UNIVERSITÀ DEGLI STUDI DI FOGGIA

PhD Course in

“INNOVAZIONE E MANAGEMENT DI ALIMENTI AD ELEVATA

VALENZA SALUTISTICA”

(XXXI Cycle)

C

OORDINATOR:

PROF.

MATTEO ALESSANDRO DEL NOBILE“OLIVE CHAIN BY-PRODUCTS FOR THE

FUNCTIONALIZATION OF FOODS

”

Dottorando:

Dott.ssa Annamaria Cedola

Tutor:

Dott.ssa Angela Cardinali

Co-tutor:

Dott.ssa Amalia Conte

1

Index

ABSTRACT ………... 4

1. INTRODUCTION ………. 6

1.1 Olive Oil Industry by-product ……… 6

1.1.1 Olive mill waste water ………... 8

1.1.2 Olive pomace ………. 9

1.1.3 Olive pâtè ………. 10

1.1.4 Olive leaves ……….. 11

1.2 Management of olive oil by-products ……….. 12

1.2.1 Waste or by-products ………12

1.2.2 EU legislation of olive by-products ………. 14

1.3 Re-use of olive oil by-products ………. 16

1.3.1 Exstraction from olive mill waste water ……….. 19

1.3.2 Exstraction from olive pomace ……… 22

1.3.3 Exstraction from olive pâtè ……….. 26

1.3.4 Exstraction from olive leaves ………... 27

2. OBJECTIVE ……… 29

3. MATERIALS AND METHODS ………... 30

3.1 Fish burger with pâtè ……… 30

3.1.1 Raw materials ……….. 30

3.1.2 Fish burger preparation ……….. 30

3.1.3 Total phenols, flavonoids and antioxidant activity determination ………….. 30

3.1.4 Sensory analysis ………... 33

3.1.5 Statistical analysis ………... 33

3.2 Bread with pâtè ……….. 33

3.2.1 Bread-making process ………. 33

3.2.2 Sensory analysis ………... 34

3.2.3 Total phenolic compounds, total flavonoids and trolox equivalent …………. 34

3.2.4 Glycemic index ………. 35

3.2.5 Bio-accessibility of enriched bread ………. 35

2

3.3 Pasta with pâtè ………... 37

3.3.1 Spaghetti preparation ……….. 37

3.3.2 Sensory analysis ………... 37

3.3.3 HPLC Standards ……….. 38

3.3.4 Extraction and analysis of triterpenic acids………. 38

3.3.5 Tocochromanols and carotenoids extraction and analysis ………. 39

3.3.6 Extraction and fatty acids analysis ………. 39

3.3.7 Extraction and analysis of free and total phenolic compounds ………40

3.3.8 Pasta characteristics determination ……… 40

3.3.9 Polyphenols bio-accessibility of enriched pasta ……….. 41

3.3.10 Statistical analysis ………. 41

3.4 Bread and pasta with pâtè and olive mill waste water……….... 41

3.4.1 Raw materials ………..……… 41

3.4.2 Sensory analysis ………... 42

3.4.3 Chemical analyses ………..…. 42

3.4.4 Whole quality index ………. 43

3.4.5 Statistical analysis ………... 44

3.5 Olive pomace ……….. 44

3.5.1 Raw materials ……….. 44

3.5.2 Supercritical fluid extraction ………... 44

3.5.3 Pressurized liquid extraction ………... 44

3.5.4 Ultrasound assisted extraction ……… 45

3.5.5 Chemical characterization of the extracts……… 45

3.5.6 Statistical analysis ………... 45

3.6 Taralli with extract from olive leaves ……….. 46

3.6.1 Extract preparation ………... 46

3.6.2 Taralli preparation ……….. 46

3.6.3 Sensory and chemical characterization of taralli ……… 46

3.6.4 Bio-accessibility of enriched taralli ………. 46

3.6.5 Statistical analysis ………... 47

4. RESULTS AND DISCUSSION ……….. 48

4.1 Fish burger with OP ……….. 48

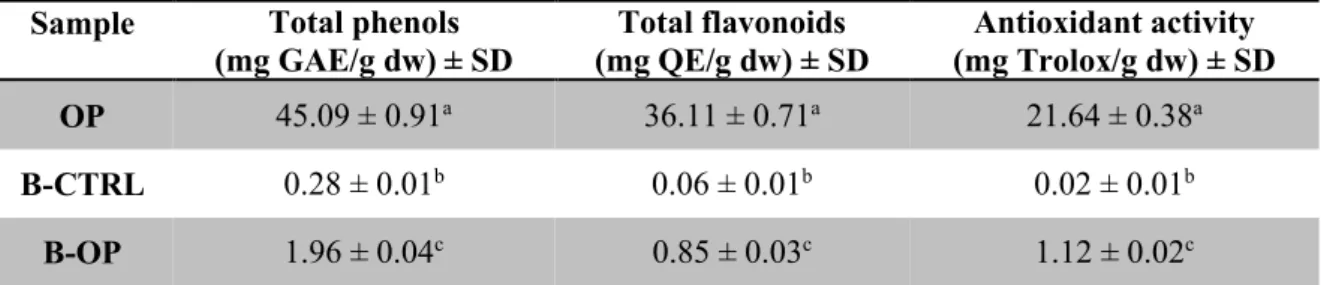

4.1.1 Production and characterization of olive pâtè ……… 48

3

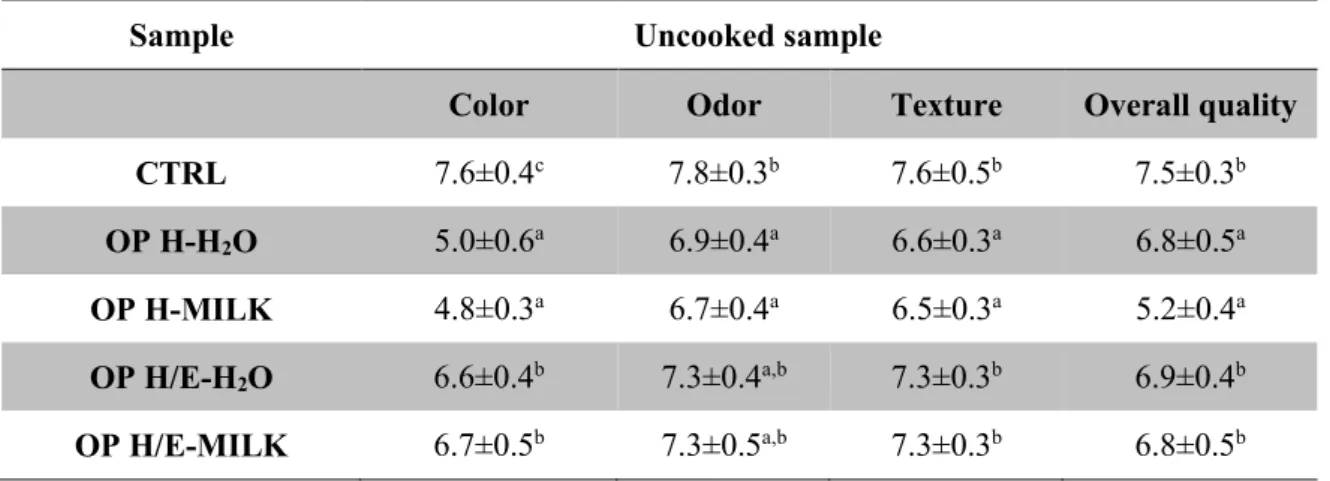

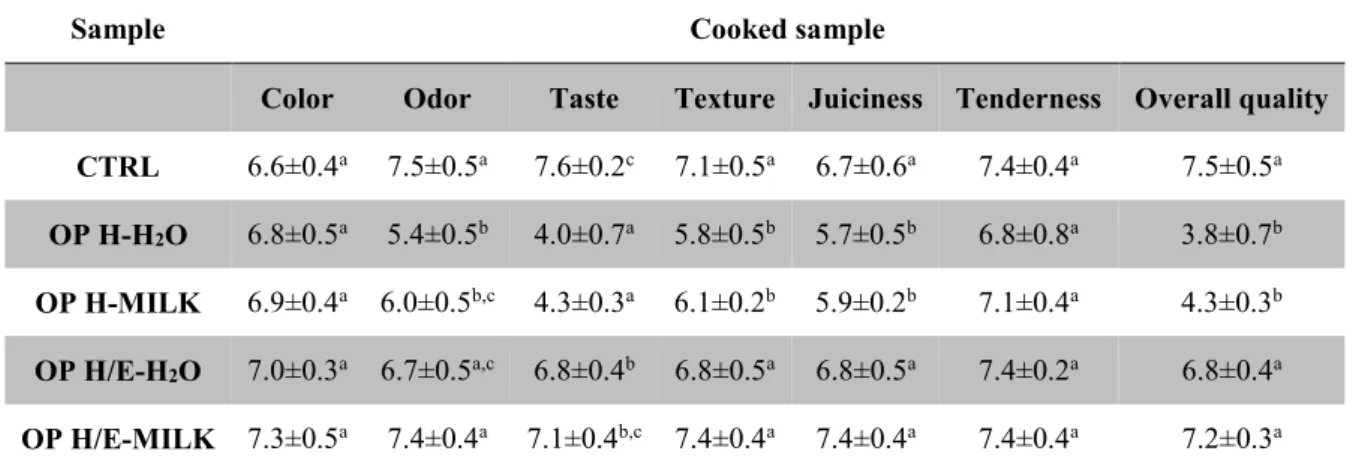

4.1.3 Formulation optimization of olive pâtè of enriched burger ……… 50

4.1.4 Sensory quality of enriched burger ……….. 51

4.2 Bread with olive pâtè ………. 54

4.2.1 Sensory and nutritional characteristics ………... 54

4.2.2 Glycemic index ………. 56

4.2.3 Polyphenol bio-accessibility ……… 57

4.3 Pasta with OP ………. 59

4.3.1 Biochemical Composition of Semolina and olive pâtè ……… 59

4.3.2 Sensory quality of spaghetti enriched with olive pâtè ………. 62

4.3.3 Effect of transglutaminase addition on spaghetti enriched with olive pâtè …. 64 4.3.3.1 Sensory quality ………. 64

4.3.3.2 Biochemical composition ………. 67

4.3.4 Polyphenols bioaccessibility of enriched pasta ……… 69

4.4 Bread and pasta with olive pâtè and olive mill waste water ……….. 72

4.4.1 Chemical quality ……….. 72

4.4.2 Sensory quality ………. 76

4.4.3 Whole quality index ………. 79

4.5 Olive pomace ……….. 80

4.5.1 Supercritical fluid extraction ………... 80

4.5.2 Pressurized liquid extraction ………... 81

4.5.3 Ultrasonic assisted extraction ………. 83

4.5.4 Comparison among SFE, PLE and UAE ………. 84

4.6 Taralli with extract from olive leaves ……….. 86

4.6.1 Sensory and chemical analysis of enriched taralli ……….. 86

4.6.2 Bioaccessibility of enriched taralli ……….. 87

5. CONCLUSION ……… 88

4

Abstract

The olive oil industry generates an important number of by-products, such as olive mill waste water, olive pomace and olive leaves. It has been demonstrated that these vegetable wastes are rich in almost all the phenolic compounds which are present in olive oil. Nevertheless, olive oil by-products have not yet been exploited at industrial scale, for example as sources of bioactive compounds. For this purpose, it is necessary to study how the processing conditions (raw material pre-treatment, extraction, etc.) affect their properties, as well as explore new applications in the food industry. Therefore, the main goal of this thesis was related to the possibility of using olive oil by-products for the formulation of new fortified foods. To this aim, it was necessary to consider that the potential incorporation of by-products into food formulation could alter the sensory properties, thus suggesting that careful selection of the type and the amount of these ingredients and proper technological options, should be adopted.

Specifically, in this research activity the effects of drying methods applied to the extracts from olive oil by-products on the polyphenol content and antioxidant capacity were investigated. Supercritical fluid extraction, pressurized liquid extraction and ultrasonic assisted extraction were adopted to choose the best extraction conditions to be applied to by-products. Fresh olive pomace and olive leaves were air dried at low temperatures to preserve bioactive compounds and then used to fortity food. Olive mill waste water was pretreated by membrane technology, with the dual aims of reducing the organic load waste water and recovering polyphenols. This technology, through the use of four membranes in cascade of microfiltration, ultrafiltration, nanofiltration and reverse osmosis is able to extract polyphenolic compounds. Innovative ceral-based and fish-based products were realized using these by-products rich in bioactive molecules. The enriched food products were characterized for the content of bioactive compounds, for sensory properties and then subjected to in vitro digestion with to purpose of evaluating the bioaccessibility of total polyphenols. The experimental results are very interesting and highlight that olive oil by-products could be valorized as promising ingredients to realize new products rich in phenolic compounds, also facing the problem of the environmental pollution.

5

Sommario

L'industria dell'olio d'oliva genera un numero importante di sottoprodotti, come le acque di scarico delle olive, la sansa di oliva e le foglie di ulivo. È stato dimostrato che questi scarti vegetali sono ricchi degli stessi composti fenolici presenti anche nell'olio d'oliva. Tuttavia, i sottoprodotti di olio d'oliva non sono ancora stati sfruttati su scala industriale, ad esempio come fonti di composti bioattivi. A tal fine, è necessario studiare a fondo in che modo le condizioni di lavorazione (pretrattamento della materia prima, estrazione, ecc.) influenzano il potenziale di bioattività, nonché esplorare nuove applicazioni nell'industria alimentare. Pertanto, l'obiettivo principale di questa tesi era legato alla possibilità di utilizzare i sottoprodotti oleari ricchi di composti polifenolici per la formulazione di nuovi alimenti funzionali. Per realizzare nuovi alimenti è necessario considerare che la potenziale incorporazione di sottoprodotti nella formulazione alimentare potrebbe alterare le proprietà sensoriali, suggerendo quindi che un'attenta selezione del tipo e la quantità di questi ingredienti e le opportune opzioni tecnologiche, dovrebbero essere adottate. In particolare, in questa attività di ricerca sono stati studiati gli effetti dei metodi di essiccazione applicati agli estratti dai sottoprodotti dell'olio di oliva sul contenuto di polifenoli e sulla capacità antiossidante. Estrazione di liquidi supercritici, estrazione liquida pressurizzata e estrazione assistita ad ultrasuoni sono stati adottati per scegliere le migliori condizioni di estrazione da applicare ai sottoprodotti. La sansa d'oliva fresca e le foglie di olivo sono state essiccate all'aria a basse temperature per preservare i composti bioattivi e poi utilizzate per alimentare la fortuna. Le acque reflue dei mulini sono state pretrattate dalla tecnologia a membrana, con il duplice scopo di ridurre l'acqua di scarico del carico organico e recuperare i polifenoli. Questa tecnologia, attraverso l'uso di quattro membrane in cascata di microfiltrazione, ultrafiltrazione, nanofiltrazione e osmosi inversa è in grado di estrarre composti polifenolici. Innovativi prodotti a base di cerali e di pesce sono stati realizzati utilizzando questi sottoprodotti ricchi di molecole bioattive. I prodotti alimentari arricchiti sono stati caratterizzati per il contenuto di composti bioattivi, per le proprietà sensoriali e quindi sottoposti a digestione in vitro allo scopo di valutare la bioaccessibilità dei polifenoli totali. I risultati sperimentali sono molto interessanti e sottolineano che i sottoprodotti dell'olio d'oliva potrebbero essere valorizzati come ingredienti promettenti per realizzare nuovi prodotti ricchi di composti fenolici, affrontando anche il problema dell'inquinamento ambientale.

6

1. INTRODUCTION

1.1 Olive oil industrial by-products

Olive (Olea europaea L.) is one of the most important crops in the Mediterranean countries. Around world more than eight million ha of olive trees are cultivated and about 98% of them is present the Mediterranean basin (Peralbo-Molina and Luque deCastro, 2013). Olive oil production is particularly important for Spain, Italy and Greece as the major producers in EU. Spain, with 2.47 million ha, has the largest area under cultivation, followed by Italy (1.16 million ha), Greece (0.81 million ha) and Portugal (0.38 million ha) (Inglezakis et al., 2012). Olives have attracted considerable attention during the past few years as sources of biophenols useful for the food and pharmaceutical industries. The technology for olive oil extraction has progressed significantly since the beginning of the seventies, when the three-phase centrifugation system appeared. By means of this system, the oil, vegetation water and solid phase of the olive can be separated in a continuous process, with the result that the traditional discontinuous press system is almost non-existent at present. The main inconvenience of the three-phase system is the generation during a short period of the year (November–February) of large quantities of olive mill waste water (OMWW), which is a very polluting liquid made of the olive vegetation water plus the water added in the different steps of oil production. In an attempt to reduce its environmental impact, different methods have been tried to make the best use of OMWW; these include storage in evaporation ponds and its direct application to agricultural soils as fertilizers. However, these methods have gradually become less viable for OMWW disposal, and so a new two-phase centrifugation system for oil extraction was developed during the early nineties. Although this is called the ecological system because it greatly reduces wastewater generation and its contaminant load, it still produces a solid and very humid by-product called ‘‘alperujo’’or olive pomace. Almost all of the olive mills in Spain use the two–phase centrifugation system for oil extraction to reduce wastewater generation and lower the contaminant load, compared with the three–phase centrifugation system (Dios–Palomares et al., 2005) which is corrently used by also other Mediterranean countries. The production of olive oil with this new centrifugation system, which saves both water and energy compared with the three-phase system, is estimated to represent about 75% of the total and the system is used roughly by 90% of olive-mills. As can be

7

seen in Figure 1, which schematically compares the three and two-phase centrifugation systems, approximately 800 kg of alperujo per ton of processed olives result from using the two-phase system, meaning that the yearly production of this by-product from the whole olive oil industry may approach four million tons. Recently, was developed an innovative two-phase decanter that produces a dehydrated husk similar to the one obtained from a three-phase decanter, but it also separates the pulp (pâté) from the husk directly after the malaxation step, so reducing thepossible oxidation processes. This by-product, named pâté, consists of awet homogeneous pulp free from residuals of kernel, peculiarity making it a suitable ingredient for possible commercial applications after drying. The phenolic fraction of olive oil comprises only 2% of the total phenolic content of the olive fruits, with the remainder being lost in olive mill waste, in the form of a solid waste and an aqueous liquid. Several research demonstrates that these by-products from olive grove farming are a good source of antioxidant compounds with antibacterial properties, which have potential applications in the food and pharmaceutical industries.

Figure 1 Comparison of the three and two-phase centrifugation systems for olive oil

8

1.1.1 Olive mill waste water

During olive oil production a considerable amount of water is employed, this water named “olive mill waste water” (OMWW) is discarded. Huge amounts (6-7 million tons/year) of OMWW, a complex medium containing polyphenols of different molecular masses, are produced in the Mediterranean countries cultivating the olive tree. In Italy, approximately 2 million cubic meters of wastewater are produced each year by the olive oil industry. This waste is claimed to be one of the most polluting effluents among those produced by the agro-food industries because of its high polluting load and high toxicity to plants, bacteria, and aquatic organisms, owing to its contents (14-15%) of organic substances and phenols (up to 10 g/L). These latter compounds, characterized by high specific chemical oxygen demand (COD) and resistance to biodegradation, are responsible for its black color, depending on their state of degradation and the olives they come from, and its phytotoxic and antibacterial properties (Capasso et al., 1992). For long time, OMWW has been regarded as a hazardous waste with negative impact on the environment and an economic burden on the olive oil industry. However, this view has changed to recognize OMWW as a potential low-cost starting material rich in bioactive compounds, particularly phenolics, that can be extracted and applied as natural antioxidants for the food and pharmaceutical industries. There is growing evidence that free radical mediated events are involved in several human diseases, because free radicals attack biomolecules such as lipids, protein, DNA, and bio-membranes, and play major roles in the oxidative degradation of food, animal feed, and cosmetics. Therefore, the extraction of biologically active phenolics from OMWW constitutes a viable alternative for valorizing this problematic agro-industrial waste (Capasso et al., 1992; Obied et al., 2008). The scientific interest in this material derives from the fact that its phenolic fraction possesses interesting biological activities. Several in vitro and in vivo studies have shown that phenols found in olives, olive oil, and OMWW exert potent biological activities including, but not limited to, antioxidant and free radical scavenging actions. They are potentially capable of preventing passive smoke-induced oxidative stress, reducing thromboxane B2 production by whole blood, and ameliorating symptoms of inflammatory diseases such as osteoarthritis (Visioli et al., 2000; Visioli et al., 2009). The antioxidant efficiency of olive phenols has been assessed in various tests (Roche et al., 2005). It has been also observed that the administration of OMWW extract fractions as well as purified

9

hydroxytyrosol in diabetic rats caused a decrease in the glucose level in plasma (Hamden et al., 2009). A typical phenolic substance identified in olive fruit is oleuropein, a secoiridoid glucoside that is absent in OMWW due to enzymatic hydrolysis during olive oil extraction resulting in the formation of side products such as hydroxytyrosol and elenolic acid. Other phenolics identified in OMWW are verbascoside, tyrosol, catechol, 4-methylcatechol, p-hydroxybenzoic acid, vanillic acid, syringic acid, and gallic acid (Visioli et al., 1999). Another potentially important compound present in OMWW is verbascoside and its isomer isoverbascoside (Wu and others, 2006). Verbascosides have demonstrated antioxidant protective effects on phospholipid membranes and have demonstrated the ability to modulate plasma antioxidant measures in vivo (Funes et al., 2009).

1.1.2 Olive pomace

The main by–product of the two–phase extraction system is olive pomace (OPO), which in Mediterranean areas is produced during a short period over the winter, from November to February (Moraetis et al., 2011), the amount generated varying between 7 and 30 million m3 per year (López-Piñeiro et al., 2011). Typically, OPO is a semi–solid to semi–liquid by-product resulting from the mix of “alpechin”, the main by–products resulting from the older three–phase extraction procedure, and “orujo”. This by-product is made mainly with water, seed and pulp and is a potentially harmful by–product for the environment, because of the phytotoxic and antimicrobial properties, low pH, relatively high salinity and organic load, and the phenolic and lipid constituents (Piotrowska et al., 2011). Direct application to rivers or soil is not allowed under most of the national regulations of the producer countries. The main physico–chemical characterization of OPO can be found in many reports (Sierra et al., 2007; Paredes et al., 1999; Alburquerque et al., 2004). According to these studies, OPO is acidic, with a very high content of organic matter and carbon, rich in potassium (K), poor in phosphorus (P), with intermediate levels of nitrogen (N) and may also contain phenolic and lipid compounds. Although being lignocelluloses material, OPO contains a great amount of bioactive compounds, with a wide range of physiological properties, such as, anti-artherogenic, anti-allergenic, anti-cancer, anti-inflammatory, antioxidant, anti-microbial, anti-thrombotic, cardioprotective and vasodilatory effects (Lozano-Sánchez et al., 2014). Among them, three glucosides, including salidroside (tyrosol–glucose),

10

nuezhenide (glucose–elenolic acid–glucose–tyrosol) and nuezhenide-oleoside, have been identified in OPO. Nuezhenide is found only in seeds as a predominant phenol, whereas verbascoside only appears in significant quantities in the seeds and pulp (Azmir et al., 2013). Thus, thanks to its low cost and large availability, several extraction techniques for OPO antioxidant components have been developed with the aim of re-valorizing the olive oil by-product and minimizing the environmental impact associated with its disposal.

1.1.3 Olive pâtè

The olive oil extraction technique has progressed significantly since the beginning of the 1970s, when the three-phase centrifugation system proved to be more efficient than the traditional pressing used for many centuries. In the 1990s was introduced in Spain the two-phase centrifugation system as a more ecological approach for olive oil production, drastically reducing the amount of added water and producing a semi-solid by-product named alperujo, or olive pomace. Recently, Pieralisi S.p.A. developed an innovative two-phase decanter named Leopard that can combine modern extraction technology without the addition of water. This decanter produces a dehydrated husk similar to the one obtained from a three-phase decanter, but it also separates the pulp from the husk directly after the malaxation step (Leopard Series, Pieralisi Group S.p.A. Jesi, Italy), so reducing the possible oxidation processes. This by-product, named olive pâté (OP), consists of a wet homogeneous pulp free from residuals of kernel, peculiarity making it a suitable ingredient for possible commercial applications after drying. It is potentially suitable for various uses, including animal feeding, but also for human consumption in the form of food supplement or food ingredient. The possibility to use the fresh OP was evaluated in one study (Luciano et al., 2013), who demonstrated that the inclusion of OP into a concentrate-based diet for lambs could be proposed as a strategy to improve the nutritional quality of meat without compromising its oxidative stability. Indeed, the inclusion of this pâté in the animal diet increased the concentration of vitamin E in muscle and extended meat oxidative stability. Reports on the use of this particular pâté for food formulations to be used in the human diet are not available so far. Clearly, the possibility of turning a by-product into a valuable resource, particularly for human consumption, would represent an important benefit for the miller. Recently, one study focused on the qualitative and quantitative characterization of this pâté

11

(Lozano-Sánchez et al., 2017); the authors analyzed one sample recovered in 2015 from a mill in the Marche region (Italy) and concluded that this particular by-product can be used as source of bioactive hydrophilic and lipophilic compounds. The authors highlighted the high oxidative stability of the pâté, even if the high moisture content could be a serious technological processing problem for long-term storage of this by-product.

1.1.4 Olive leaves

More than 8 million ha of olive trees are cultivated worldwide. It has been estimated that an average of three tons of pruning biomass is obtained each year from one olive tree hectare, making these residues a huge, cheap, and unexploited source of energy or chemicals (Conde et al., 2009). Among them, residual biomass derived from olive trees includes two types of by-products: olive tree pruning and olive mill leaf biomass. The firsts is generated in olive groves when unproductive branches are eliminated, while the olive leaf biomass is obtained in olive mills by separating the leaves and thin branches fromthe olives. These olive residues do not have industrial applications and are usually burnt or just left in the field for fertilisation purposes; however, both practices have associated environmental risks (Ruiz et al., 2017). Olive leaves (OL) are also used for animal feed (Romero-Garcı´a et al., 2016), but their medicinal properties have aroused great attention. As the other parts of olive tree, leaves contain considerable amount of biophenols (Jilani et al., 2016). Olive leaves, which historically served as folk medicine in the Mediterranean region (Talhaoui et al., 2016), became even more valuable with reports of their extract effectively curing fever and malaria in 1854 (Altınyay and Altun, 2006). Polyphenols and flavonoids from olive leaves have demonstrated anti-carcinogenic, anti-inflammatory, antihypertension, and antimicrobial properties and thus are essential to the effects that gave olive leaves their significance. Biophenols in leaves are different from those of the flowers, fruits and the branch (Ozcan and Matthaus, 2017). Folklore reports about the therapeutic effects of tea made of olive leaves against sicknesses like coughing, sore throat, fever and cystitis in the Middle East culture for hundreds of years. Additionally, the leaf was used for dermatological diseases (Marsilio et al., 2001). Olive leaf was first used medicinally in ancient Egypt, and was the symbol of heavenly power. Several brands of medical supplements containing OL have been offered as liquid extracts or tablet forms against diabetes, high

12

blood pressure, cardiovascular diseases, common cold, urinary tract infections, chronic fatigue syndrome, and to support time of recovery, immune system (Ben Salem et al., 2015). Products containing olive leaf extract are used for anti-ageing activities in the cosmetics industry. Drugs made of OL extract are used not only for human health, but also for animal health due to their antibiotic and antiparasitic properties. In addition to the phenols commonly found in other plants, OL contain secoiridoid phenols, mainly oleuropein, which are exclusive to Oleaceae (Talhaoui et al., 2015). Since OL are inexpensive, they are a useful source of by-products with high phenolic value (Vergara-Barberan et al., 2015). Some research has been reported on the use of this by-products as raw materials in the biorefinery context to producemainly sugars and bioethanol through different thermochemical pretreatments (Negro et al., 2017). Such bioactivity drives the use of different olive oil by-products infunctional and food applications. In this sense, new applications have focused in enriching the food nutritional profile, replacing or improving the technological properties of food additives, and extendingthe food product shelf-life (Nunes et al., 2016).

1.2 Management of olive oil by-products

1.2.1 Waste or by-products?

The traditional waste management practices in the olive oil sector result in environmental problems as soil contamination, underground seepage, water-bodies pollution and foul odor emissions (Cabrera et al., 1996). Phenolic concentration deserves special attention for it influence on the antibacterial effects, phytotoxic effect and dark colour of OMWW. Discharging untreated or partially safe olive mill wastewater back into natural water systems can result in a rapid rise of microorganism numbers and this could quickly offset the equilibrium of an entire ecosystem (LIFE Focus, 2010). While phenolics are mainly held responsible for the olive oil wastewater strong antimicrobial and phytotoxic properties, non-phenolic-related toxicity attributed to long-chain fatty acids and volatile acids was also reported (Ouzounidou et al., 2010). Moreover, OMWW has been shown to affect the physical and chemical properties of soil and its microbial community, while several studies have evidenced its phytotoxic effects and antimicrobial activity. Olive oil waste can be toxic to anaerobic bacteria, which may inhibit conventional secondary and anaerobic treatments in municipal treatment plants (Karaouzas et al., 2011). Furthermore, the very high BOD5 and COD,

13

which cannot be reduced in appropriate levels by anaerobic digestion poses another threat for the receivers (LIFE Focus, 2010). Landspreading and treatment in evaporation ponds could lead in groundwater pollution problems. The presence of organic matter as well as many inorganic compounds causes severe pollution when olive mill wastewater is disposed of into water bodies, but in soil it prevents erosion and can be beneficial to soil fertility (Kapellakis et al., 2008). Controlled land application of olive oil waste results in increase of soil organic matter and nutrient availability and thus, improves soil fertility and productivity by controlling the nutritional and biological equilibrium in the soil–plant interface. The use of olive oil waste in agriculture may also affect acidity, salinity, N immobilization, microbial response, leaching of nutrients and concentration of lipids, organic acids and phenolic.

One important question is “waste or by-product?”. It is true that the characterization of a waste as by-product simplifies its further use. These materials are generated from industrial processes, which are considered, by the producers at least, to be by-products rather than wastes so that they can be recycled to land as soil improvers and fertilisers with minimum restriction (EC-DG, 2001). EC Directive 2008/98 specifies in the preamble under point 22, the need to avoid confusion with regards to the various aspects of the concept of waste and so make a distinction between waste and by-products (Taccogna, 2010). However, confusion still exists and in some cases the courts resolve these issues. Pursuant to article 5 of Directive 2008/98/EC, the by-product is a substance or object resulting from a production process the primary aim of which is not the production of that item. Such a substance or object can be regarded as not being waste if the following conditions are fulfilled:

(a) further use of the substance or object is certain;

(b) the substance or object can be used directly without any further processing other than normal industrial practice;

(c) the substance or object is produced as an integral part of a production process; (d) further use is lawful; the substance or object fulfills all relevant product, environmental and health protection requirements for the specific use and will not lead to overall adverse environmental or human health impacts.

Concerning olive oil pomace and, together with above definitions, is also reported (Taccogna, 2010):

(a) the conditions for using, as a by-product, pomace from the pressing process in an olive mill, without applying the rules on waste, can exist with regard to its possible

14

uses: selling it to olive pomace refineries for chemical processing to extract olive pomace oil; spreading it as fertilizer (or mixed with backfill ground); as an additive in animal feed; for fuel (or similar), such as biomass, at energy production installations. (b) olive oil pomace (OPO) deriving from mechanically pressing olives in the mill, for producing olive oil, conclusively meets the second condition where a by-product can be obtained only if the substance is produced as an integral part of the process (or not as the primary aim of production).

(c) it might be possible to consider that OPO can be used directly without needing any special processing other than normal industrial practice and so essentially in the same state as when it is pressed in the mill. Although it is true that further drying may sometimes be needed, it can still be considered as “common industrial practice” and so it complies with the legal rules provided for by-products.

(d) since OPO is a natural substance, and considering its properties it might be assumed that there is no adverse impact. In the EWC Decision 2002/532, olive oil waste falls under Category 2: “Wastes from agricultural, horticultural, hunting, fishing and aquacultural primary production, food preparation and processing”. More specifically, the appropriate code is 02 03 “Wastes from fruit, vegetables, cereals, edible oils, cocoa, coffee and tobacco preparation and processing; conserve production”. This kind of waste is not marked by asterisk and thus is not an “absolute” hazardous waste. However, in publication for oil olive waste of the European Union Network for the Implementation and Enforcement of Environmental Law (IMPEL) is stated that “special legislative provisions are needed for the solid residue, since, in principle, could be considered hazardous waste” (IMPEL, 2003). As is well known, olive oil waste contains polyphenols which render this waste as potentially “ecotoxic”, under code H14: “‘waste which presents or may present immediate or delayed risks for one or more sectors of the environment”, in the meaning of in Annex III to Directive 91/689/EEC and to Directive 2008/98/EC.

1.2.2 EU legislation of olive by-products

The Legislative Decree n° 152 of 1999, transposition of the European Directives 91/271/CEE and 91/676/CEE, regulates the waters safeguard from pollution. The article 38 of this act makes reference to the Italian Law n° 574 of 1996 with regards to agronomic use of sewage sludge and other wastes. According to this law (n° 574), the

15

agronomic use of these by-products is allowed on the ground of their composition and the characteristics of soils. Such use has to be authorised each time by the competent public authority on the ground of simple documentation but subordinate to limitations, verifications and possible sanctions in order to avoid any fraudulent activity that can pollute water tables (More, 2009). This law allowed the direct application of the olive mill wastewater without previous treatment (Kapellakis et al., 2008). Technical aspects according to the Law 574/96 (More, 2009; Res-Hui, 2006):

Maximum tolerance limit for soils: 50 m3/ha/year for olive mill waste waters deriving from traditional mills (discontinuous extraction systems); 80 m3/ha/year for vegetable water deriving from centrifugal extraction (continuous extraction systems);

Uniform spreading in order to avoid surface runoff;

Submission of the agronomic report to the Municipality at least 30 days before the spreading. The report has to be written by an expert technician and has to cover topics such as the characteristics of the soil, the time and means of spreading;

Possibility for the Mayor of any municipality of modifying those limits or suspending fertirrigation in case of environmental risk;

It is forbidden to spread vegetable water on:

soils which are at less than three hundreds meters from the preservation areas for water

soils which are less than two hundred meters from inhabited areas; collection destined to the human consumption;

soils which are cultivated with vegetable crops;

soils where water tables are at less than ten meters depth;

soils which are frozen, covered by snow, awashed or saturated with water. Waste storage in the oil mill less than 30 days (limit protracted to 3 months – D

Lgs 22/1997)

With the 6 July 2005 Decree, “Criteria and technical rules regarding regional regulation of the agronomic use of olive mill waste waters and other mill wastes” that makes reference to article n° 38 of Decree n° 152 of 11 May 1999, some more exclusions of lands are added (Res-Hui, 2006):

16

Distance <10 m from sandy shore or lake water

Lands with slope >15% and lacking of hydraulic and agricultural setting Woods

Quarry

Gardens and public areas

Furthermore, the same Decree prohibits the mixing of olive oil wastewater with other wastewater (e.g. animal slurry) or waste. Finally, oil mill water plus stone fragments and fibrous part of the fruit can be used in agriculture and are not subject to Fertiliser Law No 748. According to Law n° 574 of 1996 wet olive husks can be used as soil amendment notwithstanding to the indications given in the Italian Law n° 748 of 1984 on fertilizers and subsequent modifications such as legislative Decree n° 217 of 29 April 2006 “Revision of regulations on fertilizer use”. According to the later, wet olive husks can be considered as a “simple notcomposted plant amendment” and therefore they can be applied to soil without any specific limitations if they comply with the thresholds set by the decree regarding some specific parameters, i.e. humidity, pH, organic carbon, organic nitrogen, total Cu referred to dry matter, total Zn referred to dry matter, total peat content and other heavy metals contents. With the D.M. 05/02/1998 and D. Lgs n. 22/97, by-products coming from olive oil pressing are allowed to be placed in the market. The same Decree specifies that olive husks (pomace) are non-dangerous waste. The same waste can be used in the energy sector, as defined in the DPCM 08/10/2004 (More, 2008; Res-Hui, 2006). Finally, The disposal of wastewaters (of any kind and, therefore, of OMWW too) in sewage systems or in superficial water bodies (rivers, lakes etc) is regulated by the Decree 152/2006. The specific thresholds set by the Decree for all the parameters to be taken in consideration for disposal are listed in Table 3 of Annex 5 of the Decree. The ELVs are set for national level (IPPB BREF, 2006b).

1.3 Re-use of olive oil by-products

Olive mill wastes require a complex management and disposal system due to their textural and organoleptic properties, as well as their negative effects on the environment (Roig et al., 2006). Nevertheless, have been studied as organic fertilizers (Fernandez-Hernandez et al., 2014; Magdich et al., 2012). Some evidences have shown that the high levels of phenolic compounds in olive by-products may be responsible for phytotocixity

17

and modifications in soil microflora (Kotsou et al., 2004). However, at a maximum spreading rate of 100 m3 ha-1, olive oil by-products did not affect olive production, despite the increasing levels of phenolic content when compared to the control soil (Magdich et al., 2012). Furthermore, phenolic compounds from olive oil by-products may act against specific plant pathogens, showing potential as natural pesticides (Cayuela et al., 2008). Olive by-products were also tested as a natural supplement in feeds of small ruminants (Yanez-Ruiz and Molina-Alcaide, 2007) and fish (Sicuro et al., 2010). However, the presence of complex polyphenols may have exhibited a negative impact on nutrient digestibility and intestine flora (Vasta et al., 2008). Olive pomace was included in sheep and goat feeds to study the effects of its phenolic content on digestibility, nitrogen losses and liver and kidney functions (Yanez- Ruiz and Molina-Alcaide, 2007). In this case, although being considered anti-nutritional factors, the phenolic compounds did not cause toxicity in the animals for the tested inclusion levels of olive pomace (122 and 128 g/kg of feed DM). Despite their controversial effects on plant growth and nutrient digestibility in animals, phenols from olive by-products are considered valuable compounds to be employed in other fields. For instance, their introduction in foodstuffs could decrease the use of synthetic antioxidants, such as butylated hydroxyanisole (BHA), butylated hydroxytoluene (BHT) and tert-butylhydroquinone (TBHQ). Due to their potential negative effects on health, these synthetic antioxidants are restricted to maximum concentrations in foodstuffs. In oils and fats, for example, those concentrations should not exceed 200 mg/kg of fat (individually or in combination with other added antioxidants) for BHA and TBHQ and 100 mg/kg for BHT (EC, 2011). These restrictions imposed by legislation, along with the health concerns related with the above mentioned synthetic antioxidants, are challenging matters for industries that need to find safer and costeffective alternatives. For instance, phenolic compounds recovered from vegetable by-products, such as olive oil by-products, can be applied in food matrices, improving their preservation and antioxidant properties. Bouaziz et al. (2010) observed that the introduction of a hydrolyzed phenolic extract of olive leaves in refined olive oil and olive oil pomace revealed a higher oxidation resistance when compared to the use of oleuropein and α-tocopherol. The authors related this antioxidant protection to the high levels of hydroxytyrosol and oleuropein aglycone in the hydrolyzed phenolic extract. Additionally, phenolic compounds of olive pomace were included in commercial sunflower oil (without added antioxidants) and compared to the use of other food

18

antioxidants by means of induction periods at 100 C (Lafka et al., 2011). Results from induction time measurement showed that phenolic extracts combined with ascorbyl palmitate contributed to a longer antioxidant protection than the one observed with the addition of ascorbyl palmitate, BHT and vitamin E. In another study, phenolic extracts from olive pomace were dissolved in ethanol/water and included in olive oil (Suarez et al., 2010). The results showed a significant improvement of the antioxidant capacity (up to 73%) of phenol-enriched olive oil when compared to the control group. In another research, De Leonardis et al. (2008) included hydroxytyrosol and oleuropein extracts from olive leaves in cod liver oil and solid fats, which led to an induction time increase with the increasing concentration of extract for all the tested matrices. Troise et al. (2014) included OMWW phenolic powder in raw milk that was then ultra-pasteurized and monitored the products derived from this thermal treatment. The author reported that the addition of this phenol-rich powder inhibited the formation of off-flavor compounds resulting from Maillard reactions during UHT treatment, improving the sensory quality of ultra-pasteurized milk. Hence, phenolic compounds from olive oil by-products may contribute to an improvement of nutritional and sensory quality in food products. The advantage of using olive oil by-products as feed supplements to reduce oxidative stress and improve meat antioxidant status, oxidative stability, and shelf life, has been demonstrated in different food producing animals, such as lambs (Luciano et al., 2013), chickens (Gerasopoulos et al., 2015; Tufarelli et al., 2016), rabbits (Dal Bosco et al., 2012), and beef cattle (Branciari et al., 2015). However, no reports are available on the use of olive pomace and the metabolic pathway of these compounds in poultry. Poultry meat is particularly prone to oxidative deterioration due to its high concentration of polyunsaturated fatty acids (Igene et al., 1979). There are many studies showing an improvement in the oxidative stability of chicken meat after feeding poultry with natural antioxidants as dietary additives (Gerasopoulos et al., 2015; Tufarelli et al., 2016; Botsoglou et al., 2002), causing an increase in the market value of the resulting products. Olive industry by-products could represent a different source of nutrients for animals and their inclusion in animal diets could be a convenient strategy to reduce oxidative deterioration in meat and increase olive oil production sustainability. Furthermore, when these compounds are present in small amounts in food, they are capable of preventing or retarding the oxidation of oils and fats, being a potential preservative of food quality (Tufarelli et al., 2016; Oroian et al., 2015). As example, one of the latest uses reported in the literature has been to include

19

thepurifiedphenol extract from OMWW to fresh sausage as a potential bioactive ingredient (Lucci et al., 2017). Currently, technology solutions are aimed at minimizing the amount of vegetable waste water effluent (Taticchi et al., 2017) andutilizing olive residues, either through promoting their overall sustainable management and conversion into an affordable source of bioactive compounds.

1.3.1 Extraction from olive mill waste water

From the oil extraction process regardless of the method used, extraction by pressure or centrifugation, olive mill waste water are formed in considerable amount. It has been estimated that for the process of the olives milling the OMWW produced are 1.1‐1.5 times the weight of the minced olives. The annual production of vegetation waters in the Mediterranean countries is greater than 3x107 m3 and this is a disadvantage for the Italian crushers, because there is the problem to dispose large quantities concentrated in periods from October to January. Always the OMWW represent an environmental problem due to their high content of pollutants and their disposal add an additional cost to the oil producers. Several studies for their use as agricultural fertilizer are been found on the literature, but the centralization of milling processes in large mills that use advanced technologies hinders this traditional procedure. On the other hand, the OMWW are rich in phenolic compounds, potentially valuable if could be possible to develop an efficient recovery process and especially if there is the ability to formulate the final products that can be used as ingredients, food, nutraceutical or cosmetic. Recently, studies have used membrane technology, with the dual aims of reducing the organic load of OMWW and recovering polyphenols from OMWW. This technology, through the use of four membranes in cascade: microfiltration (MF), ultrafiltration (UF), nanofiltration (NF) and Reverse Osmosis (RO), is able to recovered, continuously, high nutritional value able to be used in various fields of food and pharmaceutical industry and deionized water for possible agronomic applications. This system, mainly applaied for the OMWW treatment has the dual purpose of recovering substances with high added value, to be used in various fields such as pharmaceutical, food and cosmetics, and obtaining at the same time the purification of water, with obvious advantages from the environmental point of view. The flow chart of the polyphenols extraction from the vegetation water is shown in Figure 2 and described briefly below.

20

Figure 2 Flows diagrams

Microfiltration (MF) is made by tubular polymeric membranes with a 0.03 µm filter surface. From the storage tanks and the OMWW are fed into the circuit of the MF max 1200 l/h at a pressure of 5 bar pumped with an inverter for the flow regulation. Through the MF retentate side, is realized with a recycle flow rate of 110 m3/h approximately with centrifugal pump appropriate, to maintain the speed inside the membrane of 4 m/s, that should avoid the solids accumulation on the membrane filter walls, preventing so the occlusion. The pressure, in the system, is maintained by a valve skimming, self‐regulating pressure upstream, settable in the range 2 to 5 bar. Bleeding is conveyed in the system of collection and disposal drainages. Part of this water, that giving rise to the permeate through the MF membrane, has the pressure regulated by a valve skimmingwith self‐regulating pressure upstream, settable in the range 1 ÷ 4 bar, whose set is fixed manually 0.5 ÷ 1 bar below the pressure set up in the circuit of the retentate, to maintain a trans‐membrane pressure of about 1 bar. The overflow of permeate is conveyed to a suitable storage tank, from which it will be further used to feed the next section of Ultrafiltration (UF). The tank is equipped with the system of blanketing with nitrogen and with heating jacket. The MF retentate is conveyed to the waste for the untreated OMWW as it is poor in polyphenols and a few other impurities.

21

Figure 3 Micro-filtration membrane system

Ultrafiltration (UF) is carried out by a spiral wound membrane having a porosity of 5000 Da. The feeding is the permeate of the MF collected in a storage tank of 2.7 m3 to max flow of 1200 l/h with a pressure of 10 bar with a manually operated pump with inverter for adjusting the flow rate. Through the UF retentate side, is realized with recycler with a flow rate of 10 m3/h approximately by centrifugal pump. The pressure in the system is maintained by a settable valve. Part of the water through the membrane to give the UF permeate. The produced permeate is conveyed to a suitable tank, kept under nitrogen, from which will be picked up and fed to the next section of nanofiltration (NF). The UF retentate is stored in a storage tank of 2.7 m3 equipped with nitrogen blanketing system.

The Nanofiltration (NF) is carried out by a spiral membrane having a pore size of 200 Da. Power is carried out with the UF permeate collected in a small tank with a flow rate of 1200 l/h at a pressure of 20 bar with a manually operated pump with inverter for the flow rate setting. Through the NF retentate side, is realized with a recycler with a flow rate of about 10 m3/h by centrifugal pump. The pressure in the system is maintained by a settable valve. Part of the water through the membrane to NF give the UF permeate. The produced permeate is conveyed to a suitable tank, kept under nitrogen, from which will be picked up and fed to the Reverse osmosis.

22

Figure 4 Ultra- and nano-filtration membrane system

The Reverse Osmosis (RO) spiral membrane has a porosity of 100 Da. The NF permeate collected in its storage tank is drawn from a triplex pump, with flow rate of max 1200 l/h manually controlled by an inverter, feed the circuit of RO. The system can work in a range of pressures between 30 bar and 70 bar. For pressures around 30 ÷ 40 bar the pressure is maintained by a valve. Through the RO, the retentate side, is realized with a recycle flow rate of 10 m3/h approximately always with a special triplex pump. For higher values, however, the pressure is adjusted manually by a needle valve. Part of the water through the membrane of RO give the permeate. The permeate is produced is partly used for the circuit Water Services while the excess is discharged as completely made up of purified water.

1.3.2 Extraction from olive pomace

The olive pomace (OPO) is an organic lignocellulosic material with a difficult commercial collocation due to its high moisture content (55–65%), which causes a noticeable increase in oil extraction costs, but it could be conveniently reused in agriculture as a valid soil amendment (L. 574/96). The maximum amount of wet pomace that farmers may apply over a 3 year period is 210 Mg ha−1. In Italy, where the soil organic matter content is on average low and the Mediterranean climate contributes to its fast mineralization, the spreading of wet pomace on agricultural soil could increase its fertility; moreover, crops could also benefit from the dissolved water and

23

nutrients without toxic effects or yield reductions (Bonari and Ceccarini, 1993; Papini et al., 2000). Nevertheless, the OPO has some inconveniences when it is used in agriculture. The first is the difficulty to uniformly incorporate it into the soil. The second is its toxicity to plants due to the presence of high amounts of polyphenols (Marambe and Ando, 1992) which have, however, a fast decay (Camacho et al., 2000), and of oil residues that induce a slowing of the metabolism and of zymogene soil microflora multiplication, attenuated for some physiological groups after about 30 days, but continuing until 300 days for other groups such as autotrophic nitrifiers (Bedini et al., 1998). The spreading of olive-processing wet pomace on the soil seems, however, to improve the soil physical fertility. In particular, it induces an increase in the storage and transmission pores with beneficial effects on water retention, water flow in the soil and the structural stability, with the subsequent prevention of surface crusting (Bonari et al., 2001). The reductions of macro-porosity and water infiltration in the soil, just after treatments, are temporary unless applications are very high and/or take place in periods in which the biological activity is low, like in winter. It is known that the soil structural quality mostly depends on its interaction with organic matter, in the sense that the accumulation of the latter contributes to the formation and subsequent stabilization of aggregates against the dispersing action of water (Spaccini et al., 2001; Cavazza et al., 2002). An alternative for the disposal of large amount of OPO could be in evaporative ponds, but large areas would be required for this option which might also pose several potential environmental problems such as bad odor, leaching and insect proliferation (Cayuela et al., 2007). Another major preferred option would include the generation of renewable energy taking advantage of the relatively high calorific value of OPO. The process can be carried out in relatively inexpensive and simple reactor designs and operating procedures. Anaerobic digestion converts the carbonaceous matter into biogas leaving a stabilized slurry in a form suitable for reapplication to land as fertilizer. Common materials used for methane generation are often defined as waste materials, i.e. crop residues, animal and urban wastes. Manures and process waste waters have been extensively investigated as sources of biogas (Di Berardino et al., 2000).

In addition to these reuses, olive pomace can be used to enrich the human diet thanks to the many bioactive substances it contains. Although being lignocelluloses material, OPO contains a great amount of bioactive compounds, with a wide range of physiological properties, such as, artherogenic, allergenic, cancer, anti-inflammatory, antioxidant, anti-microbial, anti-thrombotic, cardio-protective and

24

vasodilatory effects (Lozano-Sánchez et al., 2014). Thus, thanks to its low cost and large availability, several extraction techniques for OPO antioxidant components have been developed with the aim of re-valorizing the olive oil by-product and minimizing the environmental impact associated with its disposal. Generally, the conventional extraction process are mainly based on basic hydrolysis or saponification and on liquid– liquid or liquid–solid extraction with the use of toxic polar solvents (McCarthy et al., 2013). Nowadays, the use of environmental-friendly extraction techniques, such as supercritical fluid extraction (SFE), pressurized liquid extraction (PLE) and ultrasonic assisted extraction (UAE) is increasingly required. In fact, these extraction techniques provide a lot of advantages, mainly connected to shorter extraction times, higher selectivity and lower consumption of organic solvents (Herrero et al., 2006, Azmir et al., 2013).

The supercritical fluid extraction (SFE) technology has advanced tremendously since its inception and is a method of choice in many food processing industries. The SFE technique is known as a green technology that minimizes damages to the environment while extracting high value-added compounds using a supercritical fluid, such as carbon dioxide (CO2) (Veggi et al., 2014). The most recent advances of SFE applications in food science, natural products, by-product recovery, pharmaceutical and environmental sciences have been published in extensive reviews. Solvent extraction (SFE) is one of the old methods of separation known and certainly dates back to Paleolithic age. The science of solvent extraction has evolved over a long period of time and much progress has been made in the understanding of solvation and the properties of liquid mixtures used in extraction processes. Hannay and Hogarth’s (1879) early observations of the dissolution of medium. However, it is only quite recently (around1960) that commercial process applications of supercritical fluid extraction have been extensively examined. Since the end of the 1970s, supercritical fluids have been used to isolate natural products; industrial applications of SFE have experienced a strong development since the early1990s in terms of patents. The main supercritical solvent used is carbon dioxide. Carbon dioxide (critical conditions tc = 31.3 °C and pc = 72.8 bar, dc = 0.467 gm/ml) is cheap, environmentally friendly and generally recognized as safe by FDA and EFSA (Dudai et al., 2006). The main downside of CO2 is its low polarity, problem that can be overcome using co-solvents, capable of hydrogen-bonding, dipole-dipole and other polarity interactions with the analyte of interest. The solvents could be unsafe to handle and unacceptable as it is harmful to human health and the environment,

25

restricting its use in the food, cosmetic and pharmaceutical industries. Furthermore, the major drawback of the solvent extracted products is the high level of residues left in the final products that must be desolventizer before consumption. Therefore, for its high safety in the food field, only food ethanol was used to improve the efficiency of extraction from olive oil by-products.

Pressurized liquid extraction (PLE) is another green extraction technique for natural product extraction from food and botanical sample matrices. PLE is a widely considered advanced extraction technique which is able to efficiently extract interesting compounds from natural matrices using low volumes of organic solvents, if any, as well as producing high extraction yields in short extraction processes (Herrero et al., 2011). Using PLE, a relatively faster extraction rate is attained due to a combination of the following:

1. liquid solvent interaction with matrix molecules

2. elevated temperature and pressure for efficient extraction of targeted components.

Elevating the temperatures of employed solvents above their atmospheric boiling points allows increased solubility and mass transfer rates between the plant matrix and the solvent of choice. Eventually, enhanced diffusivity of the solvent and plant matrix causes more prominent extraction kinetics. The application of elevated temperature decreases extract viscosity, resulting in enhanced wetting of the plant matrix, and this leads to high solubility of the targeted molecules. It also causes breakage of bonding forces (dipole-dipole, van der Waals, and H2-bonding) in order to facilitate diffusion of targeted phenolic compounds to the outer surfaces of solid matrices. Eventually, increased diffusion rates allow high extraction efficiencies with improved recovery rates (Carabias-Martınez et al., 2005; Wang and Weller, 2006). During the extraction process, the sample is placed into the extractor, followed by solvent pumping into the extraction vessel using an HPLC pump. The sample placed in the extraction cell is maintained at the desired temperature, using an electric heating jacket, until the required pressure is attained. After that the desired combination of temperature and pressure variables is reached, the extraction process starts. Extraction processes having more than 1 extraction cycles involve extraction solvent replenishment during each extraction cycle. Owing to back pressure, blocking valves are opened carefully after completion of the extraction cycle at an appropriate level in order to maintain the desired flow rate.

26

Once the extraction process is completed, the heating system and HPLC pump are shut down. Inert gases such as nitrogen may be utilized for purging the pressurized liquid extractor for the removal of residual solvent within the extractor. Also in PLE extraction food ethanol was used to improve the efficiency of extraction from olive oil by-products.

Ultrasound-assisted extraction (UAE) is a extraction process simple, inexpensive and green (Rombaut et al., 2014). UAE stands out as a sustainable alternative which requires a moderate investment of solvent and energy. Furthermore, it is easy to handle, safe, economical and reproducible due to the fact that this technology allows its development under conditions of atmospheric pressure and at an ambient temperature (Soria et al., 2010; Vieira et al., 2013). UAE is based on the principle of acoustic cavitation which is capable of damaging the cell walls of the plant matrix and thereby favoring the release of bioactive compounds (Tiwari et al., 2015). This technology can be applied to obtain different phytochemicals of which phenolic compounds stand out. These are appreciated by various fields of industry, particularly the food and pharmaceutical industries, thanks to their antimicrobial, anti-inflammatory, anticancer properties and mainly for their antioxidant capability (Parisi et al., 2014). It has been used to extract phenolic compounds from various plants, such as spruce wood (Ghitescu et al., 2015), haskap berries (Celli et al., 2015) and blueberry (He et al., 2016). Compared to conventional solvent extraction, UAE can significantly enhance the extraction yield of phenolic compounds (Mane et al., 2015). The optimization of extraction conditions with ethanol as solvent has been studied in order to obtain extra yield and better quality of the enriched product.

1.3.3 Extraction from olive pâtè

Olive oil extraction generates a variety of by-products, in different amounts depending on the production techniques used, which are all considered and treated as potential pollutants (Branciari et al., 2015). Among these, solid olive residues account for approximately 35% (w/w) of the processed olives according to the extraction method used. The particularity of the new centrifugal separator (Pieralisi Leopard DMF Technology) is the possibility to obtain a fraction of olive by-product called pâtè devoid of woody part. Indeed, this spreadable olive by-product is lignin free and consists of lipophilicandhydrophilic fractions, both characterized by technological and functional

27

properties. The absence of stone allows the use of the pâtè in the food field without further extraction. “Pâté” contains 75% moisture (both including conventional olive cake and olive mill waste waters). Moreover, it also contains a variable amount of olive oil (approximately 8–12%), depending on the water content), high levels of structural carbohydrates and sugars, and moderate concentrations of crude protein. Fatty acids are mainly represented by oleic acid and polyunsaturated fatty acids. Major phenolic compounds contained in olive cake are included in the following classes as already reported for the other by-products (Dal Basco et al., 2012; Cardinali et al., 2012; Servili et al., 2013):

(a) hydroxytyrosol (3,4-DHPEA) and tyrosol (p-HPEA) (class of phenolic alcohols); (b) dialdehydic form of decarboxymethyl elenolic acid linked to 3,4-DHPEA or p-HPEA 3,4-Dp-HPEA-EDA or p-p-HPEA-EDA) (class of secoiridoids derivatives);

(c) verbascoside (a derivative of the hydroxicinnamic acid);

(d) caffeic acid, p-coumaric acid and vanillic acid (class of phenolic acids and derivatives);

(e) lutein (class of flavones);

(f) (+)-acetoxypinoresinol and (+)-pinoresinol (class of lignans).

This kind of compounds are well-known for their beneficial effects in the human health. So, these results suggest that the olive by-product, olive pate, could be used as functional ingredients, in the production of nutraceuticals for human and animal feeding. The particularity of the new centrifugal separator is the possibility to obtain a fraction of olive by-product called pâtè devoid of woody part. Indeed, this spreadable olive by-product is lignin free and consists of lipophilicandhydrophilic fractions, both characterized by technological and functional properties. The absence of stone allows the use of the pate in the food field without the need for extraction.

1.3.4 Extraction from olive leaves

Olive leaves contain many potentially bioactive compounds that may have antioxidant, anti-hypertensive, anti-inflammatory, hypoglycaemic and hypocholesterolemic properties and antimicrobial properties against some microorganisms such as bacteria, fungi, and mycoplasma. Due to these activities and valuable biophenol compounds, usage of whole olive leaf and olive leaf extract has increased rapidly in both the pharmaceutical and food industries as food additives and functional food materials. The

28

whole leaf extract is recommended to achieve health benefits due to the presence of additive and/or synergistic effects of their phytochemicals (Ghanbari et al., 2012). Several techniques have been used to recover phenolic compounds from olive by-products, including enzymatic preparation, solvent extraction, supercritical fluids (supercritical CO2) membrane separation, centrifugation, and chromatographic procedures. Since ultrasound assisted extraction (UAE) seemed to be the most suitable technique for extraction of bioactive compounds from olive oil by-products (Jap_on-Luj_an et al., 2006), so this method was preferred to extract phenolic compounds from olive leaves.

29

2. OBJECTIVE

The possibility of turning olive oil by-product into a valuable resource, particularly for human consumption, would represent an important benefit for the miller. Reports on the use of these particular by-products for food formulations are not available so far. In this contest, my Ph-D project had the aim to realize innovative cereal-based and fish-based food enriched with by-products rich in bioactive molecules. In order to realize new foods it was necessary to consider that the potential incorporation of by-products into food formulations could alter the sensory properties, therefore, careful selection of the type and the amount of these ingredients and proper technological options were adopted.

To the aim of the research, different steps were carried out: (i) stabilization and characterization of by-products of the oil industry; (ii) addition of olive oil by-products to food formulation; (iii) sensory evaluation of new products; (iv) chemical and biological characterization of new food to evaluate macro-components, polyphenol content and antioxidant activity; (v) evaluation of bioaccessibility of fortified food by in vitro gastro intestinal digestion model.

30

3. MATERIALS AND METHODS

3.1 Fish burger with olive pâtè

3.1.1 Raw materials

The olive pâtè (OP) was obtained by a local olive mill (Bisceglie, Bari, Italy) from the organic Coratina cultivar milled using a Pieralisi Leopard with DMF technology (Multi Phases Decanter). The OP was dried at 35 °C in a dryer (SG600, Namad, Rome, Italy) for 72 h. The dried olive pâtè was reduced in a fine powder (< 500µm) by a hammer mill (16/BV-Beccaria s.r.l., Cuneo, Italy) and then stored at 4 °C until further utilization. The fish, tuna trance, was purchased by Minaba srl (Manfredonia, Foggia, Italy).

3.1.2 Fish burger preparation

Fish burger (40 g) were manufactured using tuna trance, previously thawed and chopped until to a diameter of about 12 mm (28 g), mixed with potato flour (2 g), parsley (0.2 g), salt (0.2 g) and a whey protein based crumb soaked in extra-virgin oil, as reported by (Del Nobile et al., 2009). The mixture was added with 10% w/w of dry OP. OP was added to burger formulation either as it was or pre-treated. In particular, two different pre-treatments were adopted: hydration and hydration/extraction. In the first case OP was hydrated either with water or milk with a OP/liquid ratio of 1:1 for 1 h, it will be referred as OP-H. In the second case, OP was first hydrated with either water or milk with a OP/liquid ratio of 1:5 for 1 h (extraction stage). Afterwards, the excess liquid was drained (separation stage), it will be referred as OP-H/E. The control was prepared without the olive pâtè. The mixture was mixed for a few minutes to have a greater homogenization and burger were made with a diameter of 5 cm and a height of 1 cm. Finally, the burgers were cooked in an electric convention oven (H2810, Hugin, Milan, Italy) at 240 °C for 12 min.

3.1.3 Total phenols, flavonoids and antioxidant activity determination

To determine total phenols, flavonoids and antioxidant activity, the extraction was performed as described by Meneses et al. (2013) with slight modifications. Burger with and without olive pâtè, both raw and cooked, were dried at 35 °C with a ventilated stove