II level Master Diploma on Management and Control of Environment: Circular Economy and efficient management of resources

Academic year

2018/2019

Circular economy strategy in Eni,

assessment and implementation

opportunities in the Upstream Division

Author

Fabio TomaselliAcademic tutor

PhD Eleonora AnnunziataCompany tutor – Eni SpA

1

TABLE OF CONTENTS

ABSTRACT ... 2

INTRODUCTION ... 3

1. OIL AND GAS SECTOR ... 6

1.1 The Oil and Gas industrial processes ... 6

1.2 International Oil Company (IOC) ... 7

1.3 Eni S.p.A. ... 9

1.4 Legal framework ... 10

1.5 Scope of work ... 12

2. CIRCULAR ECONOMY IN THE OIL AND GAS SECTOR ... 13

2.1. Circular Economy in Eni S.p.A. ... 17

2.2. Environmental challenges for Eni S.p.A. ... 18

2.2.1.Greenhouse gases (GHG) ... 19

2.2.2.Water treatment and management ... 21

2.2.3.Waste treatment and management ... 22

2.2.4.Oil Spill ... 23

2.2.5.Remediation ... 24

2.2.6.Assets Decommissioning ... 24

2.2.7.Energy efficiency ... 25

2.2.8.Environmental Impact Assessment (EIA) ... 26

2.2.9.Renewable Sources ... 27

3. CASE STUDY: CIRCULAR ECONOMY AND FOCUS ON Eni UPSTREAM .. 28

3.1. Circularity analysis ... 30

3.2. Circularity analysis in Eni Upstream ... 34

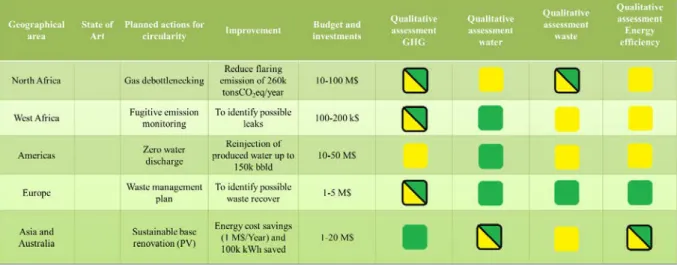

3.3. Screening of subsidiaries’ projects ... 34

3.4. Mapping of subsidiaries’ projects by geographical area ... 38

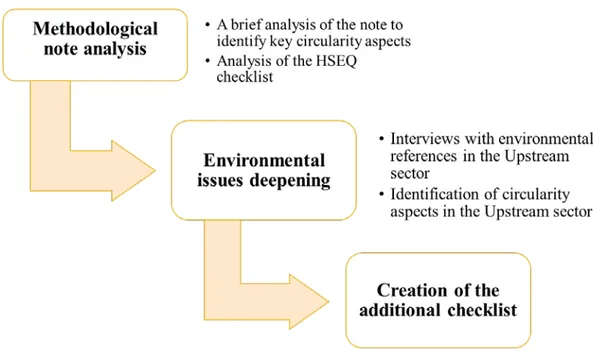

3.5. Supplementary checklist ... 47

4. CONCLUSION ... 51

REFERENCES ... 53

2

ABSTRACT

The energy sector in the coming years will tackle two complicated challenges: an adequate, secure and widespread supply of energy, and efforts to fight climate change by trying to reduce greenhouse gas emissions. In this regard, oil and gas companies have recently become aware of their effective contribution by implementing circular economy actions to protect the environment and minimize the use of natural resources. In this context, Eni SpA, the main Italian Oil and Gas Company with an international and strategic positioning, has embraced the concepts of circular economy in all the stages of its value chain. In particular, Eni's HSE departments jointly operate to provide indications on the circularity performance o the operating sites of each Business Unit since 2017. Therefore, the project work has analysed, one of the strategic components of the company, the Upstream sites of the foreign subsidiaries in order to provide more in-depth indications on the circularity aspects. Thus, a dual-task has been carried out:

1. The qualitative plans of the subsidiaries have been analysed to highlight the projects with the greatest value in terms of circularity, to map subsidiaries that have integrated circularity into their operations and to select one of the subsidiaries for a further circularity analysis;

2. Based on the documents provided by Eni Support Function and consulting the representatives of each thematic area on the environmental subjects, we developed and provided a supplementary checklist for conducting circularity analysis focused on the Upstream activities.

3

INTRODUCTION

Since the beginning of the Industrial Revolution and until now, the global economy has been based on a linear economy model consisting of “take, make, use and dispose” activities. According to the linear model, companies take raw materials, process and convert them into products, which are then sold to consumers who use them until needed and then dispose of them. This model has been used because people always thought that unlimited availability of natural resources used to make the products. The other fact is that this economic model entails an unending economic growth and the corresponding consumption of resources. Finally, it is assumed that the planet can handle all of the waste that we produce at every stage of this process. The truth is that we cannot have this overconsumption mindset anymore.

All the companies have to change their model of consumption, trying to reduce the raw material extraction as possible as they can do. For example, we can divert from the linear economy with the recovering of products already used and their exploitation in order to avoid their disposal or the use of alternative energy sources, trying to replace carbon fossil fuels with renewables. These are only a few examples of what can enhance the transition from a linear to a circular economy, «an economy that is restorative by intention and design, it replaces the end-of-life

concept with restoration»1. The concept of circular economy emphasizes on creating

closed-loop systems where waste production is reduced and the used products could gain value if reintroduced in the flow process as the new type of raw material2. The circular economy can be implemented in all the industrial sectors, but the pivotal issue is associated with the need for a cultural and structural change. We have to watch out on our daily consumption model trying to produce less waste, but on a global scale, companies have to modify their model of production, especially decreasing the raw material supply and enhance the transition to a more efficient energy system for the manufacturing services. In this context, one of the sectors that cause the highest environmental impact is the energy sector, which is trying to convert its linear economy model to a circular one.

The energy sector is one of the most resources’ exploiter, providing the majority of the energy for manufacturing purposes, not only for our personal uses. Our reliance on energy is one of

1 Definition of Circular Economy created by Ellen MacArthur Foundation and published in 2013 on Towards the

Circular Economy. Economic and business rationale for an accelerated transition.

2 The definition of Circular Economy of Ellen MacArthur Foundation seeks to rebuild capital, whether this is

financial, manufactured, human, social or natural. This ensures enhanced flows of goods and services. The Foundation created a “butterfly” diagram ( https://www.ellenmacarthurfoundation.org/circular-economy/concept/infographic) to illustrate the continuous flow of technical and biological materials through the ‘value circle’.

4

the main challenges that we have to face because of our pursuit of growth through the linear economy and, based on the United Nations forecast, the world population will reach 9.5 billion people by 20503, so the energy demand will continuously grow. Energy has been the driver of our economies’ development, we have always burnt fossil fuels (such as coal, oil and gas) to obtain energy until the recent technologic development to use alternative sources in an efficient way. We now know that fossil fuels, while they are efficient stores of energy, come with side effects. The pollutants they release are harmful to human and the entire ecosystem, while on a global effect the greenhouse gases (GHGs) they release are causing climate change that is starting to have profound effects on people around the world. In 2013 a study showed that two-thirds of the industrial greenhouse gas emissions are due to the fossil-fuel production of just ninety companies around the world (between 1751 and 2010, with half emitted since 1986)4.

Oil and gas are one of the most important resources in the world and this sector plays a crucial role in the global economy. However, the activities of oil and gas sector from most of the companies in the world have many negative impacts on the environment and we can consider this sector as the one who more embraces the linear economy model than others do. Although this sector represents this kind of model, there are high prospects for circular economy elements mainly because Oil and Gas companies are trying to diversify their energy assets. Actually many researchers are creating more and more business ideas for Oil and Gas companies to implement sustainable initiatives. In fact, there is a strong commitment by the companies, especially by the Research & Development departments that try to promote and implement sustainable technologies in the facilities for the operation processes. Some of these applications will further be discussed in the next paragraphs.

Once we have identified the economic, social and legal boundaries in which an oil and gas company have to deal with, we can analyse and discuss the commitment and the many attempts of Eni, the Italian Oil and Gas Company, for the transition to a circular economy. Following the agreements that Member States of United Nations took in the past years, Eni has tackled the main environmental challenges concerning climate change, resource depletion (especially water5), environmental monitoring and soil restoration. In order to comply with the

3 United Nations: Department of Economic and Social Affairs. World Population Prospects 2019: Highlights.

Work published on 06/17/2019, URL site:

https://population.un.org/wpp/Publications/Files/WPP2019_Highlights.pdf

4 R.HEEDE. Tracing anthropogenic carbon dioxide and methane emissions to fossil fuel and cement producers,

1854–2010. Article first access on 11/22/2013, published on Climatic Change on January 2014, Ed. Springer.

5 The environmental matrix mostly involved in the drilling operation is the water. Indeed, in the facilities where

oil production occurred, there is a huge exploitation of water for drilling or facility cleaning, so there is high amount of water to be treated.

5

sustainability objectives, there is also specific attention for what concern the social issues such as security of work environment, protection of the local communities and efforts to support them economically.

In the next paragraphs, the case study of Eni Upstream will be discussed, analysing the projects developed by the HSE Department in a circular economy perspective. The aim of this engagement by the Upstream Business Unit is to adapt the principles of Circular economy, even if the core processes regard the oil extraction.

6

1. OIL AND GAS SECTOR

1.1 The Oil and Gas industrial processes

The oil industry includes the processes of exploration, production, refining, transporting (often by oil tankers and pipelines), and marketing of petroleum and its derivative products. The largest volume products of the industry are fuel oil and gasoline, but the extracted oil is also used as raw material for many chemical products, including plastics, pharmaceuticals, solvents, fertilizers, pesticides and synthetic fragrances6. The oil and gas industry accounts for more than 57% of total global fuel consumption. The fuel mix is evolving to include more renewables, but hydrocarbons are expected to remain the dominant source of energy powering the world economy by 20357. The oil and gas industry is usually divided into three sectors of its supply chain:

• The upstream division, it consists of processes that involve exploration and discovery of new wells whether onshore or offshore, fields drilling and crude oil and natural gas production. The industry produced an average of 96.3 million barrels of oil per day in 20168. In recent years, there is an evident shift towards the inclusion of unconventional

gas as part of the upstream sector, also affecting the developments in processing and transporting Liquefied Natural Gas (LNG);

• The midstream operations, usually combined with the downstream sector, include stocking and transport of oil and gas, this segment in the supply chain, involves the transportation, storage and marketing of various oil and gas products. Transportation options can vary from small connector pipelines to massive cargo ships making trans-ocean crossings, depending on the commodity and distance covered;

• The downstream operations, with the operation of refining raw materials to obtain gasoline and natural gas. It includes the refining, processing and purification before converting it into usable and consumable products, for example, fuels, raw chemicals and finished products.

6 A. MUSPRATT. Introduction to Oil and Gas Industry. Article published on Oil and Gas iQ, URL site:

https://www.oilandgasiq.com/strategy-management-and-information/articles/oil-gas-industry-an-introduction

7 British Petroleum - Statistical Review of World Energy, 2019. URL Site:

https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2019-full-report.pdf

7

Our analysis is focused on the activities and facilities of the upstream division since it is the first process of the big and complex supply chain of the Oil and Gas industry. Therefore, it is crucial to identify key aspects of this division that can be analysed according to a circular economy perspective, with the aim to reduce ‘waste’ flows as much as possible and to optimize the midstream and downstream operations. As an example of how can be difficult to implement a circular economy on the upstream sector, we can consider the first operation, the exploration of a new well. There is no certainty in the investigation model to explore a new production well, the only way to know it is to drill a preliminary well and to evaluate if the oil amount is enough to start-up the withdrawal. To avoid needless drilling and then to minimise waste production, tools are used to calculate and to simulate the drilling operations in order to be the more accurate possible. In this way, technological progress and company investments are fundamental to develop powerful tools, these instruments can help the company to cut the cost of waste treatment and to enhance the production.

To sum up, the main drivers that the Oil and Gas sector have to undertake are:

• Continuous technological development all along the oil and gas supply chain. This is the first step to create and to promote transition actions to the circular economy, a modern industry will always tend to leave old technologies that use linear economy; • Life cycle thinking, since it is necessary that the circular perspective begins already in

the planning phase. The solutions to be provided should be the most favourable for the environment, the most economical and socially acceptable during the entire life cycle; • Continuous monitoring on the environmental matrices. Real-time monitoring of the

impacts of the supply chain, especially for the extraction operations can be essential to quickly identify where to implement a sustainable approach;

• A systemic approach in which all independent but related parties in a given system align their actions. Creating partnerships along the value chain is essential. For example, industrial symbiosis in connecting industrial clusters more and more is a way to increase resource efficiency. The partnership mechanism can involve different companies to create proactive joint ventures with the aim to achieve social, economic and environmental goals set up by International Committees.

8

International Oil Company (IOC) is a term used to identify the main Oil and Gas companies. It refers usually to Shell, BP, Texaco, Chevron Corporation, ExxonMobil, Total and Eni9 and they have a relevant role in decisional and politic actions based on their market position and geographical location where they operate. Cooperation between these “superpowers” and other operating companies is fundamental, especially if this teamwork added to international institutions is aimed to promote environmental and social performance. In 1974, the most important Oil and Gas Companies joined their forces to create the International Association of Oil and Gas Producers (IOGP)10, it represents the upstream oil and gas industry before international organisations that underlie the UN. Another role of IOGP is to share best practices to achieve improvements in health, safety, environment and social responsibility.

To coordinate each company whether for upstream or downstream operations an NGO was born later than the IOGP creation. International Petroleum Industry Environmental Conservation Association (IPIECA) is a no-profit institution that for 30 years has been working to harness the oil and gas industry’s collective expertise and technology on environmental concern. Moreover, IPIECA is also the industry’s principal channel of communication with the United Nations. IPIECA started to cooperate with the International Association of Oil and Gas Producers (IOGP) from 2012 to 2017, as a response to the oil spill incident in the Gulf of Mexico of 2010. This partnership created a Joint Industry Project on oil spill response (OSR-JIP), which produced over its lifetime:

• 24 Good Practice Guides (GPGs), covering response, strategy, preparedness and impacts;

• 11 technical and research reports, developed to communicate technical good practice or to make it accessible to external parties;

• Several outreach and communication materials, including reports about social and environmental responsibility, focusing on industry commitment to UN targets such as SDGs.

The Oil and Gas companies understood that this cooperation among them and with international organisations is fundamental to gain success into this transition and to fight against the climatic and environmental issues.

9T.BERGIN,Oil majors' output growth hinges on strategy shift, Reuters, published on August 1, 2008. URL site:

https://www.reuters.com/article/us-oilmajors-production/oil-majors-output-growth-hinges-on-strategy-shift-idUSL169721220080801.

9

1.3 Eni S.p.A.

Eni S.p.A. is the main Italian Oil and Gas Company, based in 67 countries worldwide with a global workforce of 30,950 employees. It was found in 1953 as a replacement of Agip, a State oil Company, from a vision of its founder Enrico Mattei. The core business of Eni for Upstream operations is a continuous growth through new oil and gas fields’ exploration and production, seeking new energy resources to create long-term value so that everyone can have access to energy in an efficient way. During the last year, Eni reaches a new record of hydrocarbon production of 1.85 million of boe/day11, with a hydrocarbon reserve of 7,153 million of boe that places Eni in a strategic position into the Oil and Gas market, to strive against the impossibility for poor countries to reach energy, aiding communities where its operations occur. For the Downstream sector, Eni is involved in oil refining to create and sell fuels and other petroleum products mainly in Italy and chemical products from renewables. Moreover, Eni diversified its portfolio with new strategies that involve restructuring this sector to improve its efficiency and productivity, biorefinery and green chemistry underpin Eni's green economy, increasing its investments to produce energy in a sustainable way from renewable sources. This transition has been pursued with speed of action by leveraging skills, know-how and technologies and placing the sustainability of its business model at the heart of the strategy12. To achieve the target of sustainability, Eni operates also with its societies integrated into the chemical environment, Versalis, and Eni Rewind for the remediation, environmental recovery and securing of disused industrial sites. Further initiatives with circular economy value will discuss in a dedicated paragraph, in order to underline the proactive positioning of Eni for the transition to a circular economy and its commitment to sustainability.

The strategic target of the business is a continuous production increase, handling diversified assets globally widespread, creating synergies between projects and strengthening relations with producer Countries. As one of the targets of its business model, Eni is committed in create value and promote social initiatives in the countries in which it operates, trying to develop intellectual capital of its employees or just creating sustainable projects among the local communities.

11 Barrel of oil equivalent per day.

12 The business strategy can be found and consulted on Eni for 2018 – Sustainability Report,

10

Cooperation among its societies, subsidiaries, competitors and international organisations gives Eni a powerful mean to promote the energy transition; in this way Eni is one of the best-positioned company in the Oil and Gas sector, giving it a strong decisional power that could be relevant to reach the most critical environmental targets.

1.4 Legal framework

Eni has to work in a complex legal framework, which includes the technical feasibility of each facility linked to relationships and agreements with local authorities and oil companies. These agreements helped Eni in strengthening and improving its technologies, but it is not enough to promote sustainable development and environmental protection. With this perspective, for each facility built in Italy and in all the countries where Eni is placed, the company strategy includes the compliance of local legislation, act to promote the main principles of sustainable development. In this framework, the Upstream business unit, whose activities are exploration and production, could have some problems to keep stable the sustainability performance. For the majority of the activities, there are strategies that can be implemented in order to enhance the transition to a circular economy. Eni has to comply with European legislation and their implementation in Italy about the main environmental matrices. Moreover, in the subsidiaries’ countries, where there are no environmental laws or are not as strict as in Europe, Eni applies to its facilities European legislation to fill the regulatory gap. The key Directives are:

• Directive 2008/98/EC, implemented in Italy with the Environmental Code (d.lgs. 152/2006 and its revisions), recently modified by the Directive 2018/851/EU; this Directive is part of the Circular Economy Package13 which is the European policy

strategy to achieve the transition to a circular economy. The Directive 2008/98/EC represents the legal reference for waste management, detailing its development to guarantee environmental and health protection;

• Directive 2000/60/EC which sets out rules to halt deterioration in the status of European Union (EU) water bodies and achieve ‘good status’ for Europe's rivers, lakes and groundwater by 2015. Specifically, this includes protecting all forms of water (surface, ground, inland and transitional), restoring the ecosystems in and around these bodies of

13 Circular Economy Package was introduced in 2018 as part of the shift of EU policy to the circular economy, it

includes four legislative proposal that emending six old Directives, introducing new waste management targets regarding reuse, recycling and landfilling.

11

water, reducing pollution in water bodies, guaranteeing sustainable water usage by individuals and businesses;

• Directive 2004/35/EC on the environmental liability with regard to the prevention and

remedying of environmental damage and the introduction of the polluter-pay principle.

The Directive set a clear definition of environmental damage14, the scope and who is

“affected” by this kind of responsibility, such as the activities of oil and Gas Companies. Moreover, the Directive defines how companies must act when the damage occurs; • Directive 2018/410/EU, which modifies the Directive 2003/87/EC and establishes the

regulation of Emissions Trading System (ETS). The Climate and Energy Framework for 2030 has set a strict goal for the companies interested by ETS. By 2030, they are required to lower the emissions by 43% with respect to the levels of 2005, in order to attend the Paris Agreement.

14Environmental damage means: (a) damage to protected species and natural habitats, which is any damage that

has significant adverse effects on reaching or maintaining the favourable conservation status of such habitats or species; (b) water damage, which is any damage that significantly adversely affects the ecological, chemical and/or quantitative status and/or ecological potential, as defined in Directive 2000/60/EC, of the waters concerned, with the exception of adverse effects where Article 4(7) of that Directive applies; (c) land damage, which is any land contamination that creates a significant risk of human health being adversely affected as a result of the direct or indirect introduction, in, on or under land, of substances, preparations, organisms or micro-organisms.

12

1.5 Scope of work

The present study developed thanks to the cooperation of the Upstream Business Unit of Eni S.p.A., in particular with the SEQ (Safety, Environment and Quality) department in San Donato Milanese (MI), aims to improve the circular economy opportunities in the company’s subsidiaries, in order to go ahead the linear economy model and to promote the transition into a circular economy perspective.

The analysis is focused on two targets:

• Screening of circular economy projects planned for the subsidiaries of Eni Upstream, in order to create a mapping and to identify the most relevant potential projects in a circular economy perspective. This analysis could be the point of departure of the potential circularity analysis that could be performed starting from 2020 for the plants of the Eni Upstream subsidiaries;

• Create a supplementary checklist with questions focused on the “core business” activity for the Eni Upstream plants. This additional checklist could be integrated into the original one developed by Eni Support Function or it could be independent and published as an attachment, regarding exclusively the facilities of Eni Upstream.

13

2. CIRCULAR ECONOMY IN THE OIL AND GAS SECTOR

As mentioned in the previous chapter, the oil and gas industry can have some opportunities to implement circular economy actions, but the sector needs a huge collaboration between each company and their stakeholders in order to achieve environmental, social and economic sustainability targets. This attached cooperation is necessary and it can be driven not only by following the legislation in a mandatory way but also acting proactively adhering to programmes or agreements took by the countries. Therefore, there is no only the legal framework to determine the oil industries’ business strategy and opportunities, but all the sector participates in policies promoted by the European Union’s bodies. As a part of these agreements, the companies, with the member States, adhered to the 7th Environmental Action

Programme, adopted in 2013 by the European Parliament and the European Union Council. One of the goals of the Programme is the will to build a Europe «with a low carbon emissions

economy, with an efficient management and use of resources, eco-friendly and competitive»

and «to protect the European citizens from pressures and environmental risks that could affect

their health and wellness»15.

One of the most important agreements that can be cited is the Paris Agreement, adopted in November 2015 by 196 states and signed in 2016. The Paris Agreement was developed during the 21st Conference of Parties (COP 21) within the United Nation Framework Convention on Climate Change (UNFCCC) with the aim to involve the parties against air emissions concerns. The main target of the Paris Agreement is to limit the increase in global average temperature below 2 °C above pre-industrial levels and to try to lower the increase to 1.5 °C, recognizing that this could decrease the risks and impacts of climate change. The commitment of the parties with the companies is to lower emissions as soon as possible, in order to «achieve a balance

between anthropogenic emissions by sources and removals by sinks of greenhouse gases16» in

the second half of the 21st century.

To promote sustainability and the circular economy there are not only international programmes or action plans developed by the United Nations. Often to go further into the development dynamics of a company, it is necessary to refer to associations or foundations (private or NGOs) that mainly deal with supporting companies, providing them with useful tools for progress in the world of the circular economy. An organisation that was born with the intent to help industries of all sectors to apply principles of the circular economy is the Ellen MacArthur

15 Decision n. 1386/2013/EU, «Living well, within the limits of our planet», art. 2, clause 1, letters b) and c). 16 United Nation, The Paris Agreement, art. 4.

14

Foundation. This organisation was found by Sir Ellen MacArthur in 2009 and every year it publishes a series of reports with the aim to support industries in their continuous development. One of the main goals of the Ellen MacArthur Foundation, and that can be considered one of the pillars of sustainable development is the intent to maintain the same world for our descendants and to offer them the same opportunities and to meet people’s needs, without harming the natural processes while giving an opportunity to provide natural resources and ecosystem services according to the Sustainable Development Goals. One of the aims of the circular economy is to decouple economic growth and development from the consumption of non-renewable resources. Increasingly, companies see tremendous opportunity in this model, as it not only allows them to capture additional value from their products and materials but also to mitigate risks from material price volatility and material supply17. To help people to

understand the principles of the circular economy, how to apply them and how to quantify in order to manage their continuous improvement, different kind of indices are developed, based on the preliminary information. The indices were created by European, national or independent consortia, but it cannot be unusual to find an index referred to the performance of a single company. The Ellen MacArthur Foundation recently developed the Circularity Indicators Project that stands for measure and implements raw material flows in order to quantify how ‘circular’ a company is18. The main issue about this tool is that it can only measure the flows

of goods or products. But in this case, it could be complicated to measure the circularity of all the oil and gas sector, from the facilities to the activities of the product. A further step into the feasibility of the application of the circular economy into the Oil and Gas sector could be the creation of an Index, possibly general for all the oil companies, which will help to evaluate the desired circularity level. This kind of Index could be useful to measure the performance of an oil company on the circular economy area and to compare performance with competitors. Yet before the Paris Agreement’s sign, voluntary initiatives were spread to involve Oil and Gas companies, public administrations and citizens to aware of environmental topics, such as the Oil and Gas Climate Initiative. The OGCI is a voluntary initiative created by CEOs of the major Oil and Gas industries, which will permit the sector to collaborate to address climate issues. Eni was one of the five founders of the OGCI and together with the other “superpowers”, they promote investments in innovative projects to lower the carbon emissions of the energy and industrial sectors and their value chains. The main targets of this initiative are reducing methane

17 Ellen MacArthur Foundation, Towards the Circular Economy. Economic and business rationale for an

accelerated transition, 2013

15

leakage, reduction and reuse of carbon dioxide with advanced technologies such as carbon capture storage and use (CCUS). Thanks to their coalition, OGCI invested in 2017 $6.3 billion in R&D for low carbon technologies, this fact underlines how is important the commitment of Oil and Gas companies against climate issues thanks to their financial power19.

Related to the OGCI there is the Climate and Clean Air Coalition (CCAC), it was established in 2012 to treat short-lived climate pollutants as an urgent and collective challenge. CCAC’s approach integrates climate action and air quality efforts, strengthening the commitment to the Paris Agreement against global warming and empowering the achievement of the Sustainable Development Goals. The key strategies of the CCAC focus on the capability to transform financial investments into practical actions, providing knowledge, physical and technical resources to achieve benefits for the climate and clean air.

If we technically analyse all the Oil and Gas value chain, we can notice that there are opportunities from upstream to downstream to implement new principles of the circular economy. In the upstream, there are numerous chances for recycling and reuse, many efforts and progress are made in recycling and reusing produced water from the production wells or reusing drilling fluids and chemicals to avoid their treatment as a waste. Many of the tools and equipment used in the facilities are made from steel, a good material easy to recycle. The decommissioning of an offshore platform is managed in order to dismantle all the parts that can be recycled and to reuse the assets that cannot be ripped to pieces, many projects are trying to convert decommissioned assets for the fishery or other types of farm20. The possibilities for integrating the circular economy in this sector include also the energy efficiency, preserving energy in our operations through cogeneration using spent steam, waste gas, and heat exchangers. Eni faced all these topics considering them as opportunities to improve its quality standard, providing technical guidelines that explain in an operative way how to handle these environmental issues, with the aim to implement these ‘opportunities’ in a circular economy perspective.

The downstream has opportunities to address both water use and advanced materials such as catalysts and chemicals. As an example, spent catalysts and chemicals could be recovered and recycled from the refining process, but it is not so easy and refiner plants have to develop successful methods to recover these matters. They can also conserve energy and use spent heat and steam to generate power to meet refinery needs, with the potential to export excess power

19 OGCI Annual Report – 2018.

16

to a nearby grid. The sector’s procurement strategy should begin to consider the extent to which suppliers take sustainable and circular approaches to products21.

The petrochemicals portion of the Oil and Gas industry began making R&D investments more than a decade ago to address the environmental aspects of plastics. While plastic has made a huge difference in so many areas of human life and activity, it was purposely designed to be very durable and have a long life cycle. Plastics are non-biodegradable materials that must be treated, recycled, or disposed of after use.

Renewable energy sources started to be used to supply energy systems since the 1970s with the aim to decrease the energy supply by fossil fuels. By then, technology developed efficient systems such as wind, PV, biomass and many more for environmental reasons whether to decrease the global dependence of fossil fuels22. Renewables are expected to be the

fastest-growing source of energy, with their share in primary energy increasing to 10% by 2035, up from 3% in 201523. Nevertheless, the energy supplied by renewable sources is not enough to

fulfil the global energy request, whether for installed power or for its production variability (due to adverse climate conditions). In this way, still, there is a huge contribution of fossil fuels to satisfy energy demand and the growth of the world population could reflect on an increase in fossil fuel extraction. A first step towards the circular economy transition is the replacement of coal and crude oil with natural gas as fossil fuel. This is mainly due to the less CO2 emissions,

in fact, one million BTU produced by natural gas emits 50% less CO2 compared with coal and

25% less compared with gasoline24.

The circular economy is still quite immature according to some researchers, this is because as we have said before, companies have been conceived with a different mentality, so changing towards this new type of growth model will take a long time. Eni, as one of the world's leading oil and gas companies, has shifted its focus to this new business model to ensure ever more profitable growth, guaranteeing adequate standards for fighting environmental problems and supporting sustainability.

21 S.ALNUAIM,Circular Economy: A Sustainability Innovation and Solution for Oil, Gas, and Petrochemical

Industries. Journal of Petroleum Technologies. Published in May, 01 2019, URL site:

https://pubs.spe.org/en/jpt/jpt-article-detail/?art=5340

22 B.SØRENSEN, A history of renewable energy technology, published on Energy Policy in 1991, volume 19,

page: 8-12.

23 British Petroleum Energy Outlook – 2017, URL site:

https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/energy-outlook/bp-energy-outlook-2017.pdf

24Considering the U.S. Energy Information Administration data as source, the combustion of coal, gasoline and

natural gas emits respectively, 105 kg, 71 kg and 53 kg for BTU produced, URL site:

17

2.1. Circular Economy in Eni S.p.A.

Eni’s business model is focused on creating value for its stakeholders and shareholders. Eni recognizes that the main challenge in the energy sector is providing efficient and sustainable access of local communities to energy resources while fighting against climate change. Therefore, Eni puts its efforts into operational excellence to enhance its efficiency processes, gaining a high-value resources portfolio and a strong influence on investments along all the value chain. One of the key points of its strategy is the implementation of the decarbonisation to achieve carbon neutrality in 2030. But there is no only the targets’ achievement made by the technical feasibility. Since Eni is placed in so many countries, its strategy involves also the support for the local communities where Eni is present, in order to promote social health, culture and welfare.

The UN’s 2030 Agenda for Sustainable Development, presented in New York in September 2015, identifies 17 Sustainable Development Goals (SDGs) which represent common goals for the current complex challenges and are an important reference for the international community. The goals seek to expand on the eight anti-poverty goals of the now-expired Millennium Development Goals (MDGs). The oil and gas industry’s operations and products potentially have positive and negative impacts on a range of areas covered by the SDGs, including on communities, ecosystems and economies. The industry contributes to sustainable development in a number of ways. These include generating direct and indirect jobs; supplying access to energy that enables economic activity and social development and many more. As part of these global challenges, energy plays a fundamental role in the achievement of primary needs, for the socio-economic development of Countries, and for the protection of the environment and international security.

With this awareness, in its 2019-2022 Strategic Plan, Eni has set the objectives to contribute directly or indirectly to the achievement of the SDGs and below are some examples that are then detailed in the document25.It is time to invest in a system that optimises the production of

goods by reducing the exploitation and disposal of resources. As an energy company, Eni's priority is to supply an ever-increasing amount of energy, satisfying the increasing demand, and cleaner energy as defined by the goals number 7 and 13 of the SDGs. To do this it established specific targets, such as a reduction of the intensity of emissions by 43% in the upstream sector, an 80% reduction in fugitive emissions, all targets set for 2025. In addition, Eni’s intention is

25 For an in-depth analysis of the Eni’s commitment to the SDGs, we advise to read Eni for 2018 - Sustainability

18

to build more assets to provide energy where this is scarcely available. To do this, Eni's commitment is also addressed to the SDGs number 8 and 9, which respectively guarantee a fair economic growth and an increasingly satisfactory development of the infrastructures. This is possible thanks to a continuous financial investment aimed at the professional growth of its employees and the creation of synergies with local communities, developing projects in which we try to maximize the use of resources and reduce the waste of raw materials, in order to enhance not only natural capital but also human capital.

Simultaneously to the hydrocarbon production activities, Eni shall protect a series of environmental factors that are well described in the SDGs by goals 6, 14 and 15, which respectively guarantee the use of high-quality water resources, the preservation of marine ecosystems and land. In its strategy, Eni pays particular attention to the management of water discharges, reducing procurement as much as possible from sources with poor renewability, or in asset construction operations, minimizing as much as possible the impacts on flora and fauna. The companies have to work every day with the engagement to respect the environment, converting waste into biofuels, transforming refineries into bio-refineries and reclaiming existing assets. In order to move beyond the culture of waste, Eni has also launched many research projects to transform chemical elements into biomass that can be reused in industry and in society. As a serious commitment to the environmental protection, we tried to focus on some key aspects involved on the operations of production of the oil and gas sector, underlining the major environmental impacts and the ways to contain them.

2.2. Environmental challenges for Eni S.p.A.

The Oil and Gas sector is always engaged in the continuous improvement of performance to increase earnings but, at the same time, it has to guarantee environmental protection during its activities. The management of environmental impacts, for example in terms of reduction of greenhouse gases emissions, permits to lower the effects of production on the environment. This is fully coherent with the circular economy perspective because it reduces the use of natural resources and waste production. The Upstream operations have to face many issues regarding the related activities of the field’s exploration and hydrocarbons’ extraction; some of these issues are strictly regulated by European Directives or local legislation aforementioned in paragraph 1.4. Eni operates in different geographic contexts that require specific evaluation of environmental aspects in order to minimise the activities’ impacts. In Italy, but also for most of the countries, the exploration activities are subject to a declaration of environmental compatibility made by the competent Authorities. This declaration is released only after a few

19

in-depth studies that highlight the environmental criticisms and impacts that could be generated. Moreover, as a result of the declaration, different methodologies are advised with the aim to reduce the risk of damage. In the absence of this environmental declaration, the exploration activity cannot be allowed. Among other environmental issues, there are greenhouse gas emissions, which are the main topic to fight the global warming effect and there are rigid limits of emission imposed by Authorities. But there is no only global warming, the legislation has to promote biodiversity defence, especially in some fragile areas where human activity could be disruptive for the ecosystem. For instance, most of the production facilities are offshore rigs and in this context, Eni has to cooperate with Public Administration and local activities (such as tourism, fisheries, etc.) to minimise the anthropic effect. The possibility to face up environmental issues can give some chances and opportunities to act positively for the promotion of the circular economy. Suitable management systems, for example, water or waste management systems, can help the companies to manage incoming and outflow of materials, with the possibility to lower as much as possible waste production. But even these waste could be ‘good’ for the circular economy possibilities, in fact, they can be converted into by-products used for alternative combustion way, or they can also reconvert as raw materials for production, and oil and gas sector has many ways to implement these strategies.

To ensure a uniform and adherent approach to the best international technologies and practices, Eni adopts a health, safety and environment (HSE) management system integrated into all the facilities and production units. The compliance with local administration and Directives is guaranteed by the supervision of the SEQ department, which provides Technical Guidelines that define the technical standards for health, safety and the environment in all the activities. Moreover, this series of documents underline some of the practices that can improve the circular level of each operation of Eni upstream, from the waste and water management to the environmental or air quality monitoring plan. To understanding how much these Technical Guidelines are an efficient tool to manage the impacts of the production operations and, at the same time, to highlight some key points to favour actions in a circular economy perspective, in the following paragraphs the main areas influenced by Eni's activities (but this is also effective for the other oil companies) are shown, and the possible remedies that are applied.

2.2.1. Greenhouse gases (GHG)

It is often thought in the oil companies that the refining process to obtain gasoline and other fuel products, or the combustion of these products to obtain energy, are the majority processes for greenhouse gas emissions. The reality is that this kind of emissions can occur in the

20

upstream process too, from seismic exploration and drilling to all the extraction phase of oil and natural gas, during pipeline transport and tank stock. The main greenhouse gases that could be emitted in these phases are CO2 that is the principal as amount of molecules emitted in the

atmosphere, CH4 and N2O, usually reported as tons of CO2 equivalent. In addition, methane

and nitrous oxide are chemical species more impactful than carbon dioxide on the effects of the global warming, respectively methane is 28 times and nitrous oxide 265 times more powerful than CO226, so the commitment is increased to lower these pollutants. The oil companies have

to face also some chemicals that contribute to the photochemical smog, such as NOx, SOx,

VOCs and PAH, usually emitted during the refining process or fossil fuels combustion. During production, transport, and storage, there are different procedures that regulate gas emissions for normative duty either for economic reasons, in fact, sometimes it could not be remunerative to recover this kind of gases but it depends on the technical feasibility of the recovering process. The main types of gas emissions in the upstream process are:

• Flaring, a process where there is a controlled combustion of the associated gas, which is not reinjected or reused for technical or economic reasons;

• Fugitives, unintentional emissions of a volatile gas (such as methane, propane or butane from plant facilities), do to component (valves, flanges, etc.) corrosion or breakage; • Venting, intentional volatile gas emissions due to normal functioning of the plant

equipment (compressors, controllers and pumps, storage tanks, etc.) or to the periodical maintenance activity (major turnaround);

• Stationary fuel combustion for transport or power generation.

Eni, as previously mentioned, acknowledges having to face the challenge to climate change, thus, it has adopted a series of strategies to obtain a low-carbon portfolio, mainly promoting in the Upstream sector the emission reduction of the flaring process, supporting above all a continuous progress thanks to the research and development projects that allow identifying new possibilities of reuse of the associated gas or of the CO2 emitted. Eni planned also strict

monitoring on the fugitive emissions in order to identify possible leakages and repair it.

26 IPCC is the Intergovernmental Panel on Climate Change. The IPCC was created to provide policymakers with

regular scientific assessments on climate change, its implications and potential future risks, as well as to put forward adaptation and mitigation options. As part of the Greenhouse Gas Protocol, IPCC published in 2014 its Fifth Assessment Reports where are listed chemicals and their 100-year time horizon global warming potentials (GWP) relative to CO2.

21

For the other activities, Eni pushed its strategy on the promotion of the use of natural gas instead of oil or coal combustion, furthermore, it is strictly involved in the implementation of renewable energies, with a cross-approach with other relevant environmental aspects, for example, the production of biofuels that as a lower carbon footprint, and the facility conversion from conventional refineries to biorefineries. An aspect not to be underestimated is the production of acid gases correlated to the activity of oil or gas extraction. In the latter, in fact, there may be variable quantities of H2S, which is a very powerful pollutant easily breathable, causing damage

to the environment and to humans. To overcome this problem, Eni has equipped some of its plants with higher H2S content with desulphurisation plants, which allow them to obtain

elemental sulphur ready for sale.

2.2.2. Water treatment and management

Produced water is the largest waste stream generated in oil and gas industries, it is a mixture of organic and inorganic compounds found on the water associated with the extraction of crude oil after the drilling. The ratio between the produced water found on the reservoir and the oil extracted is called water cut, the more the oil is extracted from its reservoir, the greater the amount of produced water that must be treated and destined for disposal or reuse. The treatment and disposal of produced water may be carried out in various ways, depending on whether it is produced on land or at sea. Produced water usually is reinjected in the oilfield as disposal, but it depends on the characteristics of the field. In fact, on offshore sites, the water could be reinjected or discharged at sea after being rendered compatible under the law in force target. To improve the efficiency of oil production, the produced water can be reinjected to increase the pressure of the reservoir for recovering additional oil and to prevent withdrawal from external water basins. A significant aspect concerns the commitment of Eni Upstream to increase the percentage of re-injected production water, with particular attention to its operating sites. This measure makes it possible to avoid the impacts associated with the superficial discharge of these waters, at the same time allowing them to be enhanced in cases of re-injection for IOR (Improved Oil Recovery). Many efforts are done by the Research and Development unit of each oil company to solve the problem of wastewater treatment, especially for the high treatment cost and the variability of the process that can be implemented, based on the position of the facilities. In fact, in onshore facilities, biological pre-treatment of oily wastewater can be a cost-effective and environmentally friendly method.

22

The operations produce several billion barrels of wastewater. Much of that water is brine, which can be environmentally damaging if not properly disposed of. But brine contains a high content of minerals that can potentially be extracted and sold to other industries. The wastewater can be further treated and used in other operations or disposed of. Where possible, disposal to the original formation can help to maintain reservoir pressure, increase recovery, and eliminate environmental impact.

The total freshwater used by Eni in its Upstream activities is a small amount, only 8%27. Nevertheless, the upstream operations are mainly placed in water stress areas and Eni adopts specific water management plans with the aim to reduce as much as possible the withdrawal of freshwater. Therefore, reinjection could be one of the best practices to avoid water stress.

2.2.3. Waste treatment and management

Waste management of a facility is very complex since it is necessary to deal with both the industrial waste produced during the production operations and the urban waste produced in the factories or offices. Correct waste management goes first of all from the elaboration of a waste management plan in the sites, in order to manage the amount of waste produced, their type and their destiny. Thinking in a circular economy perspective, the waste management plan shall prevent waste formation as much as possible, trying to reuse disused materials where possible, promoting repair. Alternatively, the waste management plan has to provide for a waste recycling system. Eni, in partnership with its subsidiary companies, operates in various sites trying to promote the correct recycling of waste. In fact, collaborating with Versalis, it allows the design and construction of plastic recycling plants where the amount of plastic packaging waste is enough. Not only plastic, but Eni also act on organic waste and, where possible, promotes the possibility of producing compost to be donated to local communities instead of fertilizers, promoting growth and creating a workforce.

The management of industrial waste is more complex, often it is necessary to deal with the sludge produced by the cleaning operations of the equipment, which often must, of due to the composition of extracted material. In some situations, it may be in the presence of radioactive materials28, whose management is entrusted to specialized departments for their correct

27 Eni, Eni for – Decarbonisation Pathway, 2018.

28 Radioactive materials are called NORM and TENORM, as in the definition of EPA: Technologically Enhanced

Naturally Occurring Radioactive Material (TENORM) is defined as, "Naturally occurring radioactive materials that have been concentrated or exposed to the accessible environment as a result of human activities such as manufacturing, mineral extraction, or water processing”. URL: https://www.epa.gov/radiation/technologically-enhanced-naturally-occurring-radioactive-materials-tenorm.

23

disposal. As for drilling operations, the management of drilling cuttings focuses on the possibilities of sludge treatment in such a way to recover muds as much as possible, avoiding waste to be disposed of. Usually, the recovering regards the NADF29 treatment to minimize the production of waste to be disposed of in landfills, or muds’ bioremediation and therefore the reuse of this sludge in drilling operations or their reuse as a raw material for other industrial processes. It is working on re-design its facilities, with the aim to use as fewer drilling cuts as possible.

Eni, in its strategic position to reach the commitment of the circular economy perspective, has developed a new project called Waste to Fuel. It is an Eni pilot project, conceived and tested by the Research Centre for Renewable Energy and the Environment of Novara. This is a technology that makes it possible to enhance the solid urban waste in the wet part, the so-called FORSU, and to transform it into biofuel that can be used in the production of electricity and heat, but also it can become part of the components of a particular biofuel useful for cars but also for maritime transport. It is at the site of the Gela refinery, that the first pilot plant dedicated to Waste to Fuel technology has been started to recover this bio-oil from organic waste supplied by the waste management company service in Ragusa.

2.2.4. Oil Spill

An oil spill is an unlucky event where there is an accidental leakage of oil, gas or produced water over the wellhead. This kind of accident can occur in an oil tanker, an offshore platform or on an onshore well, causing water or soil pollution with tremendous environmental effects. The main approach for sustainable management of these accidents is the creation of an emergency plan; this can permit a fast and efficient procedure for removing the spill and avoid the oil dispersion. The onshore oil spill usually occurs for a blowout30, a sort of uncontrolled ‘eruption’ of fluids. If the leak is consistent, the emergency plan involves the company and local authorities to take action in order to stop the blowout and minimise the effects. Eni prepares and upgrades technical documents such as the Emergency Response Plan or the Oil Spill Emergency Plan (OSCP) to control the oil spill operations in order to minimise the oil spread. Unfortunately, the majority of the oil spill is due to sabotage, so one of the actions took by Eni is the enforcement of the commitment of the Authorities and the replacement and

29 NADF stands for non-aqueous drilling fluids. These are usually oil based muds used for drilling operation. 30 ENI S.P.A. AND SCUOLA ENRICO MATTEI. Hydrocarbons: origin, exploration and production. Chapter 12,

24

improvement of facilities along the pipeline and the tank stocks. Moreover, Eni will reinforce controls and monitoring of storage with direct surveillance. Thanks to the progress made by the R&D Division, Eni can count on innovative systems that allow rapid identification of any leaks and intervene before an oil spill occurs. Moreover, thanks to the efforts of the R&D, new materials are being studied that could be used in oil spill interventions, especially offshore.

2.2.5. Remediation

Environmental remediation of sites used for the production and treatment of hydrocarbons is carried out mostly in situation where the reservoir production activity has terminated and its infrastructures are dismantled and decommissioned; these operations are necessary to eliminate or render harmless substances accumulated over time which could pollute soil and groundwater. Depending on the mechanism on which they are based, the technologies used during remediation operations may be chemical, physical, thermal and biological. The remediation processes may be applied directly at the site contamination without any movement of the soil, the so-called in-situ remediation, or they can be applied after excavation, the ex-situ operation that can be done on-site or off-site if the polluted soil is brought to a treatment plan.

Eni adopts an environmental monitoring plan for its production sites so that it can act immediately in the event of damage or leakage and possible land pollution. Furthermore, based on the type of operating site and the characteristics of the soil, it already establishes at the planning stage which type of environmental remediation can be used. Nevertheless, in particular contexts, a more detailed analysis can be applied at the end of the extraction activities to be sure of the use of a technique with the least possible environmental impact.

2.2.6. Assets Decommissioning

When offshore and onshore platforms are soon to reach or have already reached their mature phase, measures will need to be taken for their eventual removal. Decommissioning is the total or partial shutting of an asset from its operation and the removal, where required or if it is possible, of all the facility, included the equipment and structures. The aim of the decommissioning is to turn the site into the existing condition before extraction’s operation. After their decommissioning, these platforms are a potential source of huge amounts of materials that could be reused in other activities or could be sold for income. The results of decommissioning activities have to guarantee that the site, including any facility that is not removed, is left in a condition that is safe for the general public and the environment. Before

25

the decommissioning takes place, a risk assessment is necessary to understand the possible options of intervention, from the complete removal to the possible reuse with another type of goal.

Thanks to the guidelines written by Eni, the procedure of decommissioning is already involved in the preliminary phases of development of a new extraction well, in order to easily understand what could be the end-use of the structures. This preliminary study is in line with the circular economy perspective because the extraction facilities can be designed in order to reduce as much as possible the raw materials for the construction, and moreover, this could enhance the reuse of equipment. Thanks to this approach that could be compared to the life cycle thinking, the decommissioning can allow, for example, the reuse of an offshore asset as a support for community activities, such as fishery. Sometimes the complete decommissioning of the facilities cannot be possible because the presence of equipment, all along with the plant life, created marine biodiversity that cannot be destroyed and it has to be preserved. Moreover, one of the most efficient reuses of these platforms is the creation of a wind electricity generator that enhance renewable energy sources and mitigate GHG emissions due to energy production.

2.2.7. Energy efficiency

Usually, energy efficiency indicates a result in the use of energy, based on how and how much this energy is potentially used to reach a specific efficiency target. It is represented as the ratio between the useful output of an energy conversion machine and the input, in energy terms. On the Upstream facilities, the energy efficiency is used to express the lord production of hydrocarbons (in terms of toe31), using as little energy as possible for machinery. The energy used for the extraction machines typically is fuel gas, diesel or electricity from the grid, so the target is to optimize this process in order to produce as much hydrocarbon as possible using the same amount of energy or trying to reduce the use. At the base of the efforts to enhance the energy efficiency is the continuous commitment to the Paris Agreement and the compliance with the GHG targets and the climate change challenge. The commitment to the Climate Strategy, combined with the results achieved to date and the targets set, has allowed the inclusion of Eni - the only one among the majors in the Oil & Gas sector - within the "A list"

26

of the CDP1132, which represents the main reference of the stock markets to assess the performance, strategies and management of climate change risk.

These results have increased and reinforced Eni's credibility in the fight against climate change. As mentioned above, a first effort is to replace the current facilities that need energy derived from fuel combustion, with machinery or compressors that exploit the gas recovered from the plant itself. In this way, the efficiency of the machinery is absolutely higher and the CO2

emission is reduced.

2.2.8. Environmental Impact Assessment (EIA)

The Upstream area operates in many different countries, but all the activities shall guarantee the environmental requirements. In this scenario, Eni provides a technical guideline to all the HSE departments to evaluate the environmental feasibility of a new project. In fact, standard procedures to evaluate new business opportunities provide for an Environmental Context Evaluation (ECE) during the development phase of a project, which addresses the Upstream area need for an early identification and analysis of environmental sensitivities and supports decision-making.

Typically, an ECE summarizes the available environmental information and their sources, used for the risk categorization, providing potential environmental criticalities and issues for the development of the project. To sum up, ECE provides a preliminary screening and evaluation of environmental sensitivities that shall be confirmed/managed in the subsequent Environmental Impact Assessment (EIA) process. The objective of EIA is to identify and assess potentially significant environmental impacts related to exploration activities (gravimetric and magnetic survey, seismic survey, exploration drilling) and development (design, construction, drilling, operation, construction technologies and decommissioning). Other targets underlined by the EIA are the identification and mapping of stakeholders, in order to evaluate and develop exploration project activities and all the possible alternatives (including geographical location and technical options). With the EIA the company can define a baseline against which changes induced by exploration activities/projects can be monitored, or it can help to identify potential business risks and opportunities or implement monitoring and management plans for the

32 CDP11: former Carbon Disclosure Project. A non-profit organization that offers companies and countries a

system to measure, detect, manage and share information on climate change. The largest companies listed on the stock exchange are invited to complete a questionnaire, from which their commitment and the policies adopted with regard to this issue emerge.

27

identified potential impacts to guarantee the protection of the natural and human environment, enhancing the positive impacts of exploration activities/new projects.

EIA gives various possibilities for the circular economy to be implemented since this is a preliminary analysis and it provides the basic information to the feasibility of a project. Thanks to the EIA, Eni could identify circular actions regarding the minimisation of environmental impacts, such as waste and water management, feasibility studies for the improvement of GHG emissions, or energy-efficient site development. One of the best implementation in a circular economy perspective and it can be taken into account during this impact assessment is the design manufacturing of the plant, in this way it can be minimised the use of less raw materials with cost savings for the company.

2.2.9. Renewable Sources

As we mentioned before, the conventional way to produce energy is by combustion of fossil fuels such as coal, oil and natural gas that are natural sources but they are finite sources. We are starting to run out of these fossil fuels and their processing methods contribute to the increase in the greenhouse effect. As a result, a series of alternative renewable energy sources have been identified that can be used without having to worry about them running out one day. These sources are the sun, water, and geothermal resources, tides, waves and the transformation of vegetable products or organic and inorganic waste. As such, the following can be described as renewable energies: geothermal energy; hydroelectric energy; marine energy; solar energy; wind energy; biomass energy; waste-to-energy; energy or cogeneration from groundwater. Eni added to its traditional business the green fuel production through the conversion of the Venice and Gela traditional refineries into biorefinery thanks to Ecofining -a proprietary technology-which enables the production of green diesel by using different typologies of biological origin raw materials (virgin vegetable oils, waste oils and oils coming from processes that treat other biological origin material, also including waste, animal fats and by-products from the food industry). Focus on the sustainability of biomass used is a priority and Eni, beyond the definition of a specific policy, is carrying out initiatives related to first-generation feedstock substitution. Recently, with the start-up of the plant in October 2019, Eni improved its portfolio of renewable source facilities building the “Bhit Solar Project” in Pakistan. The photovoltaic plant is built near the Bhit Gas Plant in order to support the Upstream operations. With its 10 MW of power plant installed, the plant could save 144 ktons CO2eq emissions during the entire

28

3. CASE STUDY: CIRCULAR ECONOMY AND FOCUS ON Eni UPSTREAM

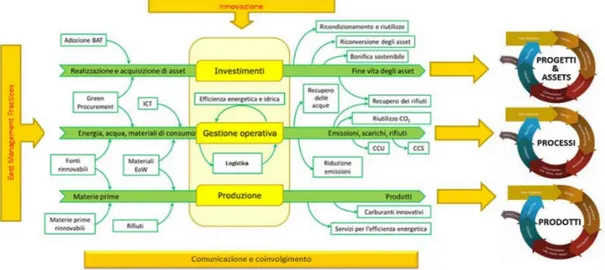

The strategies of circular economy in Eni SpA is pursued by the Support Function Department, which is the referent for the circular economy at all the Business Units of Eni, from the Exploration & Production to Refining & Marketing. Basically, Eni’s vision of a circular economy is split into an ‘external’ and ‘internal’ circular economy. The ‘external’ circular economy considers the application of these principles on its business strategy to leverage for new development opportunities, especially to activate strategies of industrial symbiosis with surrounding communities or industries. The ‘internal’ circular economy takes into account circular activities on already operating facilities in order to optimize processes, to lower resources use and emissions, to prevent waste production and to revamp the assets. The Upstream is the core business of the oil and gas industry. Fossil fuels and their derivatives are used by countries all around the world, but while the facilities where refining and production are widespread all around the world, only a small amount of countries can afford oil and gas extraction. Based on the information found on its last Sustainability Report, Eni took account of the goal set by the Paris Agreement of 2015 with a strong commitment. As an energy company, Eni has a strong duty to meet energy demand as the population will rapidly grow. The activities of Eni, which are directed on an improvement of the sustainability, regard a strength lower of greenhouse gases emissions. Eni is also pursuing a low-carbon oil and gas portfolio, developing renewable energy sources and strengthening green business through a circular economy approach.

One of the targets declared in the Eni’s vision and pursued by all the Business Units of Eni is the reduction of the GHG emissions. Since 2014, Eni defined a long term decarbonisation path, to engage a series of initiatives to fight climate change issues, such as OGCI, CCAC as we told before, or GGFR33 “Zero Routine Flaring by 2030” to avoid routine flaring on its plants. The

Upstream BU built a roadmap in order to actively contribute to reaching these goals with a series of investments in order to achieve the targets before the supposed date. By the end of 2025, Eni wants to reduce methane emissions and eliminating process flaring and it wants to

33 Global Gas Flaring Reduction Partnership is a public-private initiative comprising international and national oil

companies, national and regional governments, and international institutions. GGFR works to increase use of natural gas associated with oil production by helping remove technical and regulatory barriers to flaring reduction, conducting research, disseminating best practices, and developing country-specific gas flaring reduction programs.