UNIVERSITA’ DI PISA

FACOLTÀ DI INGEGNERIA

Corso di Laurea Specialistica in Ingegneria Informatica per la Gestione d'Azienda

TESI DI LAUREA SPECIALISTICA

Formal Execution of BPMN Specifications in Business Processes with Traceabilty Support

Candidato:

Luigi Scazzari

Relatori:

Prof. Andrea Tomasi

Dott. Alessio Bechini

To everyone is so mad, courageous, inconsiderate, trustful to believe in me.

Engineering is a great profession. There is the fascination of watching a figment of the imagination emerge through the aid of science to a plan on paper. Then it moves to realization in stone or metal or energy. Then it brings jobs and homes to men. Then it elevates the standards of living and adds to the comforts of life. That is the engineer’s high privilege.

Abstract

In this thesis work we study both the supply chain modelling for several firms in the food market sector and the employment of such models within a Business Process Management Suite (BPMS). For this purpose, we have first analysed one specific supply chain addressing black-cabbages growing. Second, the related business processes have been modelled using the BPMN formalism (BPMN stands for Business Process Modeling Notation). Then, making use of an “ad hoc” tool, we have transformed a chosen BPMN diagram into a BPEL (Business Process Execution Language) process, which can be executed over a BPEL engine. This last step allow us to set-up the proper environment for simulating the actual business process execution, as well as the related communication actions with its business partners. Finally we can state that the reported experience has shown to be a valuable approach for the effective simulation of supply chains' behaviour in the food market, and it can be regarded as a proper prototyping paradigm for medium- and small-sized supply chains.

Contents

ABSTRACT...5 CONTENTS...6 FIGURE INDEX ...8 TABLE INDEX ...8 LIST OF SYMBOLS ...10 INTRODUCTION...11CONTENTS OF THE DOCUMENT ...14

CHAPTER 1 ...15

SUPPLY CHAIN TRACEABILITY... 15

1.1 Supply chain traceability and its services... 15

1.2 Organizing method for traceability... 17

1.3 Traceability process' basic units... 19

1.3.1 Identification...20

1.3.2 Registration ...20

1.3.3 Links ...21

1.4 How businesses interact...21

CHAPTER 2 ...23

ANALYSIS OF A REAL SUPPLY CHAIN...23

2.1 Introduction ...23

2.2 Black cabbage productive processes ...23

CHAPTER 3 ...27

BUSINESS PROCESS MANAGEMENT...27

3.1 Introduction ...27

3.2 Business Process Modelling ...28

3.2.1 Supply Chain Modelling ...28

3.2.2 SCOR Model ...28

3.2.2.1 The Process Modeling Pillar ...29

3.2.3 GSCF Model...32

3.2.3.1 Customer relationship management ...33

3.2.3.2 Supplier relationship management ...33

3.2.3.3 Customer service management ...34

3.2.3.4 Demand management ...34

3.2.3.5 Order fulfilment ...34

3.2.3.6 Manufacturing flow management ...35

3.2.3.7 Product development and commercialization...35

3.2.3.8 Returns management...35

3.2.4 SCOR-GSCF comparison...36

3.2.5 RosettaNet Standard ...36

3.3 Business Process Modeling and Notation ...37

3.3.1 BPMN 2.0 ...38

3.3.2 BPMN Scope...39

3.3.3 Uses of BPMN ...39

3.3.3.1 Private (Internal) business processes...39

3.3.3.2 Abstract (Public) processes...40

3.3.3.3 Collaboration (Global) processes...41

3.3.4 BPD objects ...42

3.3.4.2 Connecting Objects...47

3.3.4.3 Swimlanes...48

3.3.4.4 Artifacts ...49

3.3.4.5 Assignments ...50

3.4 Business Process Execution Language ...51

3.4.1 Introducing Business Process Execution Language ...51

3.4.2 What is a BPEL Process? ...52

3.4.3 BPEL Process Definition Elements ...52

3.4.3.1 Partner Link Types and Partner Links...53

3.4.3.2 Variables ...54 3.4.3.3 Correlation Set...54 3.4.3.4 Fault Handler...55 3.4.3.5 Event Handler ...56 3.4.3.6 Compensation Handler...57 3.4.3.7 Activities ...58 3.5 ActiveVOS Designer 6.0 ...60

3.5.1 Business Process Management System/Suite (BPMS) ...60

3.5.2 Principles for tool selection ...61

3.5.3 Selected tools ...62

3.5.4 About ActiveVOS Designer 6.0...62

3.5.5 ActiveVOS Designer 6.0 Components ...64

3.5.5.1 ActiveVOS Designer –Designer Perspective ...65

3.5.5.2 ActiveVOS Designer –Debug Perspective...65

3.5.5.3 ActiveVOS Console – Homepage ...65

3.5.5.4 ActiveVOS Console – Monitor ...67

3.5.5.5 ActiveVOS Console – Report ...68

3.5.5.6 ActiveVOS Console – Catalog ...68

3.5.5.7 ActiveVOS Console – Admin ...69

CHAPTER 4 ...71

IMPLEMENTATION OF A TRACEABILITY PROCESS...71

4.1 Project phases ...71 4.1.1 First phase ...71 4.1.2 Second phase ...71 4.1.3 Third phase...71 4.1.4 Fourth phase ...72 4.1.5 Fifth phase ...72 4.1.6 Sixth phase ...72

4.2 First and Second Phases: Macro-processes definition and modelling ...72

4.2.1 Supply chain entry...73

4.2.2 Plants purchasing...73

4.2.3 Cabbages selling...74

4.2.4 Packagings selling ...74

4.2.5 Premises to the next phases...75

4.3 Third and Fourth Phases: Accessory files writing, BPMN-BPEL transformation and deployment...75

4.4 Fifth and Sixth Phases: Starting and execution of the BPEL process...82

CHAPTER 5 ...89

CONCLUSIONS...89

5.1 Conclusions ...89

5.2 Personal remarks ...89

APPENDIX A ...93

A.1 PROJECT FILES...93

A.1.1 PackagerExe.bpel ... 93

A.1.2 packager.wsdl ...99

A.1.3 farmer.wsdl ...101

APPENDIX B ...105

B.1.1 CatalogueType ...105

THANKS ...109

BIBLIOGRAPHY ...110

Figure Index

FIGURE 1.1: TRACKABILITY OF POTENTIALLY DANGEROUS LOTS ... 15FIGURE 1.2: SUPPLY CHAIN FLOW-SHEET ... 17

FIGURE 1.3: INTERACTION AMONG SUPPLY CHAIN PRINCIPAL ACTORS... 18

FIGURE1.4: SUPPLY CHAIN FLOWS ... 21

FIGURE 3.5:EXAMPLE OF AN ABSTRACT BUSINESS PROCESS ... 39

FIGURE 3.6:EXAMPLE OF A COLLABORATION BUSINESS PROCESS ... 40

FIGURE 3.7: SWIMLANES ... 46

FIGURE 3.8: DATA OBJECT... 47

FIGURE 3.9: GROUP ... 48

FIGURE 3.10: ACTIVEVOS CONSOLE HOME PAGE ... 63

FIGURE 3.11: ACTIVEVOS CONSOLE – MONITOR PANEL ... 65

FIGURE 3.12: ACTIVEVOS CONSOLE – REPORT PANEL ... 66

FIGURE 3.13: ACTIVEVOS CONSOLE – CATALOG PANEL ... 67

FIGURE 3.14: ACTIVEVOS CONSOLE – ADMIN PANEL... 68

Table Index

TABLE 3.1: EVENTS ... 41TABLE 3.2: ACTIVITIES ... 42

TABLE 3.3: GATEWAYS ... 44

TABLE 3.4: BASIC ACTIVITIES ... 56

TABLE 3.5: STRUCTURING ACTIVITIES... 57

List of symbols

BPM Business Process Management BPD Business Process Diagram

BPEL Business Process Execution Language BPMI Business Process Management Initiative BPMN Business Process Modeling and Notation

BPMS Business Process Management System (or Suite)

ebXML Electronic Business using eXtensible Markup Language GSCF Global Supply Chain Forum

IT Information Technology

OASIS Organization for the Advancement of Structured Information Standards OMG Object Management Group

SCOR Supply Chain Operations Reference SOA Service Oriented Architecture UBL Universal Business Language UML Unified Modeling Language

WS-BPEL Web Service - Business Process Execution Language WSDL Web Service Description Language

Introduction

In nowadays firms, great and small, the decision making process and company organization effectiveness are defined on work flow and information flow management among production processes. This explains commercial and non organization trend to use informative systems that are able to automate process management. Process management main objectives are:

Improving internal productivity and company performances. Lack of standard procedures and lack of business information acquisition tools can generate redundant activities and documents, without added value, that cause delay in process execution.

Improving response capability facing market changing and customer satisfaction effectiveness, because they cause response times that are essential to obtain successful results.

Speeding up decision making process for getting more effective decisions. Management must have a complete and coherent visibility on business process available; besides it must get up to date on significant information, in real time.

• Increasing visibility on integrated (or supply chain) processes: the analysis, acknowledgement and monitoring on internal processes aren’t often enough to grant optimal performances. The processes concerning entities that are outside company borders are factors influencing company performance such as, or perhaps more, internal processes. Managers and analysts’ work is improving process effectiveness and efficiency, by means of reducing costs and increasing quality meant as customer satisfaction. Business Process Modeling (BPM) is the activity that allows to depict business processes. BPM is complementary to process analysis, but it has a more specific context. BPM’s a way of representing organizations and processes using models, roles, structures and responsibilities. Process analysis and BPM use different notations. The most important standards of reference in this sector are:

• UML (Unified Modeling Langage): it’s a notation thought to represent software systems, but it’s very often used in depicting business aspects;

• BPMN (Business Process Model and Notation): it’s a notation that was created specially for business process modelling.

BPMN, unlike UML, hasn’t constructs available for modelling structures, roles and responsibilities. Then these two notations aren’t alternative, instead they are complementary. UML is a language

that helps software developers to specify, display and document modelling systems software. BPMN, instead, was thought to help business analysts, system architects and software engineers for understanding process development during global business life cycle, by means of process design. Nowadays, Object Management Group (OMG) is maintaining UML and BPMN and it’s developing an integration between two of them.

Another aspect of business process management is the business process execution, that’s a way to automate processes that executes the required steps of the process itself. Business process execution must expect and integrate the human intervention in business processes.

As a response to these problems, software has been developed that enables the full business process (as developed in the process modelling activity) to be defined in a computer language which can be directly executed by the computer. The system will either use services in connected applications to perform business operations (e.g. calculating a repayment plan for a loan) or, when a step is too complex to automate, will message a human requesting input. The executable computer language must use business rules providing instructions for governing business process behaviour, and a business rule engine can be used to drive business process execution and resolution.

This computer language is the Web Services Business Process Execution Language by Organization for the Advancement of Structured Information Standards (OASIS) Standard WS-BPEL 2.0, WS-WS-BPEL (or WS-BPEL for short); that’s a language for specifying business process behaviour based on Web Services. Processes in WS-BPEL export and import functionality by using Web Service interfaces exclusively.

Business processes can be described in two ways. Executable business processes model actual behaviour of a participant in a business interaction. Abstract business processes are partially specified processes that are not intended to be executed. An abstract process may hide some of the required concrete operational details. Abstract processes serve a descriptive role, with more than one possible use case, including observable behaviour and process template. WS-BPEL is meant to be used to model the behaviour of both executable and abstract processes.

WS-BPEL provides a language for the specification of executable and abstract business processes. By doing so, it extends the Web Services interaction model and enables it to support business transactions. WS-BPEL defines an interoperable integration model that should facilitate the expansion of automated process integration in both the intra-corporate and the business-to-business spaces.

Business process execution involves message exchange representing business documents among partners; this was usually achieved using a multiple industry-specific XML (eXtensible Markup Language) versions of such basic documents as purchase orders, shipping notices, and invoices. While industry-specific data formats have the advantage of maximal optimization for their business context, the existence of different formats to accomplish the same purpose in different business domains is attended by a number of significant disadvantages as well.

Developing and maintaining multiple versions of common business documents like purchase orders and invoices is a major duplication of effort.

Creating and maintaining multiple adapters to enable trading relationships across domain boundaries is an even greater effort.

The existence of multiple XML formats makes it much harder to integrate XML business messages with back-office systems.

The need to support an arbitrary number of XML formats makes tools more expensive and trained workers harder to find.

The OASIS Universal Business Language (UBL) is intended to help solve these problems by defining a generic XML interchange format for business documents that can be extended to meet the requirements of particular industries. Specifically, UBL provides the following:

A library of XML schemas for reusable data components such as “Address,” “Item,” and “Payment” — the common data elements of everyday business documents.

A set of XML schemas for common business documents such as “Order,” “Despatch Advice,” and “Invoice” that are constructed from the UBL library components and can be used in generic procurement and transportation contexts.

Contents of the document

The chapters of this relation are arranged in following way:

1. In Chapter 1 we’re going to talk about main aspects and difficulties related traceability, by doing so we’ll have a first view on which are the basic aspects to model.

2. Chapter 2 deals with natural language description of pilot firm to show work flow and information flow that are characteristic of it.

3. Chapter 3 deals with most used technologies, describing individual characteristics, and relative tools. In particular, we’ll treat BPMN, BPEL and ActiveVOS BPMS.

4. Chapter 4 talks about the project and its implementation. We start talking about BPMN diagram definition, that represents the business process, then we show BPMN-BPEL transformation and BPEL process deployment on a BPEL server; finally, we execute the BPEL process.

5. Finally, Chapter 5 resumes the endings and proposes reflections that are born from this experience.

Chapter 1

Supply chain traceability

In which we talk about supply chain traceability, pointing out elements and tools to realize a traceability integrated system.

1.1 Supply chain traceability and its services

According to the ISO 9001:2000 standard, chain traceability is the ability to trace the history, application or location of an entity by means of recorded identifications throughout the entire supply chain. In practice, chain traceability is achieved if businesses keep records of suppliers and customers and exchange this information along the entire supply chain.

In particular, each unit/batch (called lot in the following) of a component or a product must be both traceable and trackable. To trace an entity means to identify its origin by tracing back in the supply chain, whereas to track an entity means to follow the path of entity through the supply chain from supplier(s) to consumers. [1]

Both of them represent a further effort for firms in terms of honesty, professionalism and guarantee against an always growing demand of quality and transparency by customers. Traceability ultimate end is to establish trust between producer and consumer. Therefore, if traceability is well advertised it creates customer satisfaction and represents an important mean to promote and increase the value of the product itself.

Supply chain organizing structure is very complex – the product during its life cycle goes through production, transformation, distribution and selling firms – but it’s the best that firms can offer in terms of guarantee about product quality. [2]

Supply chain traceability proposes a vertical integration model for companies; it’s very important, thus, to trace a product’s history identification names of the firms participating in productive system and their responsibility level within productive process itself. Traceability importance has an effect also on legal and management aspects: following European Community law disposition (regulation UE 178-2002) into force from on January 2005, traceability allows timely identification of

non-conformity cases or isolation of potentially dangerous for consumers situations, allowing to identify causes.

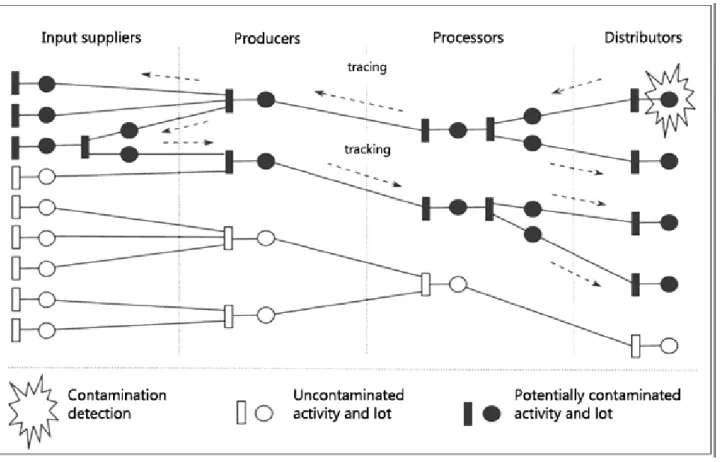

In Figure 1.1 it's illustrated traceability utility when in presence of a contaminated lot.

Figure 1.1: Trackability of potentially dangerous lots

Once a non-conform lot’s found out, it’s possible retrace supply chain to track the cause together all and only lots that were exposed to the same transformation of accused lot and then they could be at risk. Circles represent produced lots,while rectangles the activities producing such lots. Lines, finally, show link among origin lots and generated lots; then N-input lines activities indicate a composition of several ingredients making a new product, while N-output lines activities represent a splitting of original lot in several children lots. From the model depicted in Figure 1 we gather that it’s impossible in practice tracing, in respective supply chains, secondary elements such as additives, coadjuvants, packages; if we would do so the system could become too much complex, and then unmanageable. [3], [4]

The productive process’ control system is regulated by a disciplinary, that it’s made more evident for customers appending a logo onto the tag or onto the finished product’s manufacture.

Within supply chain’s traceability we can observe that materials flow monitoring is a control process tool allowing to individuate and to isolate the error causes. Therefore it’s clear how much important it’s carrying out an identification of supply chain and company critical processes since the beginning, and it’s important a procedure modelling to avoid traceability elevated informative management costs too.

A traceability system offers several services turned to both consumers and companies.

• To consumers: food safety, meant as warranty of ingredients and processes, using the withdrawal from market in emergency cases and, thus, consequent public health protection; frauds detection; animal diseases transmissible to human control; animal health control; warranty increasing of product’s conformity.

• To companies: legislation adjustment; power to adopt swift actions withdrawing from market dangerous products and defending company’s picture; costs reduction for a possible withdrawal of products form commerce; possibility to differ from competitors; possibility to guarantee information truthfulness; supply chain’s internal organization costs reduction; facilitation of supplier choosing and customers monitoring.

1.2 Organizing method for traceability

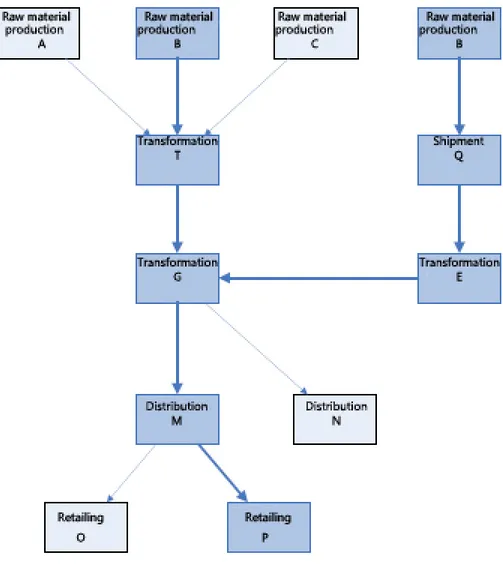

To realize a supply chain’s traceability system we need to define a flow-sheet, meant as identification of the companies, the course of principal raw material and of the most important secondary materials suppliers. Figure 1.2 depicts a sample of supply chain flow-sheet that shows as all participating firms and the roles that they hold.

Figure 1.2: Supply chain flow-sheet

Darker tonality highlights the firms take part in making of a specific product, that it will appear in traceability process. It’s easy to understand that not every firms could participate to the production of each single lot; however we need to establish a supply chain’s organizing method in its entirety and to obtain the assent form every company in the supply chain.

Moreover, we have to identify a figure that organizes and collects traceability important information: this figure is the coordinating node. This one is authorized by firms to collect data and to control the observance of the supply chain’s rules. Besides, the coordinating node acts as designate organ to customers and health authority relationship. It’s supervisor of activities carried on supply chain’s firms and it manages the trackability system, the data management and process documentation modalities and responsibilities also.

On the basis of a tracking system must be an agreement among the firms and the coordinating role, the so-called “supply chain pact”; which it’s made up of some important documents:

• Documentary system: it integrates the technical disciplinary by handbooks and forms. • Work flow: it identifies the flow of materials within supply chain.

• Controls plan: it contains control types and modalities.

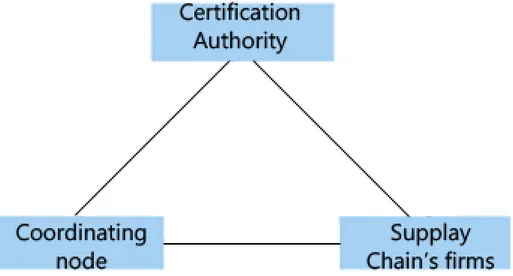

The traceability system would be submitted to a self-control and voluntary certification discipline, and it’ll work well only if there’s a complete collaboration among the three principal factors (see Figure 1.3): the supply chain’s firms, the coordinating node and the certification authority.

Figure 1.3: Interaction among supply chain principal actors

A firm’s agreement to a some supply chain is put into legal form by a purposes declaration, what is subscribed from the same firm, and it entitles the coordinating node to show clearly the firm’s name whenever a user, either public or private, calls for a whatever information about traceability.

1.3 Traceability process' basic units

The products that are inside a supply chain are managed by trackable parts that can be physically tracked in certain points of the supply chain self. The whole of these products is called traceability or identification lots, and we have not to confuse them with the logistic lots. It’s important to remember that we need to identify only the supplier firm, thus we can consider belonging to the

same lot the masses contained in different receptacles if they have homogeneous characteristics, then they came from the same productive process.

Input and output identification lots’ management critical point must be controlled by registration of date, product identification, firm and sites’ names, total weight of considered lot. Therefore, within a traceability system we need to individualize principal composing elements, which can be summarized in the operation of identification and registration lots, the awareness of linking among lots selves and the communication among supply chain actors.

1.3.1 Identification

Identification lies in individualization of lots that were previously exposed to the same transformation process. The management of such productive processes must occur by lots, because traceability refers to a physically identifiable product; doing so it’s possible a timely recognition of firms contributed to the process. Managing traceability means giving a single identification to each assemblage of finished products as well as following its path to retail selling, thus to the final consumer. Thus it’s fundamental, for every distinct firm, the contribution of management informative technologies, meant as capability to read and produce standardized information, and the transferring information method, meant as guarantee of compatibility and coherence of the managed information.

1.3.2 Registration

Managing the traceability system means, in addition, to choose whatever information register among those accumulated during the lot’s path into supply chain. Consequently, it’s necessary to register the only information that allows to reconstruct the:

• Input flows;

• Transformation process; • Output flows.

Regulations oblige the firms to show onto the tag for final customers some information, and therefore to register these information inside business informative systems. Further information, such as those about product’s making are arbitrary and the firm self chooses it as a way to

differentiate its own product among the competitor’s ones. Determining that information could be traced it’s one of most delicate aspect of the entire traceability process. The primary source to carry out this choice is just the final consumer.

We have to add that the mass of information to trace influences in a considerable way the size of a lot: all materials forming it have to present homogeneous characteristics as regards that information. Number of information growing increases consequently the system’s complexity and it can affect lot’s composition, necessary revision operation quantity and, obviously, production costs too. It’s obvious that the supply chain’s traceability system could be efficient only if there’s an updating, archived and easily available registration of information about productive process’ activities and flows.

1.3.3 Links

It’s important to register relations between lots and following logistic units, during the transformation, too. Inside a firm only a capillary link management allows to go up completely to nexus between input and output goods. The firm’s responsible for relations among its suppliers and customers. If any supply chain’s actors don’t manage properly such links, we have a traceability loss.

There are three kind of links that we have to monitor for managing product traceability during all the transformation processes whose they are subjected:

1. Links among production lots: they concern raw materials, packing, and finished products. 2. Links among production lots and logistic units: if logistic units aren’t assembled at the end

of the productive chain, it’s needed to register warehousing and logistic links.

3. Links among logistic units: they are the whole of received and sent logistic units through the supply chain. [5], [6]

1.4 How businesses interact

The cornerstone of the supply chain’s trackability is made by communication process, that is guarantor for the entire system.

Figure1.4: Supply chain flows

Information flow diffusion (see Figure 1.4) may occur in several ways – by papers, electronics or tags – and it’s guaranteed by the specificity of each operator’s tasks; everyone must communicate traced lots characteristics (identifiers) to next operator, allowing it to apply trackability basic principles in its turn.

Therefore, the process is inter-business:to guarantee the success of the trackability system it’s needed to adopt a shared standard among all of supply chain’s actors. This choice present several advantages among them the reinforcement of system itself, obviously, but also the interoperability among business informative systems and the technological independence from a given services provider; a greater efficiency of the logistic system and a considerable decrease of implementation costs.

Chapter 2

Analysis of a real supply chain

In which we examine carefully the description of the supply chain that is subject of this thesis.

2.1 Introduction

After examining in the last chapter the critical factors related to a traceability system, now we are going to try to analyse a real case of food-farming supply chain, as to try applying it to the traceability system. For analysing the supply chain and extracting actors and fundamental processes, we used some documents as “Manuale di corretta prassi per la produzione del cavolo broccolo e verza” by Umbria’s food-farming technological park [7] and the “schede di produzione e post-raccolta” by Region Tuscany (L.R. 25/99) [8].

We’re going to start from a natural language description of the supply chain in exam, trying to highlight all essential aspects for trackability purposes, about vegetables sector; from farming to final consumer distribution. These aspects we’ll guide us to the formulation of a formal model, based on BPMN notation.

2.2 Black cabbage productive processes

Black cabbage is a plant with a two-year biologic cycle, usually annual in agriculture. It has a rooted apparatus that reaches 60 cm, an erect and wooden stem in its basis. Leaves are plain, more or less blistered and wrinkled, dark green or violet coloured, with white vein more or less subtle; its large leafs, that act as shell, form a compact head, with a spherical look more or less flat, with weight from 0,5 to 3 kg and it represents its edible part. The optimal germination temperature is 20°C, while the basic temperature for vegetative growth is 5°C with optimal values between 18° and 22°C. It fits to several kinds of soil preferring the average slurry ones, with optimal PH between 6,5 and 7,5.

Due to erosion risks it’s forbidden to cultivate these plants on soils with average incline greater than 15%. It’s forbidden, besides, the mono-succession; and thus returning of the culture on the same soils can’t take place before two years. Then, the soil part must be well distinguished among them and for every portion must be recorded a cultural intervention registry. The soil preparation takes place with ploughing deep about 40 cm – if available, it’s filled manure with earth – followed by lighter and lighter harrows. Transplantation is the usual implantation technical because direct sowing with successive thinning out, even though more efficient, involves an unable to be borne expense.

It’s not allowed using variety derived from genetically modified organism (O.G.M.), for this reason it’s needed to have a certification of seeding , or seeds, origin given by producer provided tags or cards.

During the vegetative phase, black cabbage need irrigation and nourishing intervention; it’s strictly forbidden using effluents come from transformation and/or purification plants.

Talking about the fertilization, maximum allowed doses of nutritive elements are the following: • Nitrogen 80 kg/hectare;

• Phosphorus 60 kg/hectare; • Potassium 140 kg/hectare; • Magnesium 25 kg/hectare.

The contribution of nitrogen must be fractionated in at least two interventions, unless total contribution could be less or equal to 50% of the maximum allowed contribution. In the case of ferti-irrigation, the maximum quantities must be decreased by 20%.

It’s compulsory the drawing up of a fertilization plan by a technician with a degree in the agricultural sector. To Verify the observance of this plan is needed to adopt a warehouse registry in which fertilizers stocks are booked. Whereas, the interventions must be registered in cultural interventions registry.

The harvest is carried out when the “head” has been reached typical dimension of the cultivar and it seems well-formed and with a compact look. The number and frequency of the crops depend on the cultivar’s kind, but there are usually 2 or 3 harvests every year. The process consists of chopping off the plant onto the soil level by a clean cut. After harvesting, it’s obligatory cleaning the product by each residue caused by the field.

For transport to the conditioning phase, during the harvest the product have to be placed either into plastic washable containers or into wooden, or card, disposable containers. Cabbages must be processed and conditioned within 6 hours since the harvesting.

To guarantee the entire productive supply chain’s traceability is needed that the product is stored in separate and distinct areas by production from different origins. Lots will be marked by cards indicating producer firm’s name, variety and harvesting date.

The product must be processed on distinct lines or, if this couldn’t be possible, on the same line but in different times and only after the line was improved; there must be always guaranteed space-time separation among product form different origins.

The characteristics that the product must possess after conditioning and packaging are: • Not open or pre-in bloom;

• Sound, not afflicted with rottenness; • Not bruised or otherwise damaged; • Exempt form insects and parasites; • Exempt from frost caused alterations;

• Clean, devoid of visible extraneous substances.

The product must be subdivided into categories, defined by the looking, and by gauge, defined by net weight; or the weight of the most heavy ball must be, at the most, double rather then the most light ball in the same packaging. Unitary net weight haven’t to be less to 350 g, with a tolerance of 10% in number or in weight.

Each packaging, or each lot, must contain only products coming from the same origin and be devoid of whatever foreign body. Packaging’, or lot’s, visible part has to be representative of the content. The materials that are used for packaging must be new, clean and made by substances that can’t provoke internal or external alterations to the product. The packaging has to bear, with aligned letters on the same side, readable, indelible and visible from the outside the following information:

• Identification of the packager or of the deliverer; • Product nature, if it’s not visible form the outside; • Product origin;

The product must be preserved into proper cold storage rooms, but it’s compulsory selling it to final consumer within five (5) days since harvesting. The transport must happen by transportation either equipped with freezer or non-conducting.

What is written above represents essential processes and rules to follow for black cabbages production. We individuated responsible actors too, thus they manage primary products; we mention that to traceability purposes it's not needed registering secondary elements such as, e.g., chemical additives, packagings, etc., but for these it's sufficient registering suppliers. Consequently, the firms in the supply chain are:

• Plants supplier

He takes care of seeds cultivation into greenhouse to obtain plants that they will be sold to farmers. Furthermore, he occupies himself with some plants cultivation too; doing so he gets back news seeds.

• Farmer

He's charged with cabbages cultivation, harvesting and the first selection and warehousing. • Packager

He takes care of harvested cabbages conditioning and packaging. • Distributor

Chapter 3

Business Process Management

In which we occupy ourselves in business process management and its categories such as modelling and execution. Then we'll deal with standard like BPMN and BPEL, and BPMS tools.

3.1 Introduction

Business Process Management (BPM) is a field of knowledge at the intersection between management and information technology, encompassing methods, techniques and tools to design, enact, control, and analyse operational business processes involving humans, organizations, applications, documents and other sources of information.[10] The term operational business processes refers to repetitive business processes performed by organizations in the context of their day-to-day operations, as opposed to strategic decision-making processes which are performed by the top-level management of an organization. BPM differs from business process re-engineering, a management approach popular in the 1990s, in that it does not aim at one-off revolutionary changes to business processes, but at their continuous evolution. In addition, BPM usually combines management methods with information technology.

BPM covers activities performed by organizations to manage and, if necessary, to improve their business processes. While such a goal is hardly, new software tools called business process management systems (BPM systems or BPMS) have made such activities faster and cheaper. BPM systems monitor the execution of the business processes so that managers can analyse and change processes in response to data, rather than just a hunch.

In short, Business Process Management is a management model that allows the organizations to manage their processes as any other assets and improve and manage them over the period of time. In a medium to large organization scenario, a good business process management system allows business to accommodate day to day changes in business processes due to competitive, regulatory or market challenges in business processes without overly relying IT departments. This strikes a fine balance between dynamic business areas that want to avoid every risk and grab every opportunity on their way through agile changes in their way to business but are very often restricted by a very stable and hard to change IT infrastructure.

3.2 Business Process Modelling

Business Process Modelling in systems engineering and software engineering is the activity of representing processes of an enterprise, so that the current ("as is") process may be analysed and improved in future ("to be"). BPM is typically performed by business analysts and managers who are seeking to improve process efficiency and quality. The process improvements identified by BPM may or may not require Information Technology involvement, although that is a common driver for the need to model a business process, by creating a process master.

The productive cycle described in Chapter 2 using natural language needs to be reduced to essentials, doing so we could analyse production control informative flows inside the supply chain. Thus it's needed a formalism to model processes in a meaningful form by anyone participates to system design, whoever they are; supply chain actors or stakeholders, among them we can number the future users of BPMS self. Before discussing about tool that was used to model business processes, it's useful doing a brief exploration in supply chain modelling.

3.2.1 Supply Chain Modelling

During past years it has been developed several solutions to modelling supply chain business process, among them we chose to examine the following ones:

• SCOR model; • GSCF model;

• RosettaNet standard; • BPMN notation.

3.2.2 SCOR Model

The SCOR (Supply Chain Operations Reference) model, developed by the Supply Chain Council (SCC), measures total supply chain performance. It is a process reference model for supply-chain management, spanning from the supplier's supplier to the customer's customer. It includes delivery and order fulfilment performance, production flexibility, warranty and returns processing costs,

inventory and asset turns, and other factors in evaluating the overall effective performance of a supply chain.

Due the nature of SCOR model, a firm has to adapt its business processes to model ones; it's not possible to follow the opposite path. Adhering to SCC, and thus using SCOR model, costs a few thousands dollars. [11]

The model is based on 3 major "pillars": • Process Modeling;

• Performance Measurements; • Best Practices.

Due the aim of this thesis work, we're going to examine just the Process Modeling Pillar.

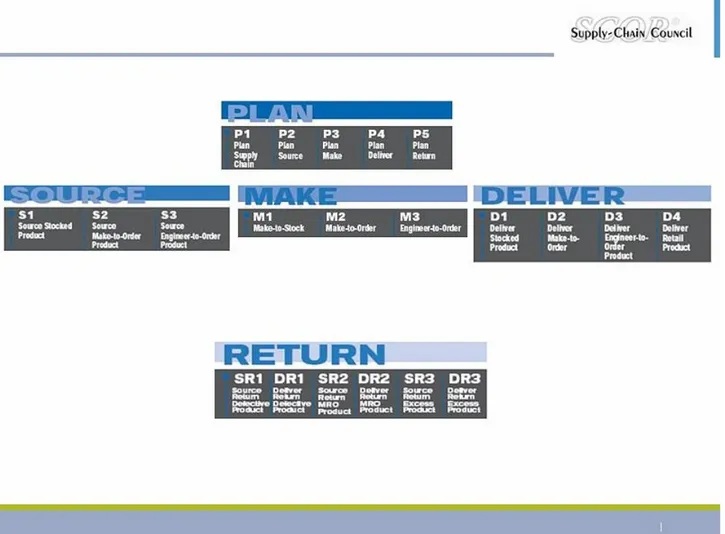

3.2.2.1 The Process Modeling Pillar

SCOR is based on five distinct management processes: Plan, Source, Make, Deliver, and Return. • Plan - Processes that balance aggregate demand and supply to develop a course of action

which best meets sourcing, production, and delivery requirements.

• Source - Processes that procure goods and services to meet planned or actual demand. • Make - Processes that transform product to a finished state to meet planned or actual

demand.

• Deliver - Processes that provide finished goods and services to meet planned or actual demand, typically including order management, transportation management, and distribution management.

• Return - Processes associated with returning or receiving returned products for any reason. These processes extend into post-delivery customer support.

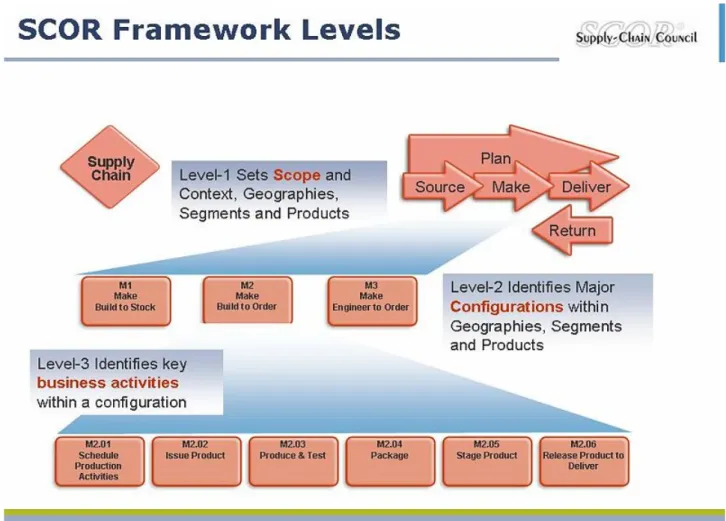

SCOR provides three-levels of process detail (see Figure 3.1). Each level of detail assists a company in defining scope (Level 1), configuration or type of supply chain (Level 2), process element details, including performance attributes (Level 3). Below level 3, companies decompose process elements and start implementing specific supply chain management practices.

Figure 3.1: SCOR Process Framework

In the example provided above the Level 1 relates to the Make process. This means that the focus of the analysis will be concentrated on those processes that relate to the added-value activities that the model categorizes as Make processes.

Level 2 includes 3 sub-processes that are “children” of the Make “parent”. These children have a special tag - a letter (M) and a number (1, 2, or 3). This is the syntax of the SCOR model. The letter represents the initial of the process. The numbers identify the “scenario”, or “configuration”.

M1 equals a “Make build to stock” scenario. Products or services are produced against a forecast. M2 equals a “Make build to order” configuration. Products or services are produced against a real customer order in a just-in-time fashion. M3 stands for “Make engineer to order” configuration. In this case a blueprint of the final product is needed before any make activity can be performed. Level 3 processes, also referred to as the business activities within a configuration, represent the best practice detailed processes that belong to each of the Level 2 “parents”.

The example shows the breakdown of the Level 2 process “Make build to order” into its Level 3 components identified from M2.01 to M2.06. Once again this is the SCOR syntax: letter-number-dot-serial number.

The model suggests that to perform a “Make build to order” process, there are 6 more detailed tasks that are usually performed. The model is not prescriptive, in the sense that it is not mandatory that all 6 processes are to be executed. It only represents what usually happens in the majority of organizations that compose the membership base of the Supply Chain Council.

The Level 3 processes reach a level of detail that cannot exceed the boundaries determined by the industry- agnostic and industry-standard nature of the SCOR model. Therefore all the set of activities and processes that build - for instance - the M2.03 “Produce & test” process will be company-specific, and therefore fall outside the model’s scope. [12]

Figure 3.2: Caption from SCOR 8.0

SCOR model quotes many times terms such as data collection and data management, within several activities, but it never mentions product traceability and trackability explicitly. [13]

3.2.3 GSCF Model

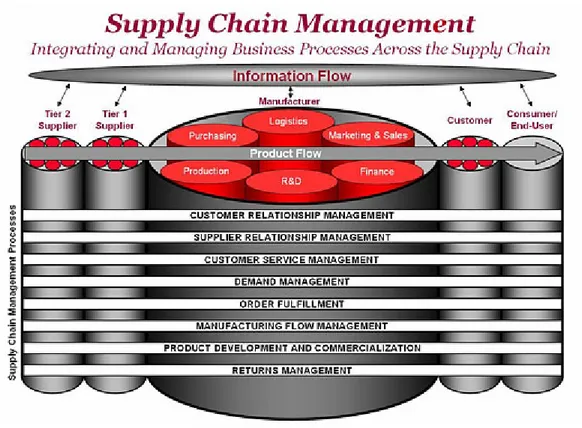

The Global Supply Chain Forum (GSCF) introduced another Supply Chain Model (SCM). This framework [14] is built on eight key business processes that are both functional and cross-firm in nature. Each process is managed by a cross-functional team, including representatives from logistics, production, purchasing, finance, marketing and research and development. While each process will interface with key customers and suppliers, the customer relationship management and supplier relationship management processes form the critical linkages in the supply chain.

GSCF model processes are:

1. Customer Relationship Management; 2. Supplier Relationship Management; 3. Customer Service Management; 4. Demand Management;

5. Order Fulfilment;

6. Manufacturing Flow Management;

7. Product Development and Commercialization; 8. Returns Management.

Figure 3.3: GSCF Model – Supply Chain Management Processes

3.2.3.1 Customer relationship management

It provides the structure for how the relationships with customers will be developed and maintained. Management identifies key customers and customer groups to be targeted as part of the firm’s business mission. The goal is to segment customers based on their value over time and increase customer loyalty by providing customized products and services. Cross-functional customer teams tailor Product and Service Agreements (PSA) to meet the needs of key accounts and for segments of other customers. The PSAs specify levels of performance. The teams work with key customers to improve processes and eliminate demand variability and non-value added activities. Performance reports are designed to measure the profitability of individual customers as well as the financial impact on the customer.

3.2.3.2 Supplier relationship management

It is the process that defines how a company interacts with its suppliers. As the name suggests, this is a mirror image of customer relationship management. Just as a company needs to develop

relationships with its customers, it also needs to foster relationships with its suppliers. As in the case of customer relationship management, a company will forge close relationships with a small subset of its suppliers, and manage arm-length relationships with others. A PSA is negotiated with each key supplier that defines the terms of the relationship. For segments of less critical suppliers, the PSA is not negotiable. Supplier relationship management is about defining and managing these PSAs. Long-term relationships are developed with a small core group of suppliers. The desired outcome is a win-win relationship where both parties benefit.

3.2.3.3 Customer service management

It is the firm’s face to the customer. It provides the key point of contact for administering the PSA. Customer service provides the customer with real-time information on promised shipping dates and product availability through interfaces with the firm’s functions such as manufacturing and logistics. The customer service process may also include assisting the customer with product applications.

3.2.3.4 Demand management

It is the supply chain management process that balances the customers’ requirements with the capabilities of the supply chain. With the right process in place, management can match supply with demand pro-actively and execute the plan with minimal disruptions. The process is not limited to forecasting. It includes synchronizing supply and demand, increasing flexibility, and reducing demand variability. A good demand management process can enable a company to be more proactive to anticipated demand, and more reactive to unanticipated demand.

3.2.3.5 Order fulfilment

This process involves more than just filling orders. It includes all activities necessary to define customer requirement and to design a network and a process that permits a firm to meet customer requests while minimizing the total delivered cost as well as filling customer orders. This is not just the logistics function, but instead needs to be implemented cross-functionally and with the

coordination of key suppliers and customers. The objective is to develop a seamless process from the supplier to the organization and to its various customer segments.

3.2.3.6 Manufacturing flow management

It is the supply chain management process that includes all activities necessary to move products through the plants and to obtain, implement and manage manufacturing flexibility in the supply chain. Manufacturing flexibility reflects the ability to make a wide variety of products in a timely manner at the lowest possible cost. To achieve the desired level of manufacturing flexibility, planning and execution must extend beyond the four walls of the manufacturer in the supply chain.

3.2.3.7 Product development and commercialization

It is the supply chain management process that provides the structure for developing and bringing to market products jointly with customers and suppliers. The product development and commercialization process team must coordinate with customer relationship management to identify customer articulated and unarticulated needs; select materials and suppliers in conjunction with the supplier relationship management process; and, develop production technology in manufacturing flow to manufacture and integrate into the best supply chain flow for the product/market combination.

3.2.3.8 Returns management

It is the supply chain management process by which activities associated with returns, reverse logistics, gate-keeping, and avoidance are managed within the firm and across key members of the supply chain. The correct implementation of this process enables management not only to manage the reverse product flow efficiently, but to identify opportunities to reduce unwanted returns and to control reusable assets such as containers. Effective returns management is an important part of SCM and provides an opportunity to achieve a sustainable competitive advantage. [15]

3.2.4 SCOR-GSCF comparison

SCOR and GSCF are similar in the fact that they both advocate cross-functional connectedness and recognize that business processes will not replace corporate functions. However, the number of corporate functions included in each framework is different and the type of cross-functional connectedness differs as well.

The SCOR framework is focused on interaction among a few key functions, while GSCF is focused on integration across all corporate functions.

Another key component of a business process approach is the degree of connectivity with other companies in the supply chain. The GSCF and SCOR frameworks represent examples of the two approaches to implementing business processes. While GSCF focuses on managing relationships in the supply chain, SCOR focuses on the achievement of transactional efficiency.

In summary, SCOR connects with other members of the supply chain through transactional activities related to the source, deliver, and returns processes. In contrast, the GSCF framework links firms in terms of customer-supplier relationships where all the processes are coordinated through the customer relationship management and supplier relationship management processes. [16]

3.2.5 RosettaNet Standard

RosettaNet is a non-profit consortium aimed at establishing standard processes for the sharing of business information (B2B). RosettaNet is a consortium of major Computer and Consumer Electronics, Electronic Components, Semiconductor Manufacturing, Telecommunications and Logistics companies working to create and implement industry-wide, open e-business process standards. These standards form a common e-business language, aligning processes between supply chain partners on a global basis.

The RosettaNet standard is based on XML and defines message guidelines, business processes interface and implementation frameworks for interactions between companies. Mostly addressed is the supply chain area, but also manufacturing, product and material data and service processes are in scope.

The standard is widely spread in the global Semiconductor Industry, but also electronic components, consumer electronics, telecommunication and logistics. RosettaNet originated in the US and is widely used there, but it is also well accepted and even supported by governments in Asia. Due to the wide spread use of EDIFACT (Electronic Data Interchange For Administration, Commerce, and Transport) in Europe, RosettaNet is used less, but it is growing. [17]

RosettaNet is similar to another XML-based B2B integration initiatives, namely ebXML (Electronic Business using eXtensible Markup Language) . ebXML is often described as a horizontal B2B standard, meaning a set of specifications that is common to all e-business; it is general and not specific to any particular sector or industry. RosettaNet, on the other hand, is a vertical standard; it focuses on the needs of specific industries (for example, electronic components manufacturers) and the business area of supply chain automation and optimization. [18]

Adopting any of mentioned above standards wasn't possible due the high economical effort; thus we chose to use a freely available, well-known standard to model our supply chain business processes: we selected the BPMN standard.

3.3 Business Process Modeling and Notation

The Business Process Management Initiative (BPMI) has developed a standard Business Process Modeling Notation (BPMN). Nowadays, the BPMN standard is maintained by the Object Management Group (OMG) since the two organization merged in 2005. The primary goal of BPMN is to provide a notation that is readily understandable by all business users, from the business analysts that create the initial drafts of the processes, to the technical developers responsible for implementing the technology that will perform those processes, and finally, to the business people who will manage and monitor those processes. Thus, BPMN creates a standardized bridge for the gap between the business process design and process implementation.

Another goal, but no less important, is to ensure that XML languages designed for the execution of business processes, such as WS-BPEL (Web Services Business Process Execution Language), can be visualized with a business-oriented notation.

BPMN specification defines the notation and semantics of a Business Process Diagram (BPD) and represents the amalgamation of best practices within the business modelling community. The intent of BPMN is to standardize a business process modelling notation in the face of many different modelling notations and viewpoints. In doing so, BPMN will provide a simple means of

communicating process information to other business users, process implementers, customers, and suppliers.

The membership of the BPMI Notation Working Group and OMG has brought forth expertise and experience with many existing notations and has sought to consolidate the best ideas from these divergent notations into a single standard notation. Examples of other notations or methodologies that were reviewed are UML Activity Diagram, UML EDOC Business Processes, IDEF, ebXML BPSS, Activity-Decision Flow (ADF) Diagram, RosettaNet, LOVeM, and Event-Process Chains (EPCs). [19]

BPMN is a core feature of BPM that is in fact bringing together the previously separate areas of Process Modelling, Simulation, Work-flow, Enterprise Application Integration (EAI), and Business-to-Business (B2B) integration into a single standard (BPM).

3.3.1 BPMN 2.0

The Business Process Model and Notation is the name of the working proposal for BPMN 2.0[20] The vision of BPMN 2.0 is to have one single specification for a new Business Process Model and Notation that defines the notation, meta-model and interchange format but with a modified name that still preserves the "BPMN" brand. The proposed features include:

• Aligning BPMN with the Business Process Definition Meta-model (BPDM) to form a single consistent language;

• Enabling the exchange of business process models and their diagram layouts among process modelling tools to preserve semantic integrity;

• Expand BPMN to allow model orchestrations and choreographies as stand-alone or integrated models;

• Support the display and interchange of different perspectives on a model that allow a user to focus on specific concerns;

• Serialize BPMN and provide XML schemas for model transformation and to extend BPMN towards business modelling and executive decision support.

The recommendation for the new BPMN is scheduled to be ready within 2008. There are two different groups working on competing drafts of the specification. The first group, including e.g. EDS and MEGA, aims at incorporating BPDM directly into the BPMN specification. The second group, including e.g. SAP, IBM and Oracle, does not want to include BPDM directly, but instead

provide a mapping between both standards. Since July 2008, both groups discuss how to merge both drafts to come up with a single specification. [21]

For this thesis work we used the BPMN 2.0 specification.

3.3.2 BPMN Scope

BPMN will be constrained to support only the concepts of modelling that are applicable to business processes. [19] This means that other types of modelling done by organizations for business purposes will be out of scope for BPMN. For example, the modelling of the following will not be a part of BPMN:

• Organizational structures and resources; • Functional breakdowns;

• Data and information models; • Strategy;

• Business Rules.

In addition, while BPMN will show the flow of data (messages), and the association of data Artefacts to activities, it is not a data flow Diagram.

3.3.3 Uses of BPMN

Business process modelling is used to communicate a wide variety of information to a wide variety of audiences. BPMN is designed to cover many types of modelling and allows the creation of end-to-end business processes. The structural elements of BPMN will allow the viewer to be able to easily differentiate between sections of a BPMN Diagram.

There are three basic types of sub-models within an end-to-end BPMN model: 1. Private (internal) business processes;

2. Abstract (public) processes; 3. Collaboration (global) processes .

Private business processes are those internal to a specific organization and are the type of processes that have been generally called work-flow or BPM processes. If swim lanes are used then a private business process will be contained within a single Pool. The Sequence Flow of the Process is therefore contained within the Pool and cannot cross the boundaries of the Pool. Message Flow can cross the Pool boundary to show the interactions that exist between separate private business processes.

Figure 3.4: Example of Private Business Process

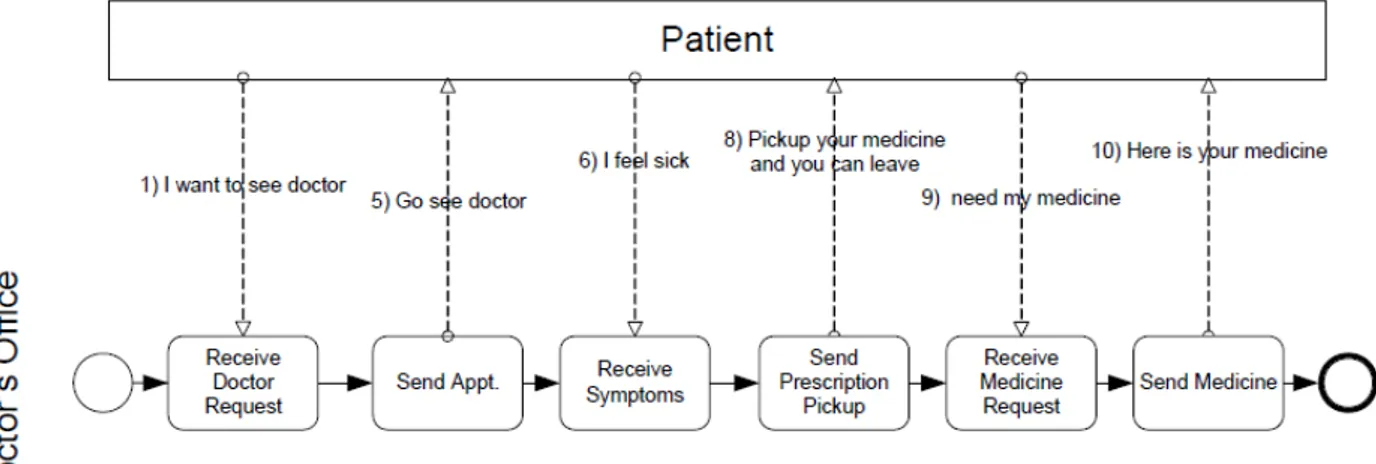

3.3.3.2 Abstract (Public) processes

This represents the interactions between a private business process and another process or participant. Only those activities that communicate outside the private business process are included in the abstract process. All other “internal” activities of the private business process are not shown in the abstract process. Thus, the abstract process shows to the outside world the sequence of messages that are required to interact with that business process. Abstract processes are contained within a Pool and can be modelled separately or within a larger BPMN Diagram to show the Message Flow between the abstract process activities and other entities. If the abstract process is in the same Diagram as its corresponding private business process, then the activities that are common to both processes can be associated.

Figure 3.5:Example of an Abstract Business Process

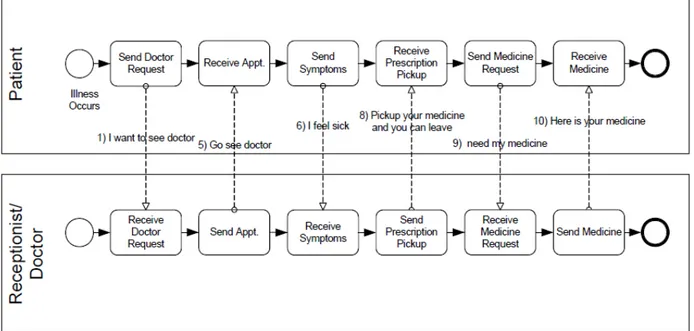

3.3.3.3 Collaboration (Global) processes

A collaboration process depicts the interactions between two or more business entities. These interactions are defined as a sequence of activities that represent the message exchange patterns between the entities involved. Collaboration processes may be contained within a Pool and the different participant business interactions are shown as Lanes within the Pool. In this situation, each Lane would represent two participants and a direction of travel between them. They may also be shown as two or more Abstract Processes interacting through Message Flow (as described in the previous section). These processes can be modelled separately or within a larger BPMN Diagram to show the Associations between the collaboration process activities and other entities. If the collaboration process is in the same Diagram as one of its corresponding private business process, then the activities that are common to both processes can be associated.

Figure 3.6:Example of a Collaboration Business Process

3.3.4 BPD objects

It should be emphasized that one of the drivers for the development of BPMN is to create a simple mechanism for creating business process models, while at the same time being able to handle the complexity inherent to business processes. The approach taken to handle these two conflicting requirements was to organize the graphical aspects of the notation into specific categories. This provides a small set of notation categories so that the reader of a BPMN diagram can easily recognize the basic types of elements and understand the diagram. Within the basic categories of elements, additional variation and information can be added to support the requirements for complexity without dramatically changing the basic look and feel of the diagram. The four basic categories of elements are:

1. Flow Objects; 2. Connecting Objects; 3. Swimlanes;

4. Artifacts.

Flow Objects are the main graphical elements to define the behaviour of a Business Process. There are three Flow Objects:

1. Events; 2. Activities; 3. Gateways.

Events

Events are things that “happen” during the course of a business process. Events affect the flow of a process and usually have a cause (trigger) or an impact (result). Events are circles with open centres to allow internal markers that differentiate triggers or results. There are three types of Events:

• Start;

• Intermediate; • End.

Start and most Intermediate events can have multiple triggers that are used to describe the cause(s) for the event. End Events may define a Result that is a consequence of the Sequence Flow ending. Boundary events define a trigger or result that occurs on the boundary of an event.

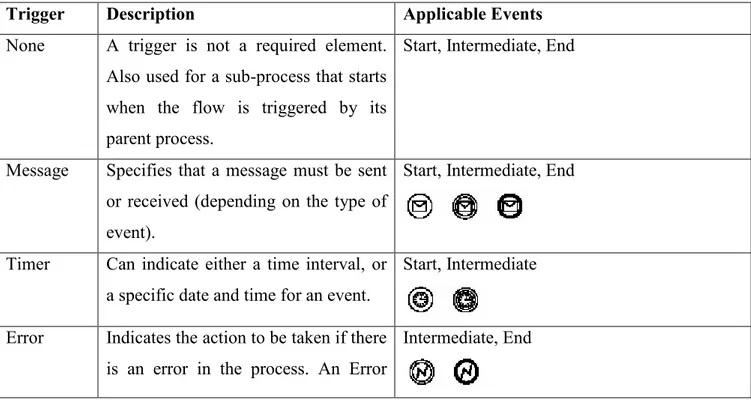

The available triggers are Message, Timer, Error, Cancel, Compensation, Rule, Link, Multiple, Terminate. The following table specifies which triggers can be used with which events, and the graphic marker (icon) for each one.

Table 3.1: Events

Trigger Description Applicable Events

None A trigger is not a required element. Also used for a sub-process that starts when the flow is triggered by its parent process.

Start, Intermediate, End

Message Specifies that a message must be sent or received (depending on the type of event).

Start, Intermediate, End

Timer Can indicate either a time interval, or a specific date and time for an event.

Start, Intermediate

Error Indicates the action to be taken if there is an error in the process. An Error

trigger can only be placed on the border of a sub-process.

Cancel Cancels the process. Often used with a transaction process to indicate that if part of the transaction (a sub-process) errors, the entire transaction will be canceled.

Intermediate, End

Compensat ion

Indicates the relationship between two activities. For example, a Compensation trigger might link a database with the associated “rollback” data.

Intermediate, End

Rule Specifies that the associated rules must be applied to the process or activity.

Start, Intermediate

Link Used to associate multiple pages of a model.

Start, Intermediate, End

Multiple Illustrates that multiple triggers apply to the process or activity.

Start, Intermediate, End

Terminate Ends all branches of a model, unless it is placed on a sub-process.

End

Activities

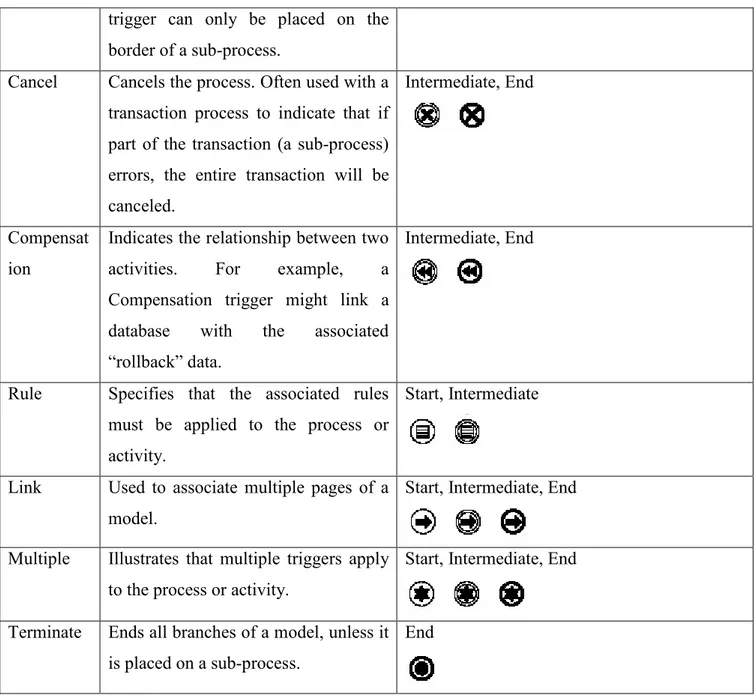

An activity is work that the company performs within a business process. An activity can be a task (atomic) or a sub-process (a compound, also referred to as non-atomic). A sub-process is a standalone work-flow, which has its own start event and end event.

The following table lists available task markers.

Table 3.2: Activities

Task A Task is a discrete item of work. It is the lowest level of activity, one that cannot be further divided into smaller components.

Standard Loop A Standard Loop activity will have a Boolean expression that is evaluated after each cycle of the loop. If the expression is still True, then the loop will continue.

Multiple Instances

Multi-Instance loops reflect the programming construct for each. The loop expression for a Multi-Instance loop is a numeric expression evaluated only once before the activity is performed. The result of the expression evaluation will be an integer that will specify the number of times that the activity will be repeated.

Compensation A Task with Compensation associates the task to another element in the model. It occurs outside the normal flow of the process and is based on an event triggered by the failure of a transaction.

An activity that might require compensation could be one that charges a buyer for some service and debits a credit card to do so. These activities usually need a separate activity to counter the effects of the initial activity. Often, a record of both activities is required, so this is another reason that the activity is not “undone.” An Intermediate Event of type Compensation is attached to the boundary of an activity to indicate that compensation may be necessary for that activity.

A sub-process is a compound activity that is included within a task (process). Each task may have its own sub-processes. Each sub-process can also contain other sub-processes.

The details of the sub-process are not visible in the diagram. A “plus” sign in the lower-centre of the shape indicates that the activity is a sub-process and has a lower level of detail. A sub-process can be independent, embedded, or referenced.