Chapter 6

DISCUSSION OF ACHIEVED RESULTS

6.1 Steady State conditions

Preliminary checks were executed to prove the correctness of the thermal-hydraulic and neutronic

nodalizations developed. In particular, a steady state transient at HFP was executed by the RELAP5

code in a stand-alone mode, with zero dimensional neutron kinetic. The main plant parameters (e.g.

total power, mass of the plant, coolant temperatures) were calculated in order to compare them with

the design values. In Table 6.1.1 is reported the list of these parameters. As can be seen, they fulfill

the established design values. In Appendix A are reported the time trend of the most significant

variables.

A check of the main parameters was also executed coupling the RELAP5 with the PARCS code, in

order to estimate the correctness of the 3D neutronic nodalization. There were checked the same

parameters used for the RELAP5 in stand alone mode, the axial power distribution for the fuel at

the BOL and at the EOC and the 3D core parameters distribution. These relevant core parameters

are showed in figures 6.1.3-8 for the HFP with BOL and EOC fuel.

Fig. 6.1.1 – HFP BOL axial power

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 0 50 100 150 200 250 300 350 400 450

Core Height

Normalized Power

Normalized Power

Fig. 6.1.2 – HFP BOL 3D normalized power distribution

Fig. 6.1.4 – HFP BOL 3D Assemblywise Moderator temperature

Fig. 6.1.5 – HFP EOC axial power

0 0.2 0.4 0.6 0.8 1 1.2 1.4 0 50 100 150 200 250 300 350 400 450 Core Height Normalized Power Normalized Power

Fig. 6.1.6 – HFP EOC 3D normalized power distribution

Table 6.1.1 – Steady State conditions – RELAP5 stand alone at HFP

QUANTITY

Unit

DESIGN

RELAP5

(41 channel)

Notes

Primary circuit balance

MWth

3000

3000

Secondary circuit balance

MWth

750

752

1 SG

PRZ pressure

MPa

15.7

15.7

SG pressure

MPa

6.3

6.4

Secondary side

SG outlet

Core inlet temperature

°K

562

563.05

Core outlet temperature

°K

593

593.62

SG inlet plenum temperature

°K

593

591.9

Design value is

not consistent

with core outlet

temperature

SG outlet plenum temperature

°K

559

562.2

SG feed–water temperature

°K

493

547

Economizer not

modeled

MCP speed

Rad/s

104.2

104.2

RPV pressure losses

MPa

0.368

0.350

Core pressure losses

MPa

0.142

0.15

MCP head

MPa

0.74/0.54

0.55

Steam Generator pressure losses

MPa

0.12

0.122

Primary side

circuit

PS total mass inventory

ton

-

221.6

SG SS mass inventory

ton

-

37.8

One SG

PS total loop coolant flow rate

Kg/s

18250

18192

SG feed-water mass flow-rate

Kg/s

408

408

One SG

Core flow-rate

(active region)

Kg/s

–

17321

Core bypass flow-rate

(LP–UP)

%

(Kg/s)

–

5.1%

(871)

DC – UH and HL nozzle bypass

Kg/s

–

240

PRZ liquid level

m

8.45

8.47

SG SS level

m

2.55

1.80

The calculated

value is the level

where void

fraction becomes

larger then 0.5

6.2 Reference cases calculations

There were executed as reference cases, a rod ejection transient with the reactor at HFP and HZP

and with the fuel at BOL and EOC. Thus, a total of four reference case was analyzed (see Table

5.2.1).

6.2.1 HZP – BOL case

The results of this transient are shown in the figures below. As reported in Table 5.2.1, this transient

generate a modest increase in the energy of the fuel; only 26.2 cal/g were obtained as peak fuel

enthalpy for the FA that experienced the rod ejection. This ‘hot spot’ value was located at 1.41 m of

height from the bottom part of the FA. The low value of the energy release was explained by these

considerations:

•

CR worth not particularly high (0.95 $)

•

High delayed neutron fraction (

b) – 0.00729 – because the fuel was at the BOL

The overall reaction of the system to the transient was generally good. In fact, despite the great

power burst (Fig. 6.2.1.1) the pressure in the UH has a small fluctuation (Fig. 6.2.1.5) as the fuel

center-line temperatures (peak on plan 8) increases only of 100 degrees. The clad temperatures are

also not of safety concern.

Figure 6.2.1.1 – Reactor Power

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 0 1 2 3 4 5 6 7 x 10 8 Power (W) WinGraf 4.1 - 02-29-2004 XXX HZP_BOL_ref rktpow3d0 X X X X X X X X X X X X X X X X X X X XFigure 6.2.1.2 – Reactivity trend

-10 -8 -6 -4 -2 0 2 -1 0 1 2 3 4 5 6 7 8 9 Time (s) Reactivity ($) Reactivity

Figure 6.2.1.3 – Energy Released – CR ejected FA

0 1 2 3 4 5 6 7 8 9 0 50000 100000 150000 200000 250000 300000 350000 400000 450000 500000 550000 600000 650000 700000 750000 800000 8500003

4

5

6

7

8

9

10

11

12

Energy Released (J)

Time (s)

Figure 6.2.1.4 – Energy Released – CR ejected FA

0 1 2 3 4 5 6 7 8 9 0 100000 200000 300000 400000 500000 600000 700000

13

14

15

16

17

18

19

20

21

Energy Released (J)

Time (s)

Figure 6.2.1.5 - PRZ pressure

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 1.56 1.57 1.57 1.57 1.57 1.57 1.58 1.58 1.58 x 10 7 Pressure (Pa) WinGraf 4.1 - 02-29-2004 XXX HZP_BOL_ref p26010000 XXXXXXXXX X X X X X X X X X X XFigure 6.2.1.6 – UH pressure

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 1.57 1.58 1.58 1.58 1.58 1.58 1.59 1.59 x 10 7 Pressure (Pa) WinGraf 4.1 - 02-29-2004 XXX HZP_BOL_ref p150080000 XXXXX X XX X X X X X X X X X X X XFigure 6.2.1.7 – HL temperature

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 551.60 551.80 552.00 552.20 552.40 552.60 552.80 553.00 Temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_BOL_ref tempf200010000 XXXXXXXX X X X X X X X X X X X XFigure 6.2.1.8 – Fuel CL Temperature – plans # 1 to 10

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 540 560 580 600 620 640 660 680 700 720 740 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_BOL_ref httemp289100101 XXXXX XX XX X X X X X X X X X X X

YYY HZP_BOL_ref httemp289100201

YYY Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_BOL_ref httemp289100301 ZZZ Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z VVV HZP_BOL_ref httemp289100401 VV V V V V V V V V V V V V V V V V V JJJ HZP_BOL_ref httemp289100501 JJ J J J J J J J J J J J J J J J J HHH HZP_BOL_ref httemp289100601 H H H H H H H H H H H H H H H H H H ### HZP_BOL_ref httemp289100701 # # # # # # # # # # # # # # # # # #

OOO HZP_BOL_ref httemp289100801

O O O O O O O O O O O O O O O O O

AAA HZP_BOL_ref httemp289100901

A A A A A A A A A A A A A A A A A BBB HZP_BOL_ref httemp289101001 B B B B B B B B B B B B B B B B

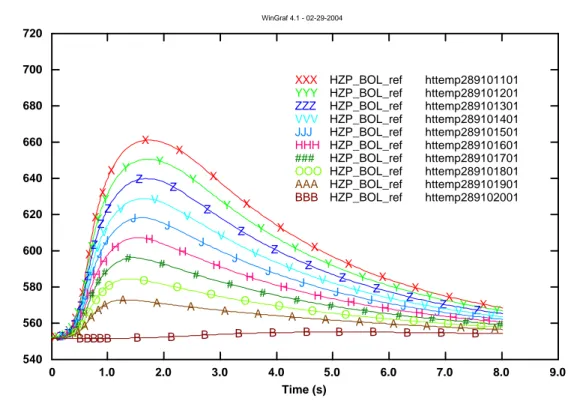

Figure 6.2.1.9 – Fuel CL Temperature – plans # 11 to 20

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 540 560 580 600 620 640 660 680 700 720 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_BOL_ref httemp289101101 XXX X X X X X X X X X X X X X X X X XYYY HZP_BOL_ref httemp289101201

YYY Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_BOL_ref httemp289101301 ZZ Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z VVV HZP_BOL_ref httemp289101401 VV V V V V V V V V V V V V V V V V V JJJ HZP_BOL_ref httemp289101501 JJ J J J J J J J J J J J J J J J J HHH HZP_BOL_ref httemp289101601 HH H H H H H H H H H H H H H H H H ### HZP_BOL_ref httemp289101701 ## # # ## # # # # # # # # # # # #

OOO HZP_BOL_ref httemp289101801

OO O OO O O O O O O O O O O O O

AAA HZP_BOL_ref httemp289101901

AA AAA A A A A A A A A A A A A BBB HZP_BOL_ref httemp289102001 BBBBB B B B B B B B B B B B

Figure 6.2.1.10 – Clad Surface Temperature – plan # 1 to 10

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 550.0 552.0 554.0 556.0 558.0 560.0 562.0 Clad temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_BOL_ref httemp289100112 XXXXX XXX X X X X X X X X X X X X

YYY HZP_BOL_ref httemp289100212

YYYY Y Y YY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_BOL_ref httemp289100312 ZZZ Z Z Z ZZ Z Z Z Z Z Z Z Z Z Z Z VVV HZP_BOL_ref httemp289100412 VV V V V V V V V V V V V V V V V V V JJJ HZP_BOL_ref httemp289100512 JJ J J J J J J J J J J J J J J J J HHH HZP_BOL_ref httemp289100612 HH H H H H H H H H H H H H H H H H ### HZP_BOL_ref httemp289100712 # # # # # # # # # # # # # # # # # #

OOO HZP_BOL_ref httemp289100812

O O O O O O O O O O O O O O O O O

AAA HZP_BOL_ref httemp289100912

A A A A A A A A A A A A A A A A A BBB HZP_BOL_ref httemp289101012 B B B B B B B B B B B B B B B B

Figure 6.2.1.11 – Clad Surface Temperature – plan # 11 to 20

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 550.0 552.0 554.0 556.0 558.0 560.0 562.0 Clad temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_BOL_ref httemp289101112 XXX X X X X X X X X X X X X X X X X XYYY HZP_BOL_ref httemp289101212

YYY Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_BOL_ref httemp289101312 ZZZ Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z VVV HZP_BOL_ref httemp289101412 VV V V V V V V V V V V V V V V V V V JJJ HZP_BOL_ref httemp289101512 JJ J J J J J J J J J J J J J J J J HHH HZP_BOL_ref httemp289101612 HH H H H H H H H H H H H H H H H H ### HZP_BOL_ref httemp289101712 ## # # # # # # # # # # # # # # # #

OOO HZP_BOL_ref httemp289101812

OO O O O O O O O O O O O O O O O

AAA HZP_BOL_ref httemp289101912

AA A A A A A A A A A A A A A A A BBB HZP_BOL_ref httemp289102012 BB B B B B B B B B B B B B B B

6.2.2 HFP – BOL case

The results of this transient are shown in the figures below. As reported in Table 5.2.1, this transient

caused a peak fuel enthalpy of 63.9 cal/g localized in the FA that experienced the rod ejection. In

particular, this value was found at 1.41 m of height from the bottom part of the FA.

It has to be noted that the energy increase of the fuel, for this type of transient (HFP), is smaller than

the HZP case. In fact, the higher value that was found here, compared to the HZP case, was due

mainly to the energy previously stored into the fuel because it was operating at an higher

temperature. Thus, the power burst generated an increase of energy like the 10% of the initial stored

energy. For the HZP, instead, there was an increase like the 300% of the initial stored energy. This

different behavior can be explained by the fact that at the HFP case there was a greater value of the

Doppler effect caused by the higher starting fuel temperature.

Furthermore, the same considerations reported for the HZP – BOL case for explain the low value of

the energy release, are also here suitable:

•

CR worth not particularly high (0.2263 $)

•

High delayed neutron fraction (

b) – 0.00729 – because the fuel was at the BOL

Figure 6.2.2.1 – Reactor Power

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 0 .5 1 1.5 2 2.5 3 3.5 4 4.5 x 10 9 Power (W) WinGraf 4.1 - 02-29-2004 XXX HFP_BOL_ref rktpow3d0 X XXXXX X X X X X X X X X X X X X X

Figure 6.2.2.2 – Reactivity trend

-18 -16 -14 -12 -10 -8 -6 -4 -2 0 2 -1 0 1 2 3 4 5 6 7 8 9 Time (s) Reactivity ($) ReactivityFigure 6.2.2.3 – Energy released – CR ejected FA

0 2 4 6 8 0 100000 200000 300000 400000 500000 600000 700000 800000 900000 1000000 1100000 1200000 1300000 1400000 1500000 1600000

3

4

5

6

7

8

9

10

11

12

Energy Release (J)

Time (s)

Figure 6.2.2.4 – Energy released – CR ejected FA

0 2 4 6 8 0 250000 500000 750000 1000000 1250000 150000013

14

15

16

17

18

19

20

21

Energy Released (J)

Time (s)

6.2.2.5 – PRZ pressure

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 1.56 1.56 1.57 1.57 1.57 1.57 1.57 1.58 1.58 1.58 x 10 7 Pressure (Pa) WinGraf 4.1 - 02-29-2004 XXX HFP_BOL_ref p26010000 XXXXXXXX X X X X X X X X X X X XFigure 6.2.2.6 – UH pressure

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 1.54 1.55 1.56 1.57 1.58 1.59 1.6 x 10 7 Pressure (Pa) WinGraf 4.1 - 02-29-2004 XXX HFP_BOL_ref p150080000 XXXX XXXXX X X X X X X X X X X XFigure 6.2.2.7 – HL temperature

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 570.0 575.0 580.0 585.0 590.0 595.0 600.0 Temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HFP_BOL_ref tempf200010000 XXXXXXXX X X X X X X X X X X X XFigure 6.2.2.8 – Fuel CL Temperature – plans # 1 to 10

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 550 600 650 700 750 800 850 900 950 1000 1050 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HFP_BOL_ref httemp284100101 XXXX XXXXX X X X X X X X X X X XYYY HFP_BOL_ref httemp284100201

YY YY YYY Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HFP_BOL_ref httemp284100301 ZZ ZZ ZZ ZZ Z Z Z Z Z Z Z Z Z Z Z VVV HFP_BOL_ref httemp284100401 VV VV VV V V V V V V V V V V V V V JJJ HFP_BOL_ref httemp284100501 JJ JJ JJ J J J J J J J J J J J J HHH HFP_BOL_ref httemp284100601 H H H HH H H H H H H H H H H H H H ### HFP_BOL_ref httemp284100701 # # # # ## # # # # # # # # # # # #

OOO HFP_BOL_ref httemp284100801

O O O O OO O O O O O O O O O O O

AAA HFP_BOL_ref httemp284100901

A A A A A A A A A A A A A A A A A BBB HFP_BOL_ref httemp284101001 B B B BB B B B B B B B B B B B

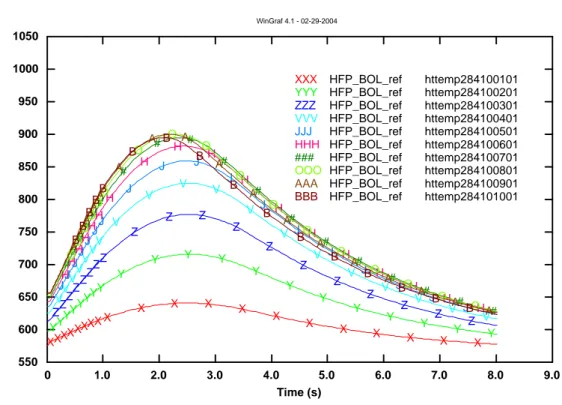

Figure 6.2.2.9 – Fuel CL Temperature – plans # 11 to 20

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 550 600 650 700 750 800 850 900 950 1000 1050 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HFP_BOL_ref httemp284101101 X X X X X X X X X X X X X X X X X X X X

YYY HFP_BOL_ref httemp284101201

Y Y Y Y Y Y YY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HFP_BOL_ref httemp284101301 Z Z Z Z Z ZZ Z Z Z Z Z Z Z Z Z Z Z Z VVV HFP_BOL_ref httemp284101401 V V V V V VV V V V V V V V V V V V V JJJ HFP_BOL_ref httemp284101501 J J J J JJ J J J J J J J J J J J J HHH HFP_BOL_ref httemp284101601 H H H HH HH H H H H H H H H H H H ### HFP_BOL_ref httemp284101701 ## ## ## # # # # # # # # # # # #

OOO HFP_BOL_ref httemp284101801

OO OOO O O O O O O O O O O O O

AAA HFP_BOL_ref httemp284101901

AA AAA A A A A A A A A A A A A BBB HFP_BOL_ref httemp284102001 BBBBB B B B B B B B B B B B

Figure 6.2.2.10 –Clad Temperature – plans # 1 to 10

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 560.0 565.0 570.0 575.0 580.0 585.0 590.0 Clad temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HFP_BOL_ref httemp284100112 XXXXXX XX X X X X X X X X X X X XYYY HFP_BOL_ref httemp284100212

YYYY YYYY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HFP_BOL_ref httemp284100312 ZZ ZZ ZZZ Z Z Z Z Z Z Z Z Z Z Z Z VVV HFP_BOL_ref httemp284100412 VV VV VV V V V V V V V V V V V V V JJJ HFP_BOL_ref httemp284100512 J JJ JJ JJ J J J J J J J J J J J HHH HFP_BOL_ref httemp284100612 H H HH HH H H H H H H H H H H H H ### HFP_BOL_ref httemp284100712 # # ## ## # # # # # # # # # # # #

OOO HFP_BOL_ref httemp284100812

O O O OO O O O O O O O O O O O O

AAA HFP_BOL_ref httemp284100912

A A A A A A A A A A A A A A A A A BBB HFP_BOL_ref httemp284101012 B B B BB B B B B B B B B B B B

Figure 6.2.2.11 –Clad Temperature – plans # 11 to 20

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 565.0 567.5 570.0 572.5 575.0 577.5 580.0 582.5 585.0 587.5 Clad temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HFP_BOL_ref httemp284101112 XX X X X X X X X X X X X X X X X X X X

YYY HFP_BOL_ref httemp284101212

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HFP_BOL_ref httemp284101312 Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z VVV HFP_BOL_ref httemp284101412 V V V V V V V V V V V V V V V V V V V JJJ HFP_BOL_ref httemp284101512 J J J J J J J J J J J J J J J J J J HHH HFP_BOL_ref httemp284101612 H H H H H H H H H H H H H H H H H H ### HFP_BOL_ref httemp284101712 # # # # # # # # # # # # # # # # # #

OOO HFP_BOL_ref httemp284101812

O O O O O O O O O O O O O O O O O

AAA HFP_BOL_ref httemp284101912

A A A A A A A A A A A A A A A A A BBB HFP_BOL_ref httemp284102012 B B B B B B B B B B B B B B B B

6.2.3 HZP – EOC case

The results of the transient are shown in the figures below. As reported in Table 5.2.1, this was the

transient that caused the most severe increase of the energy released to the fuel. The FA that

experienced the rod ejection had an overshot of power that caused a peak fuel enthalpy of 81.0

cal/g. This maximum value was found at an height of 3.0 m from the bottom part of the FA.

The behavior of this HZP case, with fuel at the EOC, can be explained by these considerations:

•

CR worth particularly high (1.573 $)

•

Lower delayed neutron fraction (

b) – 0.0055

•

Small feedback negative reactivity inserted by the Doppler effect; the fuel starts the transient

with a low temperature (552 °K)

These conditions caused a super prompt critical reactivity insertion (Fig. 6.2.3.2); the consequences

were a sharp increase in the fuel and clad temperature for the FA that experienced the rod ejection

(Hot channel) and for its neighbor FAs. Details of their main parameters trend are reported in

Appendix B.

In Figure 6.2.3.12-13 there is reported the time trend of the void fraction and the coolant

temperature at the exit of the Hot Channel; it can be seen that there is not ebullition, so the coolant

remained in a subcooled state.

In Figure 6.2.3.7 there is also reported the time trend for coolant temperature in the Hot Legs. It can

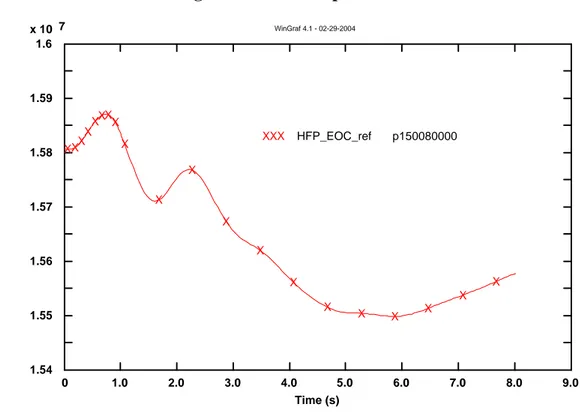

be noted that its slight increase caused an increase in the UH pressure (Fig. 6.2.3.6).

All the values assumed by the parameter were not of safety concern.

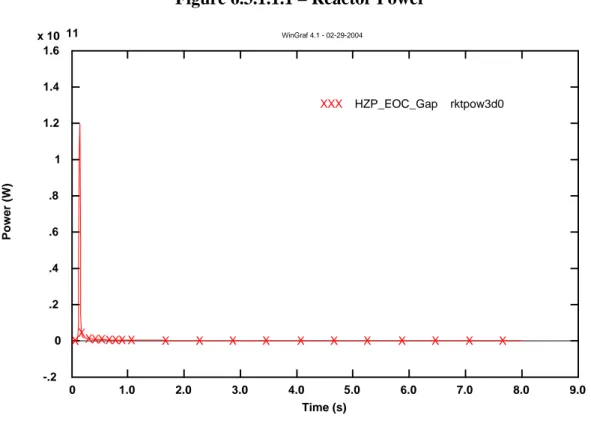

Figure 6.2.3.1 – Reactor Power

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) -.2 0 .2 .4 .6 .8 1 1.2 1.4 x 10 11 Power (W) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_ref rktpow3d0 X X XXXXXX X X X X X X X X X X X X

Figure 6.2.3.2 – Reactivity trend

-12 -10 -8 -6 -4 -2 0 2 4 -1 0 1 2 3 4 5 6 7 8 9 Time (s) Reactivity ($) ReactivityFigure 6.2.3.3 – Energy released – CR ejected FA

0 1 2 3 4 5 6 7 8 9 0 500000 1000000 1500000 2000000 2500000 3000000 3500000 4000000 4500000 5000000 5500000 6000000 6500000 7000000

3

4

5

6

7

8

9

10

11

12

Energy Released (J)

Time (s)

Figure 6.2.3.4 – Energy released – CR ejected FA

0 1 2 3 4 5 6 7 8 9 0 500000 1000000 1500000 2000000 2500000 3000000 3500000 4000000 4500000 5000000 5500000 6000000 6500000 7000000 7500000 800000013

14

15

16

17

18

19

20

21

Y Axis Title

X axis title

Figure 6.2.3.5 – PRZ pressure

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 1.56 1.57 1.57 1.57 1.57 1.57 1.58 1.58 x 10 7 Pressure (Pa) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_ref p26010000 XXXXXXXX X X X X X X X X X X X XFigure 6.2.3.6 – UH pressure

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 1.57 1.58 1.59 1.6 1.61 1.62 1.63 1.64 1.65 x 10 7 Pressure (Pa) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_ref p150080000 XX X X X X X X X X X X X X X X X X X XFigure 6.2.3.7 – HL temperature

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 550.0 552.0 554.0 556.0 558.0 560.0 562.0 564.0 566.0 Temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_ref tempf200010000 XXXXXXXX X X X X X X X X X X X XFigure 6.2.3.8 – Fuel CL Temperature – plans # 1 to 10

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 Time (s) 400 600 800 1000 1200 1400 1600 1800 2000 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_ref httemp289100101 X XXXXXXXX X X X X X X X X X X XYYY HZP_EOC_ref httemp289100201

Y YYY YYYY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_ref httemp289100301 Z ZZZ ZZZZ Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_ref httemp289100401 VVV VVVV V V V V V V V V V V V V JJJ HZP_EOC_ref httemp289100501 JJJ JJJJ J J J J J J J J J J J HHH HZP_EOC_ref httemp289100601 HHHHH H H H H H H H H H H H H H ### HZP_EOC_ref httemp289100701 ##### # # # # # # # # # # # # #

OOO HZP_EOC_ref httemp289100801

OOOOOO O O O O O O O O O O O

AAA HZP_EOC_ref httemp289100901

AAAAA A A A A A A A A A A A A BBB HZP_EOC_ref httemp289101001 BBBBB B B B B B B B B B B B

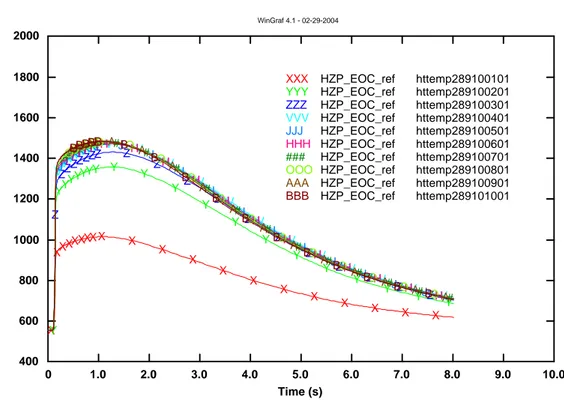

Figure 6.2.3.9 – Fuel CL Temperature – plans # 11 to 20

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 400 600 800 1000 1200 1400 1600 1800 2000 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_ref httemp289101101 X XXX XXXX X X X X X X X X X X X X

YYY HZP_EOC_ref httemp289101201

Y YYY YYYY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_ref httemp289101301 Z ZZZZZZZ Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_ref httemp289101401 VVV VVVV V V V V V V V V V V V V JJJ HZP_EOC_ref httemp289101501 JJJJ JJJ J J J J J J J J J J J HHH HZP_EOC_ref httemp289101601 HHHHHH H H H H H H H H H H H H ### HZP_EOC_ref httemp289101701 ###### # # # # # # # # # # # #

OOO HZP_EOC_ref httemp289101801

OOOOOO O O O O O O O O O O O

AAA HZP_EOC_ref httemp289101901

AAAAA A A A A A A A A A A A A BBB HZP_EOC_ref httemp289102001 BBBBB B B B B B B B B B B B

Figure 6.2.3.10 – Clad Temperature – plans # 1 to 10

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 540.0 550.0 560.0 570.0 580.0 590.0 600.0 610.0 620.0 630.0 640.0 Clad temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_ref httemp289100112 X X XX XX XX X X X X X X X X X X X XYYY HZP_EOC_ref httemp289100212

Y Y Y Y Y YYY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_ref httemp289100312 Z ZZ Z Z Z ZZ Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_ref httemp289100412 V VV V V VV V V V V V V V V V V V V JJJ HZP_EOC_ref httemp289100512 J JJ J J JJ J J J J J J J J J J J HHH HZP_EOC_ref httemp289100612 H HH H H H H H H H H H H H H H H H ### HZP_EOC_ref httemp289100712 ### # # # # # # # # # # # # # # #

OOO HZP_EOC_ref httemp289100812

OOO O O O O O O O O O O O O O O

AAA HZP_EOC_ref httemp289100912

AAA A A A A A A A A A A A A A A BBB HZP_EOC_ref httemp289101012 BB B B B B B B B B B B B B B B

Figure 6.2.3.11 – Clad Temperature – plans # 11 to 20

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 540 560 580 600 620 640 660 Clad temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_ref httemp289101112 X X X X XXX X X X X X X X X X X X X X

YYY HZP_EOC_ref httemp289101212

Y Y Y Y YY Y Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_ref httemp289101312 Z Z Z ZZZZ Z Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_ref httemp289101412 V V V VVVV V V V V V V V V V V V V JJJ HZP_EOC_ref httemp289101512 J J J J JJJ J J J J J J J J J J J HHH HZP_EOC_ref httemp289101612 H H HHHHH H H H H H H H H H H H ### HZP_EOC_ref httemp289101712 # # #### # # # # # # # # # # # #

OOO HZP_EOC_ref httemp289101812

O OOOOO O O O O O O O O O O O

AAA HZP_EOC_ref httemp289101912

A AAAA A A A A A A A A A A A A BBB HZP_EOC_ref httemp289102012 B B BBB B B B B B B B B B B B

Fig. 6.2.3.12 – FA Channel outlet temperature

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 540.0 550.0 560.0 570.0 580.0 590.0 600.0 610.0 620.0 630.0 Temperature (°K) WinGraf 4.1 - 03-02-2004 XXX HZP_EOC_ref tempf289200000 XX X X X X XXX X X X X X X X X X X XFig. 6.2.3.13 – FA Channel Void Fraction

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 Time (s) 0 .2 .4 .6 .8 1 1.2 x 10 -6 Void Fraction WinGraf 4.1 - 03-02-2004 XXX HZP_EOC_ref voidg289010000

YYY HZP_EOC_ref voidg289020000

ZZZ HZP_EOC_ref voidg289030000

VVV HZP_EOC_ref voidg289040000

JJJ HZP_EOC_ref voidg289050000

HHH HZP_EOC_ref voidg289060000

### HZP_EOC_ref voidg289070000

OOO HZP_EOC_ref voidg289080000

AAA HZP_EOC_ref voidg289090000

BBB HZP_EOC_ref voidg289100000

CCC HZP_EOC_ref voidg289110000

DDD HZP_EOC_ref voidg289120000

EEE HZP_EOC_ref voidg289130000

FFF HZP_EOC_ref voidg289140000

GGG HZP_EOC_ref voidg289150000

III HZP_EOC_ref voidg289160000

LLL HZP_EOC_ref voidg289170000

MMM HZP_EOC_ref voidg289180000

NNN HZP_EOC_ref voidg289190000

Fig. 6.2.3.14 – FA Channel flowrate

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 96.0 98.0 100.0 102.0 104.0 106.0 108.0 110.0 Mass flowrate (Kg/s) WinGraf 4.1 - 03-04-2004 XXX HZP_EOC_ref mflowj289010000 X X X X X X XX X X X X X X X X X X X XFig. 6.2.3.15 –Core flowrate

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 1.85 1.86 1.86 1.86 1.86 1.87 1.87 1.87 1.87 1.88 1.88 x 10 4 Mass flowrate (Kg/s) WinGraf 4.1 - 03-04-2004 XXX HZP_EOC_ref mflowj100010000 X X X X X XX X X X X X X X X X X X X X

6.2.4 HFP – EOC case

The results of this transient are shown in the figures below. As reported in Table 5.2.1, the peak fuel

enthalpy was 59.5 cal/g. It was released in the FA that experienced the rod ejection (‘Hot Channel’)

at 0.7 m of height from its bottom part. Also in this case, as in the HFP – BOL case, there was a

small quantity of energy released to the fuel, because the higher temperature of the fuel itself (i.e. a

greater Doppler effect). The energy increase was about 10% of the initial stored energy (52.1 cal/g).

The consequences were in a less severe temperature transient for the FA (see Figures 6.2.4.8 to

6.2.4.11 and Appendix B) and in a less severe transient for the whole plant (see Figure 6.2.4.6).

Figure 6.2.4.1 – Reactor Power

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 0 1 2 3 4 5 6 x 10 9 Power (W) WinGraf 4.1 - 02-29-2004 XXX HFP_EOC_ref rktpow3d0 X XX X X X X X X X X X X X X X X X X X

Figure 6.2.4.2 – Reactivity trend

-25 -20 -15 -10 -5 0 5 -1 0 1 2 3 4 5 6 7 8 9 Time (s) Reactivity ($) ReactivityFigure 6.2.4.3 – Energy released – CR ejected FA

0 2 4 6 8 0 250000 500000 750000 1000000 1250000 1500000 1750000

3

4

5

6

7

8

9

10

11

12

Energy Released (J)

Time (s)

Figure 6.2.4.4 – Energy released – CR ejected FA

0 2 4 6 8 0 250000 500000 750000 1000000 125000013

14

15

16

17

18

19

20

21

Energy Released (J)

Time (s)

Figure 6.2.4.5 – PRZ pressure

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 1.56 1.57 1.57 1.57 1.57 1.57 1.58 1.58 x 10 7 Pressure (Pa) WinGraf 4.1 - 02-29-2004 XXX HFP_EOC_ref p26010000 XXXXXXXX X X X X X X X X X X X XFigure 6.2.4.6 – UH pressure

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 1.54 1.55 1.56 1.57 1.58 1.59 1.6 x 10 7 Pressure (Pa) WinGraf 4.1 - 02-29-2004 XXX HFP_EOC_ref p150080000 XXX XX XXX X X X X X X X X X X X XFigure 6.2.4.7 – HL temperature

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 570.0 575.0 580.0 585.0 590.0 595.0 600.0 Temperature (°K) WinGraf 4.1 - 03-02-2004 XXX HFP_EOC_ref tempf200010000 XXXXXXXX X X X X X X X X X X X XFigure 6.2.4.8 – Fuel CL Temperature – plans # 1 to 10

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 550 600 650 700 750 800 850 900 950 1000 1050 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HFP_EOC_ref httemp284100101 XX XX XX XX X X X X X X X X X X X XYYY HFP_EOC_ref httemp284100201

Y Y Y YY YY Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HFP_EOC_ref httemp284100301 Z Z Z Z Z ZZ Z Z Z Z Z Z Z Z Z Z Z Z VVV HFP_EOC_ref httemp284100401 V V V V VV V V V V V V V V V V V V V JJJ HFP_EOC_ref httemp284100501 J J J J JJ J J J J J J J J J J J J HHH HFP_EOC_ref httemp284100601 H H HH HH H H H H H H H H H H H H ### HFP_EOC_ref httemp284100701 # # # ## # # # # # # # # # # # # #

OOO HFP_EOC_ref httemp284100801

O O OO OO O O O O O O O O O O O

AAA HFP_EOC_ref httemp284100901

A AA AA A A A A A A A A A A A A BBB HFP_EOC_ref httemp284101001 B BB BB B B B B B B B B B B B

Figure 6.2.4.9 – Fuel CL Temperature – plans # 11 to 20

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 550 600 650 700 750 800 850 900 950 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HFP_EOC_ref httemp284101101 X X X X X X XX X X X X X X X X X X X X

YYY HFP_EOC_ref httemp284101201

Y Y Y Y Y Y YY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HFP_EOC_ref httemp284101301 Z Z Z Z Z ZZ Z Z Z Z Z Z Z Z Z Z Z Z VVV HFP_EOC_ref httemp284101401 V V V V V VV V V V V V V V V V V V V JJJ HFP_EOC_ref httemp284101501 J J J J JJ J J J J J J J J J J J J HHH HFP_EOC_ref httemp284101601 H H H H HH H H H H H H H H H H H H ### HFP_EOC_ref httemp284101701 # # # ## # # # # # # # # # # # # #

OOO HFP_EOC_ref httemp284101801

O O O OOO O O O O O O O O O O O

AAA HFP_EOC_ref httemp284101901

A A AAA A A A A A A A A A A A A BBB HFP_EOC_ref httemp284102001 BBBBB B B B B B B B B B B B

Figure 6.2.4.10 – Clad Temperature – plans # 1 to 10

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 562.5 565.0 567.5 570.0 572.5 575.0 577.5 580.0 582.5 585.0 Clad temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HFP_EOC_ref httemp284100112 XX XX XXX X X X X X X X X X X X X XYYY HFP_EOC_ref httemp284100212

Y Y Y YY YY Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HFP_EOC_ref httemp284100312 Z Z Z Z ZZ ZZ Z Z Z Z Z Z Z Z Z Z Z VVV HFP_EOC_ref httemp284100412 V V V V V VV V V V V V V V V V V V V JJJ HFP_EOC_ref httemp284100512 J J J J JJ J J J J J J J J J J J J HHH HFP_EOC_ref httemp284100612 H H H H HH H H H H H H H H H H H H ### HFP_EOC_ref httemp284100712 # # # # ## # # # # # # # # # # # #

OOO HFP_EOC_ref httemp284100812

O O O O OO O O O O O O O O O O O

AAA HFP_EOC_ref httemp284100912

A A A A A A A A A A A A A A A A A BBB HFP_EOC_ref httemp284101012 B B B B B B B B B B B B B B B B

Figure 6.2.4.11 – Clad Temperature – plans # 11 to 20

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 565.0 567.5 570.0 572.5 575.0 577.5 580.0 582.5 585.0 587.5 590.0 Clad temperature (°K) WinGraf 4.1 - 03-02-2004 XXX HFP_EOC_ref httemp284101112 XX X X X X X X X X X X X X X X X X X X

YYY HFP_EOC_ref httemp284101212

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HFP_EOC_ref httemp284101312 Z Z Z Z Z Z ZZ Z Z Z Z Z Z Z Z Z Z Z VVV HFP_EOC_ref httemp284101412 V V V V V V V V V V V V V V V V V V V JJJ HFP_EOC_ref httemp284101512 J J J J J J J J J J J J J J J J J J HHH HFP_EOC_ref httemp284101612 H H H H H H H H H H H H H H H H H H ### HFP_EOC_ref httemp284101712 # # # # # # # # # # # # # # # # # #

OOO HFP_EOC_ref httemp284101812

O O O O OO O O O O O O O O O O O

AAA HFP_EOC_ref httemp284101912

A A A A A A A A A A A A A A A A A BBB HFP_EOC_ref httemp284102012 B B B B B B B B B B B B B B B B

6.3 Sensitivity analyses calculations

Sensitivity analyses were performed on the HZP – EOC case, because, as shown in the Chapter

6.2.3, it was found to be the most severe transient for the fuel and for the plant itself.

As reported thoroughly in Chapter 5.3, these analyses were executed varying various physical

parameters of the fuel (geometrical and nuclear characteristics), the flow regime of the plant, the

cross section libraries resolution. In the Figure 6.3.1, it is reported the results of the calculations for

the energy released to the fuel for the all cases analyzed; in Table 6.3.1 is also reported the main

parameters variation. Then, below, the results are described in details.

Fig. 6.3.1 – HZP EOC sensitivity analyses – Peak Fuel Enthalpy

0 20 40 60 80 100 120 140

XSec_20 - Reference case

XSec_42 - increased resolution

Doppler weighting factor increase

Natural Circulation1 pump in operation2 pump in operationXenon poisoning

Gap closure & fuel restructuredHeat Conductivity & Rim Zone

Delayed neutron fraction specified

Peak Fuel Enthalpy (cal/ g)

Energy Released Initial Stored Energy

+22% +18.5% -20% +1.5% +0.9% +66.8% +2.6% +13.2% +12.3%

Table 6.3.1 – Main parameters variation for the Hot Spot

Transient

HZP

Delta

Energy

Release

(%)

Maximum

Fuel CL

temperature

Maximum

Fuel Clad

Temperature

Minimum

DNBR

----

Boiling

channel

Notes

XSec_20

61.13 cal/g

1580 K

630 K

3.03 on

plan #18

NO

Reference

case

XSec_42

+21.9%

+12.6%

same behav.

~ +1%

same behav.

1.99 on

plan #18

YES

Doppler

weighting

factor

+18.5%

+10.7%

same behav.

~ +1%

same behav.

2.09 on

plan #18

YES

Natural

Circulation

-19.9%

-11.4%

same behav.

+11.2%

sharp

increase

0.88 on

plan #18

YES

Code

crashing

@ 1.4 s

1 pump

+1.5%

+0.6%

same

behavior

+17.9%

sharp

increase

0.447 on

plan #18

YES

Code

crashing

@ 1.35 s

2 pump

+0.9%

+0.6%

same behav.

+31.1%

slow cool

down

0.97 on

plan #18

YES

Gap closure &

delta density

+2.6%

+0.6%

faster cool

down

+55.2%

greatest

increase

1.01 on

plan #18

YES

Rim Effect &

delta

conductibility

+13.2%

+10.12%

cool down

very slow

-0.4%

same behav.

3.64 on

plan #18

NO

Xenon

+66.8%

+32.27%

same

behavior

+55.7%

same behav.

1.0 on plan

#17,18

YES

Beta point

+12.3%

+6.9%

same behav.

+0.8%

same behav.

2.22 on

plan #18

YES

6.3.1 Fuel characteristics variation

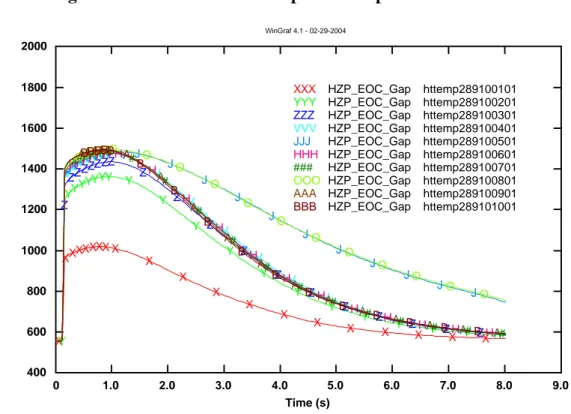

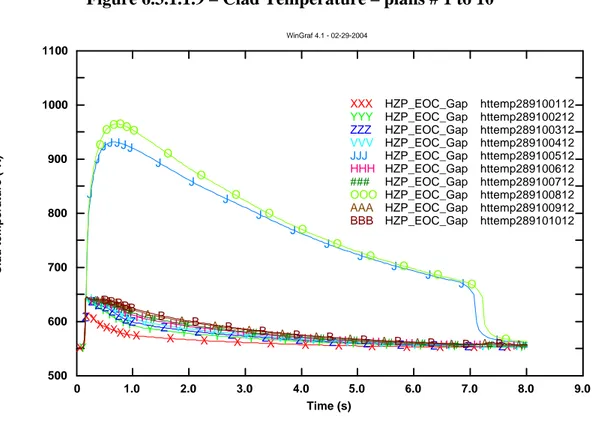

6.3.1.1 Gap closure and fuel restructuring

Preliminary consideration is that this type of sensitivity analysis was executed only on the FA that

experienced that rod ejection. It was found that the gap closure and the fuel restructuring did not

affect the value of the maximum energy deposited (+2.6%). On the other hand, these modifications

affected greatly the temperature transient of the FA. In fact, as can be seen in the figures

6.3.1.1.7-10, the maximum clad surface temperature, experienced a huge increase of the +55%. The fuel

centerline temperature, instead, did not increase so much (+0.6%).

Figure 6.3.1.1.1 – Reactor Power

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) -.2 0 .2 .4 .6 .8 1 1.2 1.4 1.6 x 10 11 Power (W) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Gap rktpow3d0 XXXXXXXX X X X X X X X X X X X XFigure 6.3.1.1.2 – Energy Released –CR ejected FA

0 1 2 3 4 5 6 7 8 9 0 500000 1000000 1500000 2000000 2500000 3000000 3500000 4000000 4500000 5000000 5500000 6000000 6500000 7000000 7500000

3

4

5

6

7

8

9

10

11

12

Energy Release (J)

Time (s)

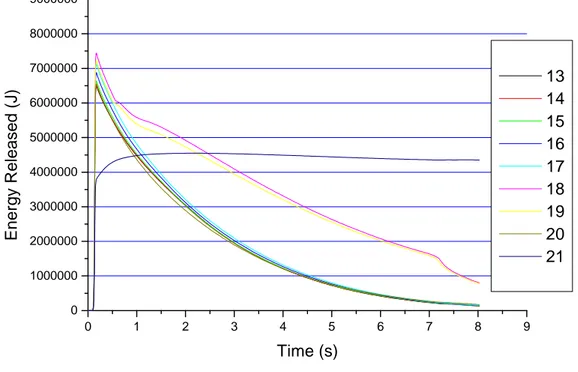

Figure 6.3.1.1.3 – Energy Released –CR ejected FA

0 1 2 3 4 5 6 7 8 9 0 1000000 2000000 3000000 4000000 5000000 6000000 7000000 8000000 900000013

14

15

16

17

18

19

20

21

Energy Released (J)

Time (s)

Figure 6.3.1.1.4 – PRZ pressure

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 Time (s) 1.57 1.57 1.57 1.57 1.58 1.58 1.58 x 10 7 Pressure (Pa) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Gap p26010000 XXXXXXXXX X X X X X X X X X X XFigure 6.3.1.1.5 – UH pressure

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 1.57 1.58 1.59 1.6 1.61 1.62 1.63 1.64 1.65 1.66 x 10 7 Pressure (Pa) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Gap p150080000 XX X X X X X X X X X X X X X X X X X XFigure 6.3.1.1.6 – HL temperature

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 550.0 552.0 554.0 556.0 558.0 560.0 562.0 564.0 566.0 Temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Gap tempf200010000 XXXXXXXX X X X X X X X X X X X XFigure 6.3.1.1.7 – Fuel CL Temperature – plans # 1 to 10

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 400 600 800 1000 1200 1400 1600 1800 2000 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Gap httemp289100101 X XXXXXXX X X X X X X X X X X X XYYY HZP_EOC_Gap httemp289100201

Y YYY YYYY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_Gap httemp289100301 Z ZZZZZ ZZ Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_Gap httemp289100401 VVV VVVV V V V V V V V V V V V V JJJ HZP_EOC_Gap httemp289100501 J JJJ J JJ J J J J J J J J J J J HHH HZP_EOC_Gap httemp289100601 HHHHHH H H H H H H H H H H H H ### HZP_EOC_Gap httemp289100701 ###### # # # # # # # # # # # #

OOO HZP_EOC_Gap httemp289100801

OOOOOO O O O O O O O O O O O

AAA HZP_EOC_Gap httemp289100901

AAAAA A A A A A A A A A A A A BBB HZP_EOC_Gap httemp289101001 BBBBB B B B B B B B B B B B

Figure 6.3.1.1.8 – Fuel CL Temperature – plans # 11 to 20

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 400 600 800 1000 1200 1400 1600 1800 2000 2200 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Gap httemp289101101 X XXXX XXX X X X X X X X X X X X X

YYY HZP_EOC_Gap httemp289101201

Y YYYYYYY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_Gap httemp289101301 Z ZZZZZZZ Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_Gap httemp289101401 VVVVVVV V V V V V V V V V V V V JJJ HZP_EOC_Gap httemp289101501 J JJJ JJJ J J J J J J J J J J J HHH HZP_EOC_Gap httemp289101601 HHHHHH H H H H H H H H H H H H ### HZP_EOC_Gap httemp289101701 ###### # # # # # # # # # # # #

OOO HZP_EOC_Gap httemp289101801

OOOOOO O O O O O O O O O O O

AAA HZP_EOC_Gap httemp289101901

AAAAA A A A A A A A A A A A A BBB HZP_EOC_Gap httemp289102001 BBBBB B B B B B B B B B B B

Figure 6.3.1.1.9 – Clad Temperature – plans # 1 to 10

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 500 600 700 800 900 1000 1100 Clad temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Gap httemp289100112 X XX XXXXX X X X X X X X X X X X XYYY HZP_EOC_Gap httemp289100212

Y YYYY YYY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_Gap httemp289100312 ZZZZZZZZ Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_Gap httemp289100412 VVVVVV V V V V V V V V V V V V V JJJ HZP_EOC_Gap httemp289100512 J J JJ JJJ J J J J J J J J J J J HHH HZP_EOC_Gap httemp289100612 HHHHHH H H H H H H H H H H H H ### HZP_EOC_Gap httemp289100712 ###### # # # # # # # # # # # #

OOO HZP_EOC_Gap httemp289100812

O OOOOO O O O O O O O O O O O

AAA HZP_EOC_Gap httemp289100912

AAAAA A A A A A A A A A A A A BBB HZP_EOC_Gap httemp289101012 BBBBB B B B B B B B B B B B

Figure 6.3.1.1.10 – Clad Temperature – plans # 11 to 20

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 500 600 700 800 900 1000 1100 Clad temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Gap httemp289101112 X X X X XXXX X X X X X X X X X X X X

YYY HZP_EOC_Gap httemp289101212

Y YYYYYYY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_Gap httemp289101312 ZZZZZZZZ Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_Gap httemp289101412 VVVVVVV V V V V V V V V V V V V JJJ HZP_EOC_Gap httemp289101512 J JJJ JJJ J J J J J J J J J J J HHH HZP_EOC_Gap httemp289101612 HHHHHH H H H H H H H H H H H H ### HZP_EOC_Gap httemp289101712 ## # ## # # # # # # # # # # # # #

OOO HZP_EOC_Gap httemp289101812

OO OOO O O O O O O O O O O O O

AAA HZP_EOC_Gap httemp289101912

AAAAA A A A A A A A A A A A A BBB HZP_EOC_Gap httemp289102012 BBBBB B B B B B B B B B B B

Figure 6.3.1.1.11 – FA Channel Void Fraction – plans # 1 to 10

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) -.01 0 .01 .01 .02 .02 .03 .03 .04 .04 Void Fraction WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Gap voidg289010000 XXXXXXXX X X X X X X X X X X X XYYY HZP_EOC_Gap voidg289020000

YYYYYYYY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_Gap voidg289030000 ZZZZZZZZ Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_Gap voidg289040000 VVVVVVV V V V V V V V V V V V V JJJ HZP_EOC_Gap voidg289050000 J JJJ JJJ J J J J J J J J J J J HHH HZP_EOC_Gap voidg289060000 HHHHHH H H H H H H H H H H H H ### HZP_EOC_Gap voidg289070000 ###### # # # # # # # # # # # #

OOO HZP_EOC_Gap voidg289080000

OOOOOO O O O O O O O O O O O

AAA HZP_EOC_Gap voidg289090000

AAAAA A A A A A A A A A A A A

BBB HZP_EOC_Gap voidg289100000

B B

BBB B B B B B B B B B B B

Figure 6.3.1.1.12 – FA Channel Void Fraction – plans # 11 to 20

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) -.10 0 .10 .20 .30 .40 .50 .60 .70 Void Fraction WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Gap voidg289110000 XXXXXXXX X X X X X X X X X X X X

YYY HZP_EOC_Gap voidg289120000

YYYY YY YY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_Gap voidg289130000 ZZZ Z Z Z ZZ Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_Gap voidg289140000 VVV V V V V V V V V V V V V V V V V JJJ HZP_EOC_Gap voidg289150000 J J J JJ J J J J J J J J J J J J J HHH HZP_EOC_Gap voidg289160000 H H H H H H H H H H H H H H H H H H ### HZP_EOC_Gap voidg289170000 # # # # # # # # # # # # # # # # # #

OOO HZP_EOC_Gap voidg289180000

O O O O O O O O O O O O O O O O O

AAA HZP_EOC_Gap voidg289190000

A A AA A A A A A A A A A A A A A BBB HZP_EOC_Gap voidg289200000 B B B B B B B B B B B B B B B B

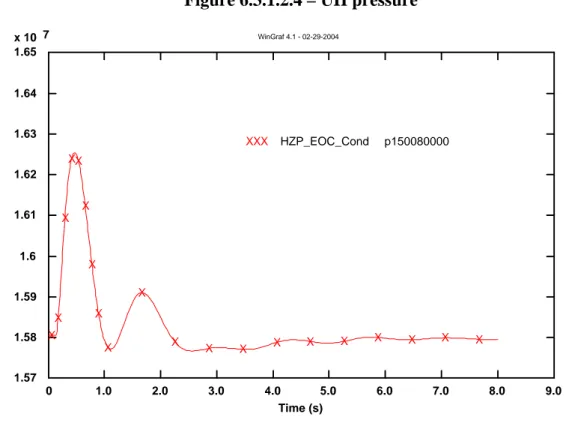

6.3.1.2 Heat conductivity variation

In order to simulate the effect of the decreased pellet thermal conductivity caused by the Plutonium

buildup on the border (‘rim effect’) and by this zone fragmentation, it was changed in the RELAP5

code, the fuel pellet mesh structure. In particular, it was increased the number of mesh point from

12 to 13, so modeling a special zone on the border with a decreased thermal conductivity (-50%).

The results show that this kind of modification cause only an increase in the fuel CL temperature

and a delaying in the cool down of the pellets. No variations were found to affect the clad maximum

temperature. The energy released, instead, shown a small increase (+13.2%); this was explained by

the better adiabatic conditions established by the decreased thermal conductivity in the external

zone of the pellet. On the other hand, this phenomenon, causing the increase of fuel CL

temperature, increased also the Doppler effect, minimizing the energy released increase.

Figure 6.3.1.2.1 – Reactor Power

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) -.2 0 .2 .4 .6 .8 1 1.2 1.4 1.6 x 10 11 Power (W) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Cond rktpow3d0 XXXXXXXX X X X X X X X X X X X X

Figure 6.3.1.2.2 – Energy Released –CR ejected FA

0 1 2 3 4 5 6 7 8 9 0 1000000 2000000 3000000 4000000 5000000 6000000 7000000 8000000 90000003

4

5

6

7

8

9

10

11

12

Energy Released (J)

Time (s)

Figure 6.3.1.2.3 – Energy Released –CR ejected FA

0 1 2 3 4 5 6 7 8 9 0 1000000 2000000 3000000 4000000 5000000 6000000 7000000 8000000 9000000

13

14

15

16

17

18

19

20

21

Energy Released (J)

Time (s)

Figure 6.3.1.2.4 – UH pressure

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 1.57 1.58 1.59 1.6 1.61 1.62 1.63 1.64 1.65 x 10 7 Pressure (Pa) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Cond p150080000 X X X XX X X X X X X X X X X X X X X XFigure 6.3.1.2.5 – HL temperature

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 550.0 552.0 554.0 556.0 558.0 560.0 562.0 564.0 Temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Cond tempf200010000 XXXXXXXX X X X X X X X X X X X XFigure 6.3.1.2.6 – Fuel CL Temperature – plans # 1 to 10

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 250 500 750 1000 1250 1500 1750 2000 2250 2500 2750 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Cond httemp289100101 X XXXXXXX X X X X X X X X X X X XYYY HZP_EOC_Cond httemp289100201

Y YYYYY YY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_Cond httemp289100301 ZZZ ZZZZZ Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_Cond httemp289100401 VVVVV VV V V V V V V V V V V V V JJJ HZP_EOC_Cond httemp289100501 J JJJ J JJ J J J J J J J J J J J HHH HZP_EOC_Cond httemp289100601 HHHHH H H H H H H H H H H H H H ### HZP_EOC_Cond httemp289100701 ###### # # # # # # # # # # # #

OOO HZP_EOC_Cond httemp289100801

OOOOOO O O O O O O O O O O O

AAA HZP_EOC_Cond httemp289100901

AAAAA A A A A A A A A A A A A

Figure 6.3.1.2.7 – Fuel CL Temperature – plans # 11 to 20

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 400 600 800 1000 1200 1400 1600 1800 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Cond httemp289101101 X XXX XXXX X X X X X X X X X X X X

YYY HZP_EOC_Cond httemp289101201

Y YYY YYYY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_Cond httemp289101301 Z ZZZZZZZ Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_Cond httemp289101401 VVV VVVV V V V V V V V V V V V V JJJ HZP_EOC_Cond httemp289101501 JJJJ JJJ J J J J J J J J J J J HHH HZP_EOC_Cond httemp289101601 HHHHHH H H H H H H H H H H H H ### HZP_EOC_Cond httemp289101701 ###### # # # # # # # # # # # #

OOO HZP_EOC_Cond httemp289101801

OOOOOO O O O O O O O O O O O

AAA HZP_EOC_Cond httemp289101901

AAAAA A A A A A A A A A A A A BBB HZP_EOC_Cond httemp289102001 BBBBB B B B B B B B B B B B

Figure 6.3.1.2.8 – Clad Temperature – plans # 1 to 10

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 540.0 550.0 560.0 570.0 580.0 590.0 600.0 610.0 620.0 630.0 640.0 Clad temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Cond httemp289100113 X X XX XX XX X X X X X X X X X X X XYYY HZP_EOC_Cond httemp289100213

Y Y Y Y Y Y YY Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_Cond httemp289100313 Z ZZ Z Z Z ZZ Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_Cond httemp289100413 V VV V V V V V V V V V V V V V V V V JJJ HZP_EOC_Cond httemp289100513 J J J J J J J J J J J J J J J J J J HHH HZP_EOC_Cond httemp289100613 H H H H H H H H H H H H H H H H H H ### HZP_EOC_Cond httemp289100713 ### # # # # # # # # # # # # # # #

OOO HZP_EOC_Cond httemp289100813

OO O O O O O O O O O O O O O O O

AAA HZP_EOC_Cond httemp289100913

AA A A A A A A A A A A A A A A A BBB HZP_EOC_Cond httemp289101013 BB B B B B B B B B B B B B B B

Figure 6.3.1.2.9 – Clad Temperature – plans # 11 to 20

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Time (s) 540 560 580 600 620 640 660 Clad temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_Cond httemp289101113 X X X XXXX X X X X X X X X X X X X X

YYY HZP_EOC_Cond httemp289101213

Y Y Y YYYY Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_Cond httemp289101313 Z Z Z ZZZ Z Z Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_Cond httemp289101413 V V V VVV V V V V V V V V V V V V V JJJ HZP_EOC_Cond httemp289101513 J J JJ JJJ J J J J J J J J J J J HHH HZP_EOC_Cond httemp289101613 H H HHHH H H H H H H H H H H H H ### HZP_EOC_Cond httemp289101713 # # #### # # # # # # # # # # # #

OOO HZP_EOC_Cond httemp289101813

O OOOOO O O O O O O O O O O O

AAA HZP_EOC_Cond httemp289101913

A A AAA A A A A A A A A A A A A BBB HZP_EOC_Cond httemp289102013 B B BBB B B B B B B B B B B B

6.3.2 Plant flow regime variations

6.3.2.1 Natural circulation

This transient investigated the effect of the natural circulation regime on the REA. It was assumed

that:

•

all the 4 MCP were shut down, thus they were stopped at the accident time

•

the RHR system was not in operation

•

the reactor was cooled with a ‘feed and bleed’ mode on the secondary site of the SG

The calculations of the energy released to the fuel shown there was a significant decrease of that

amount in these conditions (70 cal/g, -20%). This was explained by the greater feedback effects that

played the negative moderator temperature coefficient and the Doppler coefficient for the decreased

thermal transfer. Indeed the initial conditions shown the presence of voids in the channels (see Fig.

6.3.2.1.11-12) and their increasing during the transient evolution; furthermore the clad also has to

experience a greater temperature transient (+11% for the maximum value). On the other hand, the

maximum fuel centerline temperature decrease as consequence of the less energy released. The

power of the reactor core is decreased in this case (-40 % for the maximum value) as the global

reactivity insertion (see Fig. 6.3.2.1.2). At least, it has to been known that PARCS code crashed

during the calculation, not allowing to continue transient investigation after the 1.4 seconds time.

Figure 6.3.2.1.1 – Reactor Power

0 .20 .40 .60 .80 1.00 1.20 1.40 1.60 Time (s) -.2 0 .2 .4 .6 .8 1 1.2 x 10 11 Power (W) WinGraf 4.1 - 03-02-2004 XXX HZP_EOC_NC rktpow3d0 X X X X X X X X X X X X X X X X X X X X X

Figure 6.3.2.1.2 – Reactivity trend

-6 -5 -4 -3 -2 -1 0 1 2 -0.2 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 Time (s) Reactivity ($) ReactivityFigure 6.3.1.2.3 – Energy Released –CR ejected FA

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 0 500000 1000000 1500000 2000000 2500000 3000000 3500000 4000000 4500000 5000000 5500000 6000000 6500000

3

4

5

6

7

8

9

10

11

12

Energy released (J)

Time (s)

Figure 6.3.1.2.4 – Energy Released –CR ejected FA

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 0 500000 1000000 1500000 2000000 2500000 3000000 3500000 4000000 4500000 5000000 5500000 6000000 650000013

14

15

16

17

18

19

20

21

Energy Released (J)

Time (s)

Figure 6.3.2.1.5 – PRZ pressure

0 .20 .40 .60 .80 1.00 1.20 1.40 1.60 1.80 Time (s) 1.56 1.56 1.56 1.57 1.57 1.57 1.57 1.58 1.58 1.58 1.58 x 10 7 Pressure (Pa) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_NC p26010000 X X X X X X X X X X X X X X X X X X X X XFigure 6.3.2.1.6 – UH pressure

0 .20 .40 .60 .80 1.00 1.20 1.40 1.60 Time (s) 1.57 1.57 1.58 1.58 1.59 1.59 1.6 1.6 1.61 1.61 x 10 7 Pressure (Pa) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_NC p150080000 X X X X X X X X X X X X X X X X X X X X XFigure 6.3.2.1.6 – HL temperature

0 .20 .40 .60 .80 1.00 1.20 1.40 1.60 Time (s) 564.42 564.44 564.46 564.48 564.50 564.52 564.54 Temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_NC tempf200010000 X X X X X X X X X X X X X X X X X X X X XFigure 6.3.2.1.7 – Fuel CL Temperature – plans # 1 to 10

0 .20 .40 .60 .80 1.00 1.20 1.40 1.60 Time (s) 0 500 1000 1500 2000 2500 3000 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_NC httemp289100101 X X X X X X X X X X X X X X X X X X X X XYYY HZP_EOC_NC httemp289100201

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_NC httemp289100301 Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_NC httemp289100401 V V V V V V V V V V V V V V V V V V V JJJ HZP_EOC_NC httemp289100501 J J J J J J J J J J J J J J J J J J HHH HZP_EOC_NC httemp289100601 H H H H H H H H H H H H H H H H H ### HZP_EOC_NC httemp289100701 # # # # # # # # # # # # # # # # #

OOO HZP_EOC_NC httemp289100801

O O O O O O O O O O O O O O O O

AAA HZP_EOC_NC httemp289100901

A A A A A A A A A A A A A A A

BBB HZP_EOC_NC httemp289101001

B B B B B B B B B B B B B B

Figure 6.3.2.1.8 – Fuel CL Temperature – plans # 11 to 20

0 .20 .40 .60 .80 1.00 1.20 1.40 1.60 Time (s) 400 600 800 1000 1200 1400 1600 Fuel CL temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_NC httemp289101101 X X X X X X X X X X X X X X X X X X X X X

YYY HZP_EOC_NC httemp289101201

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_NC httemp289101301 Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_NC httemp289101401 V V V V V V V V V V V V V V V V V V V JJJ HZP_EOC_NC httemp289101501 J J J J J J J J J J J J J J J J J J HHH HZP_EOC_NC httemp289101601 H H H H H H H H H H H H H H H H H ### HZP_EOC_NC httemp289101701 # # # # # # # # # # # # # # # # #

OOO HZP_EOC_NC httemp289101801

O O O O O

O O O O O O O O O O O

AAA HZP_EOC_NC httemp289101901

A A A A A A A A A A A A A A A

BBB HZP_EOC_NC httemp289102001

Figure 6.3.2.1.9 – Clad Temperature – plans # 1 to 10

0 .20 .40 .60 .80 1.00 1.20 1.40 1.60 Time (s) 500 550 600 650 700 750 800 Clad temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_NC httemp289100112 X X X X X X X X X X X X X X X X X X X X XYYY HZP_EOC_NC httemp289100212

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_NC httemp289100312 Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_NC httemp289100412 V V V V V V V V V V V V V V V V V V V JJJ HZP_EOC_NC httemp289100512 J J J J J J J J J J J J J J J J J J HHH HZP_EOC_NC httemp289100612 H H H H H H H H H H H H H H H H H ### HZP_EOC_NC httemp289100712 # # # # # # # # # # # # # # # # #

OOO HZP_EOC_NC httemp289100812

O O O O O O O O O O O O O O O

O

AAA HZP_EOC_NC httemp289100912

A A A A A A A A A A A A A A A

BBB HZP_EOC_NC httemp289101012

B B B B B B B B B B B B B B

Figure 6.3.2.1.10 – Clad Temperature – plans # 11 to 20

0 .20 .40 .60 .80 1.00 1.20 1.40 1.60 Time (s) 550 575 600 625 650 675 700 725 750 775 Clad temperature (°K) WinGraf 4.1 - 02-29-2004 XXX HZP_EOC_NC httemp289101112 X X X X X X X X X X X X X X X X X X X X X

YYY HZP_EOC_NC httemp289101212

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y ZZZ HZP_EOC_NC httemp289101312 Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z Z VVV HZP_EOC_NC httemp289101412 V V V V V V V V V V V V V V V V V V V JJJ HZP_EOC_NC httemp289101512 J J J J J J J J J J J J J J J J J J HHH HZP_EOC_NC httemp289101612 H H H H H H H H H H H H H H H H H ### HZP_EOC_NC httemp289101712 # # # # # # # # # # # # # # # # #

OOO HZP_EOC_NC httemp289101812

O O O O O O O O O O O O O O O

O

AAA HZP_EOC_NC httemp289101912

A A A A A A A A A A A A A A A BBB HZP_EOC_NC httemp289102012 B B B B B B B B B B B B B B