Chapter 1: NEW PARADIGM

1.1 Automatic Assembly Systems: the weaknesses of present approaches.

The major problems incurred by companies dealing with assembly all relate to uncertainty. First of all, it is very difficult for companies to predict the type and range of products that will have to be developed. The second uncertainty regards the production volumes and lifespans reached by these future products.

For these reasons, in the process of development of a new product (or even a new/adapted version), every company needs to optimise:

- the cost

- the lead time / Time-to-Market / Time-to-Volume

These are the basic conditions for customer satisfaction, that allows the enterprise to survive.

In the case of a product-specific traditional assembly system, we have high initial cost and long assembly system development time, but the lead times when producing will be short. If the product is modified or another product needs to be fabricated, the assembly system has to be adapted or exchanged, which will take time.

The overwhelming reaction to these problems has been to attempt to develop extremely flexible assembly machines. In the late eighties and early nineties, the general trend in precision assembly was, to develop Flexible Assembly Systems (FAS) and Flexible Automatic Assembly (FAA) cells or Hyper Flexible Automatic Assembly, going a bit further with stepwise automation, standard assembly machines and sub-batch principle.

The goal was to have general flexibility, but the actual assembly processes were not studied in depth and therefore unstable / non-robust or badly adapted solutions resulted. They were fairly adequate to many different product types, but failed to be very performing in any domain. The high cost of such installations was another heavy problem, especially for smaller companies.

Flexibility, instead of the actual assembly process, has been the core issue of most of these developments.

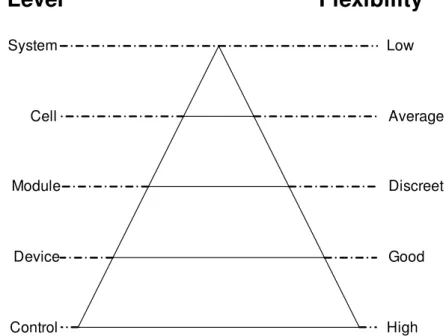

As shown in the picture below, the lower a component is positioned in the hierarchical structure, the more flexibility is necessary to ensure a certain flexibility to the whole system; this means even a system with low flexibility needs a very flexible Control.

System Cell Module Device Control Low Average Discreet Good High

Level

Flexibility

Fig. 2. Flexibility decreases with complexity.

The next step were Re-configurable Assembly Systems (RAS). They focus on the principle that innovative product design must not be limited by assembly process constraints.

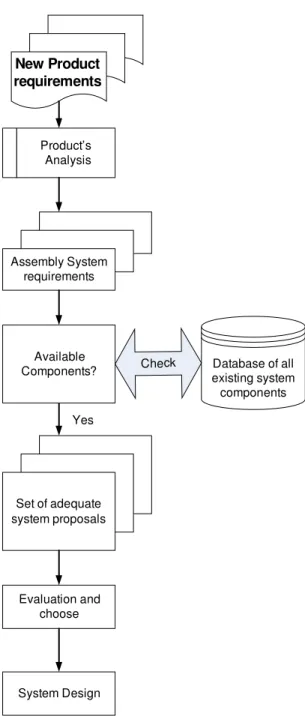

In the following scheme, we show the process that leads to the Assembly System design in a product-specific traditional assembly system approach.

New Product requirements Product’s Analysis Assembly System requirements Database of all existing system components Check Set of adequate system proposals Evaluation and choose System Design Yes Available Components?

Fig 3. Assembly System design in RMS

As you can see, the Assembly System design starts from the “New Product Requirements”. The product that is going to be assembled is analysed in order to find all the “Assembly

System Requirements”, and this means that the driver of the whole process is the Product.

In such an approach there are no links between the Product Design process and the successive steps: it leaves the maximum freedom to the designers, but this is not always the right strategy for the company success. A parallel development of the Product and of the Assembly System produces a better global performance.

In order to fulfil the established requirements, all the existing possibilities offered by the market are investigated, and a Set of adequate system proposal are produced; then it is necessary to compare and evaluate the different solutions and choose the final concepts. These steps need to be carried out by very skilled people in a considerable amount of time: we can consider every system built with this method like a prototype.

In this phase, especially if the new product is not that different from the previous version, it is possible to adapt the former Assembly System (or only some of its parts) to the present needs. The investment for a new / adapted assembly system can be calculated, and of course it takes money and time.

Summarizing Product design approach has the following drawbacks:

- New products lead to new assembly systems, which is economically unbearable.

- Product based assembly systems lead to badly-adapted, complicated or even impossible processes and therefore expensive and complicated solutions.

- The necessary time to develop new assembly systems for each product is far too high compared with the requited Time-to-Market of products.

- The product cannot be the origin of all, this is a wrong approach and leads to one-sided results as the reality strikingly shows.

The following list shows the problems or lack in the alternative main approaches.

Mechanical or Production Engineering approaches:

- These approaches underestimate the complexity of the problem often. Things are not as simple as they seem!

- There is often a lack of structure in mechanically based concepts.

- As there is no real link to products, the danger of creating the wrong assembly capabilities is considerable.

- Enormous programming efforts will be required to run the systems.

- The control structure cannot be adapted to modular hardware if it is not taken into account from the beginning.

Control / computer engineering approach:

- These approaches are often too abstract.

- Computer engineers have rarely enough knowledge about assembly systems, processes and products to be able understand the entire complexity.

- Approaches without focus on mechanics run the risk of leading to expensive hardware.

1.2 Evolvable Paradigm

The need to overcome all the discussed drawbacks of previous approaches, pushes the research towards the idea to put the focus on the processes and on the modularity, instead of the

product and the flexibility.

According with Evolvable Paradigm, each system could be made by several skill-based and process-oriented equipments: these elements should be very task-specific in order to accomplish only a simple action. It is possible, in fact, to consider every complex task, like the union of a lot of simple actions, therefore each shared element can be used to accomplish the same action in different assembly cycles or in different product generations. It is clear, that such a system is accessible even for the small and medium sized companies that can spread the automation investment on a longer time.

Moreover, we will see in the fifth chapter that a process-oriented approach to the Ontology, allows to define the Assembly Systems requirements for a whole Class of Products instead of a single product. Even though in a class we actually have different products, the assembly process are common to the whole set.

A fundamental condition, that allows to an evolvable system is the plugability of all components.

One of the most important consequence of this approach is that when a system will be created according to the EAS principles, the resulting capability of the sum of the modules will not be so easily predicted. When a multitude of small entities is brought together, new and

unexpected capabilities surface from such coalition: this is called Emergent Behaviour. Of course the lower is the level of the device considered, the higher is the emergent behaviour.

Concerning the control system, nature was taken as a model: modules are given mechatronic character. Each of them is an agent, knowing its proper capabilities and possible forms of cooperation with other agents. The principles of emergence can be applied, working with module skills and forming higher capabilities out of it. For instance, a robot has the basic skill to “move”, and a gripper has the basic skill to “grab”: once together they gain the complex

skill of “Pick and Place”.

The following definitions clarify the concepts just presented.

Plugability:

The ability to re-arrange & integrate system components within the framework of a given system architecture. The resulting new layout does not preclude efficient performance, one simply and physically plugs together a new arrangement.

Reconfigurability (interoperability):

The ability to re-arrange available system components to perform new, but pre-defined operations (plugability plus characteristics that ensures the efficient performance of the resulting new layout).

Granularity:

The lowest level of device being considered within a reference architecture. The lower the level of building block (tool, gripper), the higher the emergent behaviour.

Evolvability:

It is not, hereby, understood as a natural evolvability but, rather, as a system's ability to stepwise acquire self-knowledge and adjust its performance accordingly.

EAS may therefore be assigned the following characteristics:

• It is a fully ”reconfigurable” system platform that exhibits an emergent behaviour. • Mechatronically integratable assembly units.

• The reconfigurable system has to be composed of process-oriented components (gives granularity of emergent behaviour).

• A system that can automatically determine its functionality based on the components’ skills.

• The change in paradigm is, partly, that we no longer invest in the programming & coding, but, rather, in how to establish and exploit relations.

• Maintenance, documentation and the ability to store information in support of operational stability.

As stated earlier, the principle of EAS is the scientific novelty: the ability to develop system components with the capacity to interpret process characteristics, presents four main innovations, as given below:

1. The emergent behaviour can lead to the elimination of programming and

codification, and also opens the way for semi-autonomous adaptability. Installation

times for systems will be down to minutes.

2. Having modelled process aspects allows the users to link back to the product design

phase, thus allowing for a concurrent evolution of assembly system and product design.

3. The potential assembly system is more easily emulated prior to its finalisation, for evaluation purposes: Process-oriented, skill-based models of modules will visualise process discrepancies more vividly.

4. It lowers the barrier of understanding of what is occurring in the assembly system: a

common user will be able to follow the events in the EAS system (skill-based, process-oriented equipment emulated at intelligible level) and also able to extract the information of particular relevance to him/her.

The application of evolvable paradigm is not necessary with high-volume assembly of simple products with long lifecycles.

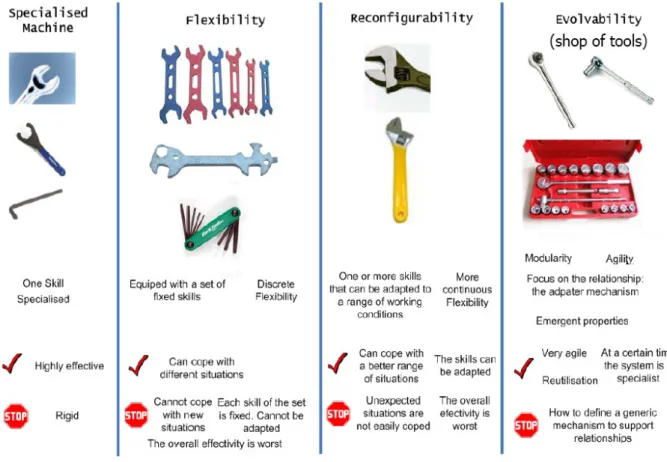

Figure 4. Evolvable process-oriented paradigm compared with previous approaches.

As you can see from the picture above the Evolvable paradigm is represented by the shop of tools. These tools are very task oriented, no focus on a particular product but on the processes to be accomplished. If in the future will surface the need, for example of a square bolt, with such a system it would be enough to design a small component (of course after a cost-effectiveness analysis).

1.3 Setting of Evolvable Assembly System.

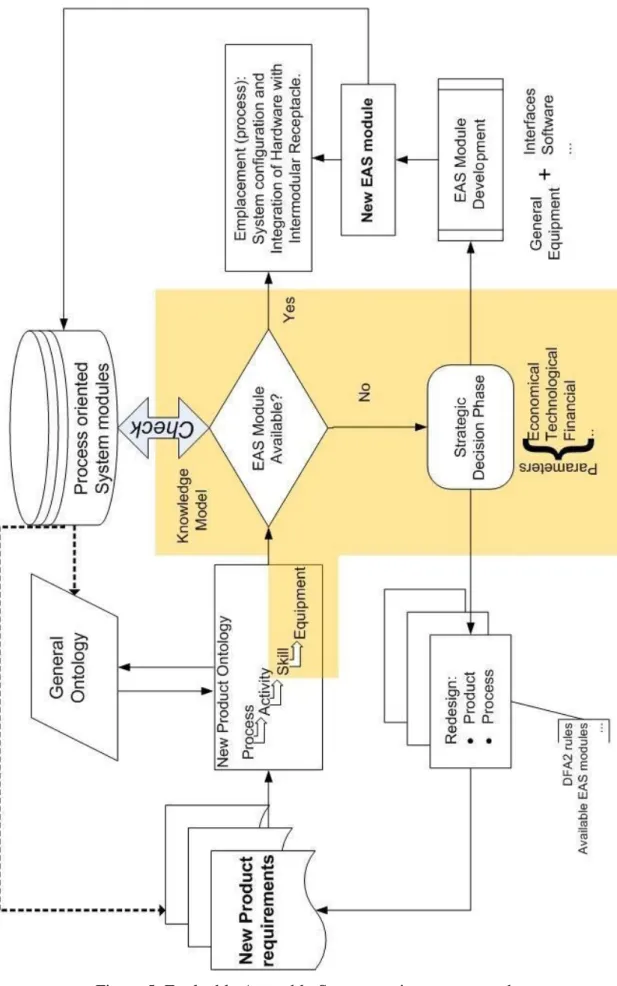

A first glance of this scheme, shows that it is not a simple stepwise approach (like the one above), but there are some loops that suggest how the different phases has to be developed at the same time.

The initial step is of course to produce the “New Product Requirements” such as in the traditional way. The main difference is that now, the designer accounts of assembly problems: the information about the assembly process and its needs go back through the steps. As we will see later, in such a method the designer already had a certain amount of hints that can drive the design choices.

The following step is to produce a “Specific Ontology” to represent all the features of the

“Class of Products”; the Specific Ontology is based on a “General Ontology” that includes

the whole Know-How about assembly processes of the company.

A part of an Ontology is made by a hierarchic list of assembly task and operation (also called

Taxonomy). Starting from the Process it is possible to detail the single Activities.

Each Activity needs a particular skill to be accomplished and therefore a particular kind of

Equipment. All the Ontologies’ aspects will be deeply explain in the next chapters.

While the General Ontology is a theoretical representation the Specific Ontology is a very practical link between the design of the product and the design of the assembly system. It could be considered like the “core” of this approach.

It is possible to find general equipment to accomplish the activities on the market, but in order to be used in an evolvable system it is necessary that it has the right interface and the capability to cooperate in a society, in other words it must be transformed in an EAS Module (Evolvable Assembly System Module).

After this we already have all the information we need to build up the Assembly System, therefore the further step is to check if the above mentioned modules are available.

A company that follow the evolvable procedure will have a Database of EAS Modules that include all the modules developed in previous applications, and of course the designers are

to use such modules (If we have a module suit for the screws, why to use a rivet? It is actually necessary?). This is the first link that this method provides between the design of the product and the design of the Assembly System.

If the warehouse lacks of the needed module, there are two possibilities: to develop a new suitable module, or to change the design of the product or of the process in order to avoid the use of such module. This is a very important Strategic Decision Phase that involves a lot of aspects (such as economical, financial, technological, strategic...).

The Development of a new EAS Module entails time, money and human resources and therefore it is fundamental to be sure that it is necessary at the moment and that it will be suitable for future projects.

All the new modules of course becomes part of the existing database that, as shown in the picture with the dotted lines, influences the general Ontology and the designer’s choices.

When all the Modules are available it is possible to set the whole system, this step is called

Emplacement and it consists of the whole necessary hardware and software configurations. It

is important to highlight that now we are making a simple setting of the system instead of a system design: the Assembly System is no longer a prototype (this means, no related costs and risks).

The colourful area in the picture outlines the Knowledge Model that is the abstract model that provides the solution for the final layout of the system. The Knowledge Model is composed by a series of relations and algorithms which allows to use the information of the Ontology. Only one solution (instead of a Set of adequate solutions, such as in a traditional approach) is found by the Knowledge Model.

1.4 Costs reduction achievable by EAS

Applying automation within the assembly sector is not always cost-effective for many reasons. Achieving a fully fluid automatic assembly within a system that is, in principle, a prototype usually requires massive programming at different levels (robot, PLC, vision system, etc.). All these must be synchronised and cooperate with the order sequencing and superior controller. To achieve this, several experts are normally engaged in this work for several weeks if not months. Moreover the costs and the risks associated with the installation-related issues of programming and fine-tuning are usually very high. The application of the principles of emergence would practically eliminate all the costs above mentioned.

Another advantage is that it is possible to easily emulate the final system since the beginning and it is fundamental for evaluation purposes: process-oriented, skill-based models of modules can visualise process discrepancies more vividly.

The Emergent Behaviour can also lead to the elimination of programming and codification, and also opens the way for semi-autonomous adaptability. Installation times for systems will be down to minutes. A reduced Time To Market is one of the most important goal in present Industrial situation.

Summarizing the costs that we can reduce with the new paradigm are:

• Development • Start-up • Set-up • Diagnostics • Maintenance