1

1 INTRODUCTION

1.1 MOTIVATION

The ability of the internal combustion engine to convert the big energy amount (by volume) inside the hydrocarbon fuels has resulted in a huge development and production of it.

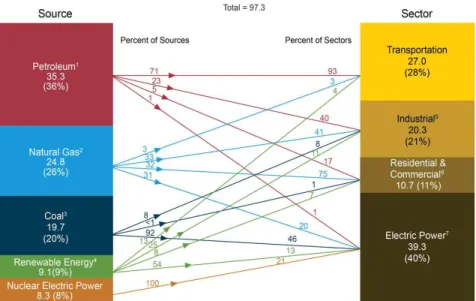

As well as engines are the most widely used propulsion system for vehicle, the combustion is also the most important way to generate electrical energy. For example in USA about the 80% of the demanded energy is supplied by combustion process, as it is possible to see in the Figure 1.1.

Figure 1.1 - Energy source and use in the united states, from US Energy information, www.eia.goc

In the future the contribution of the renewable source of energy will increase, but in this sector are also included the bio-fuels that will need again to be burned in an internal combustion engine in the most efficient way. In conclusion it is expected that the internal combustion engine will be still the most important energy-converter device for the forthcoming decades.

2

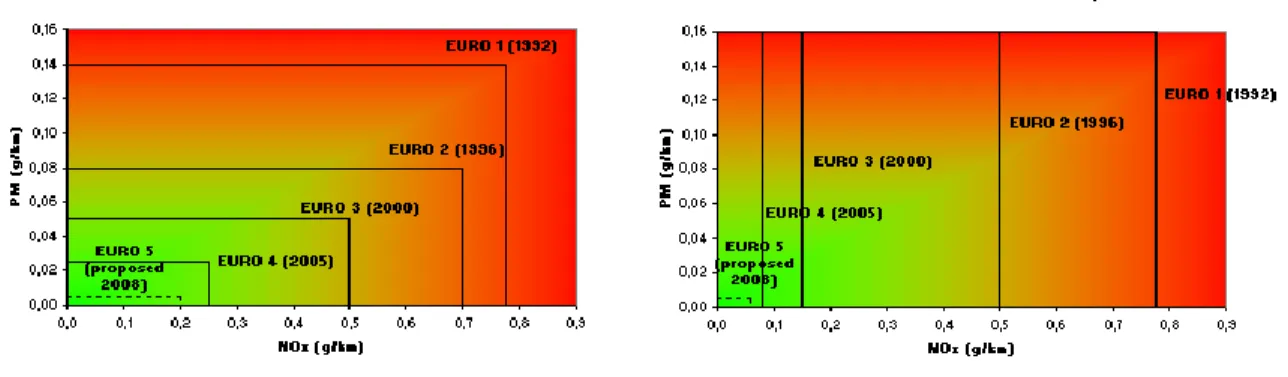

However transportation pollutant emission regulations are every year more tighten, calling for the need of better combustion quality. As it is possible to see in Figure 1.2, in the last two decades the developing of regulations has been very rough, forcing constructor to work very hard in order to reduce the pollutant emission of the vehicle, both for gasoline and diesel fueled ones. This figure shows the development of the legislation in the European zone but similar laws are being introduced all over the world.

These kinds of regulation are not limited to on-road passenger vehicle, but are also developing in other field of employment of internal engine combustion such as off-road and recreational vehicles.

Figure 1.2 - Diesel and gasoline cars EURO legislation developing

Furthermore recently legislations, as well as to control the PM, NOX, CO and HC, also start to impose a limitation of the production of CO2. That, in addition to rising fuel costs with and the need to be more independent from hydrocarbon consumption, generates a huge effort to improve the efficiency of the entire vehicle, and of course the efficiency of the combustion.

Until now the most effort has been focused to improve the traditional mode of combustion, such as spark-ignited engine (SI) and compression-ignited engine (CI), which will be briefly summarized.

Spark-ignited engine (SI)

The fuel used is characterized by high volatility and high resistance to auto ignition (usually gasoline), so inside the chamber a virtually homogenous mixture forms and is ignited by the spark produced by the spark plug. If conditions of the mixture near the spark are proper, a flame front forms which then spreads throughout the chamber. In the vicinity of the spark the mixture will necessarily

3

have to be within an equivalence ratio inside the flammability limit (around the stoichiometric), to allow the initialization of the flame front. The combustion is of a progressive type, which spreads from the spark plug (usually at the center of the combustion chamber), to the outer part of the combustion chamber. The need to avoid detonation (auto-ignition of the end-gas) does not allow adopting high compression ratios (usually naturally aspirated SI engines have 10-11) such as compression-ignition engine (around 20). Furthermore, the load adjustment is made reducing the quantity of fresh mixture which enters the cylinder every cycle through a throttle valve in the intake manifold. It reduces the amount of mixture that enters into the chamber, but always maintaining the same equivalence ratio. This leads an increase of the work necessary during the scavenging exhaust and intake stroke (pumping loss) at part load operations, reducing the efficiency of the engine.

Low compression ratios and losses caused by the throttle valve are two of the main causes of low indicated efficiency of spark-ignition engines, which in fact is typically between 30-35 %.

Compression-ignited engine (CI)

The fuel used typically has a low resistance to self-ignition (diesel) and is directly injected into the combustion chamber (Direct Injected Compression ignition DICI). Here thanks to the high compression ratio, fuel reaches the conditions necessary for auto-ignition. The combustion starts when both the time required to evaporation (physical delay) and to start the chemical reaction (chemical delay) are elapsed. The ratio between these two times is very important, for what concerns the ruggedness of combustion. If too much fuel is already evaporated when the ignition delay is passed, the combustion is characterized by a sudden heat release, which leads to high pressure rise rate and noise.

Basically, in this case, the timing of combustion is controlled by the injection, but this also causes a strong stratification of the mixture inside the spray causing the formation of extremely rich areas (formation of PM and CO) and areas of extremely lean condition (no ignition), as well as locally high temperature which causes the NOx production. The combustion in this type of engine is therefore of diffusive type, controlled by the spray event and fuel evaporation and mixing. Combustion takes place during the injection of the fuel itself, in areas surrounding the spray. This type of engine is, however, characterized by a greater indicated efficiency than the SI motor due to the higher

4

compression ratio and the adjustment of the load changing the amount of fuel injected. Typical current values for indicated efficiency are around 40-50% (depending on many factors).

1.2 POLLUTANT EMISSIONS FROM INTERNAL COMBUSTION

ENGINES

The combustion process that takes place in current engines emits poisonous and harmful exhaust gases which mainly include CO2, CO, UHC, NOx and particulate matter. The first is mainly

related to the quantity of hydrocarbon fuel burned, whereas the others are the product of inefficiency during the combustion process.

Carbon dioxide (CO

2)

Carbon dioxide is one of the green-house gases which are imputed to climate-change.

It’s a normal product of the ideal combustion of every hydrocarbon fuel, so its quantity depends mainly on the fuel consumption and on the ratio between carbon and hydrogen atoms of the used fuel.

Unburned hydrocarbon emissions (UHC)

Unburned Hydrocarbons are formed by a several different type of organic matter, which can be blistering or even cancerous for the human. Furthermore the UHC are an important source of natural contamination.

Hydrocarbons are the consequence of incomplete combustion of the fuel or even fuel that goes directly to the exhaust without burning due to misfire or short-circuiting of the fresh charge.

In spark-ignited engine, where usually the mixture is homogenous throughout the whole chamber, it is possible to have fuel that escapes the combustion process because during the compression stroke it is absorbed by the thin oil layer on the wall, or forced to enter into crevices connected to the combustion chamber due to the pressure raise. Then during the expansion stroke this fuel is released when the combustion is already finished and goes directly to the exhaust. Another source is the quenching layer which forms in the zone closed to the walls, due to heat transfer with the

5

walls. The subsequent lower temperature of the fluid can cause the extinguishing of the flame, especially when the walls are not well cleaned. Porous deposit of oil could indeed increase both the adsorption of the fuel and the flame quenching. In addition high content of EGR, cold cylinder walls and low equivalence ratio near the plug can lead to misfires, which as well cause the fuel to go directly to the exhaust.

In compression-ignition engine, hydrocarbon generates in regions where the flame quenches on the walls and where excess or lack of dilution prevents the combustion process to start or to reach the completion. Fuel that comes from the sac volume of the injector, which vaporizes later during the combustion process, could be another important source of unburned hydrocarbon.

Carbon monoxide (CO)

CO is a highly-toxic gas for the human health.

Carbon monoxide emission formation in internal combustion engines is controlled primarily by the fuel/air equivalence ratio. With rich fuel-air mixtures, there is insufficient oxygen to oxidize completely the fuel completely into CO2. Furthermore due to high-temperature products, even with

lean mixtures, it is possible to have generation of CO by dissociation of CO2. Usually the 90% of the

carbon monoxide produced during the combustion is completely oxidized later in the expansion stroke, but if the temperature is too low, the CO oxidation process freezes as the burned gas temperature falls.

Since spark-ignition operates close to stoichiometric at part load and fuel rich at full load, CO emissions are significant, on the other hand the CI engine always operate well on lean condition, so the CO emissions are usually low enough to be unimportant.

Nitrogen oxides (NO

x)

NOx emission stands usually for both the emission of nitric oxide (NO) and nitrogen dioxide

(NO2), being the first one usually the most predominant. Nitric oxide in the atmosphere may convert to nitric acid, which has been implicated in acid rain. NO2 is instead toxic. Furthermore, both NO and

NO2 participate in ozone layer depletion.

The principal source of NOx in engines is the oxidation of atmospheric molecular nitrogen at

6 example at the nitrogen content of the fuel.

NOx content in spark ignited engine and in compressed engine are comparable. In SI engine NOx

forms throughout the high-temperature burned gases behind the flame thorough chemical reactions involving nitrogen and oxygen atoms and molecules, which do not attain chemical equilibrium. The higher the burned gas temperature, the higher the rate of formation of NOx. As the burned gases cool

down during the expansion stroke the reactions involving NO freezes, and leaves NO concentrations far in excess of levels corresponding to equilibrium at exhaust condition. In CI engines, NOx forms in the

high-temperature burned gas regions as before, but temperature and air/fuel ratio distributions within the burned gases are now nonuniform and formation rates are highest in the close-to-stoichiometric regions.

Particulate Matter (PM)

Sometimes also identified as soot, particulate matter is dangerous for human health because its dimension is smaller than the smallest particles that lungs can filters, so this particle can enter and lie inside the organism, also carrying dangerous compound such hydrocarbon.

The formation of particle matter is usually related with the use of the direct injection, but also the presence of solid parcels or oil could act as a source of PM. The single liquid fuel drop can be surrounded by the fuel vapor, which can prevent the evaporation of the liquid core. Due to the high temperature this liquid core can agglomerate (pyrolysis) and grow, forming solid particles that can grow or be burned. Depending on which of these mechanism wins is possible to have high PM output or not.

1.3 CURRENT TECHNOLOGY STATE OF ART

The need to reduce pollutant emission and increase fuel-economy, forced the industries to improve the performance of the vehicles in numerous different ways. It is possible to distinguish between techniques which reduce the emission outside the cylinder and improve the powertrain as a system, and techniques which improve the pollutant output directly inside the cylinder during the combustion process.

7

1.4 Current external devices for powertrain pollutant

reduction

As already mentioned the only two ways to reduce the CO2 emission of the IC engines are to

improve the fuel-economy or to change fuel, using a low C/H ratio content fuel such as ethanol or methane.

Nowadays the most important steps to improve the efficiency of the vehicle which mainly rely in external devices are:

Downsizing with turbo-charging

Variable geometry turbo-charge

Advanced combustion control strategies which allow a better management of the engine in every condition, through the use of lambda probe and self-learning techniques of the Engine Control Unit (ECU)

Internal combustion engine "electrification" which allows energy recovery from braking, start/stop, cylinder deactivation and so on

Variable valve technology (VVT)

Reduction of weight and friction

Various studies are showing the possibility to further reduce in the future the CO2 emission of

both Gasoline and Diesel engine of more than 30%[1], improving the aforementioned techniques but also implementing new devices such as:

Variable compression ratio

Continuously variable valve technology

Mild-hybrid technology (electric hybrid vehicle)

Automatic high efficiency transmission

Conversion to ethanol fuel

To reduce the engine-out emission of the pollutant emission due to inefficiency of combustion such the aforementioned CO, UHC, PM and NOx, the after treatment technology has showed big

8 The current technologies include:

Thermal reactor, for complete combustion of CO and UHC, used especially for economic

little two-stroke-engines ,but with a low efficiency and with the need of very high exhaust gas temperature

Oxidizer catalyst, which helps to oxidize CO and UHC,

Three way catalyst (TWC), which can oxidize CO and HC and reduce NOx at the same time,

but only if the engine runs under stoichiometric condition causing poor fuel efficiency

Lean De-NOx reducing catalyst, which reduces the oxidizes of nitrogen, but with a not so

high efficiency, and the need of some regenerative cycle, during which the engine must run under rich condition

Selective Catalytic Reduction system (SCR) for the reduction of NOx in non-stoichiometric

engines: they have a high efficiency but need ammonia to reduce NOx, thus requiring a

second tank with urea on-board the vehicle. Moreover exhaust ammonia-slip is possible and must be avoided.

Particulate matter filter which can trap the PM in the exhaust gas and then, during a

regenerative cycle, burns it. The main concern of these filters, is that they cause an higher exhaust backpressure, which increases the pumping losses.

The current effort is focused to develop more efficient after treatment systems and to eliminate the drawbacks of these devices. One of these is the need of this devices to work at high temperature (around 700K), causing low-efficiency conversion during the engine warm-up and raise concerns about their compatibility with innovative low temperature combustion.

1.4.1 Current technology for in-cylinder pollutant reduction

Some improvement has also been made to reduce the pollutant formation directly during the combustion process inside the chamber:

Compression ratio increases, which increase the thermal efficiency of the cycle

Direct injection, because it allows a better management of the fuel quantity using engine

control unit (ECU)

9

temperature because it lowers the oxygen content and slows down the combustion chemical reactions. This reduces the NOx formation but interferes with the maximum load

of the engine

Late combustion phasing, in this case to reduce the temperature inside the chamber the combustion is forced to occur during the exhaust stroke, at the expense of the thermal efficiency, this kind of strategy could also be used to rapidly warm-up the after treatment

Raising of the injection pressure, which cause the diameter of the PM, again at the expense

of the power drain needed for the high pressure pump

Multi-injection strategy (Common rail), which strongly increase the combustion quality of

CI engine

Stratified charge operation, whereby thanks to a deep study of the flow and spray motion

inside the chamber, it is possible, for SI engine at low load, to avoid or limit throttling, increasing the cycle efficiency

Intercooler, which reduces intake temperature, this reducing combustion temperature as

well

Post-injection strategies, to reduce the soot formed in the initial part of the combustion

with a little injection some degree after the top dead center which helps the complete oxidation of the soot formed.

Other technologies are currently under study such as:

Different type of cycle, with a higher efficiency respect the traditional Diesel and Otto

cycles, like Miller/Atkinson cycle

Low temperature combustion, which will be analyzed in more detail in the next chapter

1.5 INNOVATIVE COMBUSTION

The aforementioned current techniques to decrease pollutant emission of the engine usually played against the fuel-economy. Furthermore the additional devices have a cost, which increase the total cost of the vehicle, as well as its weight, which again decrease the fuel-economy.

10

Innovative types of combustion have the great appeal to reduce both emission and fuel consumption at the same time. With this kind of combustion it is possible to achieve emission under the regulated limit, directly inside the cylinder, without the need of after-treatment, in most of the operating range of the engine. At the moment no one of this combustion has been completely and diffusively applied to commercial engines but the latest concepts are more and more close to reach the necessary performance to be finally commercialized.

The concept of this kind of combustion is to combine the advantages of both the SI and CI engines, while avoiding their disadvantages. The mixture inside the cylinder is more or less homogeneous, such as in SI engine, but the combustion starts by auto-ignition of the whole mixture at the same time. This allows the use of lean mixtures, the control of the load without throttling, reduced pumping loss, and the raise of compression ratio. These combustions are mostly kinetically controlled, which means that the whole process is mainly dominated by the speed of the chemical reactions of combustion, so these combustion processes are strongly dependent on temperature.

Furthermore the auto-ignition process allows burning different type of fuels, so these concepts are completely compatible whit the need to reduce the consumption of traditional hydrocarbon fuels, such as diesel and gasoline, using bio-fuels.

Next a briefly summary of the different types of innovative combustion will be listed. The boundary between a type of combustion and a different one is not well defined and similar mode of combustion have been proposed by different authors. To have a further insight of all these type of combustion and a complete literary review of all the work done, is helpful to refer to Lu et.al [2].

All types of compression ignition combustion are very well represented in Figure 1.3, which shows the local conditions that usually are reached inside the chamber, in a plane Equivalence ratio – temperature. This diagram shows the zone where the PM forms, at high equivalence ratio, and where NOx forms, at high temperature. In a conventional DICI engine both this condition can happen locally,

the center of the spray is inside at the soot formation zone, and the combustion zone can be in the NOx

formation zone. The basic concept of innovative combustion strategy (HCCI, LTC, and PCCI) is to avoid that part of the mixture in the cylinder reach one of this pollutant formation zone.

11

Figure 1.3 - Phi-T diagrams showing innovative combustion and traditional DICI combustion, from[3]

Activated Thermo Atmosphere Combustion (ATAC)

ATAC combustion was proposed a long time ago. The first recognized work was made by Onishi et al.[4] in the late seventies to control the autoignition problem in a conventional ported two-stroke engine at low load. Indeed at throttled condition, a lot of residual hot gas remains in the cylinder, often causing auto-ignition of the premixed mixture. ATAC concept relies on the formation of pockets of residual gas at high temperature. Then due to the compression stroke the temperature further increases finally causing the start of the combustion of the mixture which surrounds them. This concept also solved the problem of the cycle-to-cycle variability at low load. Indeed it was not required to maintain an ignitable mixture near the plug and the combustion sustaining did not rely on flame propagation. Both of these effects are usually disturbed by the high residual gas content at low load, typical feature of two-stroke engines. Latest work on ATAC has been performed by Ishibashi et al.[5] and Gentili et al.[6] , who have proved the possibility to implement this kind of combustion at light load for small two-stroke engine with indirect and direct injection respectively. Both authors agree that to reach this favorable combustion, the most important thing is to keep the exhaust gas inside the chamber in concentrate zones, where, thanks to residual gas high temperature and radical content, the

12

combustion of the fresh mixture initializes. To reduce the mixing between fresh charge and exhaust gas, the most studied way is to reduce the speed of the scavenging process, using throttle valve at the exhaust or in the transfer duct between the crankcase and the cylinder. This kind of combustion is achievable only at low load, but has delivered good results in terms of stability, fuel-economy and emissions.

Homogeneous charge compression ignition (HCCI)

After the proposal of ATAC combustion, Najt and Foster [7] studied the way to implement auto-ignition combustion of a homogenous mixture in a four-stroke engine and then many other researchers have studied and developed this initial idea. As just said the idea is to have a homogeneous mixture inside the cylinder which auto-ignites after the ignition delay is passed. The whole mixture burns at the same time, without a proper flame front, avoiding the production of NOx

and soot. To keep the pressure rise rate at acceptable level, highly diluted mixture, high level of EGR or special inhibitor are required.

The main advantages of HCCI combustion are:

high efficiency, mainly because the high compression ratio and reduced heat transfer loss

low emission of NOx and Soot, the first are avoided because the absence of very high

temperature zone, and the second avoided thanks to the absence of rich mixture pockets

fuel flexibility

The main disadvantages are:

higher pressure rise rate and severe combustion noise, because the whole mixture inside

the chamber burns instantaneously

poor control of the combustion phasing, because the combustion is controlled only by

chemical kinetics, the phasing of combustion is very sensitive with respect to a lot of parameters like intake charge temperature, wall temperature and mixture composition, this leads for example to big cycle-to-cycle variation

small ranges of application, because of the need of high EGR content to keep the pressure

rise rate low enough for the mechanical integrity of the engine and the noise emission

13

increase in CO and UHC, because of the homogeneous charge the wall effect of adsorption

of UHC and flame quenching are increased with respect to conventional diesel; moreover the high diluted and low temperature conditions prevents its oxidation

Therefore the main challenges are:

increase the operating range

control the pressure rise rate and the combustion phasing

Speed-up the control system of the engine, in order to handle the high sensitivity of combustion behavior with respect to the variations of external conditions

These issues are important because more or less, they affect every kind of innovative combustion and have guided the pathway of the research.

Low temperature combustion (LTC)

It was found that the in-cylinder temperature play an important role on the formation of pollutant emission, and then a new concept of combustion was proposed by Sandia National Laboratories[8] , trying to keep the temperature low enough to avoid the formation of Soot and NOx.

As just said HCCI combustion is only controlled by fuel/air chemical kinetics. Low temperature combustion uses a similar concept, but employs higher level of EGR and moderate inhomogeneity of whole mixtures, trying to remain outside the zone of formation of soot and NOx showed in Figure 1.3. Furthermore turbulence and mixing play an important role to reduce the mixing time of the fuel.

To achieve LTC the most important requirement is to inject all fuel into the cylinder and promote homogenous mixture formation prior to spontaneous ignition. To increase the ignition delay high level of EGR are required (EGR>60%), whereas to reduce the time of mixture formation high level of turbulence and appropriate spray design are used.

Using the little inhomogeneity of the mixture and varying the injection strategy is possible to achieve a better control of the combustion with respect to HCCI combustion, but the high EGR content could increase the cycle-to-cycle variation and forbid to reach the higher load. Furthermore a high content of EGR affects the efficiency (because of the effect of the lower ratio of specific heats) and from the point of view of the control of the engine during the transient it could be an issue: indeed if external EGR are used the time required to modify the engine breathing features is too much. The

14

better way seems to be utilizing internal EGR, with the use of Variable Valve Timing system (VVT), which otherwise are more complicated and expensive.

Partially Premixed Charge combustion (PPC)

This concept is something in between the HCCI concept and the traditional DICI engine, where the effort is to increase the control over the combustion phasing, and keep low the pressure rise-rate in order to broad the limit of applicability towards high load. PPC concept tries to achieve this objectives using charge stratification inside the cylinder. The most part of the fuel is port-injected in the scavenging manifold (or injected early during the intake stroke) and at the time of combustion is essentially homogenous, whereas the remaining part of the fuel is direct-injected inside the cylinder, controlling the combustion phasing.

This approach could create two different types of stratification inside the cylinder: temperature and equivalence ratio stratification. It was found that both these stratification could help to achieve a mild staged combustion, and can be used to extend the operating range. It has to be pointed out that generally the easier to achieve, the equivalence ratio one, could generate an increase of the NOx and Soot formation, such as in DICI engine.

1.5.1 Fuel behavior and design

Because HCCI combustion concept is dominated by the chemical kinetics of the fuel/air mixtures, the used fuel has a big impact on the engine behavior and so the behavior of this must be well known and modeled. Much emphasis has been placed on the study of n-heptane and iso-octane, because they are the primary reference fuels (PRF) for spark-ignited engine, and usually used to model diesel and gasoline in numerical simulation. A lot of improvement in the knowledge of the chemical pathways followed by the combustion process has been made, trying to detail end explain different behaviors, such as Negative Temperature Coefficient behavior (NTC) which cause the appearance of the low temperature heat release (LTHR) typical of HCCI combustion.

The LTHR is highlighted in the Figure 1.4, which shows typical HCCI combustions. As it is possible to see very well with n-heptane (black-curve), before the main heat release, there is a little bump (indicated by light blue arrow) in the heat released and subsequently in the pressure trace. This

15

former stage of heat release is the abovementioned LTHR. As you can see moving on high PRF (light-blue curve), the LHTR is progressively lowered, until its disappearance. It has found that this behavior is caused by the NTC region, a peculiar region where the reactivity of the fuel decreases with the increase of temperature. It is not a feature of all fuels but mainly depends on the composition of the fuel and on the chemical pathway followed by the combustion process. In a conventional way the LTHR is the heat released at temperature less than 1000K, while HTHR is when the temperature is above 1000K.

Figure 1.4 - HCCI combustion with different PRF fuels, from [2]

This kind of two-staged combustion has been usually found also in the other innovative type of combustion. The LTHR, even if is a small part of the entire amount of heat released, has a significant influence on the following heat release (High Temperature Heat Release), as more is the LTHR as much anticipated is the HTHR and so the main combustion phase. Furthermore it was found that fuels with a strong LTHR shows more sensitivity between ignition delay and equivalence ratio, allowing a little control over the combustion phasing varying the local equivalence ratio, whereas single-stage heat release fuel is relatively insensitive to equivalence ratio stratification, for what concerns ignition delay [9].

Several studies have been performed and have highlighted the impact of the different fuel on innovative combustion. The principal concepts are:

16

high cetane number (high reactivity fuels) reduce the ignition delay, improving the cold start capacity and broaden the field of application at low load, at the same time the drawback is that at medium load the combustion is too fast, causing not acceptable pressure rise rate

high octane number (low reactivity fuels) effect is opposite with respect to the cetane number one: increasing the ignition timing, so the combustion is difficult to achieve at low load without pre-heating the charge, but the operation field could be extended at medium load

Increasing the oxygen content, using for example biofuels, it is possible to extend the load limit and to increase combustion efficiency

high latent heat of evaporation could reduce the temperature at the beginning of the compression stroke, increasing the ignition delay and reducing as well the combustion temperature

Fuel with low boiling point and distillation temperature have better ability to evaporate and form a homogeneous mixture inside the cylinder

The great impact of the fuel composition and of the chemical combustion pathway have also demanded and improved capacity of the numerical methods to predict the combustion process. To do that a huge effort has been profuse to made detailed chemical mechanism and to reproduce the composition of real fuels (composed by many different hydrocarbons) using appropriate surrogates. It was found that modeling the chemical pathway of the combustion process is more indicated to study the innovative combustion strategies, controlled by chemical auto-ignition, compared with the traditional model used until now to simulate SI and CI combustion process. Unfortunately these techniques are very expensive from the computational time point of view of. Reduced chemical mechanism (namely skeletal) has been proposed, where the number of reactions and species is reduced, trying to catch anyhow the right fuel behavior but reducing the computational time [10].

![Figure 1.3 - Phi-T diagrams showing innovative combustion and traditional DICI combustion, from[3]](https://thumb-eu.123doks.com/thumbv2/123dokorg/7649487.119120/11.918.203.717.110.492/figure-diagrams-showing-innovative-combustion-traditional-dici-combustion.webp)

![Figure 1.4 - HCCI combustion with different PRF fuels, from [2]](https://thumb-eu.123doks.com/thumbv2/123dokorg/7649487.119120/15.918.255.721.341.670/figure-hcci-combustion-different-prf-fuels.webp)