelativereactivityoftheparapositionsofthese

compoundsisabout3timeslowerthantheorthoones.The

compar-isonoftheseresultswiththealmostequalrelativereactivityofthe

orthoandparapositions,observedinthecyclohexylationof

phe-nolinthepresenceofAmberlyst15asacatalyst,suggestsastrong

effectofthesterichindranceofthemethylgroupsonthe

selectiv-OH + O OH OH + OH Cy Cyisomers

acid catalyst

acid cata lyst acidca talyst + OCy Cy isomers + acid catalyst

n

acid catalyst300 250 200 150 100 50 0 0.0 0.2 0.4 0.6 0.8 1.0 concent rat io n (mol L -1 )

time (minutes)

cylohexene

cyclohexyl phenyl ether

2-cyclohexyphenol

4-cyclohexyphenol

Fig.10.Reactivityof2,3-dimethylphenol.Runconditions:T358K,solvent 1,2-dichloroethane,Amberlyst15,400mg,reactionvolume10mL.

ity.Furthersupporttothisistheequalreactivityoftheorthoand

parapositionsofthe2,5-dimethylphenol.Inthiscase,itislikely

thatthemethylin5-positionhasthesameeffectonthereactivity

oftheorthoandparapositionwiththeconsequentequalrelative

reactivity.

When CH3SO3H is used the ortho selectivity increases as

already observed for phenol. For instance, cyclohexylation of

3,5-dimethylphenol catalyzed byCH3SO3H shows an very high

ortho–pararatio(o/p=140)andinanycase,foreachphenolwith

unsubstituted orthoand para position, there is a neat increase

oftheorthoselectivityinthepresenceofCH3SO3Hcomparedto

Amberlyst15.Sucha behaviorisnotstraightforward,sinceitis

not clear what are the reasonsof such a specific ortho

direct-ingaction of theCH3SO3H, however,either themechanism via

cyclohexyl phenyl ether rearrangement [37–39], or that via a

methanesulfonic–phenolcomplex[40]canberesponsibleforthis

behavior. 250 200 150 100 50 0 0.00 0.05 0.8 0.9 1.0 cyclohexene (mol/ L) time (minutes)

cyclohexene

cyclohexylphenyl ether

2 cyclohexyl phenol

4 cyclohexyl phenol

Fig.11.Reactivityof2,3-dimethylphenol.Runconditions:T358K,solvent 1,2-dichloroethane,CH3SO3H180mg,reactionvolume10mL.

3.4. Reactionpathproposedforthereactions

Alkylation, etherification and olefin oligomerization are the

reactionsbetweenphenolsandcyclohexeneobservedinthe

pres-enceofacidcatalysts.Alltheexperimentalevidencessuggestthe

reactionpathdepictedinScheme1.Therearethreeparallelandtwo

consecutiveacidcatalyzedreactions.Inparticular,theformation

ofcyclohexylphenyletherisreversible(alsotheformationofthe

aliphaticetherisreversible[41]),whileringalkylationofphenol,

cyclohexeneoligomerizationcyclohexylphenylether

rearrange-mentand alkylphenolsisomerizationarepracticallyirreversible

[39].

4. Conclusions

Thereactionbetweenphenolandcyclohexeneoccursviaa

com-plexpath,whichischaracterizedbytheformationofthecyclohexyl

phenyletherasreversibleintermediateanditscomplete

conver-siontotheproductsofringalkylationattheendofthereaction,

whenevercatalystdeactivationdoesnotoccur.Thereactionsof

O-alkylation,ringalkylation,etherrearrangementandcyclohexene

oligomerizationoccursimultaneously,butthelatterispractically

negligiblebyselectingthepropersolventorcarryingoutthe

reac-tionin excessof phenols. Inthepresence of Amberlyst15 and

36resinstheselectivityofringalkylationofphenolseemstobe

drivenbythetypicalortho/paraorientingeffectofthehydroxyl

group.Onthecontrary,aspecificactionofhomogeneoussystems

(CH3SO3HandAlCl3)towardformationoftheorthoisomershas

beenobserved,butitisnotclearwhatisthereasonofsucha

behav-ior.The electrophilicattackof thecyclohexylcation isstrongly

influencedbythesterichindranceofthemethylgroupasamatter

offact,thealkylationof2,4,6-trimethylphenolpracticallydoesnot

occur,andtheactivation,duetotheinductiveeffecttothe

con-tiguouspositionsofthemethylgroup,isnegligiblecomparedto

thedeactivationinducedbythesterichindrance.

Acknowledgments

FinancialsupportbyCa’FoscariUniversityofVeniceisgratefully

acknowledged(Ateneofund2009).AthanktoDr.DavideMontin

forsomepreliminaryexperimentscarriedoutduringhisdegreein

IndustrialChemistry.Finally,aspecialthanktoMr.ClaudioTortato

forthehelpfuldiscussions.

References

[1]K.Komiya,S.Fukuoka,M.Aminaka,K.Hasegawa,H.Hachiya,H.Okamoto,T. Watanabe,H.Yoneda,I.Fukawa,T.Dozono,in:P.T.Anastas,T.C.Williamson (Eds.),GreenChemistry:DesigningChemistryfortheEnvironment,American ChemicalSociety,Washington,DC,1996,p.20.

[2]V.C.Malshe,E.S.Sujatha,React.Funct.Polym.43(2000)183–194. [3]A.Sato,I.Shimizu,E.Matsuzaka,US4144279.

[4]M.A.Harmer,Q.Sun,Appl.Catal.A:Gen.221(2001)45–62. [5]W.F.Hölderich,G.Heitmann,Catal.Today38(1997)227–233. [6]A.Mitsutani,Catal.Today73(2002)57–63.

[7]K.G.Chandra,M.M.Sharma,Catal.Lett.19(1993)309–317.

[8]H.Zhang,S.M.Mahajani,M.M.Sharma,T.Sridhar,Chem.Eng.Sci.57(2002) 315–322.

[9]A.deAngelis,C.Flego,P.Ingallina,L.Montanari,M.G.Clerici,C.Carati,C.Perego, Catal.Today65(2001)363–371.

[10]R.A.Rajadhyaksha,D.D.Chaudhari,Ind.Eng.Chem.Res.26(1987)1276–1280. [11]R.H.Rosenwald,AlkylationinKirkOhtmerEncyclopediaofChemical

Technol-ogy,vol.2,Wiley,1978,p.50.

[12]H.W.B.Bird,AlkylphenolsinKirkOhtmerEncyclopediaofChemical Technol-ogy,vol.2,Wiley,1978,p.73.

[13]G.D.Yadav,S.Ganesh,Pathre,Ind.Eng.Chem.Res.46(2007)3119–3127. [14]G.D.Yadav,P.Kumar,Appl.Catal.A:Gen.286(2005)61–70.

[15]N.Bhatt,A.Patel,J.Mol.Catal.A:Chem.264(2007)214–219. [16]R.Anand,K.U.Gore,B.S.Rao,Catal.Lett.81(2002)33–41.

[17] R.Amandi,K.Scovell,P.Licence,T.J.Lotz,M.Poliakoff,GreenChem.9(2007) 797–801.

[19]M.M.Sharma,React.Funct.Polym.26(1995)3–23. [20] A.J.Hoefnagel,H.vanBekkum,Catal.Lett.85(2003)7–11.

[21]K.Wilson,D.J.Adams,G.Rothenberg,J.H.Clark,J.Mol.Catal.A:Chem.159 (2000)309–314.

[22]P.F.Siril,H.E.Cross,D.R.Brown,J.Mol.Catal.A:Chem.279(2008)63–68. [23]A.Akelah,A.Moet,FunctionalizedPolymersandTheirApplications,Chapman

andHall,1990.

[24] G.A.Olah,A.M.White,D.H.O’Brien,Chem.Rev.70(1970)561–591. [25]G.A.Olah,G.K.SuryaPrakash,J.Sommer,Superacids”,J.Wiley,1985,p.90. [26] N.S.Isaacs,PhysicalOrganicChemistry,Longman,1987,p.395.

[27]Y.Tsuji,M.M.Toteva,H.A.Garth,J.P.Richard,J.Am.Chem.Soc.125(2003) 15455–15466.

[28]R.Klimkiewicz,H.Grabowska,H.Teterycz,Appl.Catal.A:Gen.246(2003) 125–136.

[29]B.Chaudhuri,M.M.Sharma,Ind.Eng.Chem.Res.30(1991)227–231. [30] E.Modrogan,M.H.Valkenberg,W.F.Hoelderich,J.Catal.261(2009)177–187. [31]Q.Ma,D.Chakraborty,F.Faglioni,R.P.Muller,W.A.Goddard,T.Harris,C.

Camp-bell,Y.Tang,J.Phys.Chem.A110(2006)2246–2252.

[32]B.Bjoerkqvist,H.Toivonen,J.Chromatogr.178(1979)271–276.

[33]G.W.Roberts,in:P.N.Rylander,H.Greenfield(Eds.),CatalysisinOrganic Syn-thesis,AcademicPress,1976,p.1.

[34]S.Kajount,B.M.Kierman,D.R.Brown,H.G.M.Edwards,J.A.Dale,S.Plant,Catal. Lett.85(2003)33–40.

[35]N.C.Marziano,A.tommasin,C.Tortato,J.Chem.Soc.Trans.2(1991)1575–1580. [36]C.Reichardt,SolventsandSolventEffectsinOrganicChemistry,2nded.,VCH,

Weinheim,1988,p.22.

[37]K.Schofield,AromaticNitration,CambridgeUniversityPress,Cambridge,1980. [38] P.B.D.DeLaMare,J.H.Ridd,AromaticSubstitution,ButtherworthsScientific

Pubblications,London,1959.

[39] C.B.Campbell,A.Onopchenko,D.C.Young,Ind.Eng.Chem.Res.29(1990) 642–647.

[40] G.Sartori,F.Bigi,R.Maggi,A.Arienti,J.Chem.Soc.PerkinTrans.1(1997) 257–260.

[41] J.F.Izquierdo,F.Cunill,M.Vila,M.Jhorra,J.Tejero,Ind.Eng.Chem.Res.33(1994) 2830–2835.