Life Cycle Thinking in decision-making for sustainability: from public policies to private businesses

Proceedings of the 12th Italian LCA Network Conference

Messina, 11-12th June 2018

Edited by Giovanni Mondello, Marina Mistretta, Roberta Salomone, Arianna Dominici Loprieno, Sara Cortesi, Erika Mancuso

ISBN: 978-88-8286-372-2

2018 ENEA

Italian National Agency for New Technologies, Energy and Sustainable Economic Development

Cover: Cristina Lanari

Editorial review: Giuliano Ghisu

Index

Scientific Committee 5

Organising Committee 6

Conference program 7

Preface 11

Energy and building 13

Agri-Food applications 63

Life cycle thinking methods and tools 111

Waste management 167

Life cycle thinking methods and tools 223

Poster 275

SCIENTIFIC COMMITTEE

Michele Aresta – Interuniversity Consortium for the Chemical Reactivity and Catalysis-CIRCC

Grazia Barberio – ENEA - Italian National Agency for New Technologies, Energy and Sustainable Economic Development, Laboratory Resources valorization (RISE)

Maurizio Cellura – University of Palermo Department of Energy, Information Engineering and Mathematical Models (DEIM), Palermo, Italy

Vito D’Incognito – Take Care International, Milano, Italy

Giuseppe Ioppolo – University of Messina, Department of Economics, Messina, Italy Arianna Dominici – Loprieno, ENEA Territorial and Production Systems Sustainability Department, Laboratory Resources valorization (RISE), Bologna, Italy Monica Lavagna – Politecnico di Milano, Department of Architecture, Built environment and Construction Engineering (ABC), Milano, Italy

Paolo Masoni – Ecoinnovazione srl, spin-off ENEA, Bologna, Italy

Anna Mazzi – University of Padova, Department of Industrial Engineering, Padova – Italy

Marina Mistretta – University of Reggio Calabria, Department of Heritage, Architecture, Urban planning, Reggio Calabria, Italy

Bruno Notarnicola – University “Aldo Moro” of Bari, Ionian Department of Law, Economics and Environment, Dipartimento Jonico, Bari, Italy

Andrea Raggi – University “G. d’Annunzio of Chieti-Pescara”, Department of Economic Studies, Pescara, Italy

Lucia Rigamonti – Politecnico di Milano, Department of Civil and Environmental Engineering (DICA), Milano, Italy

Serena Righi – University of Bologna, Campus of Ravenna, Department of Physics and Astronomy (DIFA) and Inter-Departmental Research Centre for Environmental Science (CIRSA)

Roberta Salomone – University of Messina, Department of Economics, Messina, Italy Giuseppe Saija – University of Messina, Department of Economics, Messina, Italy Simona Scalbi – Territorial and Production Systems Sustainability Department, Laboratory Resources valorization (RISE), Bologna, Italy

Antonio Scipioni – University of Padova, Department of Industrial Engineering, Padova, Italy

Marzia Traverso – Institute of Sustainability in Civil Engineering, RWTH Aachen University, Aachen, Germany

Alessandra Zamagni – Ecoinnovazione srl, spin-off ENEA, Padova, Italy

ORGANISING COMMITTEE

Marco Ferraro – National Research Council of Italy - Institute for Advanced Energy Technologies “Nicola Giordano”, Messina, Italy

Giuseppe Ioppolo – University of Messina, Department of Economics, Messina, Italy Marina Mistretta – University of Reggio Calabria, Department of Heritage, Architecture, Urban planning, Reggio Calabria, Italy

Francesco Pira – University of Messina, Department of Ancient and Modern Civilizations, Messina, Italy

Andrea Raggi – University “G. d’Annunzio” of Pescara, Department of Economic Studies, Pescara Italy

Serena Righi – University of Bologna, Campus of Ravenna, Department of Physics and Astronomy (DIFA)and Inter-Departmental Research Centre for Environmental Science (CIRSA)

Giuseppe Saija – University of Messina, Department of Economics, Messina, Italy Roberta Salomone – University of Messina, Department of Economics, Messina, Italy

TECHNICAL AND ORGANISATIONAL SECRETARIAT

Giovanni Mondello – Roma Tre University, Department of Business Economics, Rome, Italy

Conference program

JUNE 11th, 2018 - Monday

08.30 - 09.00 Registration to Italian LCA Network Conference

09.00 - 09.30 Italian LCA Network Conference - Opening ceremony Salvatore Cuzzocrea - Rector of the University of Messina Augusto D’Amico - Director of the Department of Economics Maurizio Cellura - President of the Italian LCA Network Roberta Salomone - Conference Chair

09.30 - 11.00 SESSION I (in Italian language) LCA, LOCAL GOVERNMENTS, AND CIRCULAR ECONOMY

Chairs: Maurizio Cellura – University of Palermo Giuseppe Saija – University of Messina

EU Policies for ENERGY Research: the SET Plan and the new 2018-19 Horizon 2020 Work Program

Riccardo Basosi – Italian Permanent Representative H2020 Energy EU Programme and

MIUR Delegate in the SET Plan Steering Committee

Life Cycle Assessment of electrochemical storage technologies Marco Ferraro – CNR-ITAE

European Environmental Footprint methods: status update and future outlook Michele Galatola – European Commission - DG Environment - Sustainable Production,

Products & Consumption

The Accredia’s experience in environmental conformity assessment, supporting LCA-based activities

Filippo Trifiletti – General Director ACCREDIA

11.00 - 11.30 Coffee break

11.30 - 13.00 SESSION II

ENERGY AND BUILDING

Chairs: Giuseppe Ioppolo – University of Messina Marina Mistretta – Mediterranea University

Comparative LCA of renovation of buildings towards the nearly Zero Energy Building Grazia Barberio – ENEA

Life Cycle Analysis of an innovative component for the sustainability in the building sector

Maria Laura Parisi – University of Siena Life Cycle Assessment of building end of life Serena Giorgi – Politecnico of Milano

ELISA: A simplified tool for evaluating the Environmental Life-cycle Impacts of Solar Air-conditioning systems

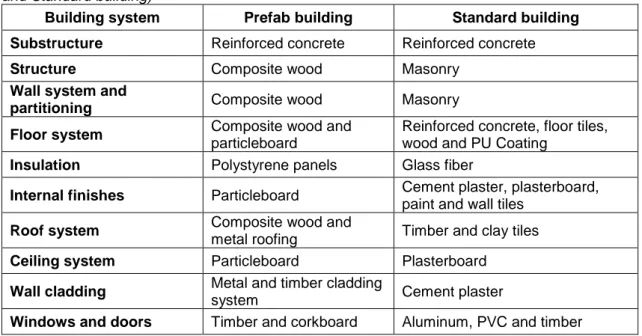

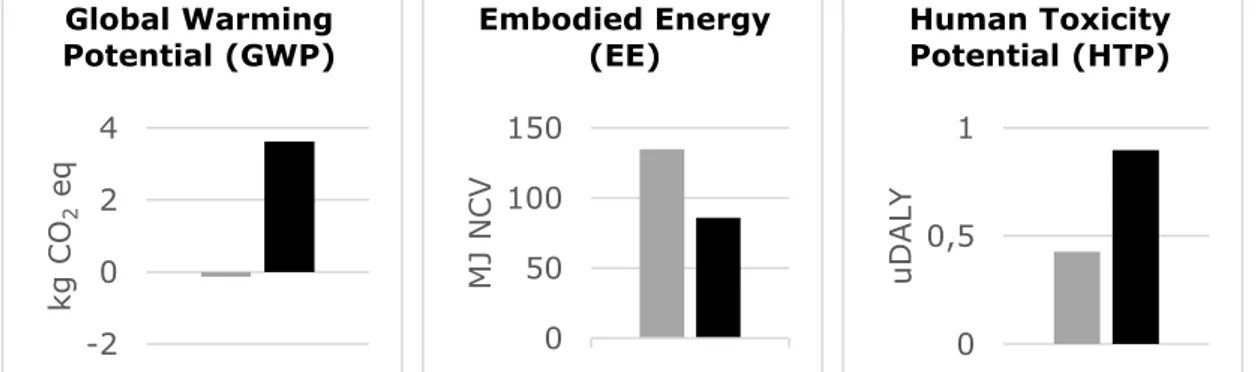

A comparative study between a Prefab building and a Standard building for the characterisation of production and construction stages

Mónica Alexandra Muñoz Veloza – Politecnico of Torino Energy saving in LT/MT transformers

Simone Maranghi – University of Siena 13.00 - 14.00 Lunch

14.00 - 15.00 Poster Session

15.00 - 16.30 SESSION III

AGRI-FOOD APPLICATIONS

Chairs: Bruno Notarnicola – University of Bari “Aldo Moro” Roberta Salomone – University of Messina

Steps towards SDG 4: teaching sustainability through LCA of food Nicoletta Patrizi – University of Siena

The blue water use of milk production in North Italy – a case study Doriana Tedesco – University of Milan

Practitioner-related effects on LCA results: a case study on Energy and Carbon footprint of wine

Emanuele Bonamente – University of Perugia

Environmental impacts and economic costs of nectarine loss in Emilia-Romagna: a life cycle perspective

Fabio De Menna – University of Bologna

Grana Padano and Parmigiano Reggiano cheeses: preliminar results towards an environmental eco-label with Life DOP project

Daniela Lovarelli – University of Milan

Life Cycle studies in agrifood sector: focus on geographical location Anna Mazzi – University of Padova

16.30 - 17.00 Tea break

17.00 - 17.30 YOUNG RESEARCHER AWARDS

Chairs: Grazia Barberio – ENEA

Andrea Raggi – University “G. d’Annunzio”

Environmental implications of future copper demand and supply in Europe Luca Ciacci – University of Bologna

Multifunctional agriculture and LCA: a case study of tomato production Cristian Chiavetta – ENEA

Development of a method to integrate particular matter formation in climate change impact assessment

Andrea Fedele – University of Padova

17.30 - 18.30 ITALIAN LCA NETWORK CONFERENCE ASSEMBLY

18.30 - 20.00 Free time

20.00 Bus transfer to Gala Dinner 20.30 - 22.30 Gala Dinner – Villa Ida

JUNE 12th, 2018 - Tuesday

9.30 - 11.00 SESSION IV

LIFE CYCLE THINKING METHODS AND TOOLS

Chairs: Grazia Barberio – ENEA

Serena Righi – University of Bologna

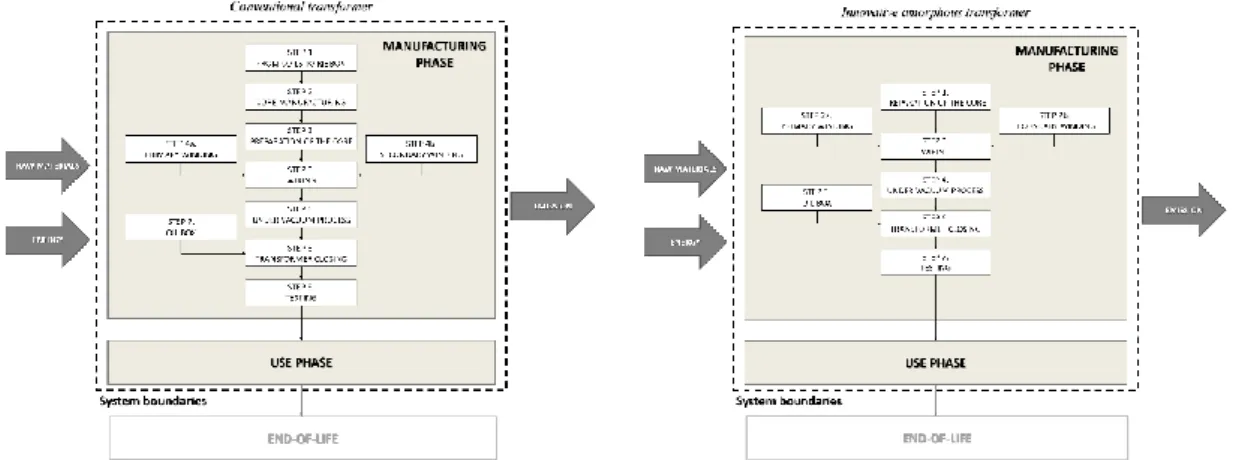

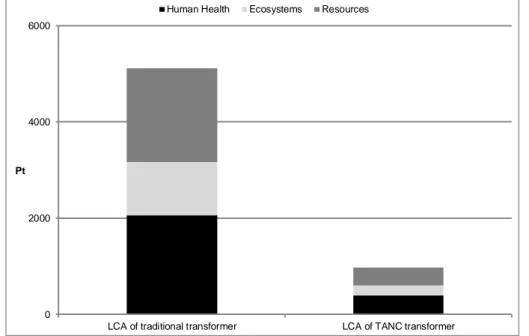

A case study of green design in electrical engineering: an integrated LCA/LCC analysis of an Italian manufactured HV/MV power transformer

Emanuela Viganò – CESI S.p.A.

Eco-design of wooden furniture based on LCA. An armchair case study Isabella Bianco – Politecnico Torino

Life Cycle Thinking in online accommodation booking platforms: making a more sustainable choice

Ioannis Arzoumanidis – University “G. d’Annunzio”

Matching Life Cycle Thinking and design process in a BIM-oriented working environment

Anna Dalla Valle – Politecnico Milano

Lithium-ion batteries for electric vehicles: combining Environmental and Social Life Cycle Assessments

Silvia Bobba – Politecnico Torino

State of art of SLCA: case studies and applications Gabriella Arcese – University of Bari “Aldo Moro” 11.00 - 11.30 Coffee break

11.30 - 13.00 SESSION V

WASTE MANAGEMENT

Chairs: Anna Mazzi – University of Padova

Marzia Traverso – RWTH Aachen University

Life cycle assessment applied to biofuels from sewage sludge: definition of system boundaries and scenarios

Serena Righi – University of Bologna

Analysis of a recycling process for crystalline silicon photovoltaic waste Fulvio Ardente – European Commission - Joint Research Centre

Environmental comparison of two organic fraction of municipal solid waste liquid digestate’s management modes

Federico Sisani – University of Perugia

Life Cycle Thinking for Food waste management alternatives, an experience in Costa Rica

Laura Brenes-Peralta – University of Bologna/Researcher Instituto Tecnológico de Costa Rica

The way towards sustainable policies: combining LCA and LCC for construction waste management in the region of Flanders, Belgium

Andrea Di Maria – KU Leven

Highlighting food waste in school canteens: a preliminary assessment of the associated environmental and economic impacts

Laura García-Herrero - University of Bologna 13.00 - 14.00 Lunch

14.00 - 15.00 Poster Session

9.30 - 11.00 SESSION VI

LIFE CYCLE THINKING METHODS AND TOOLS

Chairs: Marco Ferraro – CNR-ITAE

Giuseppe Tassielli – University of Bari “Aldo Moro”

The Constructal Law to optimize performances of energy systems through the Life Cycle approach

Francesco Guarino – University of Palermo

Walk-the-talk: Sustainable events management as common practice for sustainability conferences

Rose Nangah Mankaa – RWTH Aachen University

A Preliminary LCA Analysis of Snowmaking in Fiemme Valley Paola Masotti – University of Trento

Life Cycle Assessment of a calcareous aggregate extraction and processing system Rosa Di Capua – University of Bari “Aldo Moro”

Efficient Integration of Sustainability aspects into the Product Development and Materials Selection Processes of Small Businesses

Jonathan Schmidt – RWTH Aachen University

Bioplastics in designing beauty and home packaging products. A case-study from Aptar Italia SpA

Michele Del Grosso – APTAR Italia SpA 16.30 - 17.00 Tea break

17.00 - 18.20

ROUND TABLE

LIFE CYCLE THINKING IN DECISION-MAKING FOR SUSTAINABILITY: FROM PUBLIC POLICIES TO PRIVATE BUSINESSES

Moderators: Maurizio Cellura – University of Palermo

Bruno Notarnicola – University of Bari “Aldo Moro”

Methodological advancements and remaining challenges after 5 years of Environmental Footprint road field testing

Michele Galatola – European Commission - DG Environment - Sustainable Production, Products & Consumption

Life Cycle Thinking in the U.S. Public Policy Sangwon Suh – University of California

Life cycle based environmental assessment of EU consumption

Serenella Sala – European Commission - Joint Research Centre - Directorate D – Sustainable Resources, Bio-Economy Unit (D1)

18.30 Bus transfer to Regional Museum

PREFACE

The 12th Italian LCA Network Conference (the 7th Italian LCA Network Association Conference) was held on 11-12 June in Messina (Italy), under the patronage of Ministry for Environment, Land and Sea Protection, SETAC Italian Branch, Municipality of Messina, ARPA Sicilia, AIDIC, AICARR, the Council of Sicily consultant associations of Engineers, the consultant associations of Engineers of Palermo, Agrigento, and Ragusa Provinces, and the consultant association of Architects of Trapani Province. The conference focused on the role of the “Life Cycle Thinking” (LCT) approach as support to decision-making in the definition of sustainability strategies, thus supporting both public and private businesses in making more informed decisions.

Indeed, life-cycle information is considered crucial to guide policy decisions and business strategies in many contexts.

Policy makers have to promote sustainable consumption and production strategies to respond to national and international environmental challenges, by gathering baseline and future-oriented environmental impact information for market-oriented policies and developing strategies for resource efficiency and eco-design.

Private businesses have to improve efficiency to boost margins and competitiveness, while contributing to sustainability.

Thus, LCT and product sustainability aims to reduce their environmental and socio-economic burdens, while maximizing socio-economic and social value.

The Italian LCA Network conference has become a representative venue for enterprises, public authorities, international academics and researchers in the LCT field in order to discuss, share, and disseminate innovative ideas and advancement on the LCT methodology and case-studies.

The papers published in the volume contribute to new approaches, methods and applications, in order to discuss developments, current policy progress and pathways toward sustainability.

The conference proceedings report 60 papers, which were presented at the conference, both in the oral and poster sessions, after a double blind peer review process, managed by the Scientific Committee.

− Life Cycle Thinking methods and tools in public policies: experiences, limitations and perspectives.

− Life Cycle Thinking methods and tools in private businesses: experiences, limitations and perspectives.

− Life Cycle Thinking and Circular Economy: policies and practices. − Life Cycle Thinking and the UN Sustainable Development Goals.

− Methodological developments of LCA, LCC, S-LCA and integrated Life Cycle Sustainability Assessment.

The last section includes the three papers awarded the 9th Edition of LCA Young Researcher Award, addressed to promote and disseminate the research activities of young researchers involved in the Life Cycle Assessment research activities.

The President of Italian LCA Network Maurizio Cellura

Comparative LCA of renovation of buildings towards

the nearly Zero Energy Building

Cutaia L.1, Barberio G. 1, Elmo G. 1, Longo S. 2, Cellura M.2, Guarino F.2, Gulotta T.M.2 1ENEA, Italy

2 Università degli Studi di Palermo, Italy

Email: [email protected]

Abstract

The building sector is one of the key sectors to achieve the 20/20/20 targets of the EU as there is the potential to lead to significant energy savings reducing the EU’s total energy consumption by 5-6% and lowering CO2 emissions by 5%. One powerful mechanism to apply principle and criteria of nearly zero-energy buildings (nZEB). This work, done in the framework of the agreement between the Italian Ministry of Economic development and ENEA on the “Research of electric system” (Ricerca di Sistema Elettrico), has the aim to evaluate the environmental impacts of the technological improvements needed for enhancing the performances of an average building to a nZEB (or at least in the direction of a nZEB), performing a comparative Life Cycle Assessment study. Data on building upgrading and energy consumption reduction come from a test case performed by Università degli Studi di Palermo.

1. Introduction

Buildings are responsible for approximately 40% of energy consumption and 36% of CO2 emissions in the EU and almost 75% of building stock is energy

inefficient, while only 0.4-1.2% (depending on the country) of building stock is renovated each year. So, the building sector is one of the key sectors to achieve the 20/20/20 targets of the EU and to achieve reductions of greenhouse gas emissions in the residential and service sectors of 88% to 91% compared to 1990 by 2050. In particular, renovation of existing buildings can lead to significant energy savings, which could reduce the EU’s total energy consumption by 5-6% and lower CO2 emissions by about 5% (European

Commission). Main directive, laws and strategies, at European and international level, have been promoted to foster the requalification and improve the energy efficiency of building (for instance Energy Performance of Buildings Directive and Energy Efficiency Directive of the EU Parliament). So building renovation and new buildings construction will require low amount of energy and this energy will come mostly from renewable sources, following the principle of nearly zero-energy buildings (nZEB). Improving the energy efficiency of buildings can also generate other economic, social and environmental benefits. This work has been done in the framework of the agreement between the Italian Ministry of Economic development and ENEA on the “Research of electric system” (Ricerca di Sistema Elettrico - RdS) that foresee R&D activities for reducing cost of energy for end-users, boosting the quality of service provided, reducing impacts on environment and health of electric system and using energetic resources in a better way. The amount for the contribution for financing the RdS is defined by the Italian Authority for the Electric Energy, Gas and Water Service. Activities are planned every 3 years and subdivided year by year (from October to September). This work has been realised between October 2016 and September 2017, as second year of the three years

2015-2017 and it is in the specific part of the project addressed to improving and studying energy efficiency and energy use in the building sector.

Aim of the study is evaluating the environmental impacts of the technological improvements needed for enhancing the performances of an average building to a nZEB (or at least in the direction of a nZEB) on their life cycle. Practical application of this kind of assessment is choosing technologies or technical solutions for improving performances of buildings towards a nZEB, with energetic and environmental load that doesn’t overcome, over the life cycle, the reduction of consumption during the use phase. This work focus the investigation on environmental performance of a restored office building in two main scenarios: a medium upgrading and a high upgrading towards nZEB conditions, performing a comparative Life Cycle Assessment study on different geographical areas in Italy (North, Centre, South Italy). The focus of this paper is the South Italy (Palermo - Sicilia Region).

1.1. Building certification

Sustainability in building is defined as the control of impacts that the entire building process has on the environment and on the quality of life of users. The following figure shows the articulation of ISO standards on the theme of sustainable construction (Barucco, 2011).

Figure 1: of ISO standards on the theme of sustainable construction

The EU regulation n. 305/2011 establishes conditions for the marketing of construction products, introducing the requirement of sustainable use of natural resources. Buildings shall be designed, built and demolished according to the sustainable use of resources. The reuse or recyclability of construction materials after demolition shall be guaranteed, as well as the use of environmentally compatible raw and secondary materials (Barucco, 2011). The sustainability criteria of buildings are grouped in six thematic areas: - Efficiency in resource consumption; Limitation of the impact of construction materials, Optimization of the relationship between the building and the

surrounding environment, Indoor comfort, Safety, maintenance and building management, and Ethical and social aspects.

Assessments of building sustainability with rating system methods, based on life cycle thinking approach, are used with the purpose give an environmental label to the examined building. Thanks to the certification and the label the overall sustainability performance of a building becomes “visible” to the end-users. The rating system methods work as an “environmental report” of the building, which is then evaluated according to different requirements grouped into classes with a minimum threshold. Final rating goes from a minimum - corresponding to the achievement of threshold values - to a maximum ranking level. The scoring methods depend on the type, size and destination of the building. For example, a requirement on energy performance can not include the same thresholds for both residential and commercial buildings, new buildings or major renovations (Bertagni, 2016).

The most important certification methods or protocols used in Italy are ITACA (Manfron, 2005), LEED (Bertagni, 2016) and BREEAM (Bertagni, 2016).

The ITACA Protocol has been adopted by many local administrations to promote sustainable construction through: regional laws, building regulations, calls for tenders, urban plans, etc. The Protocol is derived from the SBTool international evaluation model, adapted to the Italian environmental context. ITACA protocol has different versions, for the evaluation of residential, commercial, school, industrial buildings, etc. both for the new building and for the major renovations. ITACA divides the various requirements into five evaluation areas: Site Quality / Resource Consumption / Environmental Loads / Indoor Environmental Quality / Service Quality (www.proitaca.org).

The LEED protocol is managed by United States Green Building Council. There are numerous versions of LEED, valid for different types of buildings. LEED divides the various requirements in the following areas: Site Sustainability / Water Management / Energy and Atmosphere / Materials and Resources / Internal Environmental Quality / Design Innovation / Regional Priority. LEED provides different levels of performance (result of the sum of totalized points), ranging from basic level to Silver, Gold and - the highest level - Platinum.

The BREEAM protocol is developed by the British Institute Building Research Establishment. BREEAM also has numerous versions that adapt to different types of applications. BREEAM divides the requirements into classes: Energy / Health and wellbeing / Innovation / Land use / Materials / Management / Pollution / Transport / Waste / Water. Depending on the score obtained with BREEAM the certificates vary in five levels: Exceptional, Excellent, Very Good, Good, Sufficient.

The Directive 2010/31/EU set a limit on December 31st, 2020, when all new buildings are expected to be nZEB. The key points for a design aimed at creating a nZEB building include architectural planning aspects deriving from a detailed knowledge of the geographical context where the building will be located and from design aspects related to technological systems. All these

aspects can be well connected in each phase using a certification protocol. In summary the guiding criteria for a nZEB building construction are (Sasso, 2006; Bertagni, 2016):

- The layout must favour the maximum level of sunshine and protection from the prevailing winter winds.

- Compact and lightly dispersed forms shall be preferred.

- The type of building must guarantee the same thermal/energy potential for every accommodation. Terraced and in-line buildings are preferred.

- The internal distribution must favour the positioning of staircases and bathrooms towards the North front and living spaces on the South front. - Use of passive systems for thermal control and for proper ventilation

(thermal mass, greenhouses and solar spaces, solar chimney, green roof, etc.).

- Introduction of shading systems for summer radiation control (vegetation, fixed or adjustable screens).

- Use of active systems for the reduction of residual energy consumption (solar thermal and photovoltaic collectors)

- The openings system must guarantee an excellent level of natural lighting inside each accommodation.

- A careful study of the thermal bridges must be carried out for subsequent elimination or attenuation where not possible.

- Each building must be constructed using eco-compatible materials and with excellent thermal insulation performance of the surface (thermal coat).

- Providing storm-water collection systems reducing water consumption. 2. LCA Study

The comparative LCA study was aimed to evaluate the environmental performance of an average “conventional” building upgrading towards a nZEB by means of new plants and substitution of materials and components. Data on upgrading and energy consumption reduction come from a Test Case analysed by University of Palermo.

2.1. Goal and scope definition

This work has been done in the framework of the RdS activities, financed by part of the fee for the electric energy consumed by Italian end-users, and the whole study will be published on ENEA website and on the CSEA (Cassa per i Servizi Energetici ed Ambientali) website.

Aim of the study is the evaluation of potential advantages coming from building retrofit actions for improving the energy efficiency respect to the potential impacts of upgrading itself in two retrofit scenarios (European Parliament 2010; Presidenza della Repubblica Italiana, 2011, 2015 and 2017): Scenario 1: medium level of retrofitting; Scenario 2: retrofitting to nZEB.

A comparative Life Cycle Assessment study has been carried out on different geographical areas and the focus of this paper is the South Italy (Palermo). The assessment method is Impact 2002+ and the tool used in the study is Simapro 8.5.

Functional unit is the whole retrofitted building, considering 1 year of activity. Concerning system boundaries of the comparative study, the following phases are considered (same phases are deleted in the comparison): new materials production and supply; building maintenance; retrofit actions (new processes and materials replacement, removal and disposal); use phase (energy consumption and production). A general description of retrofit actions and their lifespan is shown in the following table (more details in paragraph 2.2):

Table 1: Retrofit actions and related lifespan

Category Scenario 1 Scenario 2 Lifespan (y)

Opaque wall External insulation with EPS External insulation with EPS 30 Transparent

wall

Replacement of the existing fixtures

Replacement of the existing

fixtures 30

Power generation

Replacement of the power generation and distribution system.

Replacement of the power generation and distribution system.

15 Lighting

system

Replacement of the lighting system with LED

Replacement of the lighting

system with LED 8

Renewable sources

NO Solar thermal system 15

NO Photovoltaic system 20

2.2. Life Cycle Inventory 2.2.1 The examined building

The examined building is an office of the 70s located in Palermo (South Italy) with an area of 403.5 m2, a net height of 3 m and a volume of 1,210.50 m3. The

layout of the building is shown in Figure 2.

The buildings structure is made of reinforced concrete. The external walls (U = 1.183 W/m2K) include 27 cm of perforated brick blocks, with lime-based

external plaster and gypsum internal plaster. The internal walls (U = 3.045 W/m2K) are 8 cm of perforated bricks covered with gypsum and painting. The

floor (U = 1.974 W/m2K) is 17 cm thick, including bricks and ceramic slabs. The

flat roof (U = 1.453 W/m2K) has a structure made by reinforced concrete and

brick blocks, mortar, screed and a clinker external floor.

With regard to the transparent surface, it is about 24 m2 and represents about

12% of the external vertical surface. In detail, the building is equipped with metal frame and single-glazing windows (Uframe = 7.00 W/m2K; Uglazing = 5.75

W/m2K), with no shielding and blinds.

The building lighting is made by ceiling lights with 34 fluorescent lamps (total power of about 2.3 kW).

Heating and domestic hot water (DHW) are provided by a 36 kW diesel boiler and an 80 l water storage. The heating system is equipped with cast iron

radiators and insulated copper pipes for the distribution, except for office 4 that is equipped with a fan-coil system, due to the high heating loads. The heating system uses also further components such as distribution manifolds, electric pumps, valves, etc., while a cooling system is not available.

Figure 2: Layout of the building

The energy performance of the building was calculated with a simulation of the thermo-physical characteristics of the building, performed with an energy simulation tool certified by the Comitato Termotecnico Italiano. According to the Italian law, the energy class of the building is E (Presidenza della Repubblica Italiana, 2015).

2.2.2 The retrofitting scenarios

In order to improve the energy performance of the building and to move towards Scenario 1 and 2, some retrofit actions were identified and simulated. In detail, the two scenarios are based on the transmittance limits for both the glazed and opaque surfaces reported in (Presidenza della Repubblica Italiana, 2015) respectively for medium level of retrofitting and nZEB retrofitting.

In order to plan economically, technologically and operationally realistic interventions and to avoid demolition and subsequent replacement in the two scenarios, the retrofit actions of Scenario 1 were selected to be able also to ensure compliance with the nZEB requirements, except for the retrofit of vertical opaque walls. For Scenario 1, the following retrofit actions have been identified:

- External insulation of opaque walls by using EPS (vertical wall) and XPS (floor and roof) insulation panels;

- Replacement of the existing fixtures with PVC frames, with thermal break 12 mm air chamber (air) and 24 mm glass surfaces (U = 2.98 W/m2K);

- Replacement of the power generation/distribution system. In detail, the new air conditioning system is made by a reversible air/water heat pump

equipped with an inverter and a distribution system with fan coils. The DHW is produced by an electric water heater. Other components complete the system (copper pipes, distribution manifolds, electric pumps, etc);

- Replacement of the lighting system composed by 37 LED lamps with a total power of 1 kW.

To achieve the nZEB requirements (Scenario 2), considering the low transmittance of the roof and the floor, only an additional insulation of the vertical opaque walls was hypothesized (1 cm thickness of EPS). In addition, two renewable energy systems were introduced:

- A photovoltaic system of about 1 kW (8 m2 and 5 PV modules) for electricity

production;

- A solar thermal system (2.5 m2 of flat collectors and a tank with a storage

capacity of 180 l) for DHW production.

Table 2 shows the energy consumption during operation for the three scenarios, highlighting the energy savings during the operation due to the implemented scenarios.

For each retrofit action and for each scenario, the main materials and components needed for their implementation were estimated. As an example, Table 3 shows the materials required for retrofit the vertical opaque walls in both scenarios.

Table 2: Energy consumption of the building during operation

Existing building Scenario 1 Scenario 2 Electricity consumption (kWh/year) 13,330.38 7,059.22 5,676.83* Diesel consumption (kg/year) 5,902.95 0 0

*1,327.52 kWh/year self-consumption

Table 3: Materials required for retrofit the vertical opaque walls (kg)

Material Scenario 1 Scenario 2

Mesh reinforcement 77.35 77.35

EPS 284.72 35.59

Adhesive 3,321.78 3,321.78

Water 2,524.56 2,524.56

External plaster 6,643.56 6,643.56

2.3. Life Cycle Assessment and conclusion

Main results from Life Cycle Impact Assessment are here presented: comparative results from normalisation and single score assessment and sensitivity analysis on different time horizons. From the single score assessment, that is the most aggregated result, is possible the identification of the worst performance and the scenario 2 seems to have greater environmental impacts respect to scenario 1 (Figure 3a). From the normalisation, most significant impact categories are, for both scenarios, respiratory inorganic, global warming and non-renewable energy (Figure 3b).

Figure 3: Comparative LCA single score (a) and normalisation (b) results (IMPACT 2002+)

Significant contribute to respiratory inorganic value is due to the opaque wall retrofit action; global warming and non-renewable energy are mainly related to energy consumption and transportation of materials supply, in particular for opaque walls retrofit actions and for new energy systems (photovoltaic and

solar thermal systems). A sensitivity analysis has been performed to evaluate a time horizon of 20 years, in order to compare lifespan of the different technologies used as retrofit actions.

As final result it is important to underline that benefits achieved in building upgrading for enhancing energy efficiency not always reflect advantages on other environmental indicators. Further investigations on other R&D actions in technological improvements and further integrated analysis with other payback evaluation are needed in order to have a holist evaluation and to guarantee that energy saving options and policies are coupled to environmental and economic exploitations.

3. References

European Parliament, 2010, Directive 2010/31/EU of The European Parliament and of the Council of 19 May 2010 on the energy performance of buildings –EPBD (recast), Official Journal of the European Union. L 153/13, 18.6.2010.

European Commission, Building Stock Observatory project. Support for setting up an observatory of the building stock and related policies. Service contract n. ENER/C3/2014-543. Presidenza della Repubblica Italiana, 2011, Decreto Legislativo 3 marzo 2011, n. 28, Attuazione della direttiva 2009/28/CE sulla promozione dell’uso dell’energia da fonti rinnovabili, recante modifica e successiva abrogazione delle direttive 2001/77/CE e 2003/30/CE. (11G0067) (GU Serie Generale n.71 del 28-03-2011 - Suppl. Ordinario n. 81).

Presidenza della Repubblica Italiana, 2015, Decreto interministeriale 26 Giugno 2015 – Applicazione delle metodologie di calcolo delle prestazioni energetiche e definizione delle prescrizioni e dei requisiti minimi degli edifici.

Presidenza della Repubblica Italiana, 2017, Decreto interministeriale 19 giugno 2017 - Piano per l’incremento degli edifici a energia quasi zero.

0 5 10 15 20 25 30 35 40 45 SCENARIO 1 SCENARIO 2

Human health Pt Ecosystem quality Pt Climate change Pt Resources Pt

0 5 10 15 20 25 30 Pt SCENARIO 1 SCENARIO 2 b a

Life Cycle Analysis of an innovative component for

the sustainability in the building sector

Irene Bartolozzi1, Elena Baldereschi2, Alessandro Mordini3, Riccardo Basosi3,4,

Maria Laura Parisi4

1Sant’Anna School of Advanced Studies, Institute of Management,

Piazza Martiri della Libertà 33, 56127 Pisa, Italy

2 Ergo S.r.l., c/o Technology Centre, Via Giuntini 25/29 – int. 29, 56023 Navacchio (PI), Italy 3 Italian National Council for Research, Institute for the Chemistry of OrganoMetallic

Compounds (CNR-ICCOM), Via Madonna del Piano 10, 50019 Sesto Fiorentino (FI), Italy

4Department of Biotechnology Chemistry and Pharmacy, University of Siena, Via A. Moro 2,

53100 Siena, Italy Email: [email protected]

Abstract

The research project SELFIE, funded by MIUR and Tuscany Region in 2016, aimed at the development of innovative building components to increase energy saving of buildings in the Mediterrenean area. Thanks to the combination of several elements, SELFIE modules bear adaptive properties and self-production of renewable energy. The ecoprofile of the innovative component SELFIE2 was evaluated with life cycle analysis and, through a contribution analysis, the most impacting components were identified. In an eco-design approach, improvement actions to reduce the environmental burdens were suggested and validated by applying a sensitivity analysis.

1. Introduction

The building sector contributes significantly to the primary energy consumption and to the associated greenhouse gases emissions. It is estimated to account for about 40% of primary energy consumption in the EU (EPDB, 2010), and the growth of energy consumption in this sector is obviously correlated to the population growth, which, in turn, increases the demand for residential buildings and services. Among the strategies adopted to invert the impacts of the building sector in terms of energy consumption and environmental burdens, the main ones are focused on the use of renewables and on the development of energy efficient buildings, and specifically of new façade systems.

At the policy level, in the EU, the targets set by the Energy Performance of Buildings Directive 2010/31/UE and the Energy Efficiency Directive 2012/27/UE (EE, 2012) concerning the energy performance of buildings, together with the increasing cost of fossil fuels, boost the development of such systems. This framework led the research to aim to what is called ‘Near zero energy building’ (NZEB), both working on the envelopes and on self-production of renewable energy.

Among the innovative solutions, adaptive envelopes are considered very promising since, thanks to the integration of smart materials and building management systems, they are able to answer in real time to the climatic conditions and to minimize the energy consumption of buildings, providing also occupants’ comfort (Baetens, 2010; Kuznik, 2011, Perino, 2007; Saelens, 2003; Favoino, 2014).

Life cycle analysis (LCA) is commonly used to assess the sustainability of buildings. In particular, LCA is a valuable tool to assess the contribution of innovative materials, often used in the new adaptive envelopes, and to compare the global environmental performances of energy-efficient and traditional buildings (Sartori and Hestnes, 2007; Ramesh, 2007; Sierra-Perez, 2016). In this context, the research project SELFIE (Sistema di Elementi avanzati multi Layer basato su superFici e materiali Innovativi nanostrutturati per una Edilizia sostenibile ed energeticamente efficiente, http://www.progettoselfie.it), funded by the Italian Ministry of University and Research and the regional administration of Tuscany, is aimed to increase the energy saving of buildings in the Med area, by developing and testing innovative envelope solutions.

The SELFIE concept is an adaptive system, combining different innovative technological elements to provide energy and GHGs savings and also adaptation to different construction typologies. Within the SELFIE project, LCA was applied, during the prototypes development, as a tool to support the eco-design of the modules, to highlight the environmental hotspot stages and to suggest for improvement actions.

2. Methodology

LCA was carried out according to ISO 14040-44 standards (ISO, 2006) adopting a cradle to gate approach.

2.1. Goal and scope definition

The objective of this study is the development of a cradle to gate analysis of the innovative modules developed within the SELFIE project and in particular of SELFIE 2 module (Fig. 1). This includes the following elements that contribute to the multifunctionality and to the adaptive properties:

- A Dye Sensitized Solar Cell (DSSC) panel for self energy production. This innovative photovoltaic technology is based on a functioning process that mimics the photosynthesis; moreover, it allows for the use of small quantities of readily-available materials produced by well-established processes and it’s characterized by a high level of versatility, architectural integrability and potentially low cost of fabrication (Parisi et al, 2014). The panel employed in the project is based on the configuration glass-titanium dioxide-ruthenium dye- iodine/triiodide redox couple-platinum-glass, which is one of the most stable and durable configuration developed so far.

- Inorganic support loaded with PCM (phase change material), to enhance the ability to reduce energy consumption for space conditioning and reduce peak loads as well as improving occupant comfort;

- Thermoacustic panel applied on a support frame in aluminum thermal break, with good mechanical properties able to ensure the mechanical safety performance needed for the interior space features.The panel has a sandwich structure: an expanded PET layer (from recycled PET bottles) between two

plasterboard layers, a further expanded polystyrene layer and two external aluminium layers to close the component.

- Sensors and actuators, used for an integrated control on humidity and temperature of the building, and thus of its energetic performance.

- Aluminium frame. The frame is taylor-made to assemble the different components and allows easy inspection and maintenance operations, which may be needed during the module lifetime.

Figure 1: SELFIE 2 module

The system boundaries include the raw materials production and transport; the production of components and finally the assembly of the SELFIE 2 module. The functional unit applied is ‘1 SELFIE 2 modular component’, with dimensions 90x140 cm. This is the size of the component as elaborated during the project, which is being tested for the operational phase and as it is undergoing the patenting process.

In this study, we have used the LCA software SimaPro 8.02 integrated with the Ecoinvent 3.0 database, and we have applied the ILCD 2011 Midpoint+ method (version 1.0.9, May 2016), developed by the Joint Research Centre of the European Commission, for the impact assessment (EC, JRC, 2012)

2.2. Life cycle inventory analysis

Inventory data were collected during the project (year 2016) through interviews and checklists distributed to the partners involved in the components development and in the assembly of the module. Primary data concern raw materials used for the components production and their provision, production processes of the components (in particular the production of the DSSC

photovoltaic panel and of the inorganic support loaded with PCM), the aluminium frame production and, finally, the assembly process of the components into the module. Since some of the components are the outputs of experimental research work developed during the project and still ongoing, data regarding their production have been modeled based on laboratory scale production process. Background data for modelling materials and energy production, transports etc. were taken from the Ecoinvent 3.0 database, eventually customized when necessary. Table 1 lists the main aggregated inventory data for SELFIE 2 module.

Table 1: Aggregated Life cycle inventory data for the production of SELFIE 2 module

Material inputs Quantity Units

Flat glass 40 kg Solar glass 16,9 kg Support for PCM 7,68 kg PCM 16 kg Insulating material 27,68 kg Aluminium 33,25 kg Dye N719 0.001 kg Electrolyte 0.06 kg Titanium Dioxide 0.05 kg Silver 0.020 kg Platinum 1,68∙10-5 kg Thermoplastic (Polyethylene) 0,3 kg Transport

Transport lorry EURO4 34314 kg*km

SELFIE 2 production processes inputs/outputs

Natural gas 8,41E-03 m3

Electricity 180.22 kWh

Water 0,12 m3

Diesel 0,4 l

Solvents 8,28 kg

Waste - non hazardous 23,27 kg

3. Results and discussion

Table 2 lists the impact assessment results of the analysis, referred to the functional unit and Figure 3 shows the contribution of the different components to each impact category.

Table 2: Life cycle impact assessment results for SELFIE 2 module

Impact category Unit Total

Climate change kg CO2 eq 8,54E+02

Ozone depletion kg CFC-11 eq 1,64E-04

Human toxicity, non-cancer effects CTUh 1,98E-04 Human toxicity, cancer effects CTUh 3,73E-05

Particulate matter kg PM2.5 eq 1,02E+00

Ionizing radiation HH kBq U235 eq 3,31E+01

Ionizing radiation E (interim) CTUe 1,67E-04 Photochemical ozone formation kg NMVOC eq 2,74E+00

Acidification molc H+ eq 6,78E+00

Terrestrial eutrophication molc N eq 1,00E+01

Freshwater eutrophication kg P eq 1,25E-01

Marine eutrophication kg N eq 1,15E+00

Freshwater ecotoxicity CTUe 3,53E+03

Land use kg C deficit 1,44E+03

Water resource depletion m3 water eq -1,80E+00

Mineral, fossil & ren resource depletion kg Sb eq 1,18E-01

The contribution analysis shows that the largest impacts on most of the impact categories are provided by the aluminium used in the module frames and by the DSSC module.

For instance, aluminium contributes for about 60% to Climate change, Human toxicity, cancer effects, Particulate matter, Water resource depletion, for about 50% to Photochemical ozone formation, Acidification, Terrestrial eutrophication and for about 40% to Marine eutrophication.

The DSSC photovoltaic panel greatly contributes to Ozone depletion, Human toxicity, non-cancer effects, Ionizing radiation, Freshwater eutrophication, Freshwater ecotoxicity and Mineral, fossil and renewable resource depletion with a percentage contribution ranging from 50% to almost 80%. These impacts are mostly due to the dye molecules and electrolyte solution involved in the photovoltaic modules production process, along with all metals and solvent employed for the syntheses and preparation of the various components of the solar cells.

The PCM-loaded component contributes for about 45% to Land use impact category and for about 35% to Marine eutrophication, due to the production of the PCM material.

Finally, the insulating panel component contribution is between 5 and 10 % to most of the impact categories, achieving 20% only for Particulate matter impact category.

3.1. Sensitivity analysis

In an eco-design approach, to contribute to a reduction of the environmental burdens of the SELFIE 2 module, we tested feasible alternatives on the most contributing components.

In order to reduce the large contribution of the aluminium frame, which is 100% virgin material, we tested with a sensitivity analysis, different contents of recycled aluminium, up to 100%. The aluminium recycled content was modelled applying the CFF (Circular Footprint Formula) formula, recommended for the PEF methodology application (EC, 2017). The parameters used in the ‘cradle to gate’ CFF module for the recycled aluminium production are : Ev = Aluminium,

wrought alloy {GLO}| market for | Alloc Rec, U, Erecycled = Aluminium, wrought

alloy {RER}| treatment of aluminium scrap, post-consumer, prepared for recycling, at remelter | Alloc Rec, U; A = 0,2; Qs/Qp = 1. R1 varies depending on

the recycled content percentage (0,5; 0,8; 1).

In general, a reduction of the impacts up to 10-15% is observed on several impact categories such as Climate change, Human toxicity, Particulate matter, Human toxicity, cancer effects. However, this option has only risible effect on other impact categories such as Ozone depletion, Human toxicity, non cancer effects, Resource depletion.

Concerning the other major contributor to the SELFIE 2 eco-profile, namely the DSSC panel, a sensitivity analysis has been performed to assess the potential benefit related with the use of a full organic dye instead of a metallorganic one in the same solar cell configuration. In general, the environmental burden on most of the impact categories of the photovoltaic panel is decreased by 75%. Such trend is much lower (~15%) for the climate change, ozone depletion and water consumption categories due to the use of large quantities of solvents and electricity for the synthesis of the full organic dye. This outcome can be attributed to the fact the organic dye synthesis is not yet optimized compared to

that of the ruthenium based dye employed in the solar cell configuration of the SELFIE 2 photovoltaic component.

4. Conclusions

This study reports on the preliminary results of the LCA analysis carried out on the SELFIE 2 component, developed during the SELFIE project. The analysis aimed to support the eco-design of the module, investigating the hot spots of the production stage to provide suitable alternatives for the reduction of the environmental burdens. As emerged, the main contributors have been identified in the aluminium frame and in the DSSC photovoltaic panel. The effect in reducing the impacts of the suggested alternatives, namely the use of recycled aluminium for the frame and the use of a full organic dye for the DSSC, were tested with sensitivity analyses. As much as regards the use of recycled aluminium, this would allow to reduce in general the environmental burdens of up to 15% on most of the impact categories, while the use of a full organic dye would result in an environmental benefit up to 75% for the DSSC photovoltaic panel eco-profile, thus contributing to further lower the environmental footprint of the SELFIE 2 module.

In a further approach, LCA will be used in parallel to the testing phase, which will provide information regarding the module performance during its use phase.

5. References

Baetens R., Jelle B.P., Gustavsen A., 2010. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings, Solar Energy Materials and Solar Cells 94.

EPDB 2010, Directive 2012/…/EU of the European Parliament and of the Council of on the Energy Performance of Buildings (recast)

EE 2012, Directive 2012/…/EU of the European Parliament and of the Council of on the Energy Efficiency

European Commission, Joint Research Centre, Institute for Environment and Sustainability. Characterization factors of the ILCD recommended life cycle impact assessment methods. Database and supporting information. First edition. February 2012. EUR 25167. Luxembourg: Publications Office of the European Union; 2012

European Commission, PEFCR Guidance document, - Guidance for the development of Product Environmental Footprint Category Rules (PEFCRs), version 6.2, June 2017

Favoino F., Goia F., Perino M., Serra V., 2014. Experimental assessment of the energy performance of an advanced responsive multifunctional façade module, Energy and Buildings 68.

ISO, 2006a. ISO 14040:2006 Environmental management - Life Cycle Assessment - Principles and framework, International Organization for Standardization (ISO), Geneva.

ISO, 2006b. ISO 14044:2006 Environmental management - Life Cycle Assessment - Requirements and guidelines, International Organization for Standardization (ISO), Geneva.

Kuznik F., David D., Johannes K., Roux J., 2011. A review on phase change materials integrated in building walls, Renewable and Sustainable Energy Reviews 15:1.

M. Perino editor. Requirements and guidelines, International Organization for Standardization (ISO), Geneva.,” IEA–ECBCS Annex 44. Integrating Environmentally Responsive Elements in Buildings”, State of the art Review, 2007

Parisi M.L, Maranghi S., Basosi R., 2014. The evolution of the Dye Sensitized Solar Cells from Grätzel prototype to up-scaled solar applications: a life cycle assessment approach. Renewable and Sustainable Energy Review, 39, 124-138.

Ramesh T., Prakash R, Shukla K.K., 2010. Life cycle energy analysis of buildings: An overview, Energy and Buildings. 42, 1592–1600.

Saelens D., Carmeliet J., Hens H., 2003. Energy performance assessment of multiple skin facades, International Journal of HVAC&R Research 9 (2).

Sartori I, Hestnes A.G., 2007. Energy use in the life cycle of conventional and low-energy buildings: A review article, Energy and Buildings. 39, 249–257.

Sierra-Perez J, Boschmonart-Rives J, Gabarrell X, 2016. Environmental assessment of façade-building systems and thermal insulation materials for different climatic conditions, Journal of Cleaner Production. 113, 102-113.

UNI EN 15804, Sustainability of construction works, Environmental product declarations, Core rules for the product category of construction products, 2012

Acknowledgement

The authors wish to acknowledge Tuscany Region for the financial support from the PAR-FAS 2007-2013, SELFIE Project.

Life Cycle Assessment of building end of life

Serena Giorgi1, Monica Lavagna1, Andrea Campioli1 1Politecnico di Milano, ABC Department

Email: [email protected]

Abstract

The paper deals with how the buildings’ end of life is assessed in LCA, throughout a study based on European Standard and literature review. End-of-life modelling is becoming more important within circular economy policies that improve the extension of buildings’ service life (through regeneration and refurbishment processes) and building’s components reuse or recycling. The paper highlights different assumptions and different approaches taken in LCA modelling of the building end of life: functional unit, system boundary, allocation method, inventory of quantity and data collection. Moreover the uncertainty and limits of modelling are analysed.

1. Introduction

In the last two decades, many LCA studies of buildings have been conducted, but a lot of them do not include an in-depth analysis of the end-of-life phase (asserted by Paleari et al., 2015). The omission is mainly caused by the lack of information and the difficulty in predicting future scenarios (Oregi et al., 2015). Many studies about building’s LCA, in fact, are focused on the product phase (A1-3) and the operational energy use stage (B6); instead the end of life is modelled choosing simplified assumptions, such as an average distance between the building and the place of disposal and landfill for demolition waste of the whole building. In this way, the impact of end-of-life stage, in comparison to the whole life cycle, is less than 1% for the life cycle energy use, so the end-of-life stage loses its relevance (Oregi et al., 2015).

The simplified assumption about landfill for demolition waste of the whole building is no longer possible under the Waste Framework Directive (WFD) 2008/98/EC, which establishes that almost 70% of construction and demolition waste (CDW) have to be reused, recycled or recovered. Hence, the LCA studies from 2008 assume a rate of recovery/reuse/recycle of material over 70%, in order to respect the WFD. Moreover, the circular economy point of view is changing the concept of ‘end of life’, therefore also the evaluation of it. Circular economy policies aim at efficient use of natural resources and at reduction of waste generation (COM 398, 2014; COM 614, 2015). It is possible to state that, in this context, the promoting routes are:

• remanufacturing / reconditioning of products, which increase the lifetime of products by rebuilding and repairing them;

• a closed-loop system, which transforms products, that have reached the end of their useful life, into something new, by process of reuse and recycling of components.

In the building sector the actions, that respect these two routes of circular economy, are:

• the regeneration of buildings, in order to give back a new function and extend the service life of buildings; in this context the practices of repair, replacement and refurbishment are incentivised;

• the management of construction and demolition waste in order to reuse and recycle waste as secondary materials, avoiding landfill and the extraction of raw materials.

Nevertheless, improper management of refurbishment practices or CDW recycling should result in considerable environmental impacts and recycling processes might cause indirect environmental impacts (JRC, 2011; Mousavi et al., 2016). Within the life cycle thinking approach, it is important to evaluate the impacts of every circular action through scientific methodologies like the internationally standardized procedure of Life Cycle Assessment. In this context, the evaluation of the end of life phase, that has been little treated in the LCA studies, becomes crucial. In fact, with the support of LCA it is possible assess the impact of repair, replacement, refurbishment processes and CDW management: in the EN 15978 (2011) these phases are identified in the Module B3, B4, B5, C1-C4. Moreover EN 15978 sets a module D in order to quantify the environmental benefits or loads resulting from reuse, recycling and energy recovery processes.

The EN 15978 defines the limit between the end-of-life stage and module D. The end-of-life stage starts from the activity that produces waste, and considers the management for waste, as a “multi-output process that provides a source of materials, products and building elements that are to be discarded, recovered, recycled or reused”. The impacts assigned to end-of-life stage regard the waste management and disposal until the landfill (considering also the impacts of landfill), if it is the final destination of waste, included the impacts of transports (from building to landfill). But the situation changes when the waste stops being ‘waste’ to became a second-hand material usable in other processes by recycling or energy recovery. The secondary materials leaves the system, and its burdens are divided between end-of-life stage and module D. The process of collection and transport until the sorting plant of secondary materials are part of the waste processing of the building, so the burdens are assigned to the end-of-life stage; instead the further processes (e.g. recycling process) concern another product system. So the processes’ burdens and avoided impacts are assigned to module D (beyond the system boundary), in according to the ‘cut-off’ approach.

End-of-life modelling needs allocation methods to divide environmental impacts and benefits between the first and second life of products. There are different approaches and different methods of allocation and the debate is open especially in the context of defining the PEF (Giorgi et al., 2016). But, in the case of the building, the EN 15978 sets out a ‘cut-off’ approach. However in literature there are many building LCA studies that use other types of allocation,

because of different goals and scope of the studies. Moreover, many methodological choice still remain without rules, and debates are still ongoing in areas like the definition of (temporal) system boundaries, life cycle inventory generation, selection and use of environmental indicators, and interpretation and communication of the LCA results (Saner at al., 2012). According to Sandin at al. (2014) the four factors that can mainly change the result of LCA are: the type of approach used in modelling between consequential and attributional approach, the end-of-life phases considered, the type of disposal that is chosen among reuse, recycling, incineration or landfill and the impact of technology assumed. This paper shows how some authors have treated LCA in case studies about buildings’ end of life, which methods are assumed and which limits have been found.

2. Different goals and scopes in end-of-life modelling

In literature, LCA studies which take into account the end-of-life stage are conducted with different ‘goal and scope’. The scientific papers analysed treated the end of life in three different way. Some studies use an approach of whole-LCA modelling in order to assess the entire environmental impact of building considering all stages of life, hence the end-of-life stage, too (e.g. Oregi et al., 2015; Blengini et al., 2010). Other studies regard a LCA which takes into account just few stages of building life. They want to evaluate the impacts of deep refurbishment of a building and assess the treatment of waste produced during the works (e.g. Ghose et al., 2017a). Moreover these studies compare buildings’ intervention strategies which minimize the waste to aid decision making (e.g. Ghose at al. 2017b). Other studies consider only the end-of-life stage modelling to assess the impact of management of waste generated from building demolition. The goal of these LCA studies is to evaluate the environmental impacts related to end of life of the different fraction of construction and demolition waste in order to assess the best type of disposal or recovery (e.g. Butera at al., 2015; Sandin at al. 2014, Vitale et al., 2017), considering, also, the quality of recycling of materials. Moreover, studies want to evaluate different alternatives of demolition scenarios and management of waste generated (e.g. Martinez et al., 2013). Different ‘goal and scope’, brings different approaches and different assumptions in LCA, such as functional unit, system boundaries, data collection, data source and allocation approach.

2.1. Functional unit and system boundary in end of life modelling

According to ISO 14040, the functional unit is a measure of the function of the studied system. The functional unit changes in relation to different studies because it also depends on the reference performance chosen. Whole-LCA studies, focused on whole-life-cycle impact assessment, use a functional unit referred to the entire building and the design requirements, such as thermal comfort. So, results are expressed per unit of useful heated floor area and per year (1 m2/years) (e.g. Oregi et al., 2015; Blengini et al., 2010; Ghose et al.

2017a; Ghose at al. 2017b). The studies that consider only end-of-life waste management, instead, take into account a functional unit aimed at management of waste generated by demolition activities. The functional unit is expressed in

weight (e.g. tonnes) of waste generated, for assessing environmental impacts and benefits of the different scenarios of the management system (e.g. Butera et al., 2015; Vitale at al., 2017).

The Standard EN 15978 states that the system boundary of end of life has to consider the process of selective demolition/deconstruction, collection of waste materials of the building and the processes of on-site sorting, transport to plants for recycling/recovery and/or disposal of waste in landfill. According to the ‘polluter pays’ principle, loads, (e.g. emissions) from waste disposal are considered part of the building life cycle. However, the benefit of reuse or recycling (for example the energy generated form waste incineration or the benefit of use of secondary materials in the other productions’ system) are assigned to module D.

In some studies different scenarios are assessed, hence different system boundaries are analysed in order to choose the most sustainable routes, considering different management processes for the same type of material. Blengini et al. (2010) in whole-LCA modelling consider the phases of: ‘pre-use and maintenance’, which include structure, finishes and equipment material (quantities estimated from building drawings and field measured data), transportation (average distances estimated from personal communication with designer and contractor), construction stage (estimated from field measured data, personal communication with designer and constructor, literature), maintenance activities (estimated from literature and personal communication with designer and constructor); ‘use’, which considers energy use for heating, ventilating and DHW, energy use for cooking, washing, lighting and use of appliances (calculated with the software); ‘end of life’, in particular, which considers three stages (estimated data from literature): selective disassembling of re-usable/recyclable materials and structures (windows, steel, aluminium and roof), controlled demolition of the structure by hydraulic hammers and shears, CDW treatment and recycling, reuse or landfill. In particular, CDW generated from the building process and during maintenance operations was considered: the mineral fraction, such as concrete, mortar, bricks, ceramics, etc., was assumed to undergo a recycling process for the production of secondary aggregates; metal and glass separation and recycling; wood incineration and mixed rubble recycling.

Ghose et al. (2017b), in LCA for different refurbishment assessments, consider three scenarios of different rates of recycling. The first scenario is ‘business as usual scenario’ which analyses conventional activities from production of refurbished components (without recycling content), transport to construction-site, construction-site activities and transport of waste to treatment construction-site, waste management considering parts of waste to landfill and a little rate of material to recycling (considering, through consequential approach, the avoid loads of production of new materials using the waste as secondary materials and the avoid loads of a avoid landfill). The second scenario regards the ‘waste minimization’, it considers a rate of materials reused at construction-site and it assumed an higher rate of materials recycling than first scenario. The third