Appendice

Appendice A: Format File

•

File .dat

Contengono la descrizione della geometria da importare in Franc3D.

Il file contiene i valori delle coordinate dei punti che costituiscono le singole superfici.

……….

Surface_7 2

1 1 0

0 0.99999994 1.99999988

0 0.99999994 -2.98023224e-008

0 -1.49011612e-008 1.99999988

0 -1.49011612e-008 -2.98023224e-008

………

•

File .bes

Nel file di input .bes sono elencati e numerati ogni singola regione, nodo ed elemento del

modello.

Vengono specificati il modulo d’elasticità ed il coefficiente di Poisson, le coordinate

(x, y, z) dei singoli nodi, il numero di nodi ed i nodi che costituiscono ogni elemento e le

condizioni al contorno per ogni singolo nodo.

cd_region_properties

1 72000 0.33

cd_define_node

1 0 0.25 0.285714…..

…….

cd_define_element

142 4 286 91 94 287

cd_element_regions

142 1 0

cd_simple_bc

142 1 1 4 0

142 1 2 4 0……

("cd_simple_bc"element_id node_i_in_list axis_id bc_code bc_value).

• File .out

Nei file d’output di Afgrow viene descritto il problema e forniti i valori di

C, Beta, R(k), R(eff), Delta-K, D( )/DN ad intervallati numero di cicli

Crack size Beta R(k) R(eff) Delta-K D( )/DN

C 0.008 1.116 0.100 0.100 1.274e+001 2.255e-007

Max stress = 80.000000 R = 0.10

0 Cycles Constant amp.: 1 Pass: 1

Crack size Beta R(k) R(eff) Delta-K D( )/DN

C 0.0080226 1.116 0.100 0.100 1.276e+001 2.261e-007

Max stress = 80.000000 R = 0.10

100 Cycles Constant amp.: 101 Pass: 101

Appendice B: Valutazione dei coefficienti Ai

I valori dei coefficienti Ai sono necessari per calcolare la funzione di apertura della cricca f,

presente nell’equazione di accrescimento della cricca per il modello “NASGRO”.

(

)

1 α S π 2 m a x := 0 .8 2 5 - 0 .3 4 × α + 0 .0 5 × α × c o s × 0 2 S 0 1 := 2 × A + A - 1 3 0 1 ⎛ ⎛ ⎞⎞ ⎛ ⎞ ⎜ ⎜ ⎟⎟ ⎜ ⎟ ⎜ ⎜ ⎟⎟ ⎝ ⎠ ⎝ ⎝ ⎠⎠(B.1)

ppendic

A S m a x A := 0 .4 1 5 - 0 .0 7 1× α × S 0 A2 := 1 - A - A - A0 1 3 AA

e C: Valori

eta e dei K

bendiPannello integrale Airbus a sette irrigidimenti.

non lineare; carico:

nello skin e 50MPa nello stringer;

dei B

ng◊

95MPa

Analisi:

a (mm) K

bending15

0.433

19

0.330

27 0.2697

31 0.1997

40 0.1343

50 0.1366

70 0.0679

90 0.0587

a (mm) Beta

(plane stress)15

1.377

19

1.442

27

1.544

31

1.440

40

1.347

50

1.209

70

1.226

90

1.220

◊ Pannello integrale “DaToN, High Speed Machined”.

te di cricca doppio *bending relativi a fronte di cricca doppio

nalisi: non lineare; carico:

a;

Analisi: non lineare; carico: 80MPa;

Beta* relativi a fron K

A

110MP

a (mm)Beta

(plane stress)Beta*

(plane stress)Beta

equivalente20

1.058

1.058

1.058

30

1.055

1.055

1.055

40

1.039

1.039

1.039

55

1.014

1.014

1.014

65

0.904

0.904

0.904

73.75

0.888

0.888

0.888

76.25

1.326

0.652

0.652

78

1.368

0.797

0.788

80

1.346

0.897

0.876

88

1.463

1.207

1.116

92

1.658

1.498

1.345

95

1.597

1.507

1.324

101.25

1.573

1.573

1.305

120

1.635

1.635

1.356

130

1.759

1.759

1.459

160

2.208

2.208

1.831

Tabella C.3

a (mm) K

bendingK*

bending20

0.033

0.033

30

0.032

0.032

40

0.030

0.030

55

0.002

0.002

65

0.112

0.112

73.75

0.081

0.081

76.25 -0.636

0.306

78 -0.416

0.220

80 -0.310

0.180

88 -0.385

0.131

92 -0.218

-0.021

95 -0.142

0.015

101.25 -0.081

-0.081

120 -0.033

-0.033

130 -0.024

-0.024

160 -0.012

-0.012

Tabella C.4

a (mm)Beta

(plane stress)55

1.007

73.75

0.888

76.25

0.650

80

0.898

88

1.217

92

1.520

101.25

1.631

120

1.702

130

1.822

Tabella C.5

a (mm)K

bending55 -0.001

73.75 0.076

76.25 0.303

80 0.174

88 0.126

92 -0.023

101.25 -0.067

120 -0.028

130 -0.023

Tabella C.6

Analisi: lineare; carico: 80MPa;

nalisi: lineare; carico: 110MPa;

a (mm)K

bending20 0.051

30 0.040

40 0.032

55 0.001

65 0.093

73.75 0.092

7

6.25 0.309

78 0.233

80 0.195

88 0.15

2

92 -0.002

95 0.042

101.25 -0.260

120 -0.147

130 -0.118

160 -0.064

Tabella C.8

a (mm)Beta

(plane stress)Beta

equivalente20

1.094

1.094

30

1.059

1.059

40

1.074

1.074

55

1.049

1.049

65

0.927

0.927

73.75

0.906

0.906

76.25

0.671

0.671

78

0.813

0.804

80

0.914

0.891

88

1.200

1.109

92

1.469

1.320

95

1.464

1.287

101.25

1.523

1.263

120

1.547

1.283

130

1.596

1.324

160

1.859

1.542

Tabella C.7

a (mm)K

bending55 0.001

73.75 0.092

76.25 0.309

80 0.195

88 0.152

92 -0.002

101.25 -0.260

120 -0.147

130 -0.118

Tabella C.10

a (mm)Beta

(plane stress)55

1.049

73.75

0.906

76.25

0.610

80

0.914

88

1.201

92

1.470

101.25

1.523

120

1.548

130

1.596

Tabella C.9

A

◊ Pannello integrale “DaToN, Laser Beam Welding”.

nalisi: non lineare; carico: 80MPa;

A

a (mm) Beta

(plane stress)20

0.813

40

0.837

55

0.801

65

0.812

73.75

0.977

76.25

0.766

78

0.941

88

1.394

92

1.641

95

1.639

101.25

1.723

120

1.731

130

1.791

Tabella C.11

Analisi: lineare; carico: 80MPa;

a (mm)K

bending20 0.098

40 0.101

55 0.064

65 0.093

73.75 0.093

76.25 0.294

78 0.238

88 0.132

92 -0.013

95 0.023

101.25 -0.080

120 -0.030

130 -0.020

Tabella C.12

a (mm)Beta

(plane stress)20

0.857

40

0.879

55

0.840

65

0.841

73.75

0.995

76.25

0.787

78

0.964

88

1.384

92

1.598

95

1.581

101.25

1.622

120

1.557

130

1.575

Tabella C.13

a (mm)K

bending20 0.111

40 0.099

55 0.059

65 0.099

73.75 0.102

76.25 0.298

78 0.249

88 0.151

92 -0.005

95 0.050

101.25 -0.258

120 -0.146

130 -0.114

Tabella C.14

Appendice D: Calcolo del baricentro e del momento d’inerzia

sizione del baricentro è sufficiente

a, è possibile valutare il baricentro per un quarto

del baricentro nella direzione normale al piano si ottiene dalla seguente

espressione:

◊ Calcolo del baricentro

Considerando le simmetrie della struttura, per valutare la po

calcolare la sua posizione nella direzione normale al piano.

Sfruttando la simmetria del problem

dell’intero pannello.

La posizione

i i G iy =

m

m y

⋅

∑

∑

(D.1)

dove m

ie la massa dei singoli componenti ed y

ila posizione del baricentro per il componente

i-esimo. Ponendo la densità della struttura uguale ad 1, l’espressione (A.1) diventa:

i i G

y =

v

v y

⋅

∑

i∑

(D.2)

in cui v

idiventa il volume dei singoli componenti.

Facendo riferimento alle figura 1.3, in cui è riportata la geometria della struttura, si ottiene,

trascurando il RUN-OUT:

(

) (

)

{

(

) (

)

}

(

)

(

)

* G 225 160 4 2+ 225 340 2 1+ 70 225 + 270 30 +171.68 1 2.5+ 300 2.5 25 y = ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⎣⎡ ⋅ ⋅ ⎤⎦⋅ ⋅ ⋅ ⋅ ⋅15.5 2.33 225 160 4+225 340 2+ 70 225+270 30+171.68 1+300 2.5 25⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ≅si considera il RUN-OUT, facendo sempre riferimento alla figura 1.3, si ottiene:

Se

(

)

(

)

run-out20 20 ⋅

20 5 2.5 3+2.5 + 2.5 3+5+6.66

2

y

=

=11.6

⋅

⋅ ⋅

⋅

⋅

20 20

20 5 2.5+

2.5

2

⋅

⋅ ⋅

⋅

e

* G run-out G * run-outy +y

y =

2.35

V +v

≅

run-out

il volume del run-out)

(V* indica il volume della struttura meno quello del run-out e v

◊ Calcolo del momento d’inerzia

Per calcolare le tensioni flessionali dovute alla presenza d’eccentricità nella struttura, è

necessario valutare il momento d’inerzia rispetto all’asse x (figura A1).

Considerando la simmetria longitudinale del problema, è sufficiente valutare il momento

d’inerzia soltanto per metà struttura e poi moltip

valore ottenuto.

Il momento d’inerzia rispetto all’asse x è dato dalla seguente espressione:

x y

in cui x

1-x

2e y

1-y

2descrivono l’area della sezione resistente.

sezione resistente, si

ame:

0 2 3

J = 2 225y dy + 2 30y dy +

⋅

∫

⋅

∫

y 38121.6

≅

Figura D.1 – Sezione resistente

licare per due il

2 2

x y 2

J =

∫ ∫

y dxdy

(D.3),

1 1

Facendo riferimento alla figura A1 in cui è riportata la geometria della

ottiene per il caso in es

2 3 28

2 2

2

⋅

2.5y d

2∫

Il valore della tensione flessionale è dato dall’espressione:

flessionale

F b

σ

=

y

J

⋅

(D.4),

nata del punto in cui si vuole valutare la

mento d’inerzia (b ed y si misurano dalla posizione del baricentro).

= 119.3 KN, b = 0.35, y = 25.65, J = 38121.6,

dove F è la forza applicata, b il braccio, y la coordi

σ

flessionalee J il mo

Per il nostro caso si ha:

F

da cui si ottiene:

σ

flessionale≈ 28 MPa

e quindi la tensione in testa all’irrigidimento è uguale a:

σ = σ

membranale- σ

flessionale≈ 81.9 MPa.

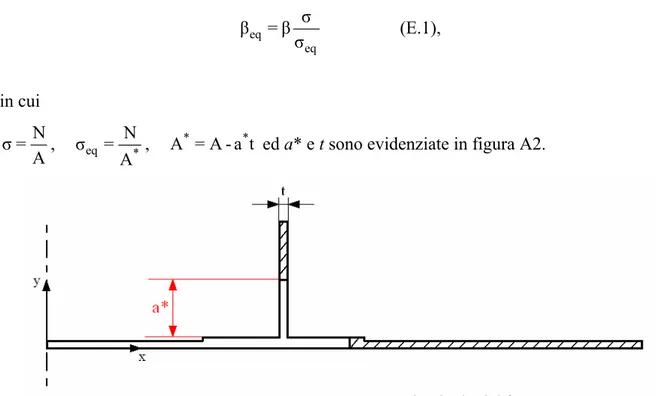

Appendice E: Calcolo del “Beta equivalente”

Nel calcolo del “beta equivalente” si tie

, dovuto alla rottura

dell’irrigidimento, che si scarica sullo spessore del pannello.

è dato dall’espressione seguente:

ne conto del sovraccarico

Il valore del beta equivalente

eq

= β

σ

σ

eq(E.1),

β

in cui

N

σ =

A

,

eq *N

σ =

A

,

ed a* e t sono evidenziate in figura A2.

ostituendo all’espressione (A.5) la σ e la σ

eqsi ottiene:

* *

A = A - a t

Figura E.1 – Dimensioni per il calcolo del β

eqS

(

*)

* eqβ A - a t

βA

β =

=

A

A

(E.2).

a β

eqdiventa esclusivamente funzione della lunghezza di cricca a* che propaga

L

Appendice F: Letture est

etrich

el trasduttore di pos

e

◊

t

esten

riche

ensim

e e d

izion

Le ture

simet

forza estensimetro1 estensimetro2 estensimetro3 estensimetro4 estensimetro5

volt Mpa µm/m µm/m µm/m µm/m µm/m 0.00 0.0 0.94 0.00 0.00 0.00 0.00 0.01 0.5 9.41 7.53 9.31 1.16 9.41 0.01 0.9 15.06 13.18 15.13 3.49 14.12 0.03 2.4 36.71 32.94 38.40 8.15 35.76 0.04 3.6 55.53 49.88 58.18 13.96 54.59 0.05 4.7 71.53 64.94 75.64 19.78 70.59 0.07 6.3 96.94 87.53 101.24 29.09 94.12 0.09 7.9 121.41 110.12 126.84 39.56 117.65 0.10 9.0 138.35 125.18 144.29 46.55 133.65 0.12 11.0 166.59 151.53 174.55 59.35 160.94 0.15 13.2 200.47 182.59 209.45 75.64 192.94 0.18 16.3 246.59 224.94 257.16 100.07 236.24 0.21 19.2 288.94 263.53 301.38 124.51 275.76 0.24 21.8 328.47 300.24 342.11 147.78 312.47 0.26 23.5 352.94 322.82 367.71 164.07 336.00 0.28 25.5 382.12 350.12 397.96 182.69 363.29 0.31 27.6 412.24 378.35 429.38 202.47 392.47 0.32 29.0 433.88 398.12 451.49 217.60 412.24 0.36 32.5 483.76 445.18 503.85 252.51 459.29 0.39 34.9 518.59 477.18 539.93 276.95 492.24 0.43 39.1 579.76 534.59 603.93 323.49 549.65 0.47 42.6 630.59 582.59 656.29 363.05 598.59 0.51 46.3 684.24 633.41 712.15 404.95 648.47 0.57 51.4 755.76 701.18 786.62 464.29 716.24 0.61 54.8 803.76 747.29 837.82 505.02 763.29 0.63 56.9 833.88 775.53 868.07 530.62 790.59 0.66 59.2 866.82 807.53 902.98 559.71 823.53 0.69 62.5 912.94 851.76 950.69 600.44 866.82 0.72 65.4 953.41 890.35 991.42 635.35 905.41 0.76 68.6 999.53 934.59 1040.29 678.40 950.59 0.80 72.1 1049.41 982.59 1091.49 722.62 997.65 0.84 75.8 1100.24 1031.53 1145.02 770.33 1046.59 0.87 79.0 1145.41 1074.82 1192.73 813.38 1089.88 0.90 81.4 1178.35 1106.82 1226.47 843.64 1121.88 0.92 83.5 1208.47 1136.00 1257.89 872.73 1151.06 0.95 86.3 1246.12 1172.71 1297.45 908.80 1186.82 0.98 88.6 1279.06 1204.71 1331.20 941.38 1218.82 1.00 90.7 1307.29 1232.00 1361.45 968.15 1246.12 1.03 93.6 1347.76 1271.53 1403.35 1008.87 1285.65 1.07 96.5 1389.18 1312.00 1446.40 1048.44 1325.18 1.10 99.5 1430.59 1352.47 1489.45 1089.16 1364.71 1.13 102.5 1472.94 1392.94 1533.67 1132.22 1405.18 1.14 103.3 1483.29 1404.24 1544.15 1142.69 1415.53 1.17 105.6 1515.29 1435.29 1577.89 1174.11 1446.59 1.19 107.6 1543.53 1462.59 1606.98 1202.04 1473.88 1.21 109.1 1564.24 1482.35 1627.93 1222.98 1493.65 1.22 110.3 1581.18 1499.29 1645.38 1239.27 1509.65

forza estensimetro6 estensimetro7 estensimetro8 estensimetro9 estensimetro10 volt Mpa µm/m µm/m µm/m µm/m µm/m 0.00 0.0 0.00 0.00 0.94 0.94 0.00 0.01 0.5 6.59 8.47 7.53 9.41 7.53 0.01 0.9 11.29 14.12 12.24 16.00 13.18 0.03 2.4 30.12 35.76 30.12 38.59 32.00 0.04 3.6 46.12 54.59 47.06 59.29 48.94 0.05 4.7 60.24 69.65 61.18 76.24 64.00 0.07 6.3 81.88 94.12 82.82 101.65 86.59 0.09 7.9 103.53 118.59 103.53 128.00 108.24 0.10 9.0 117.65 133.65 118.59 144.94 123.29 0.12 11.0 144.00 161.88 144.00 175.06 150.59 0.15 13.2 174.12 194.82 174.12 210.82 181.65 0.18 16.3 215.53 238.12 215.53 258.82 224.94 0.21 19.2 254.12 279.53 253.18 303.06 265.41 0.24 21.8 288.94 316.24 288.94 342.59 302.12 0.26 23.5 312.47 339.76 312.47 368.94 326.59 0.28 25.5 338.82 368.00 338.82 399.06 354.82 0.31 27.6 367.06 396.24 367.06 431.06 384.00 0.32 29.0 386.82 416.94 386.82 453.65 404.71 0.36 32.5 432.94 464.94 432.94 505.41 453.65 0.39 34.9 464.94 497.88 464.94 542.12 487.53 0.43 39.1 522.35 556.24 522.35 605.18 547.76 0.47 42.6 569.41 606.12 570.35 658.82 598.59 0.51 46.3 620.24 656.94 621.18 715.29 653.18 0.57 51.4 687.06 726.59 688.94 789.65 724.71 0.61 54.8 733.18 773.65 736.00 841.41 774.59 0.63 56.9 761.41 802.82 764.24 873.41 805.65 0.66 59.2 793.41 834.82 796.24 908.24 839.53 0.69 62.5 836.71 880.00 840.47 957.18 887.53 0.72 65.4 875.29 919.53 879.06 1000.47 928.94 0.76 68.6 919.53 964.71 924.24 1050.35 977.88 0.80 72.1 966.59 1012.71 972.24 1102.12 1029.65 0.84 75.8 1015.53 1063.53 1022.12 1157.65 1084.24 0.87 79.0 1058.82 1107.76 1066.35 1206.59 1131.29 0.90 81.4 1090.82 1139.76 1098.35 1242.35 1167.06 0.92 83.5 1120.00 1169.88 1128.47 1275.29 1200.00 0.95 86.3 1156.71 1206.59 1165.18 1316.71 1240.47 0.98 88.6 1187.76 1239.53 1197.18 1352.47 1276.24 1.00 90.7 1215.06 1267.76 1225.41 1384.47 1307.29 1.03 93.6 1254.59 1307.29 1265.88 1428.71 1351.53 1.07 96.5 1294.12 1347.76 1306.35 1472.94 1396.71 1.10 99.5 1333.65 1389.18 1346.82 1518.12 1440.94 1.13 102.5 1375.06 1430.59 1388.24 1565.18 1488.00 1.14 103.3 1385.41 1441.88 1399.53 1578.35 1501.18 1.17 105.6 1416.47 1473.88 1431.53 1614.12 1536.00 1.19 107.6 1442.82 1501.18 1459.76 1645.18 1567.06 1.21 109.1 1462.59 1521.88 1480.47 1667.76 1590.59 1.22 110.3 1478.59 1538.82 1497.41 1686.59 1609.41

Tabella F.1

◊

Trasdutt

ore d posizione

i

pos

izio e1

n

pos

izio e2

n

pos

izio e3

n

pos

izio e4

n

posizione5

FORZA LVDT FORZA LVDT FORZA LVDT FORZA LVDT FORZA LVDT

volt Mpa mm volt Mpa mm volt Mpa mm volt Mpa mm volt Mpa mm 0.00 0.0 0.00 0.00 0.0 0.00 0.00 -0.1 0.00 0.00 0.0 0.00 0.00 0.1 0.00 0.01 1.1 0.00 0.00 0.0 0.00 0.04 3.5 -0.07 0.00 0.0 0.00 0.00 0.0 0.00 0.05 4.4 -0.05 0.00 0.0 0.00 0.06 5.4 -0.10 0.04 3.8 -0.07 0.00 0.0 0.00 0.09 8.4 -0.08 0.02 2.0 -0.04 0.14 12.8 -0.20 0.08 7.6 -0.14 0.01 0.5 -0.01 0.11 10.1 -0.09 0.04 3.7 -0.07 0.16 14.2 -0.21 0.12 10.6 -0.19 0.04 4.1 -0.09 0.11 10.3 -0.09 0.04 3.8 -0.07 0.21 19.1 -0.25 0.12 10.8 -0.20 0.05 4.9 -0.11 0.15 13.6 -0.10 0.07 5.9 -0.10 0.22 19.8 -0.26 0.16 14.9 -0.25 0.09 8.1 -0.17 0.17 14.9 -0.10 0.11 10.3 -0.14 0.29 26.1 -0.31 0.17 15.0 -0.26 0.13 11.4 -0.23 0.20 18.0 -0.10 0.12 10.6 -0.14 0.29 26.2 -0.31 0.22 20.0 -0.32 0.15 13.6 -0.27 0.23 20.4 -0.10 0.16 14.9 -0.17 0.32 29.1 -0.33 0.22 20.3 -0.33 0.20 18.4 -0.35 0.28 25.2 -0.10 0.19 17.5 -0.17 0.36 32.4 -0.35 0.26 23.6 -0.37 0.26 23.1 -0.41 0.31 28.5 -0.10 0.25 22.8 -0.18 0.40 36.0 -0.37 0.30 27.2 -0.41 0.30 27.1 -0.46 0.35 31.9 -0.09 0.26 23.6 -0.19 0.44 39.6 -0.39 0.31 27.9 -0.41 0.33 29.4 -0.49 0.37 33.3 -0.08 0.30 26.9 -0.19 0.44 40.2 -0.39 0.33 30.2 -0.44 0.35 31.3 -0.51 0.42 37.6 -0.06 0.30 27.3 -0.19 0.47 42.5 -0.40 0.34 30.3 -0.44 0.39 35.6 -0.57 0.42 37.9 -0.06 0.32 29.2 -0.19 0.49 44.2 -0.41 0.35 31.8 -0.46 0.41 37.0 -0.57 0.44 40.0 -0.05 0.35 31.6 -0.19 0.52 47.4 -0.42 0.37 33.1 -0.47 0.46 41.3 -0.62 0.47 42.7 -0.03 0.36 32.6 -0.19 0.55 49.5 -0.43 0.38 34.5 -0.48 0.45 41.1 -0.62 0.47 42.6 -0.03 0.40 35.8 -0.19 0.55 49.9 -0.44 0.39 35.3 -0.49 0.48 43.3 -0.63 0.51 45.9 -0.02 0.41 36.9 -0.19 0.58 52.6 -0.45 0.41 37.2 -0.51 0.50 45.6 -0.65 0.52 46.7 -0.01 0.41 36.9 -0.19 0.59 53.2 -0.45 0.42 38.2 -0.52 0.50 45.5 -0.65 0.52 47.3 -0.01 0.43 39.1 -0.19 0.62 55.8 -0.46 0.43 39.0 -0.52 0.55 49.9 -0.69 0.55 49.8 0.00 0.44 39.6 -0.19 0.64 57.5 -0.47 0.45 40.7 -0.54 0.55 49.9 -0.69 0.55 49.9 0.00 0.46 41.8 -0.19 0.65 59.0 -0.47 0.46 41.4 -0.54 0.58 52.3 -0.70 0.57 51.6 0.01 0.48 43.0 -0.19 0.68 61.3 -0.48 0.49 44.7 -0.57 0.60 54.3 -0.72 0.58 52.0 0.01 0.48 43.0 -0.19 0.67 60.7 -0.48 0.50 45.0 -0.57 0.61 55.1 -0.72 0.58 52.1 0.01 0.51 46.5 -0.19 0.70 63.4 -0.49 0.53 48.2 -0.59 0.64 58.3 -0.75 0.59 53.2 0.02 0.54 48.8 -0.19 0.70 63.7 -0.49 0.54 48.7 -0.60 0.64 58.2 -0.75 0.59 53.1 0.02 0.54 49.0 -0.19 0.74 67.0 -0.50 0.57 51.7 -0.62 0.67 60.8 -0.76 0.61 55.4 0.03 0.58 52.1 -0.19 0.76 68.9 -0.50 0.58 52.4 -0.63 0.69 62.4 -0.77 0.62 56.2 0.03 0.57 51.9 -0.19 0.78 70.5 -0.51 0.60 53.8 -0.63 0.70 62.9 -0.78 0.64 57.4 0.04 0.61 54.7 -0.19 0.80 72.3 -0.51 0.60 54.4 -0.64 0.72 65.3 -0.79 0.67 60.7 0.05 0.64 57.5 -0.19 0.81 73.5 -0.52 0.63 56.6 -0.65 0.72 64.8 -0.79 0.68 61.6 0.06 0.64 57.7 -0.19 0.83 74.7 -0.52 0.64 58.1 -0.66 0.75 67.9 -0.81 0.70 63.7 0.07 0.69 62.1 -0.19 0.83 75.2 -0.52 0.66 60.0 -0.67 0.75 68.0 -0.81 0.73 65.7 0.08 0.69 62.0 -0.19 0.85 77.3 -0.53 0.68 61.4 -0.68 0.76 69.1 -0.81 0.73 65.7 0.08 0.71 64.3 -0.19 0.87 78.5 -0.53 0.69 62.6 -0.69 0.78 70.5 -0.82 0.76 69.0 0.10 0.74 66.9 -0.19 0.88 79.8 -0.53 0.72 65.0 -0.70 0.79 71.4 -0.83 0.77 69.4 0.10 0.75 67.6 -0.19 0.89 80.8 -0.54 0.72 65.1 -0.70 0.82 74.3 -0.84 0.78 70.9 0.10 0.76 68.5 -0.19 0.90 81.6 -0.54 0.75 67.5 -0.72 0.83 75.1 -0.85 0.80 72.7 0.11 0.79 71.8 -0.19 0.92 82.7 -0.54 0.75 67.8 -0.72 0.85 77.3 -0.86 0.80 72.8 0.12 0.80 72.7 -0.19 0.92 82.8 -0.54 0.78 70.3 -0.73 0.85 77.0 -0.86 0.82 74.3 0.12 0.81 73.3 -0.19 0.89 80.4 -0.54 0.78 70.4 -0.73 0.89 80.2 -0.87 0.83 75.5 0.13 0.85 76.5 -0.19 0.88 79.2 -0.54 0.80 72.7 -0.75 0.89 80.5 -0.87 0.84 75.9 0.13 0.85 76.7 -0.19 0.87 78.8 -0.54 0.81 73.1 -0.75 0.90 81.6 -0.88 0.86 78.0 0.14 0.86 77.9 -0.19 0.86 77.4 -0.54 0.84 75.6 -0.76 0.91 82.2 -0.88 0.87 78.2 0.14 0.88 80.0 -0.19 0.85 77.0 -0.54 0.84 75.7 -0.76 0.91 82.3 -0.88 0.88 80.0 0.15 0.89 80.2 -0.19 0.83 75.1 -0.53 0.87 78.7 -0.77 0.90 81.3 -0.88

posizione6

posi

zion 7

e

pos

izio e8

n

posi

zion 9

e

posizione10

FORZA LVDT FORZA LVDT FORZA LVDT FORZA LVDT FORZA LVDT

volt Mpa mm volt Mpa mm volt Mpa mm volt Mpa mm volt Mpa mm 0.00 0.0 0.00 0.00 0.0 0.00 0.00 0.1 0.00 0.00 -0.1 0.00 0.00 -0.1 0.00 0.03 2.7 -0.05 0.00 0.0 0.00 0.00 0.2 0.00 0.02 2.1 -0.05 0.05 4.5 -0.10 0.05 4.2 -0.07 0.00 0.0 0.00 0.04 3.6 -0.07 0.05 4.7 -0.10 0.05 4.6 -0.10 0.08 7.0 -0.10 0.00 0.1 0.00 0.06 5.8 -0.11 0.05 5.0 -0.11 0.10 8.9 -0.19 0.11 9.6 -0.12 0.01 1.3 -0.03 0.11 9.5 -0.17 0.08 7.7 -0.16 0.12 10.6 -0.22 0.16 14.0 -0.13 0.03 3.0 -0.07 0.14 12.9 -0.21 0.09 8.4 -0.17 0.14 12.8 -0.26 0.18 16.3 -0.13 0.03 3.1 -0.07 0.15 13.7 -0.22 0.12 10.4 -0.21 0.19 17.3 -0.33 0.21 19.4 -0.13 0.07 6.3 -0.11 0.21 18.8 -0.28 0.14 12.7 -0.24 0.20 17.8 -0.34 0.23 20.4 -0.13 0.07 6.4 -0.11 0.21 18.7 -0.28 0.14 13.0 -0.25 0.24 21.4 -0.39 0.28 25.6 -0.13 0.11 10.2 -0.16 0.25 22.8 -0.33 0.18 16.5 -0.30 0.27 24.7 -0.43 0.29 25.9 -0.13 0.12 10.6 -0.16 0.28 25.0 -0.34 0.22 20.0 -0.35 0.29 26.5 -0.46 0.32 28.5 -0.13 0.14 12.9 -0.18 0.29 26.6 -0.36 0.22 20.3 -0.36 0.33 30.1 -0.50 0.33 29.9 -0.13 0.15 13.8 -0.18 0.33 29.4 -0.38 0.26 23.3 -0.39 0.34 30.8 -0.51 0.36 32.4 -0.13 0.18 16.5 -0.20 0.34 30.6 -0.40 0.27 24.7 -0.41 0.37 33.8 -0.54 0.38 34.3 -0.12 0.20 18.5 -0.21 0.38 34.0 -0.42 0.29 26.5 -0.43 0.40 35.7 -0.56 0.39 35.7 -0.12 0.22 19.7 -0.22 0.37 33.9 -0.43 0.33 29.4 -0.46 0.42 37.8 -0.58 0.43 38.4 -0.11 0.24 21.7 -0.23 0.41 37.4 -0.45 0.34 30.4 -0.48 0.45 41.0 -0.61 0.43 38.8 -0.11 0.25 22.2 -0.23 0.42 38.0 -0.45 0.37 33.3 -0.51 0.45 40.9 -0.61 0.45 40.5 -0.11 0.27 24.4 -0.24 0.45 40.5 -0.47 0.37 33.2 -0.51 0.51 46.4 -0.66 0.46 42.0 -0.10 0.28 25.1 -0.24 0.46 41.8 -0.48 0.39 35.7 -0.53 0.52 47.4 -0.67 0.49 44.1 -0.10 0.30 27.5 -0.25 0.47 42.1 -0.49 0.40 36.4 -0.54 0.57 51.6 -0.70 0.49 44.1 -0.10 0.31 28.4 -0.26 0.50 45.5 -0.51 0.42 38.4 -0.56 0.59 53.1 -0.71 0.51 46.5 -0.09 0.34 30.6 -0.26 0.51 45.7 -0.52 0.43 38.8 -0.56 0.61 55.6 -0.73 0.52 46.9 -0.09 0.34 30.5 -0.27 0.52 47.0 -0.52 0.45 40.9 -0.58 0.64 57.9 -0.74 0.54 48.9 -0.09 0.37 33.5 -0.27 0.53 48.0 -0.52 0.46 42.0 -0.59 0.64 58.2 -0.75 0.55 49.8 -0.09 0.37 33.5 -0.28 0.56 50.3 -0.54 0.46 41.7 -0.59 0.68 61.9 -0.77 0.56 50.4 -0.08 0.39 35.6 -0.28 0.56 50.6 -0.54 0.48 43.4 -0.61 0.70 62.9 -0.78 0.58 52.2 -0.08 0.40 36.2 -0.28 0.59 53.3 -0.55 0.51 45.8 -0.62 0.72 65.2 -0.79 0.59 53.4 -0.08 0.41 37.5 -0.29 0.59 53.3 -0.56 0.52 46.7 -0.64 0.75 67.7 -0.81 0.62 55.9 -0.07 0.42 37.5 -0.29 0.63 56.9 -0.57 0.51 46.5 -0.64 0.76 68.3 -0.81 0.62 56.1 -0.07 0.43 39.1 -0.29 0.62 55.8 -0.57 0.54 49.2 -0.65 0.79 71.1 -0.82 0.65 58.5 -0.07 0.44 39.4 -0.29 0.65 58.6 -0.58 0.55 49.4 -0.66 0.79 71.1 -0.83 0.65 58.4 -0.06 0.46 41.6 -0.30 0.65 58.4 -0.58 0.55 49.6 -0.66 0.81 73.3 -0.84 0.67 60.4 -0.06 0.46 41.3 -0.30 0.70 62.9 -0.61 0.55 50.1 -0.66 0.81 73.5 -0.84 0.67 60.4 -0.06 0.48 43.0 -0.30 0.68 61.8 -0.61 0.57 51.3 -0.67 0.84 75.6 -0.85 0.70 63.4 -0.05 0.48 43.5 -0.30 0.71 64.0 -0.61 0.57 51.8 -0.67 0.84 76.1 -0.85 0.70 63.2 -0.05 0.50 45.5 -0.30 0.71 63.9 -0.61 0.57 51.9 -0.68 0.87 79.1 -0.87 0.73 65.7 -0.04 0.52 46.7 -0.30 0.72 65.0 -0.62 0.58 52.7 -0.68 0.88 79.7 -0.87 0.73 65.6 -0.04 0.52 47.2 -0.31 0.73 65.8 -0.62 0.58 52.1 -0.68 0.90 81.4 -0.88 0.75 67.7 -0.04 0.54 49.1 -0.31 0.75 68.1 -0.63 0.59 53.6 -0.69 0.90 81.5 -0.88 0.75 67.6 -0.04 0.54 49.1 -0.31 0.76 68.5 -0.63 0.61 55.4 -0.70 0.89 80.2 -0.88 0.77 69.4 -0.04 0.56 50.8 -0.31 0.80 72.7 -0.65 0.61 55.0 -0.70 0.84 76.3 -0.87 0.77 69.7 -0.03 0.56 50.8 -0.31 0.80 72.6 -0.65 0.64 57.4 -0.72 0.84 76.3 -0.87 0.80 72.0 -0.03 0.58 52.3 -0.32 0.84 75.6 -0.66 0.63 57.3 -0.72 0.82 73.7 -0.86 0.80 72.7 -0.03 0.58 52.3 -0.32 0.83 75.5 -0.67 0.65 58.8 -0.73 0.81 73.4 -0.86 0.82 73.9 -0.02 0.60 54.0 -0.32 0.87 78.4 -0.68 0.67 60.5 -0.74 0.77 69.7 -0.84 0.82 74.4 -0.02 0.60 54.7 -0.32 0.87 78.3 -0.68 0.67 60.7 -0.74 0.74 67.0 -0.82 0.84 76.2 -0.02 0.64 57.7 -0.32 0.89 80.5 -0.69 0.69 62.2 -0.75 0.73 66.0 -0.82

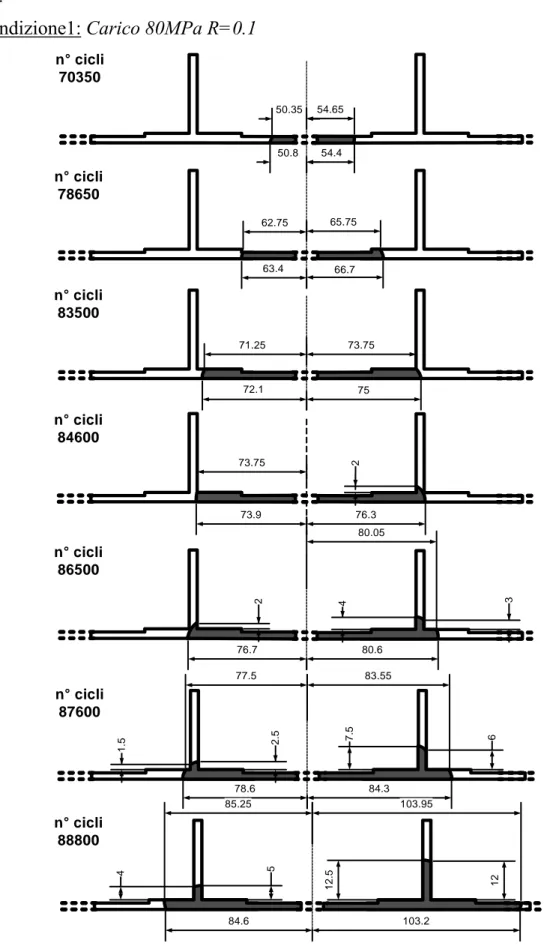

Appendice G: Configurazione criccata

Nelle figure seguenti viene riportata la configurazione della struttura criccata per alcuni valori

di cicli.

◊

Condizione1: Carico 80MPa R=0.1

n° cicli 70350 n° cicli 78650 n° cicli 83500 n° cicli 84600 n° cicli 86500 50.35 50.8 54.65 54.4 62.75 65.75 63.4 66.7 71.25 73.75 72.1 75 73.9 76.3 73.75 2 76.7 80.6 2 4 3 80.05 n° cicli 87600 78.6 84.3 1. 5 2.5 7. 5 6 77.5 83.55 n° cicli 88800 84.6 103.2 4 5 12 .5 12 85.25 103.95

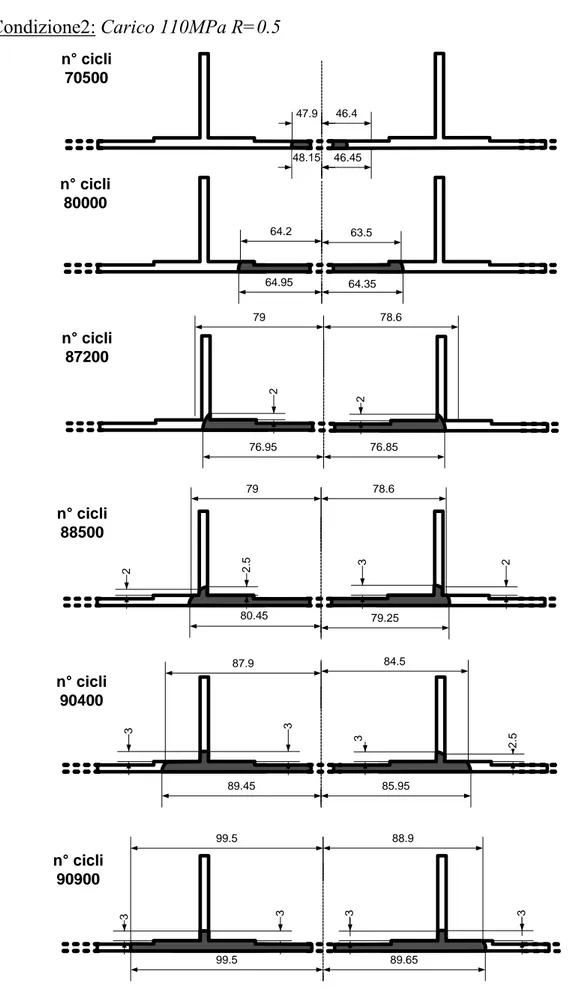

◊

Condizione2: Carico 110MPa R=0.5

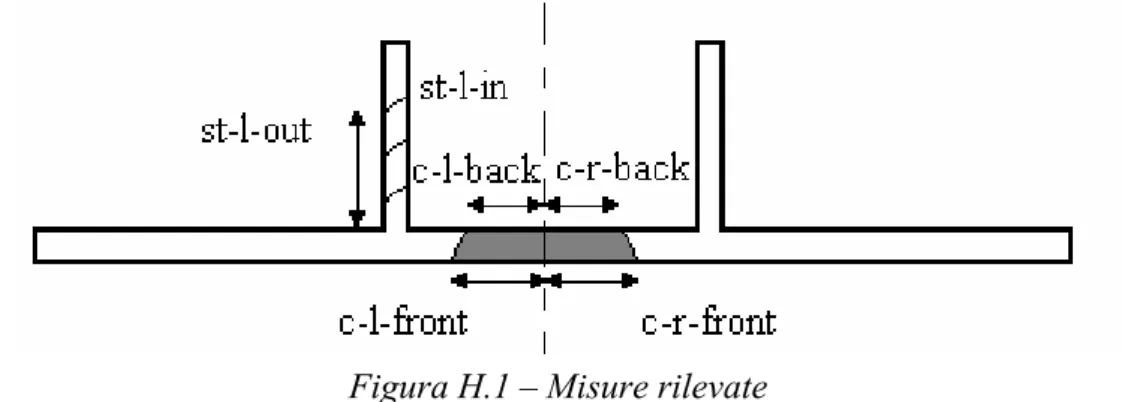

n° cicli 70500 n° cicli 80000 n° cicli 87200 47.9 48.15 46.4 46.45 64.2 63.5 64.95 64.35 76.95 76.85 2 78.6 89.45 85.95 3 3 3 2.5 87.9 84.5 99.5 89.65 3 3 3 3 99.5 88.9 2 79 n° cicli 90400 n° cicli 90900 79 78.6 80.45 79.25 n° cicli 88500 2 2.5 3 2Appendice H: Misure relative alle prove di propagazione

In figura H.1 vengono riportate le misure rilevate durante la propagazione.

◊

Test 1: carico 80 MPa R=0.1.

C

ommon

te

st prog

ram

(c

aric

o 80MPa

R

=0.1)

Fatigue Crack Propagation Test

c-r-front c-l-front N c-r-back c-l-back st-r-in st-r ut -o st-l-in st-l-out

10.8 10.7 1470 11.2 10.9 2750 10.75 10.95 11.3 11.2 3300 11.05 11.15 11.5 11.7 5100 11.35 11.35 11.8 12.1 6500 12.05 11.95 12.3 12.3 7500 12.05 12.15 12.6 12.5 8800 12.05 12.45 12.8 12.8 9800 12.05 12.65 13.3 13.2 11000 12.85 12.95 13.6 13.6 12100 13.15 13.35 13.8 14 13200 13.75 13.75 14.1 14.2 14500 13.95 13.95 14.5 14.4 15700 14.05 14.35 14.7 14.7 16500 14.25 14.55 15 15.2 17500 14.95 14.95 15.3 15.6 18500 15.45 15.35 15.7 15.9 19600 15.75 15.65 16 16.1 20000 16.05 15.95 16.3 16.4 21000 16.35 16.35 16.6 16.9 22000 16.65 16.75 17 17.2 23000 17.05 17.05 17.3 17.4 24000 17.45 17.45 17.7 17.8 24800 17.85 17.85 17.9 18 25500 18.05 18.05 18.4 18.3 26300 18.45 18.15 18.9 18.8 27000 19.05 18.75 19.1 19.2 27800 19.35 18.95 19.3 19.4 28500 19.55 19.15 19.8 19.7 29200 19.95 19.35 20.3 20.1 30100 20.45 19.65 21 20.7 31500 21.05 20.05

21.2 21.3 32300 21.55 20.65 21.9 21.7 33300 22.05 21.25 22.3 22 34000 22.35 21.85 22.7 22.3 34700 22.65 22.35 23.5 23.1 35850 23.25 22.95 23.7 23.3 36400 23.95 23.25 23.9 23.7 37000 24.05 23.55 24.2 24 37700 24.45 23.75 24.8 24.2 38300 25.05 23.95 25.2 24.5 38800 25.45 24.35 25.7 25.1 39500 25.85 24.95 26.1 25.5 40000 26.05 25.15 26.5 25.9 40700 26.55 25.95 26.9 26.7 41300 26.85 26.35 27.5 27 42000 27.45 26.95 28.1 27.5 42600 28.05 27.45 28.6 27.8 43000 28.45 27.75 29 27.9 43500 28.75 27.95 29.5 28.3 43800 29.25 28.25 29.7 28.5 44300 29.45 28.85 30.1 28.8 44600 29.75 28.95 30.3 29.3 45000 30.25 29.35 30.8 29.7 45500 30.55 29.55 31.6 30.2 46500 31.05 30.25 31.9 30.6 47000 31.55 30.55 32.1 30.9 47300 31.85 30.85 32.3 31.2 47700 32.05 31.05 32.8 31.7 48300 32.55 31.35 33.1 31.9 48800 33.15 31.75 33.6 32.4 49500 33.55 32.25 34 32.7 50000 33.85 32.45 34.3 33 50400 34.25 32.85 34.7 33.2 50700 34.45 33.25 34.9 33.4 51000 34.75 33.45 35.2 33.6 51500 34.85 33.55 35.7 34.3 52400 35.45 33.95 36.1 34.7 53500 35.65 34.25 36.3 34.9 54000 35.85 34.45 36.5 35 54600 35.95 34.65 36.7 35.2 55000 36.05 34.95 36.9 35.4 55500 36.25 35.15 37.5 36.2 57000 36.85 35.65 38.2 36.3 57800 37.55 36.05 38.4 36.9 59000 38.05 36.75 38.8 37.1 59500 38.55 36.95 39.6 37.9 60500 39.45 37.65 40.1 38.4 61000 40.05 37.95 40.6 38.9 61300 40.55 38.35 41.1 39.1 61800 41.05 39.15 41.3 39.2 62000 41.15 39.25 41.6 39.7 62300 41.65 39.45

42.5 40.6 63300 43.05 40.95 43.2 41.3 63800 43.45 41.55 43.4 41.9 64000 43.65 41.85 44.1 42.2 64500 44.05 42.35 44.7 42.7 64800 44.85 43.35 45.3 43.2 65300 45.65 43.85 45.8 43.9 65800 46.35 44.25 46 44.4 66000 46.65 44.65 47.9 45.6 67000 47.75 45.95 48.5 46.2 67400 48.65 46.25 49.1 46.7 67700 49.25 46.75 49.7 47.1 68000 50.05 47.05 50.4 47.4 68300 50.45 47.45 50.9 48.1 68600 51.05 47.95 51.7 48.7 69000 51.55 48.35 52.4 49.1 69350 52.65 48.65 53.9 50.4 70000 54.05 49.75 54.4 50.8 70300 54.65 50.35 54.9 51.1 70500 55.05 50.85 55.7 51.6 71000 55.75 51.75 56.1 52 71200 55.95 52.15 56.5 52.6 71500 56.35 52.45 57.1 52.8 71800 56.85 52.95 57.3 53.3 72100 57.35 53.25 57.7 53.7 72500 57.55 53.65 58 54.1 72700 58.05 54.55 58.3 55 73000 58.15 55.25 58.7 55.7 73300 58.25 56.35 58.9 56.4 73600 58.45 57.05 59.2 57.2 74000 58.65 57.75 59.7 58.2 74300 58.75 58.45 60.1 58.7 74700 59.05 58.95 60.3 59.1 75000 59.15 59.35 60.5 59.7 75350 59.75 59.65 61.3 59.9 75800 60.45 59.85 61.8 60.3 76100 61.15 60.05 62.3 60.7 76500 61.85 60.25 63 61.2 76800 62.35 60.35 63.4 61.5 77100 62.65 60.45 64.3 61.9 77500 63.45 60.45 65 62.4 77900 64.05 60.95 66.2 63.1 78400 65.35 61.95 66.7 63.4 78650 65.75 62.75 67.3 63.8 79000 66.45 63.55 68.3 64.2 79300 67.05 64.15 68.8 64.8 79600 67.85 64.75 69.6 65.6 79950 68.75 65.55 69.9 65.8 80000 68.95 66.05 70.2 65.9 80200 69.45 66.35 70.9 66.2 80500 69.65 66.75 71.1 66.6 80800 69.85 68.45 71.4 67.8 81100 70.15 68.95 73.3 70.4 82200 70.75 70.95

75 72.1 83500 irrigidimento 71.25 1.5 75.3 72.8 83900 irrigidimento 72.25

75.7 73.4 84200 irrigidimentoirrigidimento 76.3 73.9 84600 irrigidimento irrigidimento 2 77.8 75.1 85300 78.75 irrigidimento 2.5 1.2 78.7 75.7 85600 79 irrigidimento 3 2 1 79.2 75.9 85850 79.45 irrigidimento 80.6 76.7 86500 80.05 irrigidimento 4 3 2 81.9 77.4 86900 80.65 irrigidimento 84.3 78.6 87600 83.55 irrigidimento 6 5 1 87.1 79.6 87800 84.65 79.15 89.9 80.5 88200 94.95 81.35 9 7.5 3 3 103.2 84.6 88800 103.95 85.25 11 11 4 4.5 119.8 96.3 89300 14 13 5.5 6

Tabella H.1

◊

Test 2: carico 110 MPa R=0.5.

C

ommon test pro

gr

am

(cari

co110M

Pa R=

0.5)

Fatigue Crack Propagation Test

c-r-front c-l-front N c-r-back c-l-back st-r-in st-r ut -o st-l-in st-l-out

10.15 10.25 3900 9.9 10 10.45 10.45 4500 10.3 10.1 10.55 10.55 5000 10.4 10.3 10.65 10.75 5500 10.5 10.7 10.85 10.95 6700 10.6 10.8 10.95 11.05 7600 10.8 11 11.15 11.55 8800 10.9 11.3 11.45 11.85 9800 11.1 11.5 11.65 11.95 10500 11.3 11.8 11.75 12.05 11500 11.6 12.1 11.95 12.25 12650 11.8 12.2 12.25 12.45 13600 12.1 12.3 12.55 12.55 14750 12.4 12.5 12.75 13.05 16150 13 13 12.95 13.35 17000 13.3 13.1 13.25 13.75 18300 13.4 13.5 13.55 13.85 19000 13.7 13.6 13.75 14.25 20000 13.9 13.8 14.15 14.65 21400 14.2 14.3 14.65 14.95 23000 14.6 14.8 14.95 15.15 24300 15 15.2 15.25 15.55 25400 15.2 15.4 15.55 15.85 26600 15.6 15.8 16.05 16.35 28600 16.1 16.3 16.65 16.75 29900 16.6 16.5 16.75 17.05 30800 16.8 16.9 17.05 17.55 31800 17.1 17.3

18.55 19.35 37100 19 19.3 19.25 19.75 38100 19.2 19.9 19.45 20.15 39000 19.8 20.4 19.95 20.65 39850 20 20.7 20.65 21.35 41150 20.7 21.4 21.05 21.75 41900 20.9 21.9 21.45 22.55 43000 21.5 22.6 21.85 23.05 44000 22.1 23.1 22.45 23.35 44500 22.5 23.4 22.55 23.55 45000 22.7 23.6 23.05 24.05 46000 23.2 24.1 23.65 24.65 46800 23.7 24.7 24.05 25.35 47800 24.1 25.1 24.65 25.65 48600 24.6 25.5 25.45 26.55 50000 25.4 26.1 25.85 26.05 50800 26 26.9 26.35 27.95 51600 26.5 27.5 27.05 28.75 52900 27.3 28.9 27.85 29.25 54000 28 29.4 28.25 29.75 54500 28.5 29.9 29.15 30.65 55500 28.7 30.5 29.95 31.15 56500 29.6 31.4 30.55 32.35 57300 30.4 32.2 31.15 33.25 58300 31.3 33.2 32.25 34.25 59200 32.1 34.3 32.95 35.15 60000 33 35.1 33.55 35.65 60700 33.7 36 34.55 36.65 61600 34.7 36.8 35.65 37.75 62500 35.9 37.6 36.35 38.25 63000 36.2 38.2 37.05 38.95 63500 36.8 38.8 37.75 39.35 64000 37.2 39.4 38.55 40.05 64700 38.2 40.2 39.35 40.95 65500 38.9 41 40.15 41.75 66300 39.6 41.9 40.65 42.75 67000 40.5 42.7 42.15 44.05 68000 41.9 43.8 43.65 44.85 68800 43.6 44.7 44.95 46.15 69500 44.5 46.2 45.75 46.95 70000 45.6 47.2 46.45 48.15 70500 46.4 47.9 47.85 48.95 71000 47.3 49.1 49.05 50.35 71500 48.5 50 50.05 51.15 72000 49.9 51.1 51.15 52.25 72500 51.5 52.2 52.25 53.35 73000 52.4 52.9 53.55 54.25 73500 53.6 54.2 54.85 55.45 74000 54.6 55.3 55.75 56.15 74500 55.4 56.9 57.55 57.35 75000 56.9 57.7 58.25 58.55 75500 57.7 58.3 58.85 59.55 76000 58.8 59.1 60.05 59.95 76500 59.4 59.2

60.75 60.55 77000 59.5 59.6 61.25 60.95 77500 59.6 59.7 61.65 61.45 78000 59.8 60.2 62.55 62.05 78500 60.9 60.9 63.05 63.05 79000 62 61.8 63.95 63.65 79500 63 62.8 64.35 64.95 80000 63.5 64.2 65.25 65.75 80500 64.2 65.5 66.05 66.45 81000 65.3 66.1 67.15 68.25 81500 65.5 67.8 68.25 69.25 82000 67.8 69.4 68.65 69.95 82300 68.7 70.2 69.95 70.95 82700 non visibile 70.8 70.45 71.05 83000 non visibile 71.2 71.15 71.35 83300 non visibile 71.8 72.05 72.35 83700 non visibile 72.2 72.55 72.85 84000 non visibile irrigidimento 73.05 73.15 84300 irrigidimento irrigidimento 73.35 73.25 84800 irrigidimento irrigidimento 73.85 73.45 85200 irrigidimento irrigidimento 1 1 74.85 74.95 85500 irrigidimento irrigidimento 75.45 75.25 85800 irrigidimento irrigidimento 1.5 1.5 75.65 75.95 86200 irrigidimento irrigidimento 76.05 76.25 86500 irrigidimento irrigidimento 76.45 76.55 86800 irrigidimento irrigidimento 76.85 76.95 87200 irrigidimento irrigidimento 2 2 77.35 77.85 87500 irrigidimento irrigidimento 77.85 78.55 87800 irrigidimento 76 2.5 1 2 1.5 78.35 79.45 88200 78.1 78.8 79.25 80.45 88500 78.6 79 3 2 2.5 2 79.85 81.05 88800 78.9 80.6 81.15 82.35 89200 80.3 82.8 3 2.5 2.5 2.5 82.35 83.85 89500 80.6 83.5 83.15 84.95 89800 81 84.4 3 2.5 2.5 3 84.65 87.35 90200 83.2 86 85.95 89.45 90400 84.5 87.9 3 2.5 3 3 88.05 96.25 90700 86.7 89.9 89.65 99.45 90900 88.9 99.7 3 3 3 3 94.75 107.35 91200 94.9 110.6