ContentslistsavailableatScienceDirect

Composites

Part

C:

Open

Access

journalhomepage:www.elsevier.com/locate/jcomc

Review

Transdisciplinary

top-down

review

of

hemp

fibre

composites:

From

an

advanced

product

design

to

crop

variety

selection

Jörg

Müssig

a,∗,

Stefano

Amaducci

b,

Alain

Bourmaud

c,

Johnny

Beaugrand

d,

Darshil

U.

Shah

e a The Biological Materials Group, Biomimetics, Hochschule Bremen - City University of Applied Sciences, Neustadtswall 30, 28199 Bremen, Germany b Department of Sustainable Crop Production, Università Cattolica del Sacro Cuore, Via Emilia Parmense, 84, 29122 Piacenza, Italyc Université Bretagne Sud, UMR CNRS 6027, IRDL, F-56100 Lorient, France d INRAE, UR1268 Biopolymères Interactions Assemblages, 44316 Nantes, France

e Centre for Natural Material Innovation, Department of Architecture, University of Cambridge, Cambridge CB2 1PX, United Kingdom

a r t i c l e

i n f o

Keywords:

Structural biocomposite design Structure-property-processing relations Environmentally friendly crop Wind turbine blade Hemp fibre composites

a b s t r a c t

Giventhevastamountofavailableresearchintheareaofnaturalfibrecomposites,asignificantstepforward inthedevelopmentofnext-generationplantfibre-basedproductswouldbetodeviseaframeworkforrational design.Theauthorsuseatop-downapproach,startingwithanexamplefinalproducttodefinetheproduct specificationsforhigh-performancehempfibre-reinforcedcomposites.Thereafter,allprocessstepsarecritically analysed:fromtextilepreformandreinforcementyarnproduction,tofibreextractionandtheagriculturalprocess chain,tothemicrobiologyoffieldretting,tocultivationandselectionofcropvariety.Theaimoftheanalysisisto determinehowfarthecurrentstateofknowledgeandprocesstechnologiesareinordertousehempfibresin high-performancecomposites.Basedonthiscriticalevaluationofthestate-of-the-art,itcanbestatedthathempwillbe foundinhigh-performancecompositesintheshort-to-mediumterm.Thereis,however,aneedforperformance optimisationespeciallythroughtheselectionofcropvariety,bestpracticesinretting,andeffectivefibreextraction methodstoobtainmoreconsistentfibrequalitiessuitableforreinforcementspinningandcompositepreform manufacturingprocesses.

1. Introduction

Fibre renewable resources are being increasingly explored and utilisedinengineeringpolymersandcompositesduetotheir combina-tionofenvironmentalandtechnicalperformance.Thedevelopmentof publicationsandtheincreaseininternationalconferencesonthe sub-jectofnaturalfibre-reinforcedcompositesshowsthetimelinessofthe topic.Theincreasingimportanceofsustainable-social,ecologicaland economic-developmentofmaterialsandproductsisalsocontributing tothegrowingimportanceof compositesmadeofnaturalfibres.Our reviewis notonlyintended topresentthedevelopments inthisarea inrecentyears. Rather,by analysingtheresearch,wewant toshow waysandidentifyresearchneedsthatmakeitpossibletousebastfibres likehempinhigh-performancecomposites.Thisreviewfollowsthe ap-proachofdevelopingaframeworkforrationaldesign,whichisin con-trasttoarbitrarychoicescommonlymadeinproductdesign.Our objec-tiveistosupportthepotentialuseofhempfibresforhigh-performance compositesbasedonbottom-upandtop-downapproaches.

∗Correspondingauthor.

E-mailaddress:[email protected](J.Müssig).

Here,theauthorswilluseatop-downapproach,startingwiththe finalproducttodefinetheproductspecificationsforhigh-performance hempfibre-reinforcedcomposites.TheworkofPotterishelpfulinthis context,asitattemptstocreateapictureofanidealdesigncyclefor compositematerialsthatdealswithallthecomplexitiesofthisgroup ofmaterials[1].Wewillstartwiththedefinitionofaproduct specifi-cationinwhichwelistallrequirementsoftherotorofawindturbine (seeFig.1).Usingthislistofrequirements,wewillevaluatetheentire processchainfromproducttothebestchoiceofhempvarietytomeet thecompositespecifications.Inthistransdisciplinaryapproach,wewill reviewwhatisknownandwhathasalreadyintegratedappropriately intheproductionchain.Ourresearchwillbeusedtodiscoverwhatis stillunknownandwillhelptoopenupnewfieldsofresearch.Based onthisapproach,wewillgeneratebasicknowledgethatwillhelpmap pathwaystonewpracticalapplications.

WewilldividetheentireprocesschainshowninFig.1 intothe fol-lowingareas:

https://doi.org/10.1016/j.jcomc.2020.100010

Received9June2020;Receivedinrevisedform18July2020;Accepted20July2020

2666-6820/© 2020TheAuthors.PublishedbyElsevierB.V.ThisisanopenaccessarticleundertheCCBY-NC-NDlicense. (http://creativecommons.org/licenses/by-nc-nd/4.0/)

Fig.1. Theentireprocesschainasatop-downapproachfromproducttothebesthempvarietychoiceforreachingthecompositespecificationsforahigh-tech applicationliketherotorbladeofawindturbine.

2. Compositein-serviceproperties

Twenty-fivethousandtonnesofhempfibrewereproducedintheEU in2013, around3500tonnes(14%)ofwhich wentintothe produc-tionof bio-basedcomposites,primarily compression-mouldedfleeces andneedle-felttextilematerialsfortheautomotivesector[2].Speciality pulpandpaper(57%),andinsulation(26%)weremorelikelyend-uses forhempfibre[2].Nonetheless,theuseofshort(hemp)bastfibresin non-structuralcompositeshavebeenstate-of-the-artforseveralyears, ifnotdecades.Forinstance,inthe1990s,>95%ofhempwasdirected tospecialitypaperproduction.AsindustrialhempcultivationinEurope hasincreasedalmostthree-foldfromunder16,000hectaresin2013to over45,000hectaresin2017[3],hempfibreproductionandtheir ap-plicationinbiobasedcompositeshasalsoincreased(atleastinabsolute volume),particularlynotingthatEuropeaccountsforaroundaquarter ofglobalindustrialhempcultivation[3].

Today,there is a significantvoice, atleast in thescientific com-munitythatacknowledgesthattherealchallengesandassociated op-portunitiesformarketpenetrationandcapturelieinthedevelopment

ofalignedhempfibrecompositesforperformance-demanding applica-tions.Twoconceptcars– HenryFord’shempcarofthe1940s[4] and Lotus’slatestEcoElise– demonstratethathempbio-basedcomposites arepotentiallyapplicableforstructuralbodypanels,andnotjust inte-rior trims,forexample.Weparticularlynotethatsuchconcept prod-uctdevelopmentandfull-scalecasestudiesareparamountand much-neededinadvancingfutureapplicationsofhempbio-basedcomposites bytacklingtechnical,economical,socio-culturalchallenges.

2.1. Specificationsforahempfibre-reinforcedcompositerotorbladefora smallwindturbine(<100kW)

Of the various engineering components and structures we come acrossindailylife,therotorbladesofasmallwindturbineare chal-lenging,exemplarstructuralcomponentsduetothevarietyoffailure criteriatheyhavetobedesignedandtestedagainstforcertification[5, 6].Togiveanidea ofsizeandscale,asmallwindturbineisclassed asonewitharotordiameter<16morratedcapacity<100kW. Ro-torbladesarecriticalcomponentsofaturbinefrombothtechnicaland economicperspectives.Atthemercyofthewind,rotorbladesneedto functionwithinspecifiedlimitsduringnormaloperationconditions (de-signwindspeedsof11.9ms− 1 ),aswellassevereconditions(extreme hurricane-likegustwindspeedsof59.5ms− 1 ).Moreover,rotorblades haveatypicaldesignlifeof20yearsandcyclingatover100rpm,and theycanaccumulateinexcessof109 fatiguecycles.

Whilethedesignofstructuralcomponentsfromhemphasbeenrare eveninscientificliterature,anumberofstudieshaveexploredthe poten-tialofflaxcompositesforsmallwindturbinebladesthatrangeinlength from0.6m[7,8]to1.2m[9] to3.5m[10].Shahetal.[10,11], fol-lowingIEC61,400standards[5,6],demonstratedtheefficacyofaflax bladethroughloadanalysis,fatiguelifepredictionandfull-scale struc-turaltesting.Notably,therecentGreen2GreenAustrianresearchproject hasconcludedsimilarcapabilitiesoffullyhemp-basedgreencomposites – hempwoventextilesreinforcinganepoxidisedhempoilresin– fora developmentalwindbladeintermsofmeetingstrengthrequirements

Fig.2.(A)Loadsonarotorblade.Theloadsonsmallrotorbladescanbecategorisedasaerodynamicloads(inblue,suchasdrag,liftandshear),inertialloads (inorange,suchasgravitational,gyroscopic,andcentrifugal)andoperationalloads(ingreen,resultingfromturbinecontrolsuchasyawing,pitching).Ofthese, aerodynamicloadsaremostimportant.Theseloadscanbedividedintoflap-wise(bendingthebladedownwind),edge-wise(bendingthebladeintherotational direction)andaxial(alongthebladelength)directions.Ofthese,flap-wiseloadsaremostsignificant.Theseloadscanbefurtherexpressedastension/compression fatigueloads(seeb).(B)Designofarotorblade.Typicalsmallrotorbladeshaveashell-sparcompositestructure,withacombinationofalignedlaminatesto achievethedesiredstructuralperformance.Themulti-axialfibrereinforcementintheshellandshearwebsprovideresistanceagainsttorsion-relatedshearloads, theunidirectionalfibrereinforcedsparcapsprovideaxial(tensile)andbending(flexural)stiffnessandstrength,andthecoreintheshearwebsprovidesresistance againstbuckling.(Forinterpretationofthereferencestocolourinthisfigurelegend,thereaderisreferredtothewebversionofthisarticle.)

[12]. Forreference, therelevantproperties ofaligned flaxandglass compositesinthedesignofaturbinebladearepresentedinTable2.

To tackle the various loads a rotor blade experiences (Fig. 2a), bladesaretypicallydesignedtohave acomplex compositestructure (Fig. 2b). They comprise of a shell, a centralspar/shear webs,and possiblydetails for theleading andtrailing edge. Acombination of coreandlaminate materialsareemployed, with thecomposite lam-inates typicallybeing reinforcedby a triaxial[0,±45]fabricfor the shell(withnonwovenmaterialforthickness/bulking),biaxial(±45) fab-ricfortheshearwebsandunidirectional(0)fabricforthesparcaps. Non-crimpedfabrics(e.g.stitchedmultiaxials)arepreferredover wo-venfabricstoavoidlossinpropertyfromfibremisorientation,which

can be substantialfor plantfibrereinforcements, andbetter impreg-nation[13,14].Glass fibrereinforcementsaremost commonlyused forsmallrotorblades,withcorematerialsbeinglow-densitypolymer foamsorwood(e.g.balsa)[15].Asresinsystems,whileliquidthermoset resins arecommonlyusedfor processingviahand lay-upor vacuum infusion,thermosetprepregsforautoclavemouldingandeven thermo-plasticsforliquidinfusionorautoclavemouldingareincreasinglybeing adopted.

Hemprotorbladematerialswouldneedtopossessadiverse prop-ertyprofile,including,stiffness,yieldandultimate strengths,and fa-tigueendurance.Table1outlinesthispropertyprofile,withsupporting discussionhenceforth.

Table1

Ahempfibrecompositewindturbinebladeisrequiredtomeetanumberofselectioncriteria.Materialpropertiesofinterestandroutestoachievetheseare outlined.

Property of interest Corresponding failure criteria (from IEC 61400[5, 6]) Pointers for hemp bio-based composite material and blade design Stiffness The analysis shows possibility of blade tower collision

a rotor blade hitting the tower due to substantial tip deflection from wind loads

High stiffness is required.

Stiffness can be optimised by increasing fibre content thanks to process evolution, like using more aligned (unidirectional vs multi-axial) reinforcement preforms or prepregs with low-twist yarns/rovings and non-crimp fabric, produced from minimally-processed (low defect) fibres. Other promising process techniques include automated fibre placement (AFP).

Full-scale testing shows functional failure b– stiffness degradation of the blade – below worst case loads significant (of the order of 5–10%) and irreversible reduction in stiffness upon loading

Evolution of stiffness as a function of applied load (and

time/damage accumulation) is relevant here . Hemp biobased composites show (partly-irreversible) non-linear stress-strain response. As the initial stiffness (typically measured at below 0.15% applied strain) may not be an appropriate indicator of the practical stiffness of the composites, use the fairly stabilised residual stiffness (above 0.4% applied strain) as a suitable design value. Use of twisted yarns may aggravate non-linear response.

Strength The analysis shows that stresses experienced by the blade are above material failure stresses along the blade cross-section

High yield and ultimate strengths are required.

Both can be optimised by increasing fibre content, using more aligned (unidirectional vs multi-axial)

reinforcement preforms with low-twist yarns/rovings and non-crimp fabric, produced from minimally-processed (low defect) fibres. Process techniques, such as automated fibre placement (AFP). Reducing porosity is also recommended.

Plant fibre composites naturally have a low elastic limit (of around 0.15% applied strain), and therefore high stiffness is desired to ensure high yield strength. Observation of damage accumulation behaviour of plant fibre composites and their structure is of interest. Full-scale testing shows superficial failure abelow normal

operation loads (at design wind speeds of 11.9 ms − 1 ) Full-scale testing shows functional failure b– substantial permanent deformation upon unloading – or catastrophic

failurecbelow worst case load (typically at extreme wind speeds of 59.5 ms −1 )

Fatigue endurance The analysis shows inability to survive design fatigue

cycles at the normal operation loads (at design wind speeds of 11.9 ms − 1 )

Fatigue strength at 10 6 or 10 9 cycles is relevant here.

Fatigue strength is known to be proportional to static ultimate tensile strength.

Fatigue life design using a fully-constructed empirical constant life diagram is important.

Desirable objectives

low density – lighter blades are easier to transport, have reduced centrifugal loads, and reduce loads on the tower structure (and consequently the amount of material used in its design).

cost-effectiveness – through optimal material and manufacturing costs

environmental durability – vis. effects from UV-light, moisture, lightning – to ensure 20–30 year design life

low embodied carbon materials and safe end-of-life disposal – to minimise ‘waste’, and have opportunities to re-use, recycle, or recover (including energy through incineration), and to avoid land-filling of material/product

aSuperficialfailurehasnoimmediatestructuralconsequences.Thisincludestheformationofcracks,fibrebucklingordelaminationevenifthereisnostrength

degradation.

b Functionalfailureiswhenthereisasubstantiallossinfunctionalityofthebladethroughsubstantialpermanentdeformationorstiffnessreduction. cCatastrophicfailureiswhenthereiscompletedisintegration,collapseorfailureoftheblade.

Therequirementofhighstiffnesscanbecateredforbyoptimising compositeparameters, suchasfibrecontent,textilearchitecture,and fibreandmatrixproperties[16].Thefibreproperties,themselvesare influencedbybiochemicalandstructuralproperties,aswellasfibre pro-cessingsteps(includingrettingandextraction).

Hempfibres andtheircomposites[17,18,19]– andplant fibres andtheircompositesingeneral[20,21]– exhibitacharacteristic non-linearstress-strainresponse.Whiletraditionalfibre-reinforced compos-iteshavealinearstress-strainresponseshowingconstantstiffnessfor over0.5%appliedstrain,thestiffness(measuredthroughsecantor tan-gentmodulus)ofhempfibrecompositescandropbyover30%,even upto50%,inthestrainrangeof0–0.4%,duetoalowelasticlimitof

ca.0.15%[14,20].While,moststudiescalculateandreportinitial stiff-nessinthestrainrangeof0–0.1%(below theelasticlimit)forhemp fibrecomposites,fordesignpurposes,itmaybe moreappropriateto usethefairlystabilisedresidualstiffnessabove0.4%appliedstrainasa practicaldesignvalue.Consequently,designingarotorbladewithhemp composites– and plantfibrecomposites ingeneral-ismore

compli-cated.Thisisparticularlybecause,asperIEC61,400–23[5],ablade functionalfailureisjudgedtohaveoccurredwhenthereis a signifi-cant– oftheorderof5–10%– and/orirreversiblereductioninblade stiffness.

Furthermore,Shahetal.haveshownthatthestiffnessprofilealong thebladeisdifferentforasimilarlyconstructedflaxandE-glassblade, withthelatterbeingdoubleovermuchofthebladelength[10].The stiffness profileandconsequently,thedeflection profileoftheblade duringwindloadingwillinadvertentlyinfluencethepower characteris-ticsoftheturbine.Thiswouldbeimportanttocharacteriseanddesign forahempbio-basedcompositeblade.

Likestiffness,theultimatestrengthofhempfibrecompositescanalso beenhancedthroughoptimisationofcompositeparameters[16].A no-tableadvantageofhempfibrecomposites,incomparisontoafibreglass blade,istheopportunitytosubstantiallyreducemassandthereforethe magnitudeofcentrifugal/axialloads,providedtheneedforincreased laminate thickness(andtherefore materialmass),toachieve the de-siredstiffness andstrength,islimited.Mostloadsona bladecan be

Table2

Tensile,compressiveandfatiguepropertiesofunidirectional[0]andbiaxial[±45]flax/polyesterandE-glass/polyestercomposites.Materialperformanceindices areshaded.Datafrom[23].

Unidirectional composites Biaxial composites

Property Flax E-glass Flax/E-glass Flax E-glass Flax/E-glass

Tensile Fibre volume fraction % 30.9 42.8 – 29.2 28.0 –

Composite density gcm −3 1.31 1.79 0.732 1.30 1.61 0.807

Composite stiffness GPa 23.4 36.9 0.634 5.70 8.77 0.650

Composite specific stiffness GPa/gcm − 3 17.9 20.6 0.869 4.38 5.45 0.804

Effective fibre stiffness a GPa 67.6 81.6 0.828 – – –

Composite strength MPa 277 826 0.335 51.4 139 0.370

Composite specific strength MPa/gcm −3 213 461 0.462 39.5 86.3 0.458

Effective fibre strength † MPa 883 1920 0.460 – – –

Composite failure strain % 1.70 1.90 0.895 3.76 4.12 0.913

Compressive Fibre volume fraction % 32.5 30.0 – N/A b N/A b N/A b

Density gcm − 3 1.30 1.64 0.793 N/A b N/A b N/A b

Composite stiffness GPa 11.3 21.0 0.538 N/A b N/A b N/A b

Composite specific stiffness

GPa 1/3 /gcm −3

1.73 1.68 1.03 N/A b N/A b N/A b

Composite strength MPa 101 313 0.323 N/A b N/A b N/A b

Composite specific strength

MPa 1/2 /gcm − 3

7.73 10.8 0.717 N/A b N/A b N/A b

Composite failure strain % 3.44 3.70 0.930 N/A b N/A b N/A b

Fatigue ( R = 0.1)

Fibre volume fraction % 26.9 30.0 – 29.2 28.0 –

Density gcm −3 1.29 1.64 0.787 1.30 1.61 0.807

Single cycle strength MPa 236 567 0.416 51.4 139 0.370

Fatigue strength at 10 6 cycles MPa 115 204 0.564 22.1 57.3 0.386

aTheeffectivefibrepropertiesare‘back-calculated’usingtheruleofmixtures. b N/A=notmeasured.

expressedastensileorcompressiveloadsalongthebladelength.Itis evidentfromliteraturethatthereisagapincharacterisationand un-derstandingofcompressivebehaviourofhemp(andotherplants)fibre composites,whichcanbealimitingdesigncase,giventhelow compres-sivestrengthreportedforplantfibrecomposites[22,23].Yieldstrength ofthebladealsoneedstobeoptimisedasafunctionalfailureisdeemed ifthereissubstantialpermanentdeformation(e.g.tipdeflection)upon unloading.Asitisknownthatthecharacteristicyieldpointofplantfibre compositesisaround0.15%appliedstrain,tomaximiseyieldstrength, initialstiffnessneedstobemaximised[14,20].

Itisobservedthatfatiguestrengthisproportionaltostaticultimate tensilestrength,astherateofstrengthlossperdecadeofcyclesisfairly constant– thisistrueforarangeofplantfibretypes,fibrecontents,and textilearchitectures[24,25, 26].However,designingagainstfatigue requiresextensivematerialcharacterisationintermsofobtaining stress-lifecurvesforarangeofstressratiostoconstructaconstant-lifediagram. Forhempcomposites,onlylimiteddataexistin literatureonfatigue behaviour[24,25,26].

Inlightoftheabovediscussion,threekeyfutureresearchdirections areenvisagedattheproductscale.

Firstly,full-scaleandmulti-scalestudiesonhempfibrecomposites andtheirproductsareneeded.Thereareonlylimitedfull-scale compar-ativecasestudiesshowingthepotentialofplantfibrecomposites.While itisinterestingandexpectedthatahempcompositeturbineblade,likea hempfibreanditscomposite,haveanon-linearstress–strainbehaviour, itisinterestingandunexpectedthatahemporflaxcompositebladecan meetstrengthrequirements,butunderperformwithregardstostiffness incomparisontoafibreglassblade[10].Morefull-scaleandmulti-scale studies,acrosslabs,willenablebetterunderstandingofthebehaviour andperformanceofhempfibrecomposites,tofacilitatebetterdesignof products.

Secondly, materials development of hemp bio-based composite needstobemorecombinedwithproductdesign.Inengineeringdesign, materialselectionanddesignembodimentgohand-in-hand.Howcan webetterdesignwithhempfibrecomposites?Forexample,byaltering turbinedesignandhavinghigher tipclearance(toavoidtower colli-sion),wecandesignaroundthelowerstiffnessofhempfibrecomposites. Wecanalsohaveagradedandsteppedspar(e.g.varyingthicknessalong

thebladelength)toproduceabladestiffnessanddeflectionprofilethat wouldyieldbetterturbinepowercharacteristics.Similarly,towardsthe developmentofhigh-performancebio-basedcomposites,exploring av-enuessuchashybridisationstrategies(e.g.withcarbonorbasaltfibres [27],for stiffnessorfireperformance),routestoproducecost-viable alignedhempfibrereinforcements(non-crimpedvswoven,rovingsvs twistedyarns)andgeneratingend-of-lifere/down-cyclingoptions(e.g. usingbladematerialsfornacellecases)isofinterest.

Thirdly,extensivematerialscharacterisationofhempbio-based com-posites is needed.There is limiteddata onhempbio-based compos-itepropertiesnecessaryforthedetaileddesignofproducts. Compres-sive,fatigueandcreepbehaviourofhempfibrecompositesneed bet-terevaluation[22, 13, 24, 25, 26].Besides, development of numer-ical/computational analysisof bio-basedcompositecomponents(e.g. withfiniteelementmethods)fordesignpurposesisanecessarystep for-ward,particularlynotingthemulti-scalenuancesofhempbastfibres. Forinstance,thenon-circular,non-uniformcross-sectionofthecoarse hempfibres[28],andtheirprevalenceasbundlesasopposedtosingle fibres,standsincontrasttouniformsyntheticfibres.

3. Compositemechanicalproperties

InAsia,NorthAmerica andEurope,thehempindustryprimarily producesshort fibrebundles in adisordered line, incontrast to the streamlinedflaxindustryproducingwet-spunyarnsin alongitudinal line.InEurope,hempfibrebundlesaremainlyusedinthepaper indus-try,forregularorspecializedproductssuchasbillpapermoney,thanks toanefficientindustrialsector.However,thisplant,whosefibresare structure-supportingtissues,canalsoprovidelongfibrebundleswitha highpotentialforthetextileandcompositesindustry.Inthissection, wewillfirstpresenttheparticularitiesofthisfibreintermsofgrowth, morphologyandmechanicalperformance.Thelinkbetweenfibre ul-trastructureandmechanicalpropertieswillalsobediscussed.Second, wewillreviewthestate-of-the-artperformanceoftwomains subfami-liesofhemp-reinforcedcomposites.Wewillexploreunidirectional(UD) compositesforhigh-performanceapplications,butstartwith injection-mouldedcompositesasmid-orlow-performancecomposites,duetothe

Table3

Mainpropertiesofhempfibres.Mechanicalproperties,diameterandlengtharegivenforsinglehempsfibres.Densityisgivenforcellwallandnotapparentfibre.

Biochemical Composition in% of dry matter a

Cellulose Hemicellulose Lignin Pectin Fat and Wax References

55–90 (70) 12 (16) 2–5 (6) 3 (2) 1.7 (0.7) [ 29 , 37 , 192 , 193 , 47 , 194 , 113 , 195 ]

Structural properties a

Length in mm Diameter in μm MFA in ° Density in g/cm 3 Cristallinity index in% References

5–55 10.9–42.0 2–11 1.4–1.6 55 [ 29 , 47 , 33 , 31 , 196 , 138 , 197 , 198 , 199 , 200 , 201 , 202 , 203 ]

Mechanical properties (single fibre) ab

Young’s Modulus in GPa Strength at break in MPa Strain at break in% References

14.4–90 (65) 285–1110 (800) 0.8–3.3 (3)) [ 47 , 138 , 200 , 196 , 204 ] [205] [206]

Mechanical properties (fibre bundle)

Young’s Modulus in GPa Strength at break in MPa Strain at break in% References

17.2–40 315–1011 2.1–6.5 [207] [208] [209] [142] ]

Behaviour towards moisture

Absorption regain in% at 65% relative humidity. 20 °C Water retention in% References

6–12 50–55 [ 210 , 211 , 212 , 205 , 213 , 214 , 215 , 216 , 217 , 218 ]

aMostfrequentpublishedinbracketsaccordingto[33].

bToillustratethepossibledifferencesbetweenthestrengthofasinglefibreandasinglefibrebundle,itisworthreferringtotheworkofBosetal.[102].The

authorsdescribeforflaxthatforaclampinglengthbetween100and25mmthestrengthofasingleflaxfibrebundleisabout500MPa.Atclampinglengthssmaller than25mm,thestrengthincreasedandreachedavalueofabout850MPa(clampinglength3mm).Singlefibrespreparedfromthefibrebundlesachievedstrengths of1522MPato1834MPa,dependingonthepre-treatmentcondition.

limitedliteratureontheformer(hempUDcomposites).Finally,wewill identifythebarriersthatneedtobebrokendowntooptimisethe per-formanceofhempfibresandtheircomposites,especiallyinlinkwith retting,separationoffibrebundlesandqualityoffibreextraction.

3.1. Hempfibreproperties

3.1.1. Growthandstructuralpropertiesofhempfibres

Amongfibreplantcrops,hempisoneofthosewhosefibresimpart bendingstiffnesstotheplant.Primaryhempfibresdevelopinan intru-siveway,whichgivesthemasignificantlength.Afterastageofphloem celldivisionattheapexoftheplant[29],coordinatedgrowthbegins, duringwhichthecelldevelopsatthesamerateasthesurrounding tis-suestoreachafewhundredmicrons[30].Thenbeginstheintrusive growthphase,whichlastsonlyafewdaysbutduringwhichthefibres lengthenbyseveralmmperday[31];thankstotheirpointedendsand themultiplicationofthenuclei,theycanreachextraordinarylengths, uptoseveraltensofmm.Inthecaseofhemp,theaveragelengthofthe primaryfibresisaround15mm[32],butthereisscatteringenerally reportedvalues[33],fromafewmm tomorethan50mm [34] (see Table3).Whenintrusivegrowthiscomplete,thefillingofthefibres’ cellwallswithcelluloseandencrustingpolymersbeginsandcontinues throughthegrowthlifeoftheplant,whichgivesthefibrestheirhigh mechanicalproperties,particularlystiffness.Inhemp,thereis alsoa networkofsecondary fibres thatcanform inthevascular cambium, depending onboth theharvesttimeandtheplantsection (basal in-ternode)[35].Thesesecondaryfibres developintrusivelyabout600– 700mmfromtheapexoftheplant[31].Thesefibresgrowinalready formedtissues,andforthisreason,theydonotreachthelengthsofthe primaryfibresandrarelyexceed2mminlength[36,37].These sec-ondaryfibreshavesmallerdiametersthantheprimaryfibres[34,38]. However,afterextractionofthesecondaryfibres,itmaybechallenging todistinguishthemfromprimaryfibresbecauseabundleofsecondary fibrescanhavemorphologicalcharacteristicsverysimilartothoseofa bundleofprimaryfibres[39].Dependingonseveralfactors,notablythe cultivar,itisknownthatthefibreyieldmayalsovaryconsiderably[40]. Intermsofbiochemicalcomposition,hempfibres,likeflaxfibres,canbe classifiedintothefamilyofgelatinouscellwalls[41],withahigh con-tentofcelluloseandnon-xylanhemicellulose[42](seeTable3).Within thecellwalls,thecellulosemicrofibrils areembeddedinamatrixof non-cellulosicpolymersandorientedwiththeaxisofthefibreatan an-gleofabout11°[43],thoughsomeauthorsreportsmallerangles;see Table3. Hempfibres havea moderatelignincontent,notexceeding 5%[37].Thehydricexpansionofthehempbundlesunderhygro-and

Fig.3. Literaturereviewofsingleplantfibrestensileperformances[46]..

hygro-thermalconditionsisnotable(about0.9)[44].Indeed,therecan bewidevariationincelldimensionsduetoswellingmechanismswhich inducenotableanisotropicdeformationofthehempbundlesbetween ‘dry’and‘wet’states.Recentinvestigationsofthenanomechanical prop-ertiesofhempbastfibresconfirmedthemulti-physicalimplicationsof themoisturelevelwithinthecellwallmatrixpolymers,reportingthat indentationmodulusdecreasedwithincreasingmoisturecontent[45].

3.1.2. Mechanicalperformanceofhempfibres

Duetotheirshort length,themechanical characterisationof sec-ondaryhempfibresisdifficult.However,acomparativestudyby Bour-maudetal.showedthattheindentationmoduliofthecellwallsof sec-ondaryfibreswasclosetothoseoftheprimaryfibres.Thisisreassuring fromthepointofviewofreinforcementdevelopmentforthecomposites industryastheseparationofprimaryandsecondaryfibresispractically impossibleduringtheextractionprocess[38].Inthissection,wewill focusmainlyonthemechanicalperformanceofprimaryhempfibres.

Fig.3showsthemechanicalpropertiesofdifferentplantfibresfrom theliterature[46]. Allthese valueswereobtainedbytensiletestson singlefibres.Table3givesanoverviewofimportantpropertiesofhemp fibres;mechanicalpropertiesfromliteraturearegivenforbothsingle fibresorfibrebundles.Whenabundleisconsidered,thereadermust keepinmindthatthegaugelengthandthereforetheloadedvolume

isacrucialparameterthatcanmakecomparisonsbetweenpublished worksdifficult.

There is amarked hierarchyin fibreperformance between plant species,withhempfibresgenerallyperforminglesswellthanflaxor ramie,bothintermsofmodulusandstrengthatbreak.Indeed, consid-eringtheirmicrofibrillarangle,theirbiochemicalcompositionandtheir crystallinityrate[47],theplantcellwallsofhempdisplay characteris-ticsverysimilartothoseofflaxandthedifferencesintermsof mechan-icalperformancecannotbeexplainedbytheseendogenousparameters alone.Asmentionedabove,thepresenceofsecondaryfibrebundlesmay beresponsiblefortheloweraverageproperties.However,oneofthekey reasonsisrelatedtothesizeofthelumens[48,49].Comparative stud-ieshavehighlightedthatsizeofthelumenismorepronouncedinhemp [47]andwhich,assumingequalwallstiffness,leadstoadecreaseinthe apparentpropertiesofthefibres.Thishypothesisisfurthersupported bylowmechanicalpropertiesofkenaffibreswhichexhibitevenlarger lumensize[50].Inthe1950s,Haywardreportedthatatfibrematurity, thelumensoccupiedasmuchas30%ofahempfibrecross-sectionarea [48],whichisinstarkcontrasttorecentreportsstatingthevaluetobe afewpercenttoupto10%;perhaps,aconsequenceofagro-breeding studiesandcultivardevelopmentandselectionoverthedecades[49]. Theextractionmethods,whichwewilldiscussinoneofthefollowing sections,mayalsoberesponsibleforthisdifference.Thewidespreaduse ofhammermillsisparticularlydetrimentaltoplantcellwalls[51]and canleadtothecreationofdefects,leadingtoreducedmechanical prop-ertiesintheextractedhempfibre[52,47].

Themiddlelamellabindsadjacentfibrestogetherinafibrebundle. Melellietal.employedpeak-forcequantitativenanomechanical prop-ertymapping(PF-QNM)giveanindicationastomeasurethe indenta-tionmodulusofthemiddlelamellaandexaminewhyhempfibre bun-dlesweremoredifficulttoindividualisethanflaxfibrebundles[53]. Theyshowthatthemeanindentationmodulusofthemiddlelamellae offield-rettedhempisintherangeof16GPa,whereasinflaxbundles avalueofonly10GPawasfound.Thus,inlinewiththehigherlignin contentandcohesiveperformanceofitsmiddlelamellae,theprocessing ofhempfibresismorechallenging[54];thiswillbediscussedindetail inlatersections.

3.2. Hempfibrecomposites

Theperformancespecifications of a reinforcementaredependent on the application of the composite produced. Injection moulded short-fibre reinforced parts are generally described as low- or mid-performancecomposites.Compositeperformanceishighlydependent ontheorientationofthereinforcements,andithasbeenshownthatthis parameterisofmajorimportanceinrelationtotheintrinsicproperties ofplantcellwalls[55].Forsuchinjectionmouldedparts,intendedfor high-volumemarkets,priceisalsoanimportantfactor.Inthiscontext, hempfibresareofgreatinterest.Inaddition,accordingtoMelellietal., hempfibrebundlesaremorelignified thanflaxinmost commercial batches[53].Duetotheincreasedstiffnessofthehempfibrebundles, theyorientthemselvesintheflowdirectionduringplasticprocessing andfacilitatehigheranisotropyofpropertiesinthecomponent.Fig.4.a showsthestiffnessvaluesforpartsinjectedwitharangeofplantfibres andwithasimilarpolypropylenematrix;allsampleshavethesamefibre fraction(30%-mass)[46].Recently,acomparisonofmid-performance hemp-basedcompositeswaspublished,illustratinghowhemphasbeen researchedforsuchapplicationsinrecentyears[56].Hempfibre prop-ertiesalsoallowtheiruse inthefieldofthermo-compressed nonwo-vens(likefleecesorneedlefelts)widelyusedintheautomotivesector [57]. Alone,orincombinationwithflaxorkenaf,thefibres guaran-teealowprice andsufficientmechanicalperformanceforthese non-structuralinteriorautomotiveparts.Inaddition,theheterogeneityof theirmorphologies,particularlyintermsofdiameter,isanadvantage fortheacousticperformanceoftheseparts[58].

Forstructuralapplications,compositeswithcontinuousfibresor sta-plefibresintheformofyarnsarepreferred.Thesecompositesare gen-erallyassimilatedashigh-performancecomposites.Whilehempcanbe convertedintoreinforcementsforsuchapplications,aswewilldiscussin latersections,theindustrialsectorscurrentlyinplacedonotprovide ac-cesstothesameconsistentqualityofhempfibresasthoseprovided,for example,bytheflaxindustry.Fig.4.bcomparesthemaximumstrength ofepoxymatrixunidirectionalcompositesreinforcedwithhempfibres with similarmaterials madefromother plantfibres [46]. For unidi-rectionalcomposites,thetensilemodulusisdirectlycorrelatedwith fi-brevolumefraction[21].Inadditiontofibrecontent,thestrengthis stronglyinfluencedbytheaspectratiooffibresorfibrebundles,andby thequalityoftheinterfacebetweenthefibresandthematrix[59,60, 61],aswellasbythedegreeofindividualisationofthebundles[62]. Inthecaseofhemp,theintrinsicpropertiesofthefibrepenalisethe strengthatbreak,becausetheyareshorterandpossessasmalleraspect ratio,comparedtoflax,forexample[63].

Moreover,thequalityofrettingandfibreextractionisalsoamajor parameter.Theseprocesseshaveamajorimpactonthe individualisa-tion[64]andsurfacequalityofthefibrebundles[65],anditis impor-tanttocontrolthemtoguaranteelongfibrebundleswithoutcortical, woodycoreormiddlelamellaeresidues.Thesenon-structuralelements penalisetheinterfacewiththeresin[66],significantlyreducing inter-facialstrengthandpromotingthepresenceoffibrebundles,whichare preferredfracturezoneswithinacomposite.Hempexhibitsmore ligni-fiedbundlesthanflax,sotheirindividualisationismoredifficult,and onlyanear-perfectcontrolof rettingcanpromoteoptimalfibre divi-sion.Unfortunately,thisisstillpoorlycontrolledbyhempfibre produc-ers[67].Furthermore,asmechanicalprocessingmayhaveanegative impacton thefibrequality[68, 65,54],thisshould becarefully de-cidedinordertoensurethatthefibreshavethemechanicalproperties, morphologyandsurfacecharacteristicsrequiredfortheproductionof high-performancecomposites.Forhot-meltedquasi-isotropicshortfibre thermoplasticcomposites,typicallymadebyextrusionandinjection,the mechanicalextractionofthefibremustbeoptimisedforthesame rea-sonsasexpressedabove.Eventhoughthesecompositesarededicated tonon-structuralapplications,thehigherindividualisationratecanbe achallenge.Theaspectratioofthereinforcingelementsisalsoknown tobe aninfluencingfactorimpactingcomposites properties,likethe strengthatbreakortheYoung’smodulus[69].Thetensileproperties increasewithaspectratiouptoamaximumvalue,anddecrease ther-after,leadingtoawell-knownbell-shapedcurve[70,71,72].

4. Textilepreforms&low-twistreinforcementsforcomposites Reinforcementformhasaproperty-governingeffectontheresulting composites(seeFig.5[16].Pelletsusedforinjectionmouldingproduce hempfibrecompositeswithveryshortfibres/fibrebundles(sub-mm) andnominallyrandomorientationin3D(withsomelocalorientations duetosheareffectsattheboundariesandedges).Thelow reinforce-mentefficiencyfactorsrelatingtolengthandorientation[73,74,16] resultinlowmechanicalproperties,comparabletothatofthe unrein-forcedpolymer,whichissuitablefornon-structural,aesthetic applica-tions.Semi-finishedtextileproductslikefleecesandneedle-feltsas re-inforcementshavefibrebundlesofmoderatelength,butnominally ran-dom2Dorientation,leadingtocompositeswithgoodproperties suit-able for semi-structural(self-mass supporting) applications only.For structuralapplications, longfibrebundles, alignedreinforcements, in theformofwoven,non-crimped,stitchedorunidirectionalfabrics,are moreappropriate,ashighlengthefficiencyfactors,andoptimised orien-tationefficiencyfactorsareobtained.However,theproductionofsuch alignedtextilesrequiresspecificprocessingofhempintointermediate productssuchasyarnsandrovings.Theuseofalignedcardedslivers asquasi-UDlayersisalsopossible,whichcanadditionallyhavealower environmentalimpactastheenergy-intensivespinningprocessis

omit-Fig.4. Comparisonoftensilemodulusofinjectionmoulded(30mass%)fibre-reinforcedPPcomposites(A)andstrengthatbreakofepoxy-hempUDcomposites(B) withliteraturedata[46].

Fig.5. (A)Thelengthandorientationofthereinforcement,inthevarioustextilearchitectures,leadtoarangeofcompositeproperty-governingreinforcement efficiencyfactors.(B)Consequently,compositemechanicalpropertiesarestronglyinfluencedbythetextilearchitectureandreinforcementform.Unidirectionals (UDs)havelongandalignedfibresandconsequentlyhighestefficiencyfactorsandmechanicalproperties(whenloadedinthefibredirection).Multiaxials,suchas woventextilesandnon-crimped/stitchedfabrics,havelongfibresbutorientedinspecificmultipledirections,andthereforeintermediateproperties.Nonwovensand injectionmouldingcompoundshave(very)shortfibresthatarerandomlyoriented(in2Dor3D)andconsequentlylowestmechanicalproperties.Dataandfigure inspiredfrom[16].

ted.Dissanayakeetal.reportedthatbyusingacardedsliver,energy consumptioncanbereducedby28%comparedtoaspunyarn[75].

Thetraditionaltextileusesofhempfibrehavebeenfortwine,rope, nets,webbing,sacking,rugs,tarpaulins,heavyindustrialcanvas,and fabricsforclothing[76].ClarkeandMerlintracedthewidespread intro-ductionofhempfibreusefortextilesinAsia,Egypt,theMediterranean regionandnorthernEurope.Theyreportthatthearchaeological,aswell ashistoricalrecords,arerichinevidencesupportingtheancient impor-tanceofhempfibreasatextileresourcetohumans[76].

Yarnsarethemostprevalentintermediateproduct,andcanbe pro-cessedintodifferenttextileproducts.Fig.6givesanoverviewofyarn(or thread)basedtextilestructures,basedonthetextileclassificationfrom Schnegelsberg[77,78].Productexamplesforhemptextilearegivenfor water-retted,wet-spunhemp.

ThebraidedandwoventextileproductsshowninFig.6 arebased onwet-spunyarns,whichareverycompact.Theyarnsaregenerally highly-twisted,andforthegivenfabric(bottom-rightphotoinFig.6) theweftthreadiscomposedofseveraltwistedthreads.Thepoor im-pregnabilityof suchtwisted spunyarns,andresultingintra-yarn im-pregnationporosityandreductionincompositemechanicalproperties, iswell-documented[14,23,79].

Furthermore,itisexpectedandobservedthatthefibre misorienta-tioninherentinatwistedyarnhassubstantiallydetrimentaleffectson themechanicalpropertiesoftheiralignedcomposites[13,14].Based

onacos2 (2𝛼)effectonreinforcingpotential[13],where𝛼 isthe sur-facetwistangle,whileazero-twistrovingwouldenable100%ofthe reinforcingpotentialofthefibrebundlesintheroving,yarnswith10°, 20°,and30° wouldreceive88%,59%and25%ofthereinforcing po-tentialofthefibres.Indeed,mostcommerciallyavailablehempyarns andtheircomprisingfabricshave surfacetwistangleabove 20° Itis therefore strongly recommended thatlow-twist rovings areessential totakeadvantageofthefullfibreproperties.However,low-twist rov-ingsinhemparenotcurrentlyproduced,althoughsuchreinforcement formsdonowexistatacommercialscaleforflax.Amoot,but mean-while useful,recommendationisthatfinehempyarnswithsmall di-ametersshouldbeused[14,13].Thisisbecauseevenifahempyarn is twisted tothesamelevel (inrevolutionsper metre),asmaller di-ameterhempyarnhasa notablylowersurfacetwistangle,and con-sequently thefibres aremisorientedby alesser degree. Inaddition, dry-spinning(rotor/ring spinning)producesmoretwisted yarnsthan wet-spinning[14,23],aswet-spinning,throughthebenefitofstronger threads in wet,swollen conditions andincreasedinter-fibrefriction, is less reliantontwistingtoform a continuousproduct. Progress in wet-spinningandexploringpossibilitiesofusingbinders,ashasbeen doneforsomeflax-basedunidirectionalproducts,suchasbyLineo(now EcoTechnilinLtd)(France)withthecommercializedFlaxTape© or Flax-Preg©,areimportantareasof developmentoffuturelow-twisthemp reinforcements.

Fig.6. Traditionalthread-basedhemptextile structures(basedonthe textileclassification fromSchnegelsberg)[77,78].).Product

exam-plesaregiven.Hempbraidsandfabrics pro-ducedfromtraditionally producedwet spun hempyarnsareshown.

Whileyarn twistis a source of misorientationat thefibre scale, conversionofyarnsintospecifictextilepreformscanalsoleadto fur-ther misorientation. For instance, woven fabrics require interlacing yarns/towsoverandunderadjacentyarns/tows,andbraided materi-alsrequirefurtherinterlacing,twistingandcoiling.Thisalsoresultsin crimping.Indeed,higherlevelsofyarntwist,andcoarseryarn diame-ters,canexacerbateissuesofsuchmisorientationatthetextilepreform scaleresulting inupto5–10%furtherdropinmechanicalproperties [14,23].Avoidingout-of-planemisorientation(e.g.fromcrimp)is crit-icalinfurtherimprovingcompositemechanicalproperties.Forthis, con-sideringnon-crimpedfabricsandstitchedmultiaxials,whereinlayersof specificallyorientedunidirectionaltextilesarestitchedtogether,is im-portant[10].

Specialtextilesdevelopedforcompositesrequirelowtwistrovings andyarns.Fig.7showsthevisualizedresultofareviewofdifferent tech-niquestoproducehempyarns.Theoverviewlistsprocesslineswhichare nolongerinuse,somewhichareinuseorunderdevelopment,and oth-erswhicharefuturedevelopments.Foreachofthelistedprocesslines, wewillprovideacriticalevaluationofthepossibleadvantagesand dis-advantagestoproducehempyarnsandtextilesemi-finishedproductsto manufacturecomponentsforstructuralcompositeapplications.

4.1. Traditionalmethod

AccordingtoClarkeandMerlin,hempfibreswereusedacross all ofEuropeandAsiaformillenniatomanufacturecordageandtextiles [76].Historically,twotypesofhempfibreprocessingaretobe

distin-guishedtomanufactureyarnsuitableforweavingfabrics[76].InChina andotherAsiancountries,hempbarkwassplitintonarrowstrips(see Fig.7– striphemp)andwastiedtogethertoformayarn,whileinEurope thebarkstrip(striphemp)wascombedtorefinethefibrebundlesbefore spinning[76,80].Forabetterunderstandingoftraditionalhempyarn productioninEurope,itisworthtotakeacloserlookatHungary. Spon-neretal.provideinsightsintothetraditionalproductionmethod,from water-rettedhempstalkstowet-spunyarns[81].InHungaryscutched hempandtow(seeFig.7)usedtobespuntoyarnswithdifferent tech-niques,butsometraditionalhempprocessingtechniquesandtypesof machinerylikewater-rettingandwet-spinningdisappeared,becauseof changesindemand,highproductioncosts,unfavourableworking condi-tions,aswellasenvironmentalregulations[81].Thetraditionalprocess linecanbeoptimizedbyreplacingthewaterrettingprocessbyosmotic degumming[82].Konczewiczetal.showedthatosmoticdegumming improvesthequalityoftheextractedfibrebundlessignificantlyinterms ofcolour,odour,aspectratio,aswellasemissionsofvolatileorganic compoundscomparedtofield-rettedhemp[82].

Afterthedisappearanceofthewet-spinningprocessforhemp,both thehackledhemp(seeFig.7)andthetowweredryspuninHungary [81]. Dependingon thequalityof thehackledhemp, spinning tech-niquescanbeadoptedfromtheflaxsector.Forhackledflax,the wet-spinning processwithboilingis usedtoproducefineworstedyarns, whiledry-spinningleadstocoarseryarns[83].Hempyarnsfromthe traditionallineare,ingeneral, verycompactandarehighly-twisted, whichdoesnotmakethemthefirstchoiceforhigh-performance com-positeapplications.

Fig.7. Historical,current,andfutureconceptsofhempyarnproduction(historicalandcurrentlynolongerpursuedprocessesareinblack,currentprocessarein blue,andrecent/futuredevelopmentsareingreen);"Flax"meansthattheprocesshasbeenusedtoproduceandprocessflaxforhemp.(Forinterpretationofthe referencestocolourinthisfigurelegend,thereaderisreferredtothewebversionofthisarticle.)

4.2. Babyhempproduction

Inthelate1990sandearly2000s,whilethetraditionalprocessingof hempintoyarnswasprogressivelydisappearingthroughouttheworld, increasingdemandforsustainablehemptextilesspurredresearchand entrepreneurialactivitiestofindinnovativesolutionsand/oradapt ex-istingtechniquestoproducehempyarnsfortheclothingindustry.In theyear2000,in thenorthofItaly,in aterritory wherehemp culti-vationhadagreattradition,theConsorzioCanapaItaliawasfunded toreintroducetheproductionoftextilehempintheregion.Acomplete productionchain,fromcultivationtotheproductionofhempyarns,was establishedtoobtainhempstemsofasizesimilartothoseofflax,to pro-cesshempstemsthroughexistingflaxscutchinglines.Thiswasachieved

bygrowinghempatveryhighstands(400–500plantsm−2 )thatwere thenchemicallydesiccatedwhentheplantsreached1.2–1.4minheight. Thistechniqueisknownas“babyhemp” production[35].Hempfibre of acceptabletextilequalitywasproduced,butthelimitedyield, the inconsistent quality,theuse ofchemical productstostop theplants‘ growth(withits consequentenvironmentalimpact)andthelow eco-nomicturnoverforfarmerswerethemaincausesforthefailureofthe enterprise,only2yearsfromitsstart.

4.3. Onemstemsectioningandbio-degummingapproach

Analternativestrategytoadapthempforflaxscutchinglineswas studied in the framework of the European Hemp-Sys project

(FP5-LIFEQUALITY;no.QLK5-CT-2002-01363)[84],wasfurtherdeveloped withintheMultihempproject(EuropeanUnion’sSeventhFramework Programme; no. 311849), and is ongoing currently in the SSUCHY project(TheBio-BasedIndustriesJointUndertaking-BBIJU).Instead ofshorteningtheheightofthecrop,asinthe‘babyhemp’systems,in thiscasethehempcropisharvestedatfullfloweringwhentheplant reachesmaximumheight,andsubsequently,thestemiscutintwo sec-tionsofapproximately1mlength,whicharekeptparallelandbaledin thesamewayasflax.TheHempsysprojectinvestigatedtheprocessing ofnon-rettedstems,therebyavoidingthedifficultstepoffield-retting, throughcontrolledbio-degummingofthefibreafterscutching[84].This strategyprovedfeasibleattheexperimentallevelbothduringthe Hemp-sysproject[84]andmorerecentlyduringMultihemp[54].However,it wasneverupscaledatanindustriallevelduetothelackofdedicated harvestingmachinesthat couldcut thehempsteminto1msections andlaytheminanorderedswathforsubsequentbaling.Thevarying stemdiametersof the1mlongsectionsduringprocessing(scutching andhackling)posedafurtherproblem(inlossesandfibrebundle re-finement).Inaddition,therewereconcernsregardingthe environmen-talimpactofthebio-degummingphaseduetohighwaterandenergyuse [85].

4.4. Totalfibreline

Inthepast30years,therehavebeenvariousapproachestoseparate hempstemstoproducefinefibrebundlesforthetextileindustry. Differ-entseparationtechniquesweredevelopedandevaluated,likechemical separation,steamexplosion[86,87]orenzymatictreatment[88].An attemptwasmadetousefield-rettedorevenun-rettedhempfromthe ‘disorderedline’(seeFig.7).Uniqueconceptsforprocessingthesekinds ofhempfibres/fibrebundlesonopen-endspinningmachineswere de-veloped.Theproducedyarnswereintended,especiallyfortheclothing industry[89].

Currentresearchanddevelopmentworkreportsnovelconceptsfor lowtwistflaxandhempbastfibreyarnsfromdisorderedlines[90]. Corbinetal.reportonthedevelopmentoflow-twisthemprovings[91], theirresultsshowthatverycompetitivetensilepropertiesareobtained forfabric-basedhempcompositesincomparisontoflaxcross-ply com-positelaminates.Formid-performancereinforcements,Gregoireetal. recentlyproposedanalternativeprocessforextractingfibresbasedon fibreopeners[52].Theyreportedthatthelengthofthefibrebundles wassufficientfortextileprocessingviathecardedroute,and mechani-calinvestigationsprovidedevidencethatacombinemachinecould pro-videhempofqualitysatisfyingtherequirementsof mid-performance textiles.

4.5. Mixedroute

Thisprocesschainrepresentsthedevelopmentofhempfibre process-ingforthetextileindustryinChina,whichisreferredtoas “cottonisa-tionofhemp”[83].DevelopmentsinChinaledtonewmachineconcepts anddegummingtechnologies,whichallowproducingveryfinehemp fi-bres/fibrebundlestobeusedoncottonorwoolmachines,aswelltobe blendedwithindustriallyproducedstaplefibres [83].These develop-mentsallowtheproductionofhempfibrebundles,whichareprocessed intoyarnsinthelong-staplerangeofcottonandwoolforclothingand hometextileapplications.Becauseofthelengthofthehempfibres/fibre bundles,andthetwistandthecompactnessoftheyarns,thesehemp yarnsarelesssuitableforcompositeapplications.

Thefibres/fibrebundles neededforyarn productionmustbe ob-tainedfromthehempplantthroughdecorticationandseparation pro-cesses.Inthefollowingsection,themethodsforhempfibreprocessing arepresentedandcriticallyevaluated.

5. Hempfibreprocessingandhempstemdecorticationplus separation

Webeginwithadefinitionofterms,outlinetheproblemof compar-ingdifferentprocessingtechniquesandprovide aconceptforprecise classification.Fig.8expressesthesystematicterminologyusedin tradi-tionalhempprocessing.

Togiveaperspectiveonwhathasbeendoneforflax,itisusefulto citeAkin’swork[92].Hepointsoutthatwhiletraditionalprocessing oflongflaxrequirestheorientationofthestalksandfibrebundlesto bemaintainedthroughoutthevaluechainfromharvesttofinalyarn, thisstrictorientationcanbeomittedinmoremodernprocessinglines. Itisnotthelengthofthebundlesthatisthekeyissue,butratherthe orientation.AccordingtoMüssig[93], thefollowingdefinitionshelp todistinguishbetweentheprocessingtechniques:(1)longitudinalflax, whichisflaxwithfibresandfibrebundlesparticularlyorientatedinonly onedirection,and(2)disorderedflax,whichisflaxwithfibresandfibre bundleshavingnopreferredorientation[92].

Productionchainfor longitudinalhemp:wherehempstemshaveto bekeptparalleluntilthescutchingandhacklingphase.

Processingfor disorderedhemp:themostcommondestinationfor hempcropsinEurope,andvariouslineshavebeendevelopedforthis purpose[94].

Regardlessoftheorientationofthehempstalks,hempcanbe pro-cessedinmanydifferentways.WiththevisualisationinFig.9,an at-temptis madetosystematicallystructurethedifferent techniquesto processhempfromstrawtothefinalfibrebundles,readyforyarn pro-duction.

Hempyarnproductionis possibleforlongitudinal anddisordered hemp.Fortheselectionofsuitableprocesses(Fig.9),itisessentialto considerthefollowingproperties.

5.1. Decorticationefficiency

Afterbaleopening(seeFig.9)themechanicalprocessingofhemp stemstakesplacetoseparatebastfibresfromshives.Thisstepiscalled ‘decortication’[95]. Tonote,thereissometimesconfusionormisuse ofterms;forinstance,somereferencestodecorticationcanincludethe cleaningandevenrefiningsteps(seeFig.9).Evensomemix-upbetween defibrationanddecorticationcanbefoundbasedonthecommunityof end-usage,e.g.pulp&paper[96].Decorticationhasanessential posi-tionintheentireproductionchain,anditsefficiencyisinfluencedbythe mechanicaltreatmentemployed[94,97].Theassessmentof decortica-tionismostlydonevisualandtactile,buttheneedforamoreobjective andreproducibleevaluationofdecorticationefficiencyhasdriventhe developmentoflab-scaleassessmentmachines[95].Withthese devel-opments,theenergyconsumedduringdecorticationisnowquantifiable andispairedwiththeyieldcontentofbastfibresandshives, permit-tingasystematiccomparisonforarangeofhempvarietiesgrownunder differentconditions[98].Thissupportsboththeselectionofimproved hempgenotypesfordedicatedmaterialsapplications[99] andthe op-timisationofagro-techniques[100],withthevisionoftailoredhemp productionforspecificend-uses.

Indeed, itis worthmentioning thatthelessaggressivethe decor-tication step,thebetterarethemechanicalproperties ofthebast fi-bres,arguablybecauseoflessfibredamageinducedduringdecortication [101,52].ThisbecomesevidentthroughtheworkofBosetal.[102], whoreportsignificantlyhigherfibrestrengthformanuallydecorticated fibres comparedtofibresobtainedthroughmechanicaldecortication. Decorticationefficiencyisalsoinfluencedbystemmorphological char-acteristics[95] andbiochemicalcomposition[103].Thelatteralso im-pactsmechanicalproperties,anditisbestillustratedthroughthe com-parisonofdecorticationefficiencyofgreenstemsversusrettedstems [104] andassessingtheinfluenceofthestemdevelopmentstage[67]. Forretting,toimprovethesuitabilityofhempfibreforcurrentorfuture intendedindustrialapplications(e.g.structuralcomposites),various

bi-Fig.8. Aschematicoverviewofthesystematic termi-nologyusedintraditionalhempprocessing(adapted fromSchnegelsberg[78]).

Fig.9. Aschematicoverviewofhempfibreprocessingtechniques.

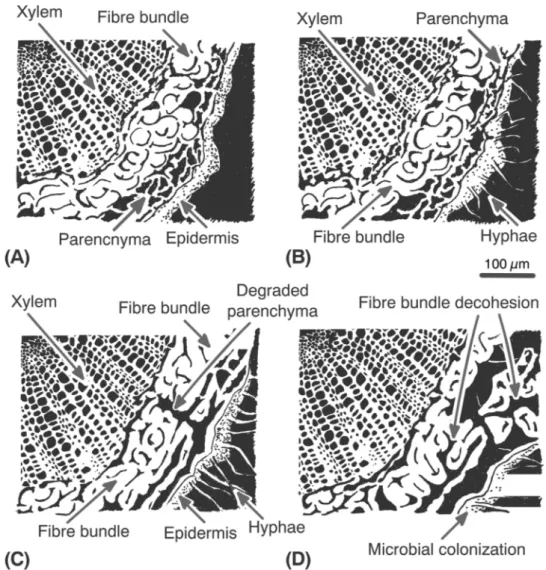

oticorabiotictreatments(sometimesboth)havebeenadoptedonthe fibres[105]andonthestems[96,92].Decorticationofstemsismade easierfollowingretting– beitwater-retting[106] ordew-retting.The underlyingmechanisminactionhereisthedecreaseinthefracture en-ergyattheinterphasesofthebastfibreswithbothshives[107] and theepidermis.Evidenceforthelatterisprovidedbyimagingthe cam-biumlayerbeingcleanedofitsxyloglucanbyimmunolabeling[108].A distinctillustrationofthisassumptionisprovidedbyscanningelectron microscopyobservation(Fig.10)[109].

Followingretting,thereisusuallynootherstemtreatmentcarried outtoassistdecortication,arguablybecauseofeconomicreasons,but alsobecauserettingisefficient.Thesteamexplosionprocessmustbe mentionedinthiscontexttoillustratetheconvenienceofacontrolled abiotictreatment.Thestemsaretreatedbymoiststeam(around200°C) underpressure(1.5–3MPa)forafewminutes,followedbyrapid explo-sivedecompression[110],boostingthe‘cleaning’efficiency. Decortica-tionisfacilitatedduetothefewercontaminantshivesadheringtothe fibres.Whenappliedtofibrebundles,steamexplosionleadstomore singlefibresandfewerbundles,withfibreelementsofsuperiorlength [111] comparedtountreatedfibrelots[112].Someotheralternatives doexist;forexample,microwave-assistedstemdecorticationiscurrently beinginvestigatedatthelaboratoryscale.Otherabioticstemtreatments thatarelowcostandindustriallyup-scalablearedesirabletoassistthe decorticationsteptowardimprovedfibre/shivesfractionationwith pre-servedfibreproperties.

5.2. Cleaningefficiencyandcontaminationwithshives

Duringthedecorticationprocess,theshivesareseparatedfromthe fibre bundlesandaremechanically brokeninto millimetricparticles [51,94].Asthepresenceofshivesisdetrimentaltocomposite proper-ties,cleaningprocessesfreefibrebundlesfromshives(seeFig.9).The growthstageofthehempplantinfluencestheadhesivestrengthbetween thehistologicalcelllayers.Consequently,ithasbeenshownthathigher cleaningefficiencycanbeobtainedbyadjustingtheharvestinggrowth stageofstems[113].Acomplementarystrategywastestedrecentlyby tinkeringwiththedecorticationparameters.Alargepanelof14selected varietiesweredecorticatedandthedecorticationefficiencyshowntobe dependentonthevarietyaswellasthebreaker(decortication)residence time.Therettingdurationisalsoshowntoinfluencethedecortication andcleaningefficiencybylooseningthebondbetweenlayersoftissue (seeFig.10);thelongertherettingstep(dewrettingwithaconventional duration),thelowertheresidualshivescontent[65].

5.3. Fibrebundlefineness

Whilethedecorticationstepaimstoseparatethebastfromtheother cell types,increasing thefineness of thefibrebundles further helps improvecompositeproperties[111].Variousprocessingtechniques in-fluencethefinenessoffibrebundles.Inpractice,enzymatictreatment

Fig.10. AschematicillustrationofSEM mi-crographsofcross-sectionsofhempstem be-foreandduringretting;(A)beforeretting,after (B)14,(C)28and(D)42daysofretting.Scale bar=100𝜇m.(inspiredbyBleuzeetal.[109].).

ofstems(aswellaswaterretting)willresultinfinerbundles. There-forerettedstemsaremuchpreferredoverunretted‘green’stems[104]. Whenabio-degummingtreatmentisappliedonstems,whichisa bio-processbasedonhydrolaseenzymes,similareffectsareobserved[54]. Inaddition,wenotethatthefinenessofthebundleswasevenbetter whensteamexplosionorenzymeswereappliedondecorticatedbundles [111].Controlledmicrobialrettinghasalsoshownpositiveresults,as hasfungi-assistedretting[114].Amechanicaloperationlikehackling orrefining(Fig.7)helpsingettingsmallerbundlesizes,andrecently [98] theeffectofthehempgenotypewasillustratedwithbetter bun-dlefinenessobtainedwitha‘yellowstem’variety(Carmaleonte).The questionoftheuseofintensiveprocessingisalwaysaquestionof bal-ancingqualityandquantity.Loweryieldstypicallyaccompanyintensive refiningprocesses.They,therefore,haveahighaddedvalueintermsof finenessandlowshivecontent,oftenattheexpenseoftheyieldoflong fibrebundles.Theresultislargequantitiesofshortandlow-valuefibres.

5.4. Fibrebundlelength

Currently,high-qualitylongflax(compareFig.7)havemechanical propertiessuitableforsomestructuralcomponents,thoughtheirhigh price(offibres,rovingsandcompositestextile)isamajorlimitingfactor. Reinforcementproducts(non-wovensandalignedtextiles) havebeen speciallydevelopedforhigh-performanceflaxcompositeapplications inFrance,BelgiumandSwitzerlandin thepastfewyears[115,116, 117].Theprocessingstepscorrespondtothetraditionalline(seeFig.7)

forflaxinEuropeusingfieldretting.Theyarnsandrovingsspecially de-velopedforflaxcompositesaregenerallybasedonlongflax(seeFig.8), whichiscardedandprocessedintowet-spunyarns.Realizinga compa-rableprocessingtechniqueforhempinEurope(TraditionalLine;Fig.7) isnotcurrentlyfeasible.Instead,newconceptsthatusehempfromthe disorderedlines(totalfibreline)needtobematerialised.Theprocessing technologyhastobeadaptedinsuchawaythatthehempfibrebundles havealengthspectrum(approx.5–10cm)whichallowcardingand pro-cessingintoyarns(dryorwet)withashorterstaplelengthcomparedto

longhemp.

Ongoingresearchaimstoprocessflaxandhempfibrebundlesfrom disorderedlinesintoyarnswithnearlyunidirectionalfibresbyan al-ternativespinningprocessatlowercosts[90].Ithasbeenshownthat unidirectionalflaxyarnsproducedfromthisalternativeprocessleadto compositeswithcomparablepropertiestothoseconstructedwith com-merciallong-flaxroving.Theworkonhempisstillindevelopment,with firstresultsthatseempromising[90].

5.5. Fibrebundledamage

Achievinghighdecorticationyieldandcleaningefficiency,alongside well-preservedfibreintrinsicproperties(mechanicaland morphologi-cal)canbechallenging,particularlyifcomplementarytreatment pro-cesses(e.g.retting)arenotused.Furthermore,evenwhenthe decorti-cationprocessisoptimised,orthecropgrowthstageiswell-adaptedto ensurelowfibre/shiveinterfacestrength,thereisatrade-off between

limitingfibredamageinducedduringdecorticationandtheother crite-ria,suchasfibre/shiveratioanddegreeofindividualisation.Fibre dam-ageduringdecorticationmanifestsasmicrometric cellwallstructural dislocations,sometimesreferredtoasdefectsorkinkbands.Theyform alongthelengthofthefibrespacedtens,hundredsorthousandsof mi-crometresapart[118,49,119,120]dependingondislocationdensity, harshnessofdecortication,andseverityofcompositeprocessing[118, 49,119,121].Thetrickypointliesinthedefinitionofthelengthscale ofthesedefects,asthelocalnanometricdislocationormisalignmentof thecellulosemicrofibrilsinafibrecouldbeconsideredadamage de-fect,and/orlargemicrometrickinkbandsinafibrebundlecouldalso beconsideredadamagedefect.

Attheoutset,itis essentialtomentionthatsuchdamagedefects arepresent,albeitinsubstantiallysmallerquantities,in unprocessed, non-decorticatedfibres,andarealsopresentinlowquantitiesinhand decorticatedfibres[122,123].Theirmultipleoriginsanddescriptions inbastfibreshavebeenwidelyreviewed[124],alongsidetheir implica-tionsoncompositeproperties[16].Thoughsuchdefectsaredetectable inunprocessedstems,forinstance,inducedbywind[118],theyarealso generatedwhenhempstemsareprocessedmechanically[123] and es-peciallyincase ofunder-retting,whenextractingconditionsmustbe severe.Indeed,thisgoesbacktothetrade-off mentionedearlierabout cleaningefficiencyandthepreservationofthestructuralpropertiesof thefibre.Theimpactofalltheproductionprocessstepsondamage evo-lutioninfibreswasinvestigatedrecently[125].Theresultshighlight thatthedecorticationstageisthemajorcontributortodamage forma-tion,andsubsequentprocessingsteps(seeFig.9)likecarding[52]also addtothetotaldefectcount,thoughtoarelativelylesserextent.The selectionof processstepsandtheirintensityshouldbe drivenbythe requiredfibrequalityforitsendproducts;forinstance,separationand cardingwillcreateadditionaldamage,butalsogeneratefinerfibre bun-dles.

The impact of thefibre extraction process on themorphological andmechanicalpropertiesof hempfibres/fibrebundles hasbeen in-vestigatedbyresearchersusingcarefullydesignedexperimentalsetups. Thygesenetal.reportamonotonicallydecreasingrelationshipbetween theprocessingstepsandthestrengthofhempfibrebundles[118].They coveredretting,scutching,carding,cottonization,andyarnproduction, andobservedastrengthreductionofapproximately30%per process-ingstep(onaverage).Consideringthatno cellulosemodification oc-curredduringanystep,theyconcludedthatthestrengthreductionwas drivenbyfibreultrastructuredamage.Inthisstudy,however,fibre mor-phologywasnotstudied,norcorrelatedwithfibrestrength.Notethat varioushempprocessingmachinesareinusetoday,andtheprincipal differencesindecorticationprocesses,i.e.breakerrollerversushammer mills,willleadtohempproductswithcontrastingqualitiesintermsof length,defectcount,andshivecontent[94].Finally,theextraction pro-cessofhempfibres,alongsidecropvarietyandgrowthconditions,isan importantcontributortothehighscatterinitsmorphological charac-teristics,whichinturnmayaccountforhemp’slowertensileproperties, comparedtoflax[126].

6. Stemharvesting,post-harvestingandretting

Theharvestingtimeandtherettingdurationofthestemsaffectthe maturityofthefibres,andarenot well-controlledbyfarmers.These parametersalsoinfluencethemechanicalpropertiesandthedegreeof individualisationofthefibres,andconsequentlyhaveaknock-oneffect ontheperformanceoftheresultingbio-basedcomposites.Thissection willcoverthreekeypointsofdiscussion.

• Themorphologicalpropertiesofhemp,andinparticularthe degra-dationmechanismsandstructuralevolutionsatthestemscaleduring rettingwillbediscussed.

• Theinfluenceofrettingonthepropertiesoffibresandplantwalls willbedescribed,intermsofdefects,modificationsoftheparietal

structure,individualisationofthefibresandevolutionoftheir me-chanicalproperties.

• Thedecorticationandseparationoffibrebundlesandthechoiceof theharvesting timewillbe discussed,inrelation tothematurity andperformanceofthefibres.Theconditionsandmonitoringofthe rettingprocesswillbeanalysed.

6.1. Impactofharvesting

Harvestingisanimportantstepinhempproduction.Thetimeand methodofharvestinghaveasignificantinfluenceonthequalityofthe hempfibres.Itdictatestheselectionoffurtherprocessingdevicesfor hempstems,andtheeconomicsofhempfibresproduction.Whilethe hempcropcanbeharvestedwithawidevarietyofprototypeand com-mercialtypesofmachinery[94],allharvestingsystemscanbegrouped in twocategories,longitudinalanddisordered,asillustratedinFig.7. Acomprehensiveoverviewofdevelopmentsinthefieldofharvesting andpost-harvestingtechnologycanbe foundinAmaducciand Guso-vius[94].

Thedisorderedsystemistheonlyoneusedinmodernhemp cultiva-tion.Itinvolvesstandardormodifiedcombineharvestersthat,inoneor twopassages,collecttheseedsandleavethestemsonthefieldina dis-orderedswath.Followingthissystem,thefarmercanbenefitfromthe incomederivedfromthesaleofseeds,andpotentiallyfromthe extrac-tionofCBDfromthethreshingresidue[127].However,inthissystem, harvestingiscarriedoutconsideringseedripeningandnotfibre qual-ity.Notably,thefibresobtainedfromstemscollectedatseedripening aremoresuitableforlowervalueapplications,suchastheproduction ofpaperandpulp[128,129,130],shortfibre/fibrebundlereinforced thermoplastics[131,25]orperhapsnon-woventextiles(needlefeltsor fleeces)[130].Severalauthorsreportthatfibrequalitydecreases dur-ingseedmaturation.Liuetal.havemeasuredthatthetensilestrength is higherin fibresobtained fromstemscollectedatthebeginningof floweringthanfromstemscollectedatseedmaturation[103].Thisis probablyduetotheaccumulationofsecondary,shortandlignified fi-bres,andtothereductionofcellulosedeposition.Musioetal.measured lowerbreakingstrengthvaluesincomposites(throughtheimpregnated fibrebundletest)madewithfibresobtainedfromstemscollectedwhen theseedmaturedratherthanatfullflowering[54].

Forthedevelopmentof newharvestingmethodsforhemp, possi-bledamagetohempfibresbytheharvestingprocesshasgenerallynot beentakenintoaccount.Intheliterature,therearefewstudies inves-tigatingthedamaginginfluenceoftheharvestingtechniqueonthe fi-brepropertiesofhemp[94].MüssigandHarigreportthatharvesting methodscauseleastdamagetofibrebundles,iffibres andshivesare notseparatedonfreshgreenstemsduringharvesting[132].Müssigand MartensaswellasGusoviusetal.cometothesameconclusions[68, 133].Thestudyalsoexaminedaharvestingmethodthatseparatesfibres andshivesfromfreshgreenstemsinthefield.Thisharvestingmethod showsatremendousdamagingeffectonthefibrebundles,witha signif-icantreductioninstrength[132,93].

6.2. Impactofrettingatthefibrescale

Duringretting,theoverallarchitectureoftheplantisimpacted. Ret-ting,whichlastsseveralweeksdependingonitsprogress,isa micro-biologicalprocessduringwhichthestemsarecolonisedbyfungiand bacteria.Thesemicroorganismssecreteenzymeswhichinduce degra-dationofthecellwalls.Usually,studiesfocusonplantpolysaccharides, althoughthedeconstructingenzymearsenalisknowntobericher.The typical degrading arsenalincludes phenol oxidases or proteases and otherhydrolasesbecausethesepolymersaremajorsconstituentsofthe cellwall.Amongstthepolysaccharides,hydrolasesandhemicellulases areofmajorimportance.Duringrettingtheyhave,forinstance,the abil-itytodegradethexyloglucanepitopeslocalizedinthecambiumlayer

inflax[108].Thishemicellulosedegradation,inturn,facilitatesthe dis-sociationofthefibrecrownfromthexylempartinhemp(seeFig.10, C)[109].Tonote,themostwell-knownandperhapsmoststudied hy-drolasesisthepectinasefamily[134,135].Thepectinsofthemiddle lamellae,thecorticalparenchyma, theepidermis, thexylemandthe bundlesoffibresaregraduallydegraded,whichfavourstheextraction anddivisionoffibrebundlesduringthemechanicalextractionstep;an improvementoftheseparationoffibrebundlesfromthewoodycoreof theplantisexpected.Thus,therettingstepinducesasignificant dis-sociationofthestemtissuesandconsequentlyadropinfibrebundle interfacialcohesion.

Atthescaleofthesinglefibre,itseemsevidentthatmulti-scaleand multi-featuremodificationsoccurandevolveduringthedynamicretting process.Thishasledtopublishedreportswithcontraryobservationsin termsofphysicalproperties(mechanicalmostly),biochemicalpatterns, andfibrecellwallpolymersarrangements(cellulosetomentionone). Thedivergentconclusionsarearguedandevenassumed,tobe princi-pallyexplainedbytheset-pointofrettingexplored.Inordertoclassify thedynamicsoftherettingprocess,itisnotsufficienttouseonlythe temporalunit(i.e.therettingduration).Rather,thepedoclimatic con-ditionsmustalwaysbedescribed,discussedandusedforcomparison. Theeffectofsoilqualityonrettingwithregardstotheconsortiaofsoil microorganismspresentisapossibleexplanationofthedifferentretting dynamicsobserved.Ribeiroetal.reportintheirstudy,whichisbasedon genesequencing,thatthemostimportantfungalandbacterialspecies areidenticalinsixdifferenthemprettingsites,buttheydiffer signifi-cantlyintheirdistribution[136].Thiscanbeinterpretedasthefield rettingprocessmayprogressdifferentlyaccordingtotherichnessofits consortiaofmicroorganisms.However,soilthatislessrichin microor-ganismscouldbesuitableiftherettingdurationisincreased.Froma mechanisticpointofview,thecombinationofbacteriaandfungiseems veryeffectiveforflax[108].Thedynamicresponseofthese microorgan-ismswillprobablyalsoincreasetheefficiencyofhempretting[137].

Theactionofsoilmicrobiotaduringrettingaidsthe individualiza-tionoflargerbundlesintosmallerbundles,thoughthiscantakeafew weeks;Mazianetal.monitoredthisprocessofseparationintosmaller bundlesafterfiveweeksoffieldretting[67].Alongsidethechangesat thebundlescale,itisclearthatnotonlythemiddlelamellaebetween bundlesbutalsothemiddlelamellaebetweenfibres facesenzymatic degradation[42,67].Thefollowingsectionswillexplorethisfurther, withthemechanicalpropertiesandbiochemicalaspectsasthefocus.

6.3. Impactofrettingondefectsandmechanicalpropertiesoffibres

Atthelevelofthesinglefibre,itsseemsevidentfromliteraturethat overtherettingdurationthefibremechanicalpropertieswillfollowa bell-shapetrend,duetotheamountanddiversityofenzymatic activi-ties[109] executedbythefungalandbacterialmicroorganisms[137]. Quantifiedenzymesmostlypoly-andoligo-saccharideshydrolases, de-spitetheexpectedrecalcitranceoflignininthefunctionalpropertiesof fibre;hence,thereistheneedtoalsoidentifyandassesoxydases(i.e. laccases).Fromamechanicalpropertypointofview,thereisfirstan increaseintensilestrengthintheearlyphaseoftherettingprocess,up toanoptimum rettingduration,beforeasustained reductionin ten-silestrengthofthefibres,thiscondition isoftenreferredtoas over-retting[68,65,101].TrendsinbothstrainatbreakandYoung’s modu-lusstandoutincomparisontothedevelopmentoftensilestrength.The strainatbreakdecreaseswithrettingduration.Thetensilestrengthof mechanicallyextractedsinglefibresfromthesamefieldconfirmthat boththeunder-rettedfibreandtheover-rettedfibresover70dayshave lowerstrength (480and340MPaafter10 and75daysrespectively; Liuetal.[104])comparedtotheoptimalrettingduration(660MPa af-ter39days).Interestingly,theapparentelasticmodulusofsinglefibres doesnotevolvesubstantiallyduringretting,remainingbetween15and 17GPa.Incontrast,thestraintofailuredecreasesby30%withretting duration,startingat3.5%after10daysofretting[101].

Liuetal.reportcomparabletrendswithhighervaluesforallreported characteristics,andhighlighttheeffectofthehempgrowthstage[104]. Indeed,ifstemsareharvestedearly,andthestemandcellshavenot ma-tured,tensilestrengthonlydecreaseswithincreasingrettingduration. This isincontrast tothebell-shapetrendobservedformaturestems withmaturecells.

Mazianetal.reportasubstantialdifferenceintensilestrength be-tweennon-retted(170MPa)andretted(340MPa)fibrebundles[67]. Buttheauthorsdidnotobserveasignificantreductioninstrengthfor aprolongedrettingduration(of63days);thisisincontrasttothe pre-viouslydescribedbell-shapedevolutionintensilestrengthwithretting duration.TheYoung’smoduluswas 8GPa forun-rettedsamplesand increasedtovaluesof12GPafortherettedsamples,independentof ret-tingtime.Theyalsoobservedthatthestrainatbreakofthefibrebundles increasedwithrettingtime[67] untilthestemwasover-retted;thisis againincontrasttothegradualdecreaseinfailurestrainwithretting durationreportedforsinglefibres[65,67].

6.4. Impactofrettingonparietalarchitectureandbiochemistry

Mostpublicationsthematicallyrelatedtothissectionattempttolink physicalpropertieswiththedevelopmentofbiochemistryandthus im-plicitly with parietalarchitecture. A sensitivityanalysis reports that atthelevelofsinglefibres,theYoungmodulusisafirst-orderfactor [138]formechanicalperformance,andisdirectlyrelatedtotheamount of crystallinecellulosein thecellwall. DelMasto etal.haveshown thatthestiffnessofafibreisstronglyinfluencedbythedispersionin themorphologicalcharacteristicsofthefibres.Tensiletestsimulations showthestronginfluenceofthedegreeofellipticity(vis.fibre cross-sectionshape)ontheformofnon-linearityofthetensile stress-strain response.Theresultssuggestthatthismorphologicaleffectisstrongly coupledwithstructuralpropertiesandphysicalmechanisms,suchasthe viscoelasticbehaviourofcellwallcomponents[126].Itmaybeassumed thatrettingdirectlyaffectsthemorphologyofthefibrebymodifyingthe fibreultrastructure(changingofthecrystallinityofthecellulose, mea-suredthroughthecrystallinityindex(CI)).Forexample,theCIdecreases whenover-rettingbegins.Asaconsequenceoftheobserveddecreasein cellulosecrystallinity,astrongreductioninstiffness,strengthand elon-gationatbreakissuspected[65].Inthementionedwork,adecrease incellulosecrystallinityfrom78%to73%wasobservedbeforeand af-terover-retting.Thisledtoapredictedlossof10%intensilestrength, whichwasconsistentwiththeexperimentalvalues.However,arecent x-raydiffraction(XRD)investigationonfibrebundlesduringrettingshow anincreaseincellulosecrystallinityfrom53%to73%at63rettingdays [67].Asimilartrendwasrecentlyshownonflaxfibres[42].Onemay hypothesizethattheover-rettingstagewasnotreachedinthese stud-ies.Whatisimperativetopointouthereisthere-occurringdifficulties incomparingdatabetweenvariousstudiescarriedoutusingdifferent techniques.WithXRD,forexample,asingletodoublecrystallinityvalue ofthecellulosecanbedetermined,dependingonthetreatmentofthe measureddata(seethediscussioninPlacetetal.[65]).

Thesamecriticismcanbemadewhendeterminingbiochemical com-ponents.Thereportedchangesinthechemicalcompositionduringthe rettingprocessaresometimescontrastingandinconsistent;thiscanonly beexplainedbythefactthatthecompositionofthefibreandfibre bun-dlehasbeenmixedup[96].Therettingprocessfirstactsonthe bun-dlesbydepectizationthatdegradespectin-enrichedstructures,likethe middlelamella.Pectins,withtheiramorphousnatureandshort-chain lengths,aregoodcarbonsubstratesforthecolonisingmicroorganisms duringretting.Thesepectinmayhave somecarbohydratemonomers incommonwithhemicelluloses,forinstancearabinoseandrhamnose monosaccharides[139].Thiscanmakeitchallengingtoconfidently at-tributethequantifiedmonomerstooneofthetwofamilies.Inparallel toenzymatichydrolysisofpectinsandhemicellulosespreferentially lo-catedinthemiddlelamellaandthethinprimarycellwall,theconsortia ofmicroorganismsalsoproduceenzymestargetingglycanpolymers,and

![Fig. 3. Literature review of single plant fibres tensile performances [46] ..](https://thumb-eu.123doks.com/thumbv2/123dokorg/8322695.132089/6.892.475.817.435.677/fig-literature-review-single-plant-fibres-tensile-performances.webp)

![Fig. 4. Comparison of tensile modulus of injection moulded (30 mass%) fibre-reinforced PP composites (A) and strength at break of epoxy-hemp UD composites (B) with literature data [46] .](https://thumb-eu.123doks.com/thumbv2/123dokorg/8322695.132089/8.892.157.735.87.319/comparison-tensile-injection-reinforced-composites-strength-composites-literature.webp)

![Fig. 6. Traditional thread-based hemp textile structures (based on the textile classification from Schnegelsberg) [ 77 , 78 ]](https://thumb-eu.123doks.com/thumbv2/123dokorg/8322695.132089/9.892.57.592.79.656/traditional-thread-based-textile-structures-textile-classification-schnegelsberg.webp)

![Fig. 8. A schematic overview of the systematic termi- termi-nology used in traditional hemp processing (adapted from Schnegelsberg [ 78 ]).](https://thumb-eu.123doks.com/thumbv2/123dokorg/8322695.132089/12.892.59.782.87.682/schematic-overview-systematic-nology-traditional-processing-adapted-schnegelsberg.webp)